Abstract

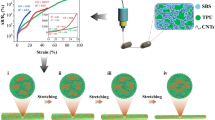

In this study, high-performance flexible strain sensors based on carbon nanotube (CNT) and graphene nanoplatelet (GNP) filled thermoplastic polyurethane (TPU) composites were fabricated via Fused Filament Fabrication (FFF) 3D printing. The introduction of GNPs generated a more complete conductive network of the composites due to the improved nanofiller dispersion. Due to the synergy of CNTs and GNPs, the printed CNT/GNP(3:1)/TPU sensor shows higher sensitivity (GF = 136327.4 at 250% strain), larger detectable range (0–250% strain), and better stability (3000 cycles) compared with the CNT/TPU and GNP/TPU sensors with a nanofiller content of 2 wt%. Furthermore, the printed sensors can accurately detect strains at different frequencies (0.01–1 Hz). A modelling study based on tunneling theory was conducted to analysis the strain sensing mechanism, and the theoretical results agreed well with the experimental data. The capability of the sensors in monitoring physiological activities and speech recognition has also been demonstrated.

Similar content being viewed by others

References

Zhao K, Niu W, Zhang S (2020) Highly stretchable, breathable and negative resistance variation textile strain sensor with excellent mechanical stability for wearable electronics. J Mater Sci 55:2439–2453. https://doi.org/10.1007/s10853-019-04189-x

Hwang B, Choi S, Lee K, Kim J (2018) Highly stretchable and transparent electrode fi lm based on SWCNT/Silver nanowire hybrid nanocomposite. Compos Part B 151:1–7. https://doi.org/10.1016/j.compositesb.2018.06.004

Meng Q, Liu Z, Han S, Xu L (2019) IFES sciences for life A facile approach to fabricate highly sensitive, flexible strain sensor based on elastomeric/graphene platelet composite film. J Mater Sci 54:10856–10870. https://doi.org/10.1007/s10853-019-03650-1

Dou Y, Liu H, Peng J et al (2016) A green method for preparation of CNT/CS/AgNP composites and evaluation of their catalytic performance. J Mater Sci 51:5685–5694. https://doi.org/10.1007/s10853-016-9871-1

Zhang R, Deng H, Valenca R et al (2013) Strain sensing behaviour of elastomeric composite films containing carbon nanotubes under cyclic loading. Compos Sci Technol 74:1–5. https://doi.org/10.1016/j.compscitech.2012.09.016

Wang Y, Hao J, Huang Z et al (2018) Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 126:360–371. https://doi.org/10.1016/j.carbon.2017.10.034

Kim JY, Ji S, Jung S et al (2017) 3D printable composite dough for stretchable, ultrasensitive and body-patchable strain sensors. Nanoscale 9:11035–11046. https://doi.org/10.1039/c7nr01865g

Liu H, Gao J, Huang W et al (2016) Electrically conductive strain sensing polyurethane nanocomposites with synergistic carbon nanotubes and graphene bifillers. Nanoscale 8:12977–12989. https://doi.org/10.1039/c6nr02216b

Ma Z, Wei A, Ma J, Shao L et al (2018) Lightweight, compressible and electrically conductive polyurethane sponges coated with synergistic multiwalled carbon nanotubes and graphene for piezoresistive sensors. Nanoscale 10:7116–7126. https://doi.org/10.1039/c8nr00004b

Peng X, Wu K, Hu Y et al (2018) A mechanically strong and sensitive CNT/rGO-CNF carbon aerogel for piezoresistive sensors. J Mater Chem A 6:23550–23559. https://doi.org/10.1039/C8TA09322A

Zhao X, Xu L, Chen Q et al (2019) Highly conductive multifunctional rGO/CNT hybrid sponge for electromagnetic wave shielding and strain sensor. Adv Mater Technol 4:1900443–1900451. https://doi.org/10.1002/admt.201900443

