Abstract

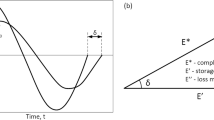

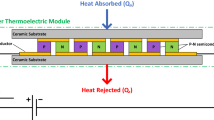

The study of shape memory alloys (SMAs) is widely spread in academic and industrial circles due to a large number of applications. In this context, understanding their critical phase transformation temperatures to use as actuators or sensors requires analysis by consolidated techniques, such as Differential Scanning Calorimetry (DSC). In this work, an experimental testing platform was developed as an alternative, whose function is to determine these phase transformation temperatures of SMAs through the electromechanical impedance (EMI) using piezoelectric sensors attached to the surface of the SMA samples. This equipment submits the PZT + SMA heterostructures to controlled thermal cycling and presents the electromechanical impedance magnitude and phase angle curves as real-time responses. To validate and survey the operational limits of the equipment, tests were performed on NiTi, and NiTiNb SMA samples, whose transformation temperatures obtained by EMI were compared with those obtained by DSC. The results showed considerable similarity compared to those by DSC. This way, an infrastructure that allows for a deeper study of the process was obtained, also promoting the optimization of the test parameters for the most diverse materials.

Similar content being viewed by others

Data Availability

Not applicable.

References

A. Ölander, The crystal structure of AuCd. Cryst. Mater. 83, 145–148 (1932). https://doi.org/10.1524/zkri.1932.83.1.145

A.B. Greninger, V.G. Mooradian, Strain transformation in metastable beta copper-zinc and beta copper-tin alloys. Am. Inst. Min. Metall. Eng. Trans. 128, 337 (1938)

G.B. Kauffman, I. Mayo, The story of nitinol: the serendipitous discovery of the memory metal and its applications. Chem. Educ. 2, 1–21 (1996)

G.S. Firstov, T.A. Kosorukova, Y.N. Koval, V.V. Odnosum, High entropy shape memory alloys. Mater. Today Proc. 2, S499–S503 (2015). https://doi.org/10.1016/j.matpr.2015.07.335

D. Piorunek, J. Frenzel, J. Niels, C. Somsen, G. Eggeler, Intermetallics chemical complexity, microstructure and martensitic transformation in high entropy shape memory alloys. Intermetallics 122, 106792 (2020). https://doi.org/10.1016/j.intermet.2020.106792

L. Peltier, P. Lohmuller, F. Meraghni, S. Berveiller, E. Patoor, P. Laheurte, Investigation and composition characterization of a “NiTi-like” alloy combining high temperature shape memory and high entropy. Shape Mem. Superelast. 6, 273–283 (2020). https://doi.org/10.1007/s40830-020-00290-2

J. Mohd Jani, M. Leary, A. Subic, M.A. Gibson, A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014). https://doi.org/10.1016/j.matdes.2013.11.084

D.J. Hartl, D.C. Lagoudas, Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng. G 221, 535–552 (2007). https://doi.org/10.1243/09544100JAERO211

Dimitris, C., Lagoudas, D.C.: Shape Memory Alloys: Modeling and Engineering Applications (2008)

F. Khaleghi, M. Tajally, E. Emadoddin, M. Mohri, The investigation of the mechanical properties of graded high-temperature shape memory Ti-Ni-Pd alloy. J. Alloys Compd. 787, 882–892 (2019). https://doi.org/10.1016/j.jallcom.2019.02.142

S. Zuo, R. Wu, G. Pang, Y. Yang, M. Jin, High temperature internal friction in Ni50.3 Ti29.7 Zr20 shape memory alloy. Intermetallics 109, 174–178 (2019). https://doi.org/10.1016/j.intermet.2019.04.006

J. Ma, I. Karaman, R.D. Noebe, High temperature shape memory alloys. Int. Mater. Rev. 55, 257–315 (2010). https://doi.org/10.1179/095066010x12646898728363

Patoor, E., Berveiller, M.: Technologie des Alliages à Mémoire de Forme, Hermès (1994)

Sczerzenie, F.: Consideration of the ASTM standards for Ni-Ti alloys. In: Int. Conf. Shape Mem. Superelastic Technol. Baden-Baden, Germany, 3–7 October, pp. 203–210 (2004)

ASTM F 2004: Standard Test Method for Transformation Temperature of Nickel–Titanium Alloys by Thermal Analysis (2008)

I. Delgadillo-Holtfort, J.D.R. Pereira, A.O. Guimarães, E.C. Da Silva, Photothermal investigations of de-emulsification of fat/water-based pasty materials: margarine. Int. J. Thermophys. 25, 587–602 (2004). https://doi.org/10.1023/B:IJOT.0000028492.71162.E4

