Abstract

This paper aims to propose a simulation procedure to predict the interlaminar fracture toughness of stitched flax fiber composites through a virtual double cantilever beam test. The proposed procedure is constituted of two steps. First, the interlaminar failure of unstitched flax fiber laminate, as the parent laminate, is modeled using cohesive elements with a nonlinear softening law in order to model the large-scale fiber bridging occurred during delamination. The experimental results are used to calibrate the parameters of the cohesive law. Second, two-node beam elements are superposed onto the cohesive interface of the parent laminate at a prescribed stitch density and distribution to model the bridging stitches present in the validation samples. The stitch material behavior and properties are obtained from the tensile test of impregnated stitch fibers. The out-of-plane flax yarn stitching was found to generate a twofold increase in the delamination resistance of the composite laminate at a medium stitch density. The FE analysis results agreed well with the experimental results, where a good fit between the predicted and experimental R-curves was achieved.

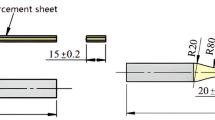

(reproduced from [36])

Similar content being viewed by others

References

Shah DU (2014) Natural fibre composites: comprehensive Ashby-type materials selection charts. Mater Des 62:21–31. https://doi.org/10.1016/j.matdes.2014.05.002

Müssig J, Haag K (2015) 2—the use of flax fibres as reinforcements in composites. In: Faruk O, Sain M (eds) Biofiber reinforcements in composite materials. Woodhead Publishing, Cambridge, pp 35–85

Faruk O, Sain M (2014) Biofiber reinforcements in composite materials. Elsevier, Amsterdam

Khanlou HM, Woodfield P, Summerscales J, Hall W (2017) Consolidation process boundaries of the degradation of mechanical properties in compression moulding of natural-fibre bio-polymer composites. Polym Degrad Stab 138:115–125. https://doi.org/10.1016/j.polymdegradstab.2017.03.004

Khanlou HM, Hall W, Heitzman MT et al (2016) Technical note: on modelling thermo-chemical degradation of poly(lactic acid). Polym Degrad Stab 134:19–21. https://doi.org/10.1016/j.polymdegradstab.2016.09.033

Bensadoun F, Verpoest I, Baets J et al (2017) Impregnated fibre bundle test for natural fibres used in composites. J Reinf Plast Compos. https://doi.org/10.1177/0731684417695461

Yan L, Chouw N, Jayaraman K (2014) Flax fibre and its composites—a review. Compos B Eng 56:296–317. https://doi.org/10.1016/j.compositesb.2013.08.014

Pickering K (2008) Properties and performance of natural-fibre composites. Elsevier, Boca Raton

Hodzic A, Shanks R (2014) Natural fibre composites: materials, processes and properties. Woodhead Publishing, Cambridge

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596. https://doi.org/10.1016/j.progpolymsci.2012.04.003

Shah DU, Schubel PJ, Clifford MJ (2013) Can flax replace E-glass in structural composites? A small wind turbine blade case study. Compos B Eng 52:172–181. https://doi.org/10.1016/j.compositesb.2013.04.027

Ravandi M, Teo WS, Tran LQN et al (2017) Low velocity impact performance of stitched flax/epoxy composite laminates. Compos B Eng 117:89–100. https://doi.org/10.1016/j.compositesb.2017.02.003

Zhong Y, Tran LQN, Kureemun U, Lee HP (2017) Prediction of the mechanical behavior of flax polypropylene composites based on multi-scale finite element analysis. J Mater Sci 52:4957–4967. https://doi.org/10.1007/s10853-016-0733-7

Kureemun U, Ravandi M, Tran LQN et al (2018) Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos B Eng 134:28–38. https://doi.org/10.1016/j.compositesb.2017.09.035

Goutianos S, Peijs T (2003) The optimisation of flax fibre yarns for the development of high-performance natural fibre composites. Adv Compos Lett 12:237–241

Goutianos S, Peijs T, Nystrom B, Skrifvars M (2006) Development of flax fibre based textile reinforcements for composite applications. Appl Compos Mater 13:199–215

Dai S-C, Yan W, Liu H-Y, Mai Y-W (2004) Experimental study on z-pin bridging law by pullout test. Compos Sci Technol 64:2451–2457

Qiao Y (2003) Fracture toughness of composite materials reinforced by debondable particulates. Scr Mater 49:491–496

Sela N, Ishai O (1989) Interlaminar fracture toughness and toughening of laminated composite materials: a review. Composites 20:423–435

Ansar M, Xinwei W, Chouwei Z (2011) Modeling strategies of 3D woven composites: a review. Compos Struct 93:1947–1963

Suppakul P, Bandyopadhyay S (2002) The effect of weave pattern on the mode-I interlaminar fracture energy of E-glass/vinyl ester composites. Compos Sci Technol 62:709–717

Mouritz AP, Cox BN (2000) A mechanistic approach to the properties of stitched laminates. Compos A Appl Sci Manuf 31:1–27. https://doi.org/10.1016/S1359-835X(99)00056-1

Iwahori Y, Ishikawa T, Hayashi Y, Watanabe N (2000) Study of interlaminar fracture toughness improvement on stitched CFRP laminates. J Jpn Soc Compos Mater (Japan) 26:90–100

Shu D, Mai Y-W (1993) Effect of stitching on interlaminar delamination extension in composite laminates. Compos Sci Technol 49:165–171

Jain LK, Mai Y-W (1994) On the effect of stitching on Mode I delamination toughness of laminated composites. Compos Sci Technol 51:331–345. https://doi.org/10.1016/0266-3538(94)90103-1

