Abstract

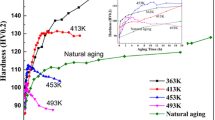

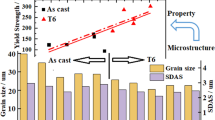

The age hardening response of Al–0.09Sc (at.%), to which trace amounts (< 100 ppm) of actinides (An = U or Th) were added, is studied by microhardness, conductivity, transmission electron microscopy, and atom probe tomography (APT). Peak-age hardening at 300 °C is associated with a high number density of nanoscale L12-Al3(Sc1 − xAnx) precipitates with core/shell structure. The first alloy Al–0.09Sc–0.006U (at.%) has a peak microhardness similar to that of binary Al–0.09Sc (at.%), but a shorter incubation period for hardening which is consistent with U diffusing faster than Sc in Al and acting as nucleant for Al3Sc. This is confirmed by APT measurements of precipitate composition, Al3(Sc0.8U0.2), showing that U has high solubility in Al3Sc precipitates and segregates at their core. The second alloy, Al–0.09Sc–0.008Th (at.%), exhibits Th-poor Al3(Sc0.98Th0.02) precipitates with Th segregation in their shells and it has microhardness evolution undistinguishable from binary Al–0.09Sc; this is indicative of low solubility of Th in L12-Al3Sc and/or low diffusivity of Th in Al. These two primordial actinides -U and Th- show different abilities to coprecipitate with Al3Sc precipitate in aluminum, they, however, both improve coarsening resistance after 143 days at 300 °C by forming core/shell structure.

Similar content being viewed by others

References

Toropova L, Eskin D, Kharakterova M, Dobatkina T (1998) Advanced aluminum alloys containing scandium. Routledge, London

Fujikawa SI (1997) Impurity diffusion of scandium in aluminum. Defect Diffus Forum 143:115–120

Novotny GM, Ardell AJ (2001) Precipitation of Al3Sc in binary Al–Sc alloys. Mater Sci Eng A Struct 318:144–154

Hyland RW (1992) Homogeneous nucleation kinetics of Al3Sc in a dilute Al–Sc alloy. Metall Trans A 23:1947–1955

Asta M, Ozoliņš V (2001) Structural, vibrational, and thermodynamic properties of Al–Sc alloys and intermetallic compounds. Phys Rev B 64:094104

Fuller CB, Seidman DN, Dunand DC (1999) Creep properties of coarse-grained Al(Sc) alloys at 300 degrees C. Scripta Mater 40:691–696

Marquis EA, Seidman DN, Dunand DC (2002) Creep of precipitation-strengthened Al(Sc) alloys. In: Mishra RS, Earthman JC, Raj SV (eds) Creep deformation: fundamentals and applications. TMS The Minerals, Metals & Materials Society, Pittsburgh, p 299–308

Harada Y, Dunand DC (2003) Thermal expansion of Al3Sc and Al3(Sc0.75X0.25). Scripta Mater 48:219–222

Marquis EA, Seidman DN (2001) Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater 49:1909–1919

Iwamura S, Miura Y (2004) Loss in coherency and coarsening behavior of Al3Sc precipitates. Acta Mater 52:591–600

Fuller CB, Murray JL, Seidman DN (2005) Temporal evolution of the nanostructure of Al(Sc, Zr) alloys: part I—chemical compositions of Al3(Sc1 − xZrx) Precipitatesy. Acta Mater 53:5401–5413

Fuller CB, Seldman DN (2005) Temporal evolution of the nanostructure of Al(Sc, Zr) Alloys: part II-Coarsening of Al3(Sc1 − XZrx) precipitates. Acta Mater 53:5415–5428

Marquis EA, Seidman DN (2005) Coarsening kinetics of nanoscale Al3Sc precipitates in An Al–Mg–Sc alloy. Acta Mater 53:4259–4268

Watanabe C, Watanabe D, Monzen R (2006) Coarsening behavior of Al3Sc precipitates in an Al–Mg–Sc alloy. Mater Trans 47:2285–2291

Simonovic D, Sluiter MHF (2011) Predicting the benefits of adding ternary elements to Al–Sc alloys. In: MRS proceedings 979: 0979-HH0911-0935

Zhang H, Wang S (2011) The Structural stabilities of Al3(Sc1 − XMx) by first-principles calculations. Comput Mater Sci 50:2162–2166

