Abstract

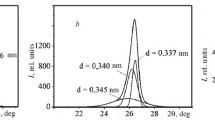

Using the Eshelby equivalent inclusion theory and the Mori–Tanaka method, a new micromechanical model is proposed to predict the tensile modulus of carbon fibers by considering crystallites, amorphous components, and microvoids of the fiber structure. Factors that affect the tensile modulus included the aspect ratio of crystallites, the aspect ratio of microvoids, the volume fraction of crystallites, the volume fraction of microvoids, and the orientation degree of crystallites. To follow the dependence of the tensile modulus of the fibers on microstructure, thirty different types of polyacrylonitrile-based fibers were prepared. The aspect ratios and orientation degrees of crystallites were calculated directly by X-ray diffraction. The aspect ratios and volume fractions of microvoids were obtained by small-angle X-ray scattering. The average tensile modulus of amorphous was estimated by dealing with thirty types of PAN-based fibers. The volume fractions of crystallites were obtained by the micromechanical model. Some relationships are concluded: (1) the tensile modulus increased with increasing volume fractions of crystallites, aspect ratios of crystallites and microvoids, and orientation degree of crystallites; (2) the tensile modulus increased with decreasing volume fractions of microvoids.

Similar content being viewed by others

References

Oberlin A (1984) Carbonization and graphitization. Carbon 22(6):521–541

Johnson DJ (1987) Structure-property relationships in carbon fibers. J Phys D Appl Phys 20(3):286–291

Johnson DJ (1987) Structural studies of PAN-based carbon fibers. In: Thrower PA (ed) Chemistry and physics of carbon, vol 20. Marcel Dekker, New York, pp 1–58

Oberlin A, Bonnamy S, Lafdi K (1989) Structure and texture of carbon fibers. In: Donnet JB (ed) Carbon fibers. Mercel Dekker Inc, New York, pp 85–159

Ruland W (1969) The relationship between preferred orientation and Young’ s modulus of carbon fibers. Appl Polym Symp 9:293–301

Northolt MG, Veldhuizen LH, Jansen H (1991) T ensile deformation of carbon fibers and the relationship with the modulus for shear between the basal planes. Carbon 29(8):1267–1279

Shioya M, Hayakawa E, Takaku A (1996) Non-hookean stress-strain response and changes in crystallite orientation of carbon fibers. J Mater Sci 31(17):4521–4532. doi:10.1007/BF00366347

Morita K, Murata Y, Ishitani A, Murayaya K, Ono T, Nakajima A (1986) Characterization of commercially-available PAN (polyacrylonitrile)-based carbon fibers. Pure Appl Chem 58:455–468

Kobayashi T, Sumiya K, Fujii Y, Fujie M, Takahagi T, Tashiro K (2012) Stress-induced microstructural changes and crystallite modulus of carbon fiber as measured by X-ray scattering. Carbon 50:1163–1169

Tanaka F, Okabe T, Okuda H, Ise M, Kinloch IA, Mori T et al (2013) The effect of nanostructure upon the deformation micromechanics of carbon fibers. Carbon 52:372–378

Andreas AF, Ruland W (2000) Microvoids in Polyacrylonitrile Fibers: a Small-Angle X-ray Scattering Study [J]. Macromolecules 33:1848–1852

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc R Soc A 241(1226):376–396

Eshelby JD (1959) The elastic field outside an ellipsoidal inclusion. Proc R Soc A 252(1271):561–569

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Met 21(5):571–574

Li Shaofan, Wang Gang (2008) Introduction to micrmechanics and nanomechanics. World Scientific, Singapore

Dvorak George J (2013) Micromechanics of composite materials. Springer, London

Spence GB (1963) Extended dislocation in the anisotropic elastic continuum approximation. Proceedings of the fifth conference on carbon. American Carbon Society, Pennsylvania, pp 531–538

Qiu YP, Weng GJ (1990) On the application of Mori-Tanaka’s theory involving transversely isotropic spheroidal inclusions. Int Eng Sci 28:1121–1137

Mura T (1987) Micromechanics of defects in solids. Martinus Nijhoff, The Netherlands

