Abstract

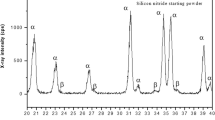

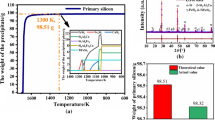

Current silicon melt-infiltrated (SMI) ceramic matrix composites (CMCs) are limited by the melting temperature of silicon (1414 °C) and the volatility of the thermally grown SiO2 scale in high-temperature water vapor environments. Replacement of the melt-infiltrated (MI) silicon with a rare-earth silicide offers the potential to address both limitations of SMI CMCs. This study focuses on the ability of yttrium silicides to form yttrium silicates (phases with greater stability in high-temperature water vapor than SiO2) in high-temperature oxidizing environments. Yttrium silicides with compositions of 41, 67 and 95 at.% Si–Y were fabricated using arc melting and oxidized in air at 1000 and 1200 °C for up to 24 h. Oxidation resulted in the rapid formation of a non-protective Y2O3 scale and rejected Si. Additional minor oxide phases of Y–Si–O, Y2SiO5, Y2Si2O7 and SiO2 were observed to form on and beneath the specimen surface. Characterization of the microstructural evolution with time and temperature helped elucidate the diffusion mechanisms that control oxide growth rates. Replacement of MI silicon with a MI yttrium silicide would significantly compromise the high-temperature performance of a CMC due to Y2O3 CTE mismatch with SiC, high oxygen permeability and the large volume change associated with its rapid subsurface formation. Results are utilized to examine the viability of other rare-earth silicides as MI materials for CMCs.

Similar content being viewed by others

References

Zok FW (2016) Ceramic-matrix composites enable revolutionary gains in turbine engine efficiency. Am Ceram Soc Bull 95:22–28

Opila EJ, Hann RE (1997) Paralinear oxidation of CVD SiC in water vapor. J Am Ceram Soc 80:197–205

Opila EJ, Smialek JL, Robinson RC et al (1999) SiC recession caused by SiO2 scale volatility under combustion conditions: II, thermodynamics and gaseous-diffusion model. J Am Ceram Soc 82:1826–1834

Gokhale AB, Abbaschian GJ (1986) The Si–Y (silicon–yttrium) system. Bull Alloy Phase Diagr 7:485–489

Gokhale AB, Abbaschian GJ (1986) The Sc–Si (scandium-silicon) system. Bull Alloy Phase Diagr 7:333–336

Bulanova MV, Zheltov PN, Meleshevich KA et al (2001) Lanthanum–silicon system. J Alloys Compd 329:214–223

Bulanova MV, Zheltov PN, Meleshevich KA et al (2002) Cerium–silicon system. J Alloys Compd 345:110–115

Gokhale AB, Munitz A, Abbaschian GJ (1989) The Nd–Si (neodymium–silicon) system. Bull Alloy Phase Diagr 10:246–251

Gokhale AB, Abbaschian GJ (1988) The Si–Sm (silicon–samarium) system. Bull Alloy Phase Diagr 9:582–585

Okamoto H (2009) Gd–Si (gadolinium–silicon). J Phase Equilib Diffus 30:213–214

Bulanova MV, Tedenac JC, Noël H et al (2004) The Ti5Si3–Tb5Si3 section of the Ti–Tb–Si system. J Alloys Compd 375:175–178

Eremenko VN, Listovnichii VE, Luzan SP et al (1995) Phase diagram of the holmium-silicon binary system and physical properties of holmium silicides up to 1050 °C. J Alloys Compd 219:181–184

Luzan SP, Listovnichii VE, Buyanov YI, Martsenyuk PS (1996) Phase diagram of the binary erbium-silicon system and physical properties of erbium silicides up to 1050 °C. J Alloys Compd 239:77–82

Palenzona A, Manfrinetti P, Brutti S, Balducci G (2003) The phase diagram of the Yb–Si system. J Alloys Compd 348:100–104