Karnesky RA, Seidman DN, Dunand DC (2006) Creep of Al–Sc microalloys with rare-earth element additions, aluminium alloys 2006, Pts 1 and 2 519–521:1035–1040

Harada Y, Dunand DC (2007) Microstructure and hardness of scandium trialuminide with ternary rare-earth additions, Thermec 2006, Pts 1–5 539–543: 1565–1570

De Luca A, Dunand DC, Seidman DN (2018) Scandium-enriched nanoprecipitates in aluminum providing enhanced coarsening and creep resistance. Light Metals 2018:1589–1594

Krug ME, Werber A, Dunand DC, Seidman DN (2010) Core-shell nanoscale precipitates in Al–0.06 at.%Sc microalloyed with Tb, Ho, Tm or Lu. Acta Materialia 58:134–145

Van Dalen ME, Dunand DC, Seidman DN (2011) Microstructural evolution and creep properties of precipitation-strengthened Al–0.06Sc–0.02Gd and Al–0.06Sc–0.02Yb (at.%) alloys. Acta Mater 59:5224–5237

Harada Y, Dunand DC (2009) Microstructure of Al3Sc with ternary rare-earth additions. Intermetallics 17:17–24

Karnesky RA, van Dalen ME, Dunand DC, Seidman DN (2006) Effects of substituting rare-earth elements for scandium in a precipitation-strengthened Al–0.08 at.%Sc alloy. Scripta Mater 55:437–440

Sawtell RR MJ (1988) In: Kim Y-W, Griffith WM (eds) Dispersion strengthened aluminum alloys, TMS, Warrendale

van Dalen ME, Karnesky RA, Cabotaje JR, Dunand DC, Seidman DN (2009) Erbium and ytterbium solubilities and diffusivities in aluminum as determined by nanoscale characterization of precipitates. Acta Mater 57:4081–4089

Vo NQ, Dunand DC, Seidman DN (2014) Improving aging and creep resistance in a dilute Al–Sc alloy by microalloying with Si, Zr and Er. Acta Materialia 63:73–85

Knipling KE, Dunand DC, Seidman DN (2006) Criteria for developing castable, creep-resistant aluminum-based alloys—a review. Z Metallkd 97:246–265

Sarapää O, Lauri LS, Ahtola T, Al-Ani T, Grönholm S, Kärkkäinen N, Lintinen P, Torppa A, Turunen P (2015) Discovery potential of hi-tech metals and critical minerals in Finland. Tutkimusraportti - Geologian Tutkimuskeskus 219:1–54

Lash LD, Ross JR (1961) Scandium recovery from uranium solutions. Jom-Us 13:555–558

Altinsel Y, Topkaya Y, Kaya Ş, Şentürk B (2018) Extraction of scandium from lateritic nickel–cobalt ore leach solution by ion exchange: a special study and literature review on previous works. Light Metals 2018:1545–1553

Rough FA, Bauer AA (1958) Constitution of uranium and thorium alloys. Battelle Memorial Institute, Columbus

Gafvert T, Pagels J, Holm E (2003) Thorium exposure during tungsten inert gas welding with thoriated tungsten electrodes. Radiat Prot Dosim 103:349–357

Costa L (2015) Welding with non-consumable thoriated tungsten electrodes. Weld World 59:145–150

Harada Y, Dunand DC (2002) Microstructure of Al(3)Sc with ternary transition-metal additions. Mater Sci Eng A Struct 329:686–695

Kelly TF, Miller MK (2007) Atom probe tomography. Rev Sci Instrum 78:1–20

Seidman DN (2007) Three-dimensional atom-probe tomography: advances and applications. Annu Rev Mater Res 37:127–158

Miller MK, Cerezo A, Hetherington MG, Smith GDW (1996) atom probe field ion microscopy. Clarendon Press, Oxford

Hellman OC, Vandenbroucke JA, Rusing J, Isheim D, Seidman DN (2000) Analysis of three-dimensional atom-probe data by the proximity histogram. Microsc Microanal 6:437–444

Kassner ME, Adler PH, Adamson MG, Peterson DE (1989) Evaluation and thermodynamic analysis of phase equilibria in the U-Al system. J Nucl Mater 167:160–168

Roy PR (1964) Determination of a-aluminium solid solubility limits in the aluminium–uranium and aluminium–plutonium systems. J Nucl Mater 11:59–66