Ligon SC, Liska R, Stampfl J et al (2017) Polymers for 3D Printing and Customized Additive Manufacturing. Chem Rev 117:10212–10290. https://doi.org/10.1021/acs.chemrev.7b00074

Kim DW, Lim JH, Yu J (2019) Efficient prediction of the electrical conductivity and percolation threshold of nanocomposite containing spherical particles with three-dimensional random representative volume elements by random filler removal. Compos Part B Eng 168:387–397. https://doi.org/10.1016/j.compositesb.2019.03.038

Xiang D, Zhang X, Li Y et al (2019) Enhanced performance of 3D printed highly elastic strain sensors of carbon nanotube/thermoplastic polyurethane nanocomposites via non-covalent interactions. Compos Part B Eng. https://doi.org/10.1016/j.compositesb.2019.107250

Mu Q, Wang L, Dunn CK et al (2017) Digital light processing 3D printing of conductive complex structures. Addit Manuf 18:74–83. https://doi.org/10.1016/j.addma.2017.08.011

Li Z, Wang Z, Gan X et al (2017) Selective Laser Sintering 3D Printing: a Way to Construct 3D Electrically Conductive Segregated Network in Polymer Matrix. Macromol Mater Eng 302:1–10. https://doi.org/10.1002/mame.201700211

Odent J, Wallin TJ, Pan W et al (2017) Highly Elastic, Transparent, and Conductive 3D-Printed Ionic Composite Hydrogels. Adv Funct Mater 27:1–10. https://doi.org/10.1002/adfm.201701807

Christ JF, Aliheidari N, Ameli A, Pötschke P (2017) 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater Des 131:394–401. https://doi.org/10.1016/j.matdes.2017.06.011

Huang P, Xia Z, Cui S (2018) 3D printing of carbon fiber-filled conductive silicon rubber. Mater Des 142:11–21. https://doi.org/10.1016/j.matdes.2017.12.051

Xiang D, Zhang X, Harkin-Jones E et al (2020) Synergistic effects of hybrid conductive nanofillers on the performance of 3D printed highly elastic strain sensors. Compos Part A Appl Sci Manuf 129:105730–105742. https://doi.org/10.1016/j.compositesa.2019.105730

Deng H, Lin L, Ji M et al (2014) Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog Polym Sci 39:627–655. https://doi.org/10.1016/j.progpolymsci.2013.07.007

Xiang D, Wang L, Tang Y et al (2018) Damage self-sensing behavior of carbon nanofiller reinforced polymer composites with different conductive network structures. Polymer 158:308–319. https://doi.org/10.1016/j.polymer.2018.11.007

Li Y, Zhou B, Zheng G et al (2018) Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing. J Mater Chem C 6:2258–2269. https://doi.org/10.1039/c7tc04959e

Zhao H, Bai J (2015) Highly sensitive piezo-resistive graphite nanoplatelet-carbon nanotube hybrids/polydimethylsilicone composites with improved conductive network construction. ACS Appl Mater Interfaces 7:9652–9659. https://doi.org/10.1021/acsami.5b01413

Lachhab A, Robin E, Le Cam JB et al (2017) Thermomechanical analysis of polymeric foams subjected to cyclic loading: anelasticity, self-heating and strain-induced crystallization. Polymer 126:19–28. https://doi.org/10.1016/j.polymer.2017.08.010

Reulier M, Matadi Boumbimba R, Walsh Korb Z, Vaudemont R, Avérous L (2017) Thermomechanical and cyclic behavior of biocomposites based on renewable thermoplastics from dimer fatty acids. J Appl Polym Sci 134:1–13. https://doi.org/10.1002/app.44610

Roh E, Hwang BU, Kim D et al (2015) Stretchable, transparent, ultrasensitive, and patchable strain sensor for human-machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano 9:6252–6261. https://doi.org/10.1021/acsnano.5b01613

