Abstract

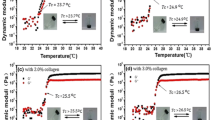

Several factors govern the improvement in the mechanical, thermal, and conductive properties, when a nanoscale filler is incorporated into a polymer matrix. These factors include the concentration, size of the filling, distribution, etc. In this research, we present how to improve the distribution of nanoparticles using nanoparticles stabilized with block copolymers of different molar masses. For this purpose, Pluronic L35 and Pluronic F68 copolymers were used to stabilize nanoparticles in order to improve their distribution in a hydrogel of poly(2-hydroxyethyl methacrylate) through an entropic mechanism of interfacial control. The nanoparticles were labelled with fluorescein, and using confocal fluorescence microscopy, it was quantitatively demonstrated that both stabilizers led to a more homogeneous distribution. The nanocomposite hydrogels presented interesting viscoelastic properties. While the hydrogels stabilized with Pluronic L35 did not present significant changes in the rheological properties (e.g. stiffness and shear thinning), the most significant rheological effects were observed for the hydrogels prepared with Pluronic F68-stabilized nanoparticles. These hydrogels exhibited a diminution in the shear complex modulus, viscosity, and critical shear rate to give rise to the shear-thinning region, which was attributed to the differences in the molar masses of the stabilizers and favoured slipping of polymer chains because of unfavourable wetting with the stabilizer coating.

Similar content being viewed by others

References

IUPAC (2014) Compendium of chemical terminology: the gold book

Senna AM, Braga J, Carmo D, Da Silva JMS, Botaro VR (2015) Synthesis, characterization and application of hydrogel derived from cellulose acetate as a substrate for slow-release NPK fertilizer and water retention in soil. J Environ Chem Eng 3:996–1002. https://doi.org/10.1016/j.jece.2015.03.008

Zhang Y, Liang X, Yang X, Liu H, Yao J (2014) An eco-friendly slow-release urea fertilizer based on waste mulberry branches for potential agriculture and horticulture applications. ACS Sustain Chem Eng 2:1871–1878. https://doi.org/10.1021/sc500204z

Naficy S, Spinks GM, Wallace GG (2014) Thin, tough, pH-sensitive hydrogel films with rapid load recovery. ACS Appl Mater Interfaces 6:4109–4111. https://doi.org/10.1021/am405708v

An B, Lee H, Lee S, Lee SH, Choi JW (2015) Determining the selectivity of divalent metal cations for the carboxyl group of alginate hydrogel beads during competitive sorption. J Hazard Mater 298:11–18. https://doi.org/10.1016/j.jhazmat.2015.05.005

Xu R, Zhou G, Tang Y et al (2015) New double network hydrogel adsorbent: Highly efficient removal of Cd (II) and Mn (II) ions in aqueous solution. Chem Eng J 275:179–188. https://doi.org/10.1016/j.cej.2015.04.040

Hoffman AS (2002) Hydrogel for biomedical applications. Adv Drug Deliv Rev 54:3–12. https://doi.org/10.1016/S0169-409X(01)00239-3

Kamata H, Li X, Chung U, Sakai T (2015) Design of hydrogels for biomedical applications. Adv Healthc Mater 4:2360–2374. https://doi.org/10.1002/adhm.201500076

Burdick JA, Prestwich GD (2011) Hyaluronic acid hydrogels for biomedical applications. Adv Mater 23:H41–H56. https://doi.org/10.1002/adma.201003963

Toh WS, Loh XJ (2015) Advances in hydrogel delivery systems for tissue regeneration. Mater Sci Eng C 45:690–697. https://doi.org/10.1016/j.msec.2014.04.026

Brandl F, Kastner F, Gschwind RM, Blunk T, Teßmar J, Göpferich A (2010) Hydrogel-based drug delivery systems: comparison of drug diffusivity and release kinetics. J Control Release 142:221–228. https://doi.org/10.1016/j.jconrel.2009.10.030

Ghobril C, Grinstaff MW (2015) The chemistry and engineering of polymeric hydrogel adhesives for wound closure: a tutorial. Chem Soc Rev 44:1820–1835. https://doi.org/10.1039/C4CS00332B

Drury JL, Mooney DJ (2003) Hydrogels for tissue engineering: scaffold design variables and applications. Biomaterials 24:4337–4351. https://doi.org/10.1016/S0142-9612(03)00340-5

