Abstract

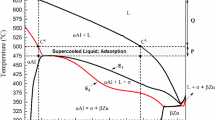

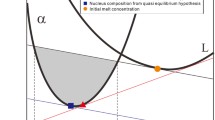

A recently derived equation for nucleation is applied for pure aluminum and Al–6 wt% Cu–3 wt% Si alloy under upward solidification conditions to calculate the surface stress, surface energy, nucleus radius, and Gibbs–Thomson Coefficient as a function of the distance from the chill. The microscopic and macroscopic fields are coupled through a Representative Elementary Volume—REV approach. As expected, higher surface energy and lower critical radius values are observed in positions in which high cooling rates occurred. Then, a nucleation model is carried out to simulate the effect of cooling rates for the molar specific heat capacity of pure Al, Fe, and Nb, and for Al2Cu and Al3Ni2 phases. In the case of Nb, a set of experimental data deviates from high temperatures from theoretical predictions, probably due to high O2 activity as previously observed for the case of pure Fe. A nucleation model for the alloy is proposed as a function of pressure, concentration, and temperature gradients in view to permit the calculation of nucleation radius, surface energy, surface stress, and Gibbs–Thomson Coefficient under non-equilibrium any given cooling rate.

Similar content being viewed by others

References

M. Aniolek, T. Smith, F. Czerwinski, Combining differential scanning calorimetry and cooling-heating curve thermal analysis to study the melting and solidification behavior of Al–Ce binary alloys. Metals 11–372, 1–17 (2021)

G.V. Poel, V.B.F. Mathot, High-speed/high performance differential scanning calorimetry (HPer DSC): temperature calibration in heating and cooling mode and minimization of thermal lag. Thermochim. Acta 446, 41–54 (2006)

J. Piatkowski, R. Przeligorz, A. Gontarczyk, The study of phase transformation of AlSi9Cu3 alloy by DSC method. Arch. Foundry Eng. 16, 109–112 (2016)

W. Zhai, W.L. Wang, D.L. Geng, B. Wei, A DSC analysis of thermodynamic properties and solidification characteristics for binary Cu-Sn alloys. Acta Mater. 60, 6518–6527 (2012)

I.L. Ferreira, A Non-equilibrium nucleation model to calculate the density of state and its application to the heat capacity of stoichiometric UO2. Int. J. Thermophys. 42, 148 (2021)

R. Shuttleworth, The surface tension in solids. Proc. Phys. Soc. 63A, 444–457 (1950)

J.S. Vermaak, C.W. Mays, D. Juhlmann-Wilsdorf, On the surface stress and surface tensor: I. Theoretical considerations. Surf. Sci. 12, 128–133 (1968)

M.E. Gurtin, A.I. Murdoch, Surface stress in solids. Int. J. Solids Struct. 14, 431–440 (1978)

P. Müller, A. Saul, Elastic effects on surface physics. Surf. Sci. Rep. 29, 157–258 (2004)

P. Müller, A. Saul, F. Leroy, Simple views on surface stress and surface energy concepts. Nanosci. Nanotechnol. 5, 013002 (2014)

M. Bobadilla, J. Lacaze, G. Lesoult, Influence des conditions de solidification sur le déroulement de la solidification de aciers inoxydable austénitique. J. Cryst. Growth 89, 531–544 (1988)

M. Rappaz, S.A. David, J.M. Vitek, L.A. Boatner, Analysis of solidification microstructures in Fe-Ni-Cr single-crystal welds. Metall. Trans. A 21A, 1767–1782 (1990)

M. Rappaz, W.J. Boettinger, On dendritic solidification of multicomponent alloys with unequal liquid diffusion coefficients. Acta Mater. 47, 3205–3219 (1999)

J. Ni, C. Beckermann, A volume-averaged two-phase model for transport phenomena during solidification. Metall. Trans. B 22B, 349–361 (1991)

C.R. Swaminathan, V.R. Voller, Towards a general numerical scheme for solidification systems. Int. J. Mass Transf. 40, 2859–2868 (1997)

I.L. Ferreira, C.A. Santos, A. Garcia, V.R. Voller, Analytical, numerical and experimental analysis of inverse macrosegregation during upward unidirectional solidification of Al-Cu alloys. Metall. Trans. B 35B, 285–297 (2004)

I.L. Ferreira, V.R. Voller, B. Nestler, A. Garcia, Two-dimensional numerical model for the analysis of macrosegregation during solidification. Comp. Mater. Sci. 46, 358–366 (2009)

I.L. Ferreira, J.F.C. Lins, D.J. Moutinho, L.G. Gomes, A. Garcia, Numerical and experimental investigation of microporosity formation in a ternary Al-Cu-Si alloy. J. Alloy. Compds. 503, 31–39 (2010)

I.L. Ferreira, J.A. de Castro, A. Garcia, Determination of heat capacity of pure metals, compounds and alloys by analytical and numerical methods. Thermochim. Acta 682, 178418 (2019)

I.L. Ferreira, On the heat capacity of pure elements and phases. Mater. Res. 24, e20200529 (2021)

I.L. Ferreira, J.A. Castro, A. Garcia, On the Determination of Molar Heat Capacity of Transition Elements: From the Absolute to the Melting Point in Book: Recent Advances on Numerical Simulation (INTECHOPEN, London, 2021)

E.H. Kim, B.J. Lee, Size dependency of melting point of crystalline nano particles and nano wires: a thermodynamic modeling. Met. Mater. Int. 15, 531–537 (2009)

N. Wu, X. Lu, R. An, X. Ji, Thermodynamic analysis and modification of Gibbs–Thomson equation for melting point depression of metal nanoparticles. Chin. J. Chem. Eng. 31, 198–205 (2021)