He F (2004) Carbon Fiber and Applied Technique [M]. Chemical Industry Press, Beijing

Liu FJ, Wang HJ, Fan LD (2009) Analysis on the microstructure of MJ series carbon fibers. New Chem Mater 37(1):41–43

Zhu YP (2008) Small angle X-ray scattering-theory, measurement, calculation and application. Chemical Industry Press, Beijing

Fukuyama Katsuya, Kasahara Yasutoshi, Kasahara Naoto, Oya Asao et al (2001) Small-angle X-ray scattering study of the pore structure of carbon fibers prepared from a polymer blend of phenolic resin and polystyrene. Carbon 39:287–324

Yin JH, Mo ZS (2001) Modern Polymer Physics [M]. SciencePress, Beijing

Sheng Y, Zhang CH, Xu Y et al (2009) Investigation of PAN-based carbon fiber microstructure by 2D-SAXS. New Carbon Mater 24(3):270–276

Shioya M, Takaku A (1985) Characterization of microvoids in carbon fibers by absolute small angle X-ray measurements on a fiber bundle. J Appl Phys 58:4074–4082

Shioya M, Takaku A (1986) Characterization of microvoids in polycrylonitrile based carbon fibers. J Mater Sci 21:4443–4450. doi:10.1007/BF01106569

Weinberg DL (1963) Absolute intensity measurements in small angle X-ray scattering. Rev Sci Instrum 34(6):691–696

Shioya M, Takaku A (1994) Rotation and extension of crystallites in carbon fibers by tensile stress. Carbon 32:615–619

Mao YM (2011) Polymorphism, preferred orientation and morphology of propylene-based random copolymer subjected to external force fields. PhD Dissertation, Stony Brook University

Deborah DDL (1994) Carbon fiber composites. Butterworth-Heinemann, Boston

Su CJ, Gao AJ, Lu S, Xu LH (2012) Evolution of the skin-core structure of PAN-based carbon fibers with high temperature treatment. New Carbon Mater 27:288–293 [in Chinese]

Acknowledgements

This work is supported by the National Natural Science Foundation of china (No. 11072069).

Author information

Authors and Affiliations

Corresponding author

Appendix: coordinate transformation

Appendix: coordinate transformation

Consider vector u in the global coordinate system O − x 1 x 2 x 3 and u ′ in the local coordinate system \( O - x^{\prime}_{ 1} x^{\prime}_{ 2} x^{\prime}_{ 3} \). See Fig. 6.

The transformation relation between two coordinate systems can be expressed u ′ = Qu, where Q is a Transformation tensor. It can be written in matrix form as

\( Q = \left[ {\begin{array}{*{20}c} {\cos \theta \cos \varphi } & { - \cos \theta \sin \varphi } & {\sin \theta } \\ {\sin \varphi } & {\cos \varphi } & 0 \\ { - \sin \theta \cos \varphi } & {\sin \theta \sin \varphi } & {\cos \theta } \\ \end{array} } \right]. \)

For second-order stress tensors σ in the global coordinate system and σ ′ in the local coordinate system, we have σ = Q T σ ′ Q. Similarly, ɛ = Q T ɛ ′ Q, where ɛ and ɛ ′ are second-order strain tensors in the global coordinate system and the local coordinate system, respectively.

Stress tensors and strain tensors can also be written in vectors form

then the transformations of stress vectors and strain vectors are σ = Tσ ′ and \( \varepsilon = \left( {T^{ - 1} } \right)^{\text{T}} \varepsilon^{{\prime }},\;\)where T and \( \left( {T^{ - 1} } \right)^{\text{T}} \) are the stress transformation matrix and strain transformation matrix, T −1 is inverse of the T, and \( \left( {T^{ - 1} } \right)^{\text{T}} \) is transpose of the T −1. T and \( \left( {T^{ - 1} } \right)^{\text{T}} \) can be expressed as

where

Rights and permissions

About this article

Cite this article

Zhong, Y., Bian, W. & Wang, M. The effect of nanostructure on the tensile modulus of carbon fibers. J Mater Sci 51, 3564–3573 (2016). https://doi.org/10.1007/s10853-015-9676-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9676-7