Massabo R, Cox BN (1999) Concepts for bridged Mode II delamination cracks. J Mech Phys Solids 47:1265–1300. https://doi.org/10.1016/S0022-5096(98)00107-0

Sun X, Tong L, Wood MDK, Mai Y-W (2004) Effect of stitch distribution on Mode I delamination toughness of laminated DCB specimens. Compos Sci Technol 64:967–981. https://doi.org/10.1016/j.compscitech.2003.07.004

Tsai G-C, Chen J-W (2005) Effect of stitching on Mode I strain energy release rate. Compos Struct 69:1–9. https://doi.org/10.1016/j.compstruct.2004.02.009

Iwahori Y, Nakane K, Watanabe N (2009) DCB test simulation of stitched CFRP laminates using interlaminar tension test results. Compos Sci Technol 69:2315–2322

Tan KT, Watanabe N, Sano M et al (2010) Interlaminar fracture toughness of vectran-stitched composites—experimental and computational analysis. J Compos Mater 44:3203–3229

Wood MDK, Sun X, Tong L et al (2007) The effect of stitch distribution on Mode I delamination toughness of stitched laminated composites—experimental results and FEA simulation. Compos Sci Technol 67:1058–1072. https://doi.org/10.1016/j.compscitech.2006.06.002

Heß H, Himmel N (2011) Structurally stitched NCF CFRP laminates. Part 2: finite element unit cell based prediction of in-plane strength. Compos Sci Technol 71:569–585

Sankar BV, Dharmapuri SM (1998) Analysis of a stitched double cantilever beam. J Compos Mater 32:2203–2225. https://doi.org/10.1177/002199839803202402

Chen L, Ifju PG, Sankar BV (2005) Analysis of Mode I and Mode II tests for composites with translaminar reinforcements. J Compos Mater 39:1311–1333. https://doi.org/10.1177/0021998305050425

Sørensen BF, Jacobsen TK (1998) Large-scale bridging in composites: R-curves and bridging laws. Compos A Appl Sci Manuf 29:1443–1451. https://doi.org/10.1016/S1359-835X(98)00025-6

Airoldi A, Dávila CG (2012) Identification of material parameters for modelling delamination in the presence of fibre bridging. Compos Struct 94:3240–3249. https://doi.org/10.1016/j.compstruct.2012.05.014

Dávila CG, Rose CA, Camanho PP (2009) A procedure for superposing linear cohesive laws to represent multiple damage mechanisms in the fracture of composites. Int J Fract 158:211–223. https://doi.org/10.1007/s10704-009-9366-z

Ravandi M, Teo WS, Tran LQN et al (2016) The effects of through-the-thickness stitching on the Mode I interlaminar fracture toughness of flax/epoxy composite laminates. Mater Des 109:659–669. https://doi.org/10.1016/j.matdes.2016.07.093

D30 Committee (2007) Test method for Mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. ASTM International, West Conshohocken

Tamuzs V, Tarasovs S, Vilks U (2001) Progressive delamination and fiber bridging modeling in double cantilever beam composite specimens. Eng Fract Mech 68:513–525. https://doi.org/10.1016/S0013-7944(00)00131-4

Sørensen BF, Goutianos S, Jacobsen TK (2009) Strength scaling of adhesive joints in polymer–matrix composites. Int J Solids Struct 46:741–761. https://doi.org/10.1016/j.ijsolstr.2008.09.024

Boyang C (2013) Numerical modelling of scale-dependent damage and failure of composites. Ph.D

Turon A, Dávila CG, Camanho PP, Costa J (2007) An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng Fract Mech 74:1665–1682. https://doi.org/10.1016/j.engfracmech.2006.08.025

Chen BY, Tay TE, Baiz PM, Pinho ST (2013) Numerical analysis of size effects on open-hole tensile composite laminates. Compos A Appl Sci Manuf 47:52–62. https://doi.org/10.1016/j.compositesa.2012.12.001

Lampani L (2011) Finite element analysis of delamination of a composite component with the cohesive zone model technique. Eng Comput 28:30–46. https://doi.org/10.1108/02644401111097000

Camanho PP, Dávila CG (2002) Mixed-mode decohesion finite elements for the simulation of delamination in composite materials. NASA-technical paper 211737, p. 33

Dassault Systèmes Simulia Corp (2011) Abaqus 6.11 documentation. Dassault Systèmes, Providence, RI, USA

Ravandi M, Teo WS, Tran LQN, Tay MSY and TE (2016) Mode I interlaminar fracture toughness of natural fiber stitched flax/epoxy composite laminates—experimental and numerical analysis. In: Proceedings of the American society for composites: thirty-first technical conference

Popelar CH, Kanninen MF (1985) Advanced fracture mechanics, 1st edn. Oxford University Press, New York

Manshadi BD, Farmand-Ashtiani E, Botsis J, Vassilopoulos AP (2014) An iterative analytical/experimental study of bridging in delamination of the double cantilever beam specimen. Compos A Appl Sci Manuf 61:43–50. https://doi.org/10.1016/j.compositesa.2014.02.001

Acknowledgements

The authors are grateful to the Agency for Science, Technology and Research (A*STAR), Singapore Institute of Manufacturing Technology, and the National University of Singapore for financial support (partially through Grant No. WBS R265000523646).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ravandi, M., Teo, W.S., Yong, M.S. et al. Prediction of Mode I interlaminar fracture toughness of stitched flax fiber composites. J Mater Sci 53, 4173–4188 (2018). https://doi.org/10.1007/s10853-017-1859-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1859-y