Yue K, Santiago GT, Alvarez MM, Tamayol A, Annabi N, Khademhosseini A (2015) Synthesis, properties, and biomedical applications of gelatin methacryloyl (GelMA) hydrogels. Biomaterials 73:254–271. https://doi.org/10.1016/j.biomaterials.2015.08.045

Li Z, Mi W, Wang H, Su Y, He C (2014) Nano-hydroxyapatite/polyacrylamide composite hydrogels with high mechanical strengths and cell adhesion properties. Colloids Surf B: Biointerfaces 123:959–964. https://doi.org/10.1016/j.colsurfb.2014.10.050

Baei P, Jalili-Firoozinezhad S, Rajabi-Zeleti S, Tafazzoli-Shadpour M, Baharvand H, Aghdami N (2016) Electrically conductive gold nanoparticle-chitosan thermosensitive hydrogels for cardiac tissue engineering. Mater Sci Eng C 63:131–141. https://doi.org/10.1016/j.msec.2016.02.056

Schadler LS, Kumar SK, Benicewicz BC, Lewis SL, Harton SE (2007) Designed interfaces in polymer nanocomposites: a fundamental viewpoint. MRS Bull 32:335–340. https://doi.org/10.1557/mrs2007.232

Kumar SK, Jouault N, Benicewicz B, Neely T (2013) Nanocomposites with polymer grafted nanoparticles. Macromolecules 46:3199–3214. https://doi.org/10.1021/ma4001385

Zhao X, Ding X, Deng Z, Zheng Z, Peng Y, Long X (2005) Thermoswitchable electronic properties of a gold nanoparticle/hydrogel composite. Macromol Rapid Commun 26:1784–1787. https://doi.org/10.1002/marc.200500534

Zhao X, Ding X, Deng Z et al (2006) A kind of smart gold nanoparticle–hydrogel composite with tunable thermo-switchable electrical properties. New J Chem 30:915–920. https://doi.org/10.1039/B601069E

Rahme K, Oberdisse J, Schweins R et al (2008) Pluronics-stabilized gold nanoparticles: investigation of the structure of the polymer-particle hybrid. ChemPhysChem 9:2230–2236. https://doi.org/10.1002/cphc.200800358

Jain TK, Foy SP, Erokwu B, Dimitrijevic S, Flask CA, Labhasetwar V (2009) Magnetic resonance imaging of multifunctional pluronic stabilized iron-oxide nanoparticles in tumor-bearing mice. Biomaterials 30:6748–6756. https://doi.org/10.1016/j.biomaterials.2009.08.042

Barick KC, Gawali SL et al (2016) Pluronic stabilized Fe 3 O 4 magnetic nanoparticles for intracellular delivery of curcumin. RSC Adv 6:98674–98681. https://doi.org/10.1039/C6RA21207G

Chong JYT, Mulet X, Waddington LJ, Boyd BJ, Drummond CJ (2011) Steric stabilisation of self-assembled cubic lyotropic liquid crystalline nanoparticles: high throughput evaluation of triblock polyethylene oxide-polypropylene oxide-polyethylene oxide copolymers. Soft Matter 7:4768–4777. https://doi.org/10.1039/C1SM05181D

Belmar L, Toledo L, Sánchez SA, Urbano BF (2018) Fluorescent nanotubes in PHEMA hydrogels: visualizing aggregation and distribution by confocal fluorescence microscopy. Mater Today Commun 16:285–292. https://doi.org/10.1016/j.mtcomm.2018.07.002

Li X, Zhang H, Jin J et al (2014) Quantifying dispersion of nanoparticles in polymer nanocomposites through transmission electron microscopy micrographs. J Micro Nano-Manuf 2:021008. https://doi.org/10.1115/1.4027339

Dong L, Li X, Qian Y et al (2016) Quantifying nanoparticle mixing state to account for both location and size effects. Technometrics 59:391–403. https://doi.org/10.1080/00401706.2016.1186563

Kim D, Lee JS, Barry CMF, Mead JL (2007) Microscopic measurement of the degree of mixing for nanoparticles in polymer nanocomposites by TEM images. Microsc Res Tech 70:539–546. https://doi.org/10.1002/jemt.20478