Brutti S, Balducci G, Ciccioli A, Gigli G (2005) Thermodynamic assessment of the Yb–Si system. Calphad 29:254–261

Lee KN, Fox DS, Bansal NP (2005) Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. J Eur Ceram Soc 25:1705–1715

Maier N, Nickel KG, Rixecker G (2007) High temperature water vapour corrosion of rare earth disilicates (Y, Yb, Lu)2Si2O7 in the presence of Al(OH)3 impurities. J Eur Ceram Soc 27:2705–2713

Klemm H (2010) Silicon nitride for high-temperature applications. J Am Ceram Soc 93:1501–1522

Liu J, Zhang L, Hu F et al (2013) Polymer-derived yttrium silicate coatings on 2D C/SiC composites. J Eur Ceram Soc 33:433–439

Fritsch M (2007) Heiβgaskorrosion keramischer Werkstoffe in H2O-Haltigen Rauchgasatmosphären. PhD Dissertation, Fraunhofer-Institut für Keramische Technologien und Systeme IKTS

Golden RA, Opila EJ (2016) A method for assessing the volatility of oxides in high-temperature high-velocity water vapor. J Eur Ceram Soc 36:1135–1147

Jacobson NS (2014) Silica activity measurements in the Y2O3–SiO2 system and applications to modeling of coating volatility. J Am Ceram Soc 97:1959–1965

Ueno S, Jayaseelan DD, Ohji T, Lin H-T (2006) Recession mechanism of Lu2Si2O7 phase in high speed steam jet environment at high temperatures. Ceram Int 32:775–778

Ueno S, Ohji T, Lin H-T (2008) Recession behavior of Yb2Si2O7 phase under high speed steam jet at high temperatures. Corros Sci 50:178–182

Ueno S, Ohji T, Lin H-T (2011) Recession behavior of Lu2SiO5 under a high speed steam jet at high temperatures. Ceram Int 37:1185–1189

Yuri I, Hisamatsu T, Ueno S, Ohji T (2001) Exposure test results of Lu2Si2O7 in combustion gas flow at high temperature and high speed. Jpn Soc Mech Eng 44:520–527

Hong Z, Cheng L, Zhang L, Wang Y (2009) Water vapor corrosion behavior of scandium silicates at 1400 °C. J Am Ceram Soc 92:193–196

Richards BT, Young KA, de Francqueville F et al (2016) Response of ytterbium disilicate–silicon environmental barrier coatings to thermal cycling in water vapor. Acta Mater 106:1–14

Costa GCC, Jacobson NS (2015) Mass spectrometric measurements of the silica activity in the Yb2O3–SiO2 system and implications to assess the degradation of silicate-based coatings in combustion environments. J Eur Ceram Soc 35:4259–4267

Verkhoglyadove TS, Dvorina LA (1967) High-temperature oxidation of silicides of some rare-earth metals. https://archive.org/details/nasa_techdoc_19670009598

Chiam SY, Chim WK, Huan ACH et al (2007) Coverage dependent reaction of yttrium on silicon and the oxidation of yttrium silicide investigated by x-ray photoelectron spectroscopy. J Vac Sci Technol, A 25:500–507

Haefling JA, Schmidt FA, Carlson ON (1964) Air oxidation of yttrium and some yttrium-base alloys. J Common Met 7:433–440

Poerschke DL, Levi CG (2013) Yttrium bearing silicon carbide matrices for robust ceramic composites. J Am Ceram Soc 96:1300–1308

Shukla A, Kang Y-B, Pelton AD (2009) Thermodynamic assessment of the Ce–Si, Y–Si, Mg–Ce–Si and Mg–Y–Si systems. Int J Mater Res 100:208–217

Barin I, Knacke O, Kubaschewski O (1977) Thermochemical properties of inorganic substances. Springer, Berlin

