Abstract

National Fire Protection Association standard 1403 provides the fire service with guidance for conducting effective live fire training with the goal of minimizing health and safety hazards. The document provides guidelines for materials to be included in the training fuel package, but the fire service has raised questions about the use of specific types of wood products for this purpose. In this study, the fire dynamics generated when utilizing five different Class A materials that have been historically employed as training fuels [low density wood fiberboard, oriented strand board (OSB), pallets, particle board, plywood] in a single compartment fire training structure (Fire Behavior Lab) were characterized. A specific focus was placed on understanding the thermal and visual environment created for firefighters located at typical locations for instructors (front and rear of structure) and students (middle of the structure). The pallet fuel package required the longest time to transition through the six ventilation cycles while the OSB fuel package was the quickest. Additionally, the most consistent fire dynamics were demonstrated with the OSB fuel followed by particle board and plywood, while fiberboard and pallets resulted in less repeatable flashover or rollover demonstration. The OSB fuel package resulted in the highest peak heat fluxes and pallets resulted in the lowest. The most severe exposures were measured at the front instructor location. To control thermal risks when conducting training in the Fire Behavior Lab structure, instructors and students should orient themselves as low as possible in the observation area and behind the interior baffle when possible. Considering the high radiant exposures for the front instructor location, providing a local shield and reducing the time in the training structure can also reduce risk for thermal injury or personal protective equipment damage. Overall, different fuels can impact thermal exposures to firefighters, but varying fuels also affects the consistency of the fire dynamics being presented to the firefighting students.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Providing training for the global fire service requires instructors to strike an important balance between achieving training objectives while prioritizing the health and safety of fire instructors and students. In the United States and several other countries, National Fire Protection Association (NFPA) 1403: Standard on Live Fire Training Evolutions outlines the minimum requirements for conducting live fire training in acquired and fixed facility training structures. NFPA 1403 includes guidance for conducting such training so that learning objectives are achieved with the goal of mitigating health and safety hazards [1]. One section of the document provides guidelines for the types of materials that can be included in the fuel package. Currently, there are no materials specifically designed for live-fire training, so the fire service will typically incorporate commonly available combustibles. In section 4.13, NFPA 1403 requires that fuel materials be only wood products, defining acceptable fuels (in the appendix) as “...pine excelsior, wooden pallets, straw, hay, and other wood-based products...”, while also specifically identifying that “...pressure-treated wood products, rubber, plastic, polyurethane foam, tar paper, upholstered furniture, carpeting, and chemically treated or pesticide treated straw or hay shall not be used as part of the fuel load” [1]. The standard does not directly address specific wood-based products, which has led to lack of clarity on their use in this purpose. Across the United States, some training organizations specifically forbid the use of certain wood-based products based on their interpretation of this standard. Others may use any wood-based products available during training exercises. The International Association of Fire Fighters (IAFF) released a white paper that highlights the challenges and lack of information available to make a holistic risk-benefit judgement [2].

Wood-based products include a wide range of materials that likely have different burning characteristics. Recent studies have shown that differences in fuel load materials, density, components, and geometry can impact the thermal environment [3, 4], in addition to environmental conditions such as ambient temperature and humidity. However, these studies do not provide insight into methods to quantify relative differences in risks in a consistent training fire environment. For example, Regan documented heat release rate characteristics of common NFPA 1403-compliant training fuel packages and compared them to characteristics of furniture items to provide the fire service with guidance on fuel selection, but focused on characterization during free burn conditions [3]. Horn et al. compared peak temperatures from three different training fire environments [4]. However, these training environments were created with different fuel materials and fuel orientation as well as different training structures and ventilation configurations, which does not allow isolation of the effects of fuel source alone.

Although an evolving body of literature exists regarding the risks to firefighters conducting training, it is also important to understand the benefits of training fire environments to achieve training objectives. Not only does live-fire training led by skilled instructors provide an opportunity to develop a practical understanding of fire dynamics in structures and proficiency in firefighting skills, it also provides a means for learners to recognize cues and conditions that are critical to effective decision-making on the fireground. Many firefighters are visual learners [5], but training fires often result in visual and tactile (e.g. thermal) cues and fire behavior that is different from what could be experienced in the field. However, using materials other than wood products in Class A training fuel packages can result in unexpected fire growth, which has caused training-related line-of-duty deaths and injuries [6,7,8,9]. The ability to conduct safe yet realistic training within the NFPA 1403 framework has been a topic of discussion for several years [10,11,12] and is particularly important when training objectives focus on recognizing key fire dynamics indicators.

