Abstract

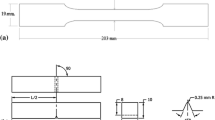

The aerospace industry uses 200-h sustained-load test (SLT), described in ASTM F-519, to evaluate hydrogen embrittlement (HE) of their 4340 steel electroplated parts. The cadmium plating used in ASTM F-519 suggest that the coating density may affect HE in an important manner. Therefore, in this work, 4340 steel notched bars were plated with five different cadmium coating densities. Then, the SLT was combined with thermal desorption spectroscopy (TDS) to evaluate: (i) the degree of HE, and (ii) the hydrogen content of the cadmium-plated 4340 steel samples. The results show strong evidences that the major factor causing HE of cadmium-plated 4340 steel is the coating density. Moreover, an advanced analysis of TDS curves using the Hertz–Knudsen equation allows distinguishing hydrogen in steel from hydrogen in the cadmium coating. The advanced analysis also gives an estimation of the coating density, and therefore indicates if the baking will be effective at relieving embrittlement. Finally, TDS could be a good complementary tool to the SLT in evaluating HE.

Graphic abstract

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time due to technical or time limitations. The processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Notes

This technique is more appropriate when the hydrogen measurement can not be perform immediately after the stripping like Berman did with his complete stripping [1].

References

Berman DA (1985) The effect of baking and stress on the hydrogen content of cadmium plated high strength steels. Mater Perform 24:36–41

Bellemare J, Laliberté-Riverin S, Ménard D, Brochu M, Sirois F (2020) Subtleties behind hydrogen embrittlement of cadmium-plated 4340 steel revealed by thermal desorption spectroscopy and sustained-load tests. Metall Mater Trans A 51A:3054–3065

Bellemare J, Ménard D, Sirois F (2020) Detection of hydrogen embrittlement in plated high-strength steels with Eddy currents: is the sensitivity sufficient? J Nondestruct Eval 39:1–15

Laliberté-Riverin S, Bellemare J, Sirois F, Brochu M (2020) Internal hydrogen embrittlement of pre-cracked, cadmium-plated AISI 4340 high strength steel with sustained load tests and incremental step-loading tests. Eng Fract Mech 223:106773

Scully JR, Dogan H, Li D, Gangloff RP (2004) Controlling hydrogen embrittlement in ultra-high strength steels. NACE, Houston

Beloglazov SM (2003) Peculiarity of hydrogen distribution in steel by cathodic charging. J Alloys Compd 356–357:240–243

Figueroa D, Robinson MJ (2010) Hydrogen transport and embrittlement in 300 M and AerMet100 ultra high strength steels. Corros Sci 52:1593–1602

Laliberté-Riverin S, Bellemare J, Sirois F, Brochu M (2020) Determination of hydrogen embrittlement stress intensity threshold by fractography. Materialia 12:100759

Wang M, Akiyama E, Tsuzaki K (2006) Determination of the critical hydrogen concentration for delayed fracture of high strength steel by constant load test and numerical calculation. Corros Sci 48:2189–2202

Gabe DR (1997) The role of hydrogen in metal electrodeposition processes. J Appl Electrochem 27:908–915

Devanathan M, Stachurski Z, Beck W (1963) A technique for the evaluation of hydrogen embrittlement characteristics of electroplating baths. J Electrochem Soc 110:886–890

Zamanzadeh M, Allam A, Kato C, Ateya B, Pickering HW (1982) Hydrogen absorption during electrodeposition and hydrogen charging of Sn and Cd coatings on iron. J Electrochem Soc 129:284–289

Sriraman KR, Brahimi S, Szpunar JA, Yue S (2013) Hydrogen embrittlement of Zn-, Zn - Ni-, and Cd-coated high strength steel. J Appl Electrochem 43:441–451

Pfeil LB (1926) The effect of occluded hydrogen on the tensile strength of iron. Proc R Soc Lond A112:128–195

Oriani RA (1987) Whitney Award Lecture-1987: hydrogen-the versatile embrittler. Corrosion 43:390–397

Gerberich WW, Oriani RA, Lji M-J, Chen X, Foecke T (1991) The necessity of both plasticity and brittleness in the fracture thresholds of iron. Philos Mag A 63:363–376

Tarzimoghadam Z, Rohwerder M, Merzlikin SV, Bashir A, Yedra L, Eswara S, Ponge D, Raabe D (2016) Multi-scale and spatially resolved hydrogen mapping in a Ni–Nb model alloy reveals the role of the \(\delta\) phase in hydrogen embrittlement of alloy 718. Acta Mater 109:69–81

Birnbaum HK (1989) Mechanisms of hydrogen related fracture of metals. Technical report

Birnbaum HK, Sofronis P (1994) Hydrogen-enhanced localized plasticity a mechanism for hydrogen related fracture. Mater Sci Eng 176:191–202

Ferreira PJ, Robertson IM, Birnbaum HK (1998) Hydrogen effects on the interaction between dislocations. Acta Mater 46:1749–1757

Robertson IM (2001) The effect of hydrogen on dislocation dynamics. Eng Fract Mech 68:671–692

Robertson IM, Sofronis P, Nagao A, Martin ML, Wang S, Gross DW, Nygren KE (2015) Hydrogen embrittlement understood. Metall Mater Trans A 46:2323–2341

Lynch SP (1988) Environmentally assisted cracking: overview of evidence for an adsorption- induced localised-slip process. Acta Metall 20:2639–2661

Lynch SP (2007) Progress towards understanding mechanisms of hydrogen embrittlement and stress corrosion cracking. NACE International, Houston, pp 1–55

Troiano AR (1959) Delayed failure of high strength steels. Corrosion 15:57–62

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Wei FG, Hara T, Tsuzaki K (2004) Precise determination of the activation energy for desorption of hydrogen in two Ti-added steels by a single thermal-desorption spectrum. Metall Mater Trans B 35:587–597

Lee HG, Lee JY (1984) Hydrogen trapping by TiC particles in iron. Acta Metall 32:131–136

Lee JL, Lee JY (1983) Hydrogen trapping in AISI 4340 steel. Metal Sci 17:426–432

Safarian J, Engh TA (2013) Vacuum evaporation of pure metals. Metall Mater Trans A 44(February):747–753

Wang M, Akiyama E, Tsuzaki K (2005) Effect of hydrogen and stress concentration on the notch tensile strength of AISI 4135 steel. Mater Sci Eng A 398:37–46

Grabke HJ, Riecke E (2000) Absorption and diffusion of hydrogen in steels. Mater Technol 34:331–342

Osterman V, Antes HJ (2010) Critical melting points and reference data for vacuum heat treating. Technical report, Solar Atmospheres

Acknowledgements

This work was supported by the Consortium de Recherche et d’Innovation en Aérospatiale au Québec (CRIAQ), the Natural Sciences and Engineering Research Council of Canada (NSERC), as well as the Fonds de Recherche du Québec – Nature et technologies (FRQNT). We also want to thank our industrial partners, i.e. Bell Helicopter, Héroux-Devtek and Safran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bellemare, J., Laliberté-Riverin, S., Ménard, D. et al. Coating density as the key factor behind hydrogen embrittlement of cadmium-plated 4340 steel. J Appl Electrochem 50, 1045–1058 (2020). https://doi.org/10.1007/s10800-020-01458-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01458-5