Fabrichnaya O, Seifert HJ, Weiland R et al (2001) Phase equilibria and thermodynamics in the Y2O3–Al2O3–SiO2 system. Z Für Met 92:1083–1097

Toropov NA, Bondar IA (1961) Silicates of the rare earth elements. Bull Acad Sci USSR Div Chem Sci 10:502–508

Cupid D, Seifert H (2007) Thermodynamic calculations and phase stabilities in the Y–Si–C–O system. J Phase Equilib Diffus 28:90–100

Zhang P, Navrotsky A, Guo B et al (2008) Energetics of cubic and monoclinic yttrium oxide polymorphs: phase transitions, surface enthalpies, and stability at the nanoscale. J Phys Chem C 112:932–938

Fukuda K, Matsubara H (2003) Anisotropic thermal expansion in yttrium silicate. J Mater Res 18:1715–1722

Ito J, Johnson H (1968) Synthesis and study of yttrialite. Am Mineral 53:1940–1952

Okada Y, Tokumaru Y (1984) Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J Appl Phys 56:314–320

Aparicio M, Durán A (2000) Yttrium silicate coatings for oxidation protection of carbon-silicon carbide composites. J Am Ceram Soc 83:1351–1355

Mayer I, Felner I (1972) High-temperature X-ray study of rare-earth silicides. J Common Met 29:25–31

Dolan MD, Harlan B, White JS et al (2008) Structures and anisotropic thermal expansion of the α, β, γ, and δ polymorphs of Y2Si2O7. Powder Diffr 23:20–25

Stecura S, Campbell WJ (1961) Thermal expansion and phase inversion of rare-earth oxides. U.S. Department of the Interior, Bureau of Mines

Deal BE, Grove AS (1965) General relationship for the thermal oxidation of silicon. J Appl Phys 36:3770–3778

Ogura Y, Kondo M, Morimoto T et al (2001) Oxygen permeability of Y2SiO5. Mater Trans 42:1124–1130

Bale CW, Bélisle E, Chartrand P et al (2016) FactSage thermochemical software and databases, 2010–2016. Calphad 54:35–53

Young DJ (ed) (2008) Chapter 5 oxidation of alloys I: single phase scales. In: High temperature oxidation and corrosion of metals. Elsevier Science, Amsterdam, pp 185–246

Borchardt HJ (1964) On the oxidation of yttrium. J Inorg Nucl Chem 26:711–719

Cubicciotti D, Lau KH (1979) Kinetics of oxidation of yttria hot-pressed silicon nitride. J Electrochem Soc 126:1723–1728

Mieskowski DM, Sanders WA (1985) Oxidation of silicon nitride sintered with rare-earth oxide additions. J Am Ceram Soc 68:C-160–C-163

Clarke DR (1983) Thermodynamic mechanism for cation diffusion through an intergranular phase: application to environmental reactions with nitrogen ceramics. In: Riley FL (ed) Progress in nitrogen ceramics. Springer, Dordrecht, pp 421–426

Zinkevich M (2007) Thermodynamics of rare earth sesquioxides. Prog Mater Sci 52:597–647

Berard MF, Wirkus CD, Wilder DR (1968) Diffusion of oxygen in selected monocrystalline rare earth oxides. J Am Ceram Soc 51:643–647

Acknowledgements

The authors would like to thank Rolls-Royce Corporation for funding this research, William Soffa and Wade Jensen for arc melting the yttrium silicides (University of Virginia), Kendall Mueller for assisting with the oxidation experiments (University of Virginia), Helge Heinrich for assistance with the TEM characterization (University of Virginia) and Roberto Garcia and Fred Stevie for providing the FIB specimens for TEM characterization (North Carolina State University).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Golden, R.A., Opila, E.J. High-temperature oxidation of yttrium silicides. J Mater Sci 53, 3981–4000 (2018). https://doi.org/10.1007/s10853-017-1823-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1823-x