The Fire Behavior Lab is a common training structure used throughout the United States for fire dynamics instruction and is specifically called out by NFPA 1403 [1]. Training activities inside this single compartment structure are typically well scripted to identify the impact of structure ventilation on fire behavior. This structure is designed to generate ventilation-limited fire conditions which can be controlled to create flame spread across the hot gas layer accumulating below the ceiling of the structure, also known as a rollover condition, and eventually floor-to-ceiling flaming in the fire area providing an indication of a flashover condition. The observation area where students and instructors are situated is 0.9 m below the fire area to allow visualization of smoke and flames and instruction to take place. Thus, the Fire Behavior Lab provides a controlled environment to study the impact of live-fire training fuels on thermal exposure.

The objective of this manuscript is to report the characterization of fire dynamics within the Fire Behavior Lab using common Class A training fuels with a specific focus on understanding the thermal environment for students and instructors along with ability of each fuel to provide an environment that achieves the training objectives. A companions manuscript (Part B of this series [13]) will focus on chemical exposure risk measurements from these experiments.

2 Methods

A technical panel of fire service training experts from across the United States was formed at the beginning of this study to help guide method development regarding the training fuels selected, specific Fire Behavior Lab protocol employed, sampling plan, and overall study design. Members of this panel also provided feedback on the observed fire dynamics and the feasibility of control measures.

2.1 Study Design

This study was designed to test five different wood-based products commercially available in eastern Pennsylvania (USA) using a single compartment, container-based structure commonly employed for live-fire training in the United States. The experimental order for each fuel package followed a block randomization scheme (each fuel was used in the first five experiments, then reordered for the next five experiments, etc.) to reduce the potential influence of environmental conditions when using this outdoor training structure. The tested products included:

-

Low density wood Fiberboard — 7.8 ± 0.1 kg per sheet

-

Orientated strand board (OSB) — 22.5 ± 0.3 kg per sheet

-

Pallets — 16.2 ± 0.6 kg per pallet

-

Particle board — 26.1 ± 0.1 kg per sheet

-

Plywood — 19.5 ± 1.6 kg per sheet

All sheet materials were approximately 1.2 m \(\times\) 2.4 m \(\times\) 11–13 mm thick. OSB, particle board and plywood sheets were utilized in a single layer, with one sheet on each of the three walls and two sheets on the ceiling. Fiberboard sheets were doubled up at each location to account for their lower mass (following typical protocols identified by the study technical panel). The 1.2 m \(\times\) 1.2 m pallets were loaded in the walls with slats oriented vertically and on the ceiling after cutting off the final slat to fit in the chains holding to the ceiling (this cut piece was added to the center of the ceiling fuel load). Two pallets were loaded along each wall and four pallets included along the ceiling. The total wall and ceiling mounted fuel package weight varied between 78 and 162 kg due to different densities of sheet goods and solid wood pallets. Furthermore, the orientation of the solid wood pallets also likely results in different exposed surface area than for the sheet goods. These differences are considered part of the fuel package selection.

In addition to the wall and ceiling fuel load, a source fuel barrel containing approximately one and a half wooden pallets and a half bale of straw (total combustible weight: 27–32 kg) was used to initiate the experiment. The fuel source barrel can contribute up to 30 % of the total weight of the fuel load, but the bulk of this material is consumed during the initial fire development period. Thus, it is expected that the fuel load on the wall and ceiling has the most impact on the environment created for fire dynamics training objectives.

2.2 Structure

The Fire Behavior Lab (Figs. 1 and 2), commonly referred to as a “Flashover Simulator”, is a live-fire training structure designed and operated to demonstrate the stages of compartment fire growth from ignition through flashover. This structure was first developed in Finland and Sweden in the 1980s [14], with variations of the original theme becoming common around the world. The structure consisted of two sections built from steel shipping containers: the fire area (3.0 m \(\times\) 2.4 m) and the observation area (6.1 m \(\times\) 2.4 m). Both areas had a ceiling height of 2.4 m. The fire area container was offset 0.9 m vertically from the bottom of the observation area container.