Wang L, Xiang D, Harkin-jones E et al (2019) A flexible and multipurpose piezoresistive strain sensor based on carbonized phenol formaldehyde foam for human motion monitoring. Macromolecul Mater Eng 2019(1900492):1–9. https://doi.org/10.1002/mame.201900492

Chen Q, Xiang D, Wang L et al (2018) Facile fabrication and performance of robust polymer/carbon nanotube coated spandex fibers for strain sensing. Compos Part A Appl Sci Manuf 112:186–196. https://doi.org/10.1016/j.compositesa.2018.06.009

Liao X, Liao Q, Yan X et al (2015) Flexible and highly sensitive strain sensors fabricated by pencil drawn for wearable monitor. Adv Funct Mater 25:2395–2401. https://doi.org/10.1002/adfm.201500094

Zeng Z, Seyed Shahabadi SI, Che B et al (2017) Highly stretchable, sensitive strain sensors with a wide linear sensing region based on compressed anisotropic graphene foam/polymer nanocomposites. Nanoscale 9:17396–17404. https://doi.org/10.1039/c7nr05106a

Amjadi M, Yoon YJ, Park I (2015) Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 26:375501. https://doi.org/10.1088/0957-4484/26/37/375501

Liang B, Lin Z, Chen W et al (2018) Ultra-stretchable and highly sensitive strain sensor based on gradient structure carbon nanotubes. Nanoscale 10:13599–13606. https://doi.org/10.1039/c8nr02528b

Lin Y, Liu S, Chen S, Wei Y et al (2016) A highly stretchable and sensitive strain sensor based on graphene-elastomer composites with a novel double-interconnected network. J Mater Chem C 4:6345–6352. https://doi.org/10.1039/c6tc01925k

Zhong W, Liu C, Xiang C et al (2017) Continuously producible ultrasensitive wearable strain sensor assembled with three-dimensional interpenetrating Ag nanowires/polyolefin elastomer nanofibrous composite yarn. ACS Appl Mater Interfaces 9:42058–42066. https://doi.org/10.1021/acsami.7b11431

He Z, Zhou G, Byun JH et al (2019) Highly stretchable multi-walled carbon nanotube/thermoplastic polyurethane composite fibers for ultrasensitive, wearable strain sensors. Nanoscale 11:5884–5890. https://doi.org/10.1039/C9NR01005J

Chen S, Wu R, Li P et al (2018) Acid-interface engineering of carbon nanotube/elastomers with enhanced sensitivity for stretchable strain sensors. ACS Appl Mater Interfaces 10:37760–37766. https://doi.org/10.1021/acsami.8b16591

Zhou X, Zhu L, Fan L et al (2018) Fabrication of highly stretchable, washable, wearable, water-repellent strain sensors with multi-stimuli sensing ability. ACS Appl Mater Interfaces 10:31655–31663. https://doi.org/10.1021/acsami.8b11766

Lozano-Pérez C, Cauich-Rodríguez JV, Avilés F (2016) Influence of rigid segment and carbon nanotube concentration on the cyclic piezoresistive and hysteretic behavior of multiwall carbon nanotube/segmented polyurethane composites. Compos Sci Technol 128:25–32. https://doi.org/10.1016/j.compscitech.2016.03.010

Lin L, Liu S, Zhang Q et al (2013) Towards tunable sensitivity of electrical property to strain for conductive polymer composites based on thermoplastic elastomer. ACS Appl Mater Interfaces 5:5815–5824. https://doi.org/10.1021/am401402x

Acknowledgements

This work was supported by the Sichuan Science and Technology Program (2017HH0086, 2017JY0152), Sichuan Provincial University Key Laboratory of Oil and Gas Field Materials (No. X151519KCL05), and the Scientific Research Foundation for the Returned Overseas Chinese Scholars of Sichuan Province.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xiang, D., Zhang, X., Han, Z. et al. 3D printed high-performance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites. J Mater Sci 55, 15769–15786 (2020). https://doi.org/10.1007/s10853-020-05137-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05137-w