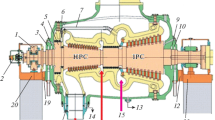

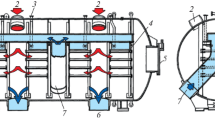

The effect of the high-temperature steam path of steam turbines with combined HP-IP cylinder and HP and IP rotors located in separate casings, operating with either double- or single-bypass thermal circuit, on the thermal stress state is studied. With the double-bypass thermal circuit, the IP and LP pressure cylinders are used for supplying steam to the turbine, increasing the speed of rotation, and initial loading after connecting the turbogenerator to the grid. In this case, the HP cylinder operates in counter-current flow, with the steam bypassed by the check valve at its outlet and discharged to the condenser through the drains of the cylinder casing and the high-pressure crossover pipes. With the single-bypass thermal circuit, the HP section is heated at an intermediate speed of rotation with no steam in the IP section and, then, during initial loading after the connection of the generator to the grid. The analysis of the thermal stresses that occur during cold start-ups shows that combining the HP and IP cylinders into one casing decreases the thermal stresses in the most stressed “critical” elements (intermediate seal and governing-stage fillet) of the HP rotor. There are no significant differences in the thermal stresses in the most stressed zones of the IP rotor during cold start-ups, as well as in the HP and IP rotors during hot start-ups for these design options. To reduce the stresses in the “critical” elements of the HP rotor located in a separate casing, it is necessary to choose the appropriate preheating temperature. It can be calculated using, for example, so-called life counters (software for on-line analysis of thermal stresses) and then tested under operating conditions. For different shaft-train designs, different rotor areas that are critical in terms of thermal stress state, determine the duration of turbine loading, and thereby affect the startup schedule are identified.

Similar content being viewed by others

References

Yu. A. Radin and I. A. Grishin, “Axial thrust balancing in high-temperature cylinders of steam turbines during transients in combined-cycle units,” Therm. Eng., 66(6), 409 – 414 (2019).

Technical Guides RTM 24.020.16–73. Stationary Steam Turbines: Electromodeling of Temperature Fields in Rotors and Cylinders of Steam Turbines [in Russian].

B. E. Neimark (ed.), Physical Characteristics of Steels and Alloys Used in Power Engineering [in Russian], Énergiya, Moscow (1967).

Technical Guides RTM 108.021.103-85. Parts of Stationary Steam Turbines. Design for Low-Cycle Fatigue [in Russian], Moscow (1985).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Élektricheskie Stantsii, No. 8, August 2020, pp. 2 – 8.

Rights and permissions

About this article

Cite this article

Radin, Y.A., Kontorovich, T.S. Influence of the Arrangement of the Highand Intermediate-Pressure Cylinders of Steam Turbines with Different Bypass Circuits on Their Thermal Stress State During Start-Ups and Shutdowns. Power Technol Eng 54, 720–725 (2021). https://doi.org/10.1007/s10749-020-01276-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-020-01276-x