The observation area walls and ceiling were 4.8 mm thick corrugated steel. The door used for venting during experimentation was 2.0 m tall and 0.9 m wide. The 0.14 m\(^2\) square roof vent was centered along the 2.4 m width of the observation area and offset 1.4 m from the fire area container. The observation area container was equipped with an interior baffle that extended across the entire width of the structure and 0.7 m below the ceiling, and was offset 2.5 m from the fire area container. The baffle was left closed for all experiments. The observation area, normally used for instructors and students to view the fire behavior, was outfitted with instruments for data collection and fire dynamics visualization.

The fire area walls and ceiling were 4.8 mm thick corrugated steel lined with 3.2 mm thick steel sheets for added thermal protection. The fuel load was placed on the upper half of the walls, ceiling, and doors. An example of the OSB fuel load is shown in Fig. 3 and the remaining fuel materials can be seen in Appendix 1. Fuels on the walls and service doors were mounted 0.9 m above the floor using steel channels and held upright by steel chains. Ceiling mounted fuels were supported by steel chains spanning the width of the fire area. The source fuel barrel used for fuel package ignition was centered in the 2.4 m wide fire area and offset 0.3 m from the service doors.

2.3 Training Protocol

A brief description of the operation of the Fire Behavior Lab structure employed in this study is outlined below, while a more detailed description is included in Appendix 1. At the start of each training evolution, the fire area doors and the ceiling baffle were closed and latched. One of the doors in the observation area was fully open and the roof vent was closed. An instructor ignited the fuel in the source fuel barrel. Once the smoke layer descended to a height of 0.3–0.6 m above the fire area floor and a temperature increase was observed, the roof vent was opened to increase the ventilation in both the observation and fire areas. The recommended training evolution from the manufacturer of the employed Fire Behavior Lab consists of two distinct time periods. The first time period (hereafter referred to as the fire development period) begins with the ignition of the source fuel barrel, which heats the fuels positioned along the ceiling and walls, causing them to pyrolyze. After the roof vent is opened and ventilation increases, the fire area typically transitions through rollover and flashover. Upon completion of initial fire dynamic instruction, the vents are closed to end the first demonstration cycle. The second distinct time period is referred to as ventilation cycling, when five additional ventilation cycles are conducted, which result in cyclic changes in environmental conditions. The exact timing of the fire development period and each ventilation cycle is dependent on the fuel package and environmental conditions. The determination of when to start and end each cycle was made by an experienced instructor who had been trained and certified by the manufacturer of the Fire Behavior Lab structure utilized in these experiments.

In these experiments, each ventilation cycle was expected to produce rollover into the observation area and eventually flashover in the fire area. If, at a minimum, rollover was not generated during a ventilation cycle, then the fire dynamics based training objective was not met. Approximately 30 s after rollover into the observation area (typical timing necessary for the instructor to complete instruction of the characteristics of dynamic fire events), the roof vent and observation area door were closed. The vents remained closed for approximately 60 s, simulating the time period over which students would rotate positions during normal instruction. Then, the next cycle began with the opening of both the roof vent and the door. For data analysis purposes, the first ventilation cycle was considered to be 45 s before the first vents open event to the first vents closed event. Ventilation cycles that followed were designated as the time between vents closed events.

Once six ventilation cycles were completed, the fire area doors were fully opened, and two firefighters in full personal protective equipment (PPE) entered the observation area with a hose line and suppressed the remaining burning fuel in the fire area. As the training structure began to cool, the remaining fuel debris was removed via the fire area doors. Depending on the sequence of evolutions and the ambient conditions, the time between tests varied from two hours to overnight.

2.4 Instrumentation

The Fire Behavior Lab was instrumented with thermocouples, heat flux gauges, pressure transducers, oxygen (\(\hbox {O}_2\)) and carbon monoxide (CO) gas analyzers, and environmental gas sampling (Fig. 4). An isometric instrumentation view of the instrumentation layout showing relative vertical distribution of sample locations can be seen in Appendix 1. The instrument locations were chosen as representative of areas where instructors and students would be situated during training. These locations were defined as front, middle, and rear. The front and rear locations were closest to and farthest from the fire area, respectively, and the middle instrument location was at the interior baffle, oriented toward the fire area. This manuscript focuses on the thermal exposure to instructors and students in the observation area, while environmental gas sampling (volatile organic compounds (VOCs), aldehydes, polycyclic aromatic hydrocarbons (PAHs)) results are discussed in the companion manuscript (Part B of this series [13]).

