Abstract

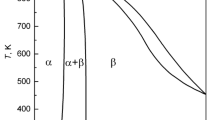

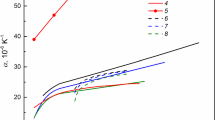

Experimental studies of the thermal expansion, heat capacity and thermal conductivity of the eutectic magnesium–lithium alloy (with composition of 23.0 at.% lithium) were performed in the temperature range of 80 K to 400 K. The relative elongation and thermal expansion coefficient of this ultralight magnesium–lithium alloy were measured by the dilatometric method using a DIL-402C setup. Measurements of the heat capacity were carried out by the differential scanning calorimetry using a DSC 404 F1 setup. Investigation of the thermal conductivity was performed by the hot-disk technique using a Hot-Disk TPS 2500S setup. The temperature dependences were constructed and tables of recommended values of the investigated properties were presented. It was found that in Mg77Li23 alloy a phase transition occurs in the range of 223 K to 253 K, where the heat capacity and the linear thermal expansion coefficient change abruptly. This transition is presumably related to the martensitic transformation of the lithium-rich bcc magnesium–lithium alloys to the hcp structure.

Similar content being viewed by others

Data Availability

Data presented in this article are available upon request from the corresponding author.

References

ASh. Agazhanov, R.N. Abdullaev, D.A. Samoshkin, Yu.M. Kozlovskii, Thermophys. Aeromech. 29, 623 (2022). https://doi.org/10.1134/S086986432204014X

A.A. Nayeb-Hashemi, J.B. Clark, A.D. Pelton, Bull. Alloy Phase Diagr. 5, 365 (1984). https://doi.org/10.1007/BF02872951

W. Gasior, Z. Moser, W. Zakulski, G. Schwitzgebel, Metall. Mater. Trans. A 27, 2419 (1996). https://doi.org/10.1007/BF02652335

H. Haferkamp, M. Niemeyer, R. Boehm, U. Holzkamp, C. Jaschik, V. Kaese, Mater. Sci. Forum 350, 31 (2000). https://doi.org/10.4028/www.scientific.net/MSF.350-351.31

R.Z. Wu, Y.D. Yan, G.X. Wang, L.E. Murr, W. Han, Z.W. Zhang, M.L. Zhang, Int. Mater. Rev. 60, 65 (2015). https://doi.org/10.1179/1743280414Y.0000000044

X. Peng, W. Liu, G. Wu, H. Ji, W. Ding, J. Mater. Sci. Technol. 99, 193 (2022). https://doi.org/10.1016/j.jmst.2021.04.072

C.P. Liang, H.R. Gong, J. Alloys Compd. 489, 130 (2010). https://doi.org/10.1016/j.jallcom.2009.09.032

C.S. Barrett, D.F. Clifton, JOM 2, 1329 (1950). https://doi.org/10.1007/BF03399158

C.S. Barrett, Acta Metall. 4, 528 (1956). https://doi.org/10.1016/0001-6160(56)90049-9

R.N. Abdullaev, R.A. Khairulin, Yu.M. Kozlovskii, ASh. Agazhanov, S.V. Stankus, Trans. Nonferr. Met. Soc. China 29, 507 (2019). https://doi.org/10.1016/S1003-6326(19)64959-9

DSC 404 F1 Pegasus. https://analyzing-testing.netzsch.com/en-US/products/differential-scanning-calorimeter-dsc-differential-thermal-analyzer-dta/dsc-404-f1-pegasus. Accessed 19 April 2023

DIL 402 Expedis Classic. https://analyzing-testing.netzsch.com/ru/pribory-resheniya/dilatometriya-dil/dil-402-expedis-classic. Accessed 19 April 2023

R.N. Abdullaev, Yu.M. Kozlovskii, R.A. Khairulin, S.V. Stankus, Int. J. Thermophys. 36, 603 (2015). https://doi.org/10.1007/s10765-015-1839-x

Yu.M. Kozlovskii, S.V. Stankus, High Temp. 52, 536 (2014). https://doi.org/10.1134/S0018151X1403016X

Hot Disk TPS 2500 S. https://www.hotdiskinstruments.com/products-services/instruments/tps-2500-s/. Accessed 19 April 2023

S.E. Gustafsson, Rev. Sci. Instrum. 62, 797 (1991). https://doi.org/10.1063/1.1142087

L.M. Heisig, R. Wulf, T.M. Fieback, Int. J. Thermophys. 44, 82 (2023). https://doi.org/10.1007/s10765-023-03190-6

R.N. Abdullaev, R.A. Khairulin, Yu.M. Kozlovskii, S.V. Stankus, ASh. Agazhanov, Int. J. Thermophys. 44, 74 (2023). https://doi.org/10.1007/s10765-023-03187-1

Springer Materials—Properties of Materials (Springer, 2023). https://materials.springer.com/. Accessed 19 April 2023

S.V. Stankus, R.A. Khairulin, High Temp. 30, 386 (1992). https://www.mathnet.ru/eng/tvt3390. Accessed 19 April 2023

A. Rudajevová, S. Kúdela, M. Staněk, P. Lukáč, Mater. Sci. Technol. 19, 1097 (2003). https://doi.org/10.1179/026708303225004648

R.N. Abdullaev, D.A. Samoshkin, ASh. Agazhanov, S.V. Stankus, J. Eng. Thermophys. 30, 207 (2021). https://doi.org/10.1134/S1810232821020041

C.Y. Ho, R.W. Powell, P.E. Liley, J. Phys. Chem. Ref. Data 3, 1 (1974)

G.W. Stinton, S.G. MacLeod, H. Cynn, D. Errandonea, W.J. Evans, J.E. Proctor, Y. Meng, M.I. McMahon, Phys. Rev. B 90, 134105 (2014). https://doi.org/10.1103/PhysRevB.90.134105

C.S. Barrett, Phys. Rev. 72, 245 (1947). https://doi.org/10.1103/PhysRev.72.245

Y.S. Touloukian, R.W. Powell, C.Y. Ho, M.C. Nicolaou, Thermophysical Properties of Matter, vol. 10 (Plenum Press, New York, 1973)

Acknowledgements

This work was supported by the Russian Science Foundation (Grant No. 20-79-10025). Link to the project information: https://rscf.ru/en/project/20-79-10025/.

Author information

Authors and Affiliations

Contributions

RNA, writing; YMK, dilatometric and hot-disk measurements; DAS, DSC and hot-disk measurements; SVS, supervision; AShA, samples preparation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdullaev, R.N., Kozlovskii, Y.M., Samoshkin, D.A. et al. Peculiarities of the Eutectic Mg–Li Alloy Thermal Expansion, Heat Capacity and Thermal Conductivity Behavior in the Temperature Range of 80 K to 293 K. Int J Thermophys 44, 104 (2023). https://doi.org/10.1007/s10765-023-03212-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-023-03212-3