Abstract

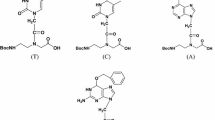

Two types of functionalized polyaniline (PAN) were synthesized based on the interfacial polymerization. PAN was characterized by scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy and Fourier transform infrared spectrometer. The results showed that synthesized PAN had different structures and was effectively modified by ionic liquids. The tribological properties of PAN as additives in polyethylene glycol (PEG) for steel/steel pairs were investigated in detail. The maximum reduction in friction and wear was achieved by PEG with addition of 0.2 wt% PAN. In particular, the wear volume was reduced by 3.8 times under 200 N. Moreover, the lubrication mechanisms were proposed by SEM and X-ray photoelectron spectroscopy (XPS) analysis of the worn surfaces.

Similar content being viewed by others

References

Holmberg K, Andersson P, Erdemir A (2012) Global energy consumption due to friction in passenger cars. Tribol Int 47:221–234

Rapoport L, Fleischer N, Tenne R (2003) Fullerene-like WS2 nanoparticles: superior lubricants for harsh conditions. Adv Mater 15:651–655

Hassani FZ, Ketabchi M, Bruschi S, Ghiotti A (2016) Effects of carbide precipitation on the microstructural and tribological properties of Co–Cr–Mo–C medical implants after thermal treatment. J Mater Sci 51:4495–4508. https://doi.org/10.1007/s10853-016-9762-5

Määttä A, Vuoristo P, Mäntylä T (2001) Friction and adhesion of stainless steel strip against tool steels in unlubricated sliding with high contact load. Tribol Int 34:779–786

Bourithis L, Papadimitriou GD, Sideris J (2006) Comparison of wear properties of tool steels AISI D2 and O1 with the same hardness. Tribol Int 39:479–489

Tobola D, Brostow W, Czechowski K, Rusek P, Wronska I (2015) Structure and properties of burnished and nitrided AISI D2 tool steel. Mater Sci 21:511–516

Tobola D, Brostow W, Czechowski K, Rusek P (2017) Improvement of wear resistance of some cold working tool steels. Wear 382–383:29–39

Zhou SX, Wu LM, Shen WD, Gu GX (2004) Study on the morphology and tribological properties of acrylic based polyurethane/fumed silica composite coatings. J Mater Sci 39:1593–1600. https://doi.org/10.1023/B:JMSC.0000016157.19241.57

Scharf TW, Prasad SV (2013) Solid lubricants: a review. J Mater Sci 48:511–531. https://doi.org/10.1007/s10853-012-7038-2

Cao ZF, Xia YQ (2017) Study on the preparation and tribological properties of fly ash as lubricant additive for steel/steel pair. Tribol Lett 65:104. https://doi.org/10.1007/s11249-017-0885-x

Ghaednia H, Hossain MS, Jackson RL (2016) Tribological performance of silver nanoparticle-enhanced polyethylene glycol lubricants. Tribol Trans 59:585–592

Amorim PM, Ferraria AM, Colaço R, Branco LC, Saramago B (2017) Imidazolium-based ionic liquids used as additives in the nanolubrication of silicon surfaces. Beilstein J Nanotechnol 8:1961–1971

Li YQ, Wang QH, Wang TM, Pan GQ (2012) Preparation and tribological properties of graphene oxide/nitrile rubber nanocomposites. J Mater Sci 47:730–738. https://doi.org/10.1007/s10853-011-5846-4

Wang BG, Tang WW, Lu HS, Huang ZY (2016) Ionic liquid capped carbon dots as a high-performance friction-reducing and antiwear additive for poly(ethylene glycol). J Mater Chem A 4:7257–7265

Yao MH, Liang YM, Xia YQ, Zhou F (2009) Bisimidazolium ionic liquids as the high-performance antiwear additives in poly(ethylene glycol) for steel-steel contacts. ACS Appl Mater Inter 1:467–471

Cao ZF, Xia YQ (2017) Corrosion resistance and tribological characteristics of polyaniline as lubricating additive in grease. J Tribol-T ASME 139:061801. https://doi.org/10.1115/1.4036271

Gao HX, Jian T, Han BX, Wang Y, Du JM, Liu ZM, Zhang JL (2004) Aqueous/ionic liquid interfacial polymerization for preparing polyaniline nanoparticles. Polymer 45:3017–3019