Buckle H (1946) Determination of free energy through microhardness testing. Metallforschung 37:43–47

Booth-Morrison C, Dunand DC, Seidman DN (2011) Coarsening resistance at 400 °C of precipitation-strengthened Al–Zr–Sc–Er Alloys. Acta Mater 59:7029–7042

Karnesky R (2007) Mechanical properties and microstructure of Al–Sc with rareearth element or Al2O3 additions. Northwestern University, Evanston

Karnesky RA, Dunand DC, Seidman DN (2009) Evolution of nanoscale precipitates in Al microalloyed with Sc and Er. Acta Mater 57:4022–4031

Voorhees PW, McFadden GB, Johnson WC (1992) On the morphological development of 2nd-phase particles in elastically-stressed solids. Acta Metall Mater 40:2979–2992

Mao Z, Chen W, Seidman DN, Wolverton C (2011) First-principles study of the nucleation and stability of ordered precipitates in ternary Al–Sc–Li alloys. Acta Mater 59:3012–3023

Asta M, Foiles SM, Quong AA (1998) first-principles calculations of bulk and interfacial thermodynamic properties for Fcc-based Al–Sc alloys. Phys Rev B 57:11265–11275

Marquis EA, Seidman DN, Asta M, Woodward C (2006) Composition evolution of nanoscale Al3Sc precipitates in an Al–Mg–Sc alloy: experiments and computations. Acta Mater 54:119–130

Kolli RP, Seidman DN (2008) The temporal evolution of the decomposition of a concentrated multicomponent FeCu based steel. Acta Mater 56:2073–2088

Hyde JM, English CA (2001) In Lucas GE, Snead L, Kirk MA, Ellman RG (eds) Materials research society symposia proceedings, Warrendale

Gault B, Moody MP, Cairney Julie M, Ringer SP (2012) Atom probe microscopy. Springer, Berlin

Beeri O, Dunand DC, Seidman DN (2010) Roles of impurities on precipitation kinetics of dilute Al–Sc alloys. Mater Sci Eng A 527:3501–3509

Ramunni VP (2014) Diffusion behavior in nickel–aluminum and aluminum–uranium diluted alloys. Comput Mater Sci 93:112–124

Li ZS, Liu XJ, Wen MZ, Wang CP, Tang AT, Pan FS (2010) Thermodynamic assessments of the Al–Th and Th–Zn systems. J Nucl Mater 396:170–175

Knipling KE, Karnesky RA, Lee CP, Dunand DC, Seidman DN (2010) Precipitation evolution in Al–0.1Sc, Al–0.1Zr and Al–0.1Sc–0.1Zr (at.%) alloys during isochronal aging. acta Mater 58:5184–5195

Forbord B, Lefebvre W, Danoix F, Hallem H, Marthinsen K (2004) Three dimensional atom probe investigation on the formation of Al3 (Sc, Zr)-dispersoids in aluminium alloys. Scripta Mater 51:333–337

Kim K, Bobel A, Baik S-I, Walker M, Voorhees PW, Olson GB (2018) Enhanced coarsening resistance of Q-phase in aluminum alloys by the addition of slow diffusing solutes. Mater Sci Eng A 735:318–323

Acknowledgements

APT was performed at the Northwestern University Center for Atom-Probe Tomography (NUCAPT). The local-electrode atom probe (LEAP 5000 XS) tomograph at NUCAPT was acquired and upgraded with equipment grants from the MRI program of the National Science Foundation (Grant No. DMR-0420532) and the DURIP program of the Office of Naval Research (Grant Nos. N00014–0400798, N00014–0610539, N00014–0910781, N00014-1712870). NUCAPT is a Research Facility at the Materials Research Center of Northwestern University and received support through the National Science Foundation’s MRSEC program (Grant No. NSF DMR-1720139) and from the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205). Additional instrumentation at NUCAPT was supported by the Initiative for Sustainability and Energy at Northwestern (ISEN). DNS and DCD disclose financial interests relative to Braidy Industries which could potentially benefit from the outcomes of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beeri, O., Baik, SI., Bram, A.I. et al. Effect of U and Th trace additions on the precipitation strengthening of Al–0.09Sc (at.%) alloy. J Mater Sci 54, 3485–3495 (2019). https://doi.org/10.1007/s10853-018-3036-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3036-3