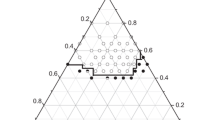

The influence of SnO on the physicochemical properties of low-melting glasses in the system Li2O–SnO–P2O5(LSP), intended for use in compositions for vacuum-tight low-temperature bonding of different materials, was studied. The low values of Tg promoted high spreadability of LSP-glass powders at temperatures below 450°C (typical for gluing electronic articles). The mass losses upon boiling of LSP-glasses varied over a wide range (0.19 – 4.55%), and in terms of chemical resistance the glasses characterized by mass losses below about 3% surpass the lead-borate glasses widely used in solders. The values of ñv for LSP-glasses were raised to values characteristic for lead-borate glasses by optimizing the alkali-content ratio.

Similar content being viewed by others

References

N. M. Pavlushkin and A. K. Zhuravlev, Fusible Glasses [in Russian], Énergiya, Moscow (1970), pp. 4, 31.

E. M. Zinina, D. K. Chakvetadze, Yu. A. Spiridonov, and V. N. Sigaev, “Investigation of the influence of Al2O3 on the technological properties of low-melting glasses of the system Li2O–SnO–P2O5,” Usp. Khim. Khim. Tekhnol., 31(1), 30 – 32 (2017).

Directive 2011/65/EC (Directive 2011/65/EC rohs) of the European Parliament and of the Council of the EU on the Restrictions on the Use of Certain Hazardous Substances in Electrical and Electronic Equipment, European Union, Strasbourg, June 8, 2011, the effect of the directive extends to the European Economic area, Strasbourg (2011).

W. Donald, “Preparation, properties and chemistry of glass and glass-ceramic-to-metal seals and coatings,” J. Mater. Sci., 28(11), 2841 – 2886 (1993).

R. Morena, “Phosphate glasses as alternatives to Pb-based sealing frits,” J. Non-Cryst. Solids, 263 – 264, 382 – 387 (2000).

Jiin-Jyh Shyu, Chih-Hsien Yeh, Lead-Free Sealing Material, Pat. US No. 20090291822A1. Int. Cl. C03C3_16, Assignee: Tatung Co Ltd, Tatung University, Lead-free sealing material, Nov. 26, 2009.

A. E. Marino, S. R. Arrasmith, L. L. Gregg, et al., “Durable phosphate glasses with lower transition temperature,” J. Non-Cryst. Solids, 289, 37 – 41 (2001).

R. K. Brow, “Nature of alumina in phosphate glass. I. Properties of Sodium aluminophosphate glass,” J. Am. Ceram. Soc., No. 4, 913 – 918 (1993).

Wei T. Y., Hu Y., Ha L. G. “Structure and elastic properties of low-temperature sealing phosphate glasses,” J. Non-Cryst. Solids, 288(1 – 3), 140 – 147 (2001).

V. B. Kalinin, A. Yu. Shashkov, V. N. Sigaev, et al., Solder Glass Composition, Inventor’s Certificate, USSR 1 1209627, cl. ÑÎ3 Ñ8/24, 10/00 [in Russian], February 7, 1986.

D. A. Geodakyan, B. V. Petrosyan, and K. D. Geodakyan, “Design and synthesis of fusible glass solder with predetermined properties,” Steklo Keram., No. 9, 27 – 33 (2007); D. A. Geodakyan, B. V. Petrosyan, and K. D. Geodakyan, “Design and synthesis of fusible glass solder with predetermined properties,” Glass Ceram., 64(9 – 10), 326 – 332 (2007).

D. K. Chakvetadze, Yu. A. Spiridonov, V. I. Savinkov, et al., “Lead titanate granulometric composition effect on CLTE of low-melting glass composite materials for vacuum-tight lowtemperature soldering of corundum parts,” Steklo Keram., No. 5, 34 – 37 (2017); D. K. Chakvetadze, Yu. A. Spiridonov, V. I. Savinkov, et al., “Lead titanate granulometric composition effect on CLTE of low-melting glass-composition materials for vacuum-tight low-temperature soldering of corundum parts,” Glass Ceram., 74(5 – 6), 176 – 179 (2017).

GOST 10134.0–82: Inorganic Glass and glass-ceramic materials. General Requirements for Methods of Determining Chemical Resistance [in Russian], Izd. Standartov, Moscow (1983).

V. B. Kalinin, G. B. Knyazher, A. G. Laptev, et al., “New fillers for low-melting solder glass compositions,” Élektron. Prom-st’, No. 6, Issue 164, 31 – 34 (1987).

Yu. A. Chakvetadze, Yu. A. Spiridonov, V. I. Savinkov, and V. N. Sigaev, The Method of Obtaining Low-Melting Glass Composition, RF Pat. No. 2614844, cl. CO3 C8/24, 8/14 [in Russian], publ. March 29, 2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 1, pp. 3 – 7, January, 2019.

Rights and permissions

About this article

Cite this article

Chakvetadze, D.K., Zinina, É.M., Spiridonov, Y.A. et al. Physical-Chemical Properties of Low-Melting Phosphate Glasses in Relation to Tin Oxide Content. Glass Ceram 76, 3–6 (2019). https://doi.org/10.1007/s10717-019-00121-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-019-00121-6