I.L. Ferreira, A.L.S. Moreira, J. Aviz, T.A. Costa, O.F.L. Rocha, A.S. Barros, A. Garcia, On an expression for the growth of secondary dendrite arm spacing during non-equilibrium solidification of multicomponent alloys: validation against ternary aluminum-based alloys. J. Manuf. Proc. 3, 634–650 (2018)

V.R. Voller, On a general back-diffusion parameter. J. Crystal Growth 226, 562–568 (2001)

J.C. Eriksson, Thermodynamics of surface phase systems: V. Contribution to the thermodynamics of the solid-gas interface. Surf. Sci. 14, 221–246 (1969)

M. Moser, L. Völgyesi, The inner structure of the Earth. Period Polytech. Chem. Eng. 26, 155–204 (1982)

S.H. Simon, The Oxford Solid State Basics, 1st edn. (Oxford University Press, Oxford, 2013)

Q. Chen, B. Sundman, Calculation of Debye temperature for crystalline structures—a case study on Ti, Zr, and Hf. Acta Mater. 49, 947–961 (2001)

F.C. Nascimento, M.C.C. Paresque, J.A. de Castro, P.A.D. Jácome, A. Garcia, I.L. Ferreira, Application of computational thermodynamics to the determination of thermophysical properties as a function of temperature for multicomponent Al-based alloys. Thermochim. Acta 619, 1–7 (2015)

W. Giauque, J. Meads, The heat capacities and entropies of aluminum and copper from 15 to 300°K. J. Chem. Phys. 63, 423–432 (1941)

C.R. Brooks, R.E. Bingham, The specific heat of aluminum from 330 to 890 K and contributions from the formation of vacancies and anharmonic effects. J. Phys. Chem. Solids 29, 1553–1560 (1968)

J.H. Awbery, E. Griffiths, The thermal capacity of pure iron. Proc. R. Soc. Lond. A 174, 1–15 (1940)

K.K. Kelley, The specific heat of pure iron at low temperatures. J. Chem. Phys. 11, 16–18 (1943)

A. Eucken, H. Werth, Die spezifische Wärme einiger Metalle und Metallegierungen bei tiefen Temperaturen. Z. Anorg. Allgem. Chem. 188, 152–172 (1930)

F. Simon, R.L. Swain, Untersuchungen über die spezifische Wärme bei tiefen temperaturen. Z. Phys. Chem. B 28, 189–198 (1935)

J.J. Valencia, P. Quested, Thermophysical properties. Casting. ASM Handb. ASM Int. 15, 468–481 (2008)

V.A. Kirillin, A.E. Scheindlin, V.Y. Chekhovskoi, I.A. Zhukova, Themodynamic properties of niobium from 0K to the melting point, 2740 K. in Advances in Thermophysical Properties at Extreme Temperature and Pressures Proceedings of the Third Symposium on Thermophysical Properties. ASME, 1965, p. 152.

A.E. Scheindlin, B.Y. Berezin, V.Y. Chekhovskoi, Enthalpy of niobium in the solid and liquid state. High Temp. High Press. 4, 611–619 (1972)

I.I. Novikov, V.V. Roshchupkin, A.G. Mozgovoi, N.A. Semashko, Specific heat of nickel and niobium in the temperature interval 300–1300 K. High Temp. 19, 694 (1981)

F. Righini, R.B. Roberts, A. Rosso, Measurements of thermophysical properties by a pulse-heating method: niobium in the range 1000–2500 K. Int. J. Thermophys. 6, 681 (1985)

K. Morohoshi, M. Uchikoshi, M. Isshki, H. Fukuyama, Surface tension of liquid iron as functions of oxygen activity and temperature. ISIJ Int. 51, 1580–1586 (2011)

M.L.M. Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.P. Kruth, J. Van Humbeeck, Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 238, 437–445 (2016)

P.A. Rometsch, H. Zhong, K.M. Nairn, T. Jarvis, X. Wu, Characterization of a laser fabricated hypereutectic Al-Sc alloy bar. Scr. Mater. 87, 13–16 (2014)

S. Ghosh, Predictive modeling of solidification during laser additive manufacturing of nickel superalloys: recent developments, future directions. Mater. Res. Express 5, 012001 (2018)

Y. Qin, P. Wen, M. Voshage, Y. Chen, P.G. Schückler, L. Jauer, D. Xia, H. Guo, Y. Zheng, J.H. Schleifenbaum, Additive manufacturing of biodegradable Zn-xWE43 porous scaffolds: formation quality, microstructure and mechanical properties. Mater. Des. (2019). https://doi.org/10.1016/j.matdes.2019.107937

C. Wei, Z. Zhang, D. Cheng, Z. Sun, M. Zhu, L. Li, An overview of laser-based multiple metallic material additive manufacturing: from macro- to micro-scales. Int. J. Extrem. Manuf. 3, 012003 (2021)

H. Dobbelstein, E.P. George, E.L. Gurevich, A. Kostka, A. Ostendorf, G. Laplanche, Laser metal deposition of refractory high-entropy alloys for high throughput synthesis and structure-property characterization. Int. J. Extrem. Manuf. 3, 015201 (2021)

Acknowledgments

The authors acknowledge the financial support provided by FAPERJ (The Scientific Research Foundation of the State of Rio de Janeiro), CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil—Finance Code 001) and CNPq (National Council for Scientific and Technological Development). A.L.S. Moreira, from Federal University of Pará, is also acknowledged for reviewing of the manuscript.

Funding

The funding was provided by CNPq (302381/2019-8).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferreira, I.L. Non-equilibrium Nucleation: Application to Solidification and Molar-Specific Heat Capacity of Pure Metals and Phases. Int J Thermophys 43, 33 (2022). https://doi.org/10.1007/s10765-021-02956-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-021-02956-0