Rempe A, Stuefer M, Kindersberger J, Wagenbauer K, Ketterer P, Dietz H (2019) Quantification of the three-dimensional nanoparticle distribution in polymer nanocomposites. IEEE Trans Dielectr Electr Insul 26:601–609. https://doi.org/10.1109/TDEI.2018.007740

Luo ZP, Koo JH (2007) Quantifying the dispersion of mixture microstructures. J Microsc 225:118–125. https://doi.org/10.1111/j.1365-2818.2007.01722.x

Li Z, Gao Y, Moon K-S, Yao Y, Tannenbaum A, Wong CP (2012) Automatic quantification of filler dispersion in polymer composites. Polymer 53:1571–1580. https://doi.org/10.1016/j.polymer.2012.01.048

Khare HS, Burris DL (2010) A quantitative method for measuring nanocomposite dispersion. Polymer 51:719–729. https://doi.org/10.1016/j.polymer.2009.12.031

Li J-L, Liu X-Y, Wang R-Y, Xiong J-Y (2005) Architecture of a biocompatible supramolecular material by supersaturation-driven fabrication of its fiber network. J Phys Chem B 109:24231–24235. https://doi.org/10.1021/jp054676y

Winey KI, Vaia RA (2007) Polymer nanocomposites. MRS Bull 32:314–322. https://doi.org/10.1557/mrs2007.229

Sunday D, Ilavsky J, Green DL (2012) A phase diagram for polymer-grafted nanoparticles in homopolymer matrices. Macromolecules 45:4007–4011. https://doi.org/10.1021/ma300438g

Sunday DF, Green DL (2015) Thermal and rheological behavior of polymer grafted nanoparticle. Macromolecules 48:8651–8659. https://doi.org/10.1021/acs.macromol.5b00987

Bansal A, Yang H, Li C, Benicewicz BC, Kumar SK, Schadler LS (2006) Controlling the thermomechanical properties of polymer nanocomposites by tailoring the polymer–particle interface. J Polym Sci Part B Polym Phys 44:2944–2950. https://doi.org/10.1002/polb.20926

Akcora P, Kumar SK, Moll J et al (2010) “Gel-like” mechanical reinforcement in polymer nanocomposite melts. Macromolecules 43:1003–1010. https://doi.org/10.1021/ma902072d

Cross MM (1965) Rheology of non-Newtonian fluids: a new flow equation for pseudoplastic systems. J Colloid Sci 20:417–437. https://doi.org/10.1016/0095-8522(65)90022-X

Osswald T, Rudolph N (2015) In: Osswald T, Rudolph N (eds) Polymer Rheology. Carl Hanser, München

Chen MH, Wang LL, Chung JJ, Kim Y-H, Atluri P, Burdick JA (2017) Methods to assess shear-thinning hydrogels for application as injectable biomaterials. ACS Biomater Sci Eng 3:3146–3160. https://doi.org/10.1021/acsbiomaterials.7b00734

Guvendiren M, Lu HD, Burdick JA (2012) Shear-thinning hydrogels for biomedical applications. Soft Matter 8:260–272. https://doi.org/10.1039/C1SM06513K

Khabibullin A, Alizadehgiashi M, Khuu N, Prince E, Tebbe M, Kumacheva E (2017) Injectable shear-thinning fluorescent hydrogel formed by cellulose nanocrystals and graphene quantum dots. Langmuir 33:12344–12350. https://doi.org/10.1021/acs.langmuir.7b02906

Acknowledgements

The authors thank FONDECYT Regular (Grant Nº 1171082) and FONDEQUIP (Grant Nº EQM140032). D.A. Palacio thanks the Graduate Direction and Project EDPG173 and University of Concepcion for the doctoral scholarship.

Author information

Authors and Affiliations

Contributions

LT was involved in conceptualization, methodology, and formal analysis; DP designed the methodology and carried out formal analysis; Susana Sánchez carried out conceptualization and methodology and wrote the original draft; BFU took part in conceptualization, methodology, formal analysis, writing the original draft, supervision, and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Toledo, L., Palacio, D., Sánchez, S. et al. Pluronic-coated nanoparticles for enhanced spatial distribution and increased softness of nanocomposite hydrogels. J Mater Sci 55, 8968–8982 (2020). https://doi.org/10.1007/s10853-020-04658-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04658-8