S. Shahab, A. Erturk, Coupling of experimentally validated electroelastic dynamics and mixing rules formulation for macro-fiber composite piezoelectric structures. J. Intell. Mater. Syst. Struct. 28, 1575–1588 (2017). https://doi.org/10.1177/1045389X16672732

G. Park, C.R. Farrar, F.L. di Scalea, S. Coccia, Performance assessment and validation of piezoelectric active-sensors in structural health monitoring. Smart Mater. Struct. 15, 1673 (2006). https://doi.org/10.1088/0964-1726/15/6/020

H. Ratnasari, Evaluation study of tnning industry wastewater treatment plant in UPT leather industry environment magetan regency. Ekp 13, 1576–1580 (2017)

C. Liang, F.P. Sun, C.A. Rogers, Coupled electro-mechanical analysis of adaptive material systems—determination of the actuator power consumption and system energy transfer. J. Intell. Mater. Syst. Struct. 8, 335–343 (1997). https://doi.org/10.1177/1045389X9700800406

Ostachowicz, W., Güemes, A.: New trends in structural health monitoring (2013)

F.G. Baptista, D.E. Budoya, V.A.D. de Almeida, J.A.C. Ulson, An experimental study on the effect of temperature on piezoelectric sensors for impedance-based structural health monitoring. Sensors 14, 1208–1227 (2014). https://doi.org/10.3390/s140101208

M.F. Cunha et al., Transformation temperatures of shape memory alloy based on electromechanical impedance technique. Meas. J. Int. Meas. Confed. 145, 55–62 (2019). https://doi.org/10.1016/j.measurement.2019.05.050

Da Rocha Souto, C., Da Silva, R.A., De Castro, A.C., Dos Santos, A.J.V., De Souza, R.C.: Thermal cycling effect on a shape memory and piezoelectric heterostructure. In: Conf. Rec. IEEE Instrum. Meas. Technol. Conf., pp. 315–319 (2014). https://doi.org/10.1109/I2MTC.2014.6860759

K.-Y. Koo, S. Park, J.-J. Lee, A. Chung-Bang Yun, Automated impedance-based structural health monitoring incorporating effective frequency shift for compensating temperature effects. J. Intell. Mater. Syst. Struct. 20, 367–377 (2009). https://doi.org/10.1177/1045389X08088664

Baptista, F., On, J. V. F.-I. T.: A new impedance measurement system for PZT-based structural health monitoring (2009). www.ieeexplore.ieee.org

D.D.S. Silva, J.M.B. Sobrinho, C.R. Souto, R.M. Gomes, Application of electromechanical impedance technique in the monitoring of sigma phase embrittlement in duplex stainless steel. Mater. Sci. Eng. A 788, 139457 (2020). https://doi.org/10.1016/j.msea.2020.139457

S. Miyazaki, H.Y. Kim, H. Hosoda, Development and characterization of Ni-free Ti-base shape memory and superelastic alloys. Mater. Sci. Eng. A. 438–440, 18–24 (2006). https://doi.org/10.1016/j.msea.2006.02.054

W. Elmay, F. Prima, T. Gloriant, B. Bolle, Y. Zhong, E. Patoor, P. Laheurte, Effects of thermomechanical process on the microstructure and mechanical properties of a fully martensitic titanium-based biomedical alloy. J. Mech. Behav. Biomed. Mater. 18, 47–56 (2013). https://doi.org/10.1016/j.jmbbm.2012.10.018

L. Peltier, S. Berveiller, F. Meraghni, P. Lohmuller, P. Laheurte, Martensite transformation and superelasticity at high temperature of (TiHfZr)74(NbTa)26 high-entropy shape memory alloy. Shape Mem. Superelast. 74, 4 (2021). https://doi.org/10.1007/s40830-021-00323-4

Acknowledgments

To the LaSEA (Active Systems and Structures Laboratory) of the Federal University of Paraíba and to the IFPE (Federal Institute of Pernambuco) Campus Caruaru for providing materials and equipment.

Author information

Authors and Affiliations

Contributions

ADS: Conceptualization, Methodology, Software, Investigation, Validation, Writing—original draft, Writing—review. JMBS: Methodology, Investigation, Writing—original draft, Writing—review & editing. FSL: Writing—original draft, Writing—review & editing. CRS: Visualization, Supervision, Project administration. RMG: Supervision, Funding acquisition, Writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silvestre, A.D., Sobrinho, J.M.B., Lima, F.S. et al. Experimental Setup for Detection of Phase Transformation Temperatures in SMA Using Electromechanical Impedance. Int J Thermophys 44, 101 (2023). https://doi.org/10.1007/s10765-023-03210-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-023-03210-5