Gas temperatures were measured with 0.5 mm diameter bare-bead, type K thermocouples arranged at all three measurement locations. A vertical array of eight thermocouples was installed, with seven of the thermocouples spaced 0.3 m apart between 0.3 m and 2.1 m above the floor and the eighth thermocouple placed 25 mm below the ceiling. The estimated total expanded uncertainty associated with the temperature measurements is ± 15 % [15, 16]. Small diameter thermocouples were utilized to limit the impact of radiative heating.

Total heat flux measurements were obtained with nominal 25 mm diameter, water-cooled Schmidt-Boelter gauges co-located with the thermocouple arrays. At each measurement location, two heat flux gauges were located approximately 0.9 m above the floor; one was oriented in the horizontal direction and the other in the vertical direction. Results from an international study on total heat flux gauge calibration and response demonstrated the total expanded measurement uncertainty of a Schmidt-Boelter gauge is typically ± 8 % [17].

Pressure measurements relative to ambient conditions were obtained with differential pressure sensors at the front and rear locations. The pressure transducers were connected to copper sampling probes via polymer tubing. Pressure sampling ports were positioned at approximately 0.3 m, 0.9 m, and 2.1 m above the floor at both locations. The differential pressure sensors had an operating range of ± 125 Pa. The estimated total expanded uncertainty associated with the pressure measurements is ± 10 % [18].

Gas concentration measurements of oxygen and carbon monoxide were gathered from the front and rear locations at 0.9 m and 2.1 m above the floor. Each sampling port consisted of a 9.5 mm stainless steel tube through which the gas sample was pulled from the structure through a course 2 micron paper filter, condensing trap, drying tube, and a fine 0.3 micron HEPA filter by a 21.3 LPM vacuum pump before reaching the gas analyzer. The estimated total uncertainty associated with the gas concentration measurements is ± 1 % when compared to span gas volume fractions [19], with an estimated expanded uncertainty of ± 12 % [20] caused by the non-uniformities and movement of combustion gases in addition to the limited amount of sampling points.

Visible light cameras as well as thermal imaging cameras were utilized to record video footage of the experiments. The video footage from each experiment was used to confirm the timing of ventilation operations and to identify fire behavior conditions during each ventilation cycle.

2.5 Fire Dynamics Visual Classification

Study staff and technical panel members examined video footage from the Fire Behavior Lab experiments and classified the observed conditions during each ventilation cycle as flashover,Footnote 1 localized rollover,Footnote 2 or surface burning. Figure 5 provides visual examples of flashover, localized rollover, and surface burning conditions from video footage of an experiment in the Fire Behavior Lab. Flashover and localized rollover both resulted in a dynamic fire event while flames moved from the fire area into the observation area. Flames remained in the fire area during surface burning behavior. The videos were viewed blinded and randomized so the fuel load was not apparent when assessing the fire dynamics cues. Classification of fire dynamics was used to determine whether fire dynamics based training objectives could be accurately completed in each ventilation cycle.

3 Results and Discussion

3.1 Thermal Exposure Analysis

3.1.1 Overview

Gas temperature (Fig. 6) and heat flux (Fig. 7) along with pressure (Fig. 17 in Appendix 2) and gas concentration (Fig. 18 in Appendix 2) are presented for an example experiment with the OSB fuel package. In each experiment, thermal conditions (gas temperature and heat flux) at the front and middle locations peaked in severity immediately prior to the end of each ventilation cycle due to the radiant heat from close proximity to the fire area and descent of the upper gas layer in front of the baffle. However, at the rear location, thermal conditions typically peaked after the vents were closed as the hot upper gas layer descended at this location after the rear door was closed. Gas temperatures above 0.9 m from the floor were most responsive to the changes in ventilation due to the offset between the fire and observation areas. Pressure measurements from the front and rear locations sharply increased for a brief period of time following each vents closed event. Peak values of temperatures, heat fluxes, and pressures were most often recorded at the end of third, fourth, or fifth ventilation cycle, likely due to heating of the steel walls until fuel consumption reduced the energy delivered to the structure. Oxygen concentrations near the observation area ceiling dropped to less than 5% and 15% volume at the front and rear locations, respectively, by the end of the first ventilation cycle. Oxygen concentrations at the front location remained below 5% for the remainder of the experiment, reinforcing the limited oxygen available for combustion of the fuels on the ceiling of the fire area. At 0.9 m above the floor, carbon monoxide and oxygen concentrations remained near ambient level until ventilation cycling began. Peak CO levels consistently exceeded 10,000 ppm, particularly at the rear instructor location, which was consistently higher than concentrations at the front instructor location.

