Abstract

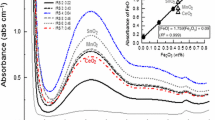

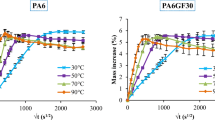

Single fibre tensile testing of thermally conditioned water sized and γ-aminopropyltriethoxysilane (APS) sized boron-free E-glass has been carried out. The fibres were produced from identical melts following which bare fibre had only water applied to it before winding whereas the sized fibre had a solution containing only APS applied to its surface. Both fibre types experience a loss of room temperature tensile strength after exposure to elevated temperature. By application of a novel method of single fibre thermal conditioning, it was demonstrated that the tensile strength of heat-treated glass fibre can be significantly underestimated. Strength loss was found, in most cases, to be caused by a combination of thermal effect and mechanical handling damage. The latter is found to be influenced by thermal loading of the fibre. The onset of mechanical handling damage in APS-sized fibre was found to be controlled by the thermal degradation of the silane sizing. This suggests that silane-based coatings, even when they are present as only a relatively thin surface layer, can protect fibres from the development or growth of critical surface flaws. The relative contribution to overall fibre strength loss from mechanical handling damage highlights the need to minimise processes which may cause fibre mechanical damage during glass fibre recycling procedures.

Similar content being viewed by others

References

Glass Fiber & Glass Fiber Reinforced Plastic (GFRP) (2014) Composites market by raw material, manufacturing process, application & by geography. Glob Trends Forecast 2019:1–347

Pickering SJ (2006) Recycling technologies for thermoset composite materials—current status. Composites A 37:1206–1215. doi:10.1016/j.compositesa.2005.05.030

Kennerley JR, Fenwick NJ, Pickering SJ, Rudd CD (1997) The properties of glass fibers recycled from the thermal processing of scrap thermoset composites. J Vinyl Addit Technol 3:58–63. doi:10.1002/vnl.10166

Feih S, Boiocchi E, Mathys Z et al (2011) Mechanical properties of thermally-treated and recycled glass fibres. Composites B 42:350–358. doi:10.1016/j.compositesb.2010.12.020

Thomas WF (1960) An investigation of the factors likely to affect the strength and properties of glass fibres. Phys Chem Glasses 1:4–18

Cameron NM (1968) The effect of environment and temperature on the strength of E-glass fibres. Part 2. Heating and ageing. Glass Technol 9:130–212

Aslanova MS (1960) The effect of different factors on the mechanical properties of glass fibers. Steklo Keram 17:10–15

Dorzhiev DB, Khazanov VE, Gorbachev VV (1990) Some features of the structure and strength of a magnesium aluminosilicate fiber. Sov J Glass Phys Chem 15:99–102

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc A 221:163–198. doi:10.1098/rsta.1921.0006

Zinck P, Mader E, Gerard JF (2001) Role of silane coupling agent and polymeric film former for tailoring glass fiber sizings from tensile strength measurements. J Mater Sci 36:5245–5252. doi:10.1023/A:1012410315601

Gao S, Mader E, Plonka R (2008) Nanocomposite coatings for healing surface defects of glass fibers and improving interfacial adhesion. Compos Sci Technol 68:2892–2901. doi:10.1016/j.compscitech.2007.10.009

Jenkins P, Thomason J, Meier R (2012) Separation of mechanical and thermal degradation of thermally conditioned sized glass fibre. In: 15th European Conference on Composite Materials, Venice

Feih S, Manatpon K, Mathys Z et al (2008) Strength degradation of glass fibers at high temperatures. J Mater Sci 44:392–400. doi:10.1007/s10853-008-3140-x

Mizuguchi J, Tsukada Y, Takahashi H (2013) Recovery and characterization of reinforcing fibers from fiber reinforced plastics by thermal activation of oxide semiconductors. Mater Trans 54:384–391

Yang L, Thomason JL (2012) Effect of silane coupling agent on mechanical performance of glass fibre. J Mater Sci 48:1947–1954. doi:10.1007/s10853-012-6960-7

Yang L, Thomason JL (2013) The thermal behaviour of glass fibre investigated by thermomechanical analysis. J Mater Sci. doi:10.1007/s10853-013-7369-7

Lund MD, Yue Y (2010) Impact of drawing stress on the tensile strength of oxide glass fibers. J Am Ceram Soc 93:3236–3243. doi:10.1111/j.1551-2916.2010.03879.x

Aslanova MS, Ivanov NV, Balashov YS (1970) Effect of chemical composition on the relaxation properties of thin glass fibers. Steklo Keram 8:21–24

Otto WH (1961) Compaction effects in glass fibers. J Am Ceram Soc 44:68–72

Ya M, Deubener J, Yue Y (2008) Enthalpy and anisotropy relaxation of glass fibers. J Am Ceram Soc 91:745–752. doi:10.1111/j.1551-2916.2007.02100.x

Hair ML (1975) Hydroxyl groups on silica surface. J Non Cryst Solids 19:299–309

Masmoudi M, Rahal C, Abdelmouleh M, Abdelhedi R (2013) Hydrolysis process of γ-APS and characterization of silane film formed on copper in different conditions. Appl Surf Sci 286:71–77. doi:10.1016/j.apsusc.2013.09.018

Culler SR, Naviroj S, Ishida H, Koenig JL (1983) Analytical and spectroscopic investigation of the interaction of CO2 with amine functional silane coupling agents on glass fibers. J Colloid Interface Sci 96:69–79

Liu XM, Thomason JL, Jones FR (2008) XPS and AFM study of interaction of organosilane and sizing with E-glass Fibre surface. J Adhes 84:322–338

Acknowledgements

The authors gratefully acknowledge the funding from Engineering and Physical Sciences Research Council (EPSRC) through the Project EP/I038616/1. The authors would also like to thank Owens Corning Vetrotex for providing the glass fibres used in this study. Special thanks are given to the Advanced Materials Research Laboratory (AMRL) at University of Strathclyde for the use of TGA, DSC and SEM equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jenkins, P.G., Yang, L., Liggat, J.J. et al. Investigation of the strength loss of glass fibre after thermal conditioning. J Mater Sci 50, 1050–1057 (2015). https://doi.org/10.1007/s10853-014-8661-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8661-x