Athawale AA, Kulkarni MV, Chabukswar VV (2002) Studies on chemically synthesized soluble acrylic acid doped polyaniline. Mater Chem Phys 73:106–110

Wang CC, Song JF, Bao HM, Shen QD, Yang CZ (2010) Enhancement of electrical properties of ferroelectric polymers by polyaniline nanofibers with controllable conductivities. Adv Funct Mater 18:1299–1306

Saini P, Choudhary V (2013) Structural details, electrical properties, and electromagnetic interference shielding response of processable copolymers of aniline. J Mater Sci 48:797–804. https://doi.org/10.1007/s10853-012-6797-0

Tan JL, Xie Z, Zhang Z, Sun YN, Shi W, Ge DT (2018) Dopamine modified polyaniline with improved adhesion, dispersibility, and biocompatibility. J Mater Sci 53:447–455. https://doi.org/10.1007/s10853-017-1520-9

And STH, Okello M (2005) The 2-position of imidazolium ionic liquids: substitution and exchange. J Org Chem 70:1915–1918

Stejskal J, Dybal J, Trchová M (2014) The material combining conducting polymer and ionic liquid: hydrogen bonding interactions between polyaniline and imidazolium salt. Synth Met 197:168–174

Pramanik S, Karak N, Banerjee S, Kumar A (2012) Effects of solvent interactions on the structure and properties of prepared PAni nanofibers. J Appl Polym Sci 126:830–836

Li R, Chen Z, Li J, Guo Q (2013) Effective synthesis to control the growth of polyaniline nanofibers by interfacial polymerization. Synth Met 171:39–44

Fan XQ, Wang LP (2015) Ionic liquids gels with in situ modified multiwall carbon nanotubes towards high-performance lubricants. Tribol Int 88:179–188

Leng C, Wei J, Liu Z, Shi J (2011) Influence of imidazolium-based ionic liquids on the performance of polyaniline-CoFe2O4 nanocomposites. J Alloys Compd 509:3052–3056

Battez AH, González R, Viesca JL, Blanco D, Asedegbega E, Osorio A (2009) Tribological behaviour of two imidazolium ionic liquids as lubricant additives for steel/steel contacts. Wear 266:1224–1228

Cai MR, Liang YM, Yao MH, Xia YQ, Zhou F, Liu WM (2010) Imidazolium ionic liquids as antiwear and antioxidant additive in poly(ethylene glycol) for steel/steel contacts. ACS Appl Mater Inter 2:870–876

Minami I (2009) Ionic liquids in tribology. Molecules 14:2286–2305

Jiménez AE, Bermúdez MD, Iglesias P, Carrion FJ, Martinez-Nicolas G (2006) 1-N-alkyl-3-methylimidazolium ionic liquids as neat lubricants and lubricant additives in steel-aluminium contacts. Wear 260:766–782

Anand M, Hadfield M, Viesca JL, Thomas B, Battez AH, Austen S (2015) Ionic liquids as tribological performance improving additive for in-service and used fully-formulated diesel engine lubricants. Wear 334–335:67–74

Nunn N, Mahbooba Z, Ivanov MG, Ivanov DM, Brenner DW, Shenderova O (2015) Tribological properties of polyalphaolefin oil modified with nanocarbon additives. Diamond Relat Mater 54:97–102

Padgurskas J, Rukuiza R, Prosyčevas I, Kreivaitis R (2013) Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol Int 60:224–232

Ge XY, Xia YQ, Cao ZF (2015) Tribological properties and insulation effect of nanometer TiO2 and nanometer SiO2 as additives in grease. Tribol Int 92:454–461

Fan XQ, Li W, Fu HM, Zhu MH, Wang LP, Cai ZB, Liu JH, Li H (2017) Probing the function of solid nanoparticle structure under boundary lubrication. ACS Sustain Chem Eng 5:4223–4233

Liu Y, Zhang XF, Dong SL, Ye ZY, Wei YD (2017) Synthesis and tribological property of Ti3 C2TX nanosheets. J Mater Sci 52:2200–2209. https://doi.org/10.1007/s10853-016-0509-0

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant 51575181) and Beijing Municipal Natural Science Foundation (Grant 2172053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Cao, Z., Xia, Y. Synthesis and tribological properties of polyaniline functionalized by ionic liquids. J Mater Sci 53, 7060–7071 (2018). https://doi.org/10.1007/s10853-018-2028-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2028-7