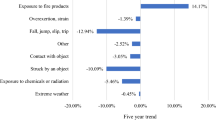

The objective of Fire Behavior Lab based training is to provide an immersive training environment for students to learn important fire dynamics concepts. Although temperature, heat flux, pressure, and gas profiles had similar responses across each experiment, the rate at which these changes in conditions occurred varied considerably. The fire development period (Table 1) varied more between replicates with the pallets and fiberboard fuels than between those with other fuels. Additionally, the fire development period was longest with the pallet fuel load and shortest with the OSB fuel load. The same was also true for the median duration of each ventilation cycle (Table 2). The relatively large range of cycle times, particularly for pallets and fiberboard, may be attributed in part to differences in environmental conditions, particularly humidity. Fuels were stored in a covered area so were not directly impacted by rain, but fluctuations in humidity levels will impact moisture concentration of the fuel. Ventilation cycle times longer than approximately 110–120 s (50–60 s vents open, 60 s vents closed) were sometimes needed to achieve rollover, flashover and/or steady state conditions.

3.1.2 Conditions at Firefighter Head Height

To focus on thermal conditions that would be present at the approximate head height for kneeling or crouching instructors and students in the observation area, the following tables summarize data collected at 0.9 m above the floor. The analysis further focuses on the time-averaged mean (Table 3) and peak (Table 4) values over the cycling period.

As expected, thermal conditions were most severe at the front instructor location, which was closest to the fire source. Though time-averaged mean temperatures were slightly lower at the middle location, the range of median values from the front and middle locations were similar across all fuels, between 87–102°C and 82–99°C, with considerable overlap in the overall range of mean temperatures between 69–116°C and 67–107°C, respectively. At the rear location, mean and peak temperatures and heat fluxes were lower than those from the middle and front positions (except for a few instances that are described below). At the front instructor location, the vertical heat flux was more intense than the horizontal due to the proximity of flames rolling overhead at the end of the fire area. Heat flux decreased with distance from the source, as did differences between vertical and horizontal measurements. Peak values regularly exceeded 10 kW/m\(^2\) at both front and middle locations. At the rear instructor location, time averaged mean heat flux never exceeded 2.7 kW/m\(^2\).

Although the median values of the time-averaged mean gas temperatures 0.9 m above the floor were typically the lowest for the plywood experiments and the highest for fiberboard, OSB, or pallets, the range of temperatures produced by the different fuel packages at each location overlapped considerably. Based solely on gas temperatures, no training fuel package produced a clearly different environment. However, heat flux values at the front and middle locations were consistently lowest for pallet experiments including the lowest minimum and maximum values of any of the fuel packages. Fiberboard experiments resulted in some of the lowest mean heat fluxes at the rear location but also produced the largest median time-averaged horizontal heat flux at the front and middle locations. Overall, increasing the distance from the fire area reduced the thermal exposure threat to the firefighting students and instructors more consistently than changing fuel packages. Exceptions to this trend occurred when flames extended under the baffle to the end of the structure during two of the five experiments with the OSB fuel load. In these experiments, the peak values at the rear heat flux gauges (16.4 and 29.2 kW/m\(^2\)) were considerably higher than peak values during the other 23 experiments (3.8 − 8.3 kW/m\(^2\)). The peak heat fluxes in both cases were sustained for only a few seconds.

Although this manuscript is primarily focused on the thermal risk to firefighting instructors and students, pressure (Table 11) and gas concentration (Tables 12 and 13) data from 0.9 m above the floor are presented in Appendix 2 for completeness. Both the time-averaged mean and overall peak pressures were indistinguishable between the front and rear locations. The fiberboard fuel package generated the lowest mean and peak pressures inside the structure. Mean pressures from pallet experiments were relatively low, however, peak values from pallet experiments immediately after vents were closed were the largest. These pressure spikes may provide insight into chemical exposure risks to firefighters operating inside the structure. Elevated pressures may drive hot gases and smoke that have accumulated inside the structure through gaps and interfaces in a firefighter’s PPE ensemble, which may increase risk for contact with the skin. For example, Mayer et al have reported contaminants such as benzene at high concentrations under firefighting PPE [21]. Future research into transient pressure changes inside burning structures should be performed to further understand this exposure risk. The oxygen and carbon monoxide gas concentrations (Tables 12 and 13 in Appendix 2) suggest a higher acute exposure risk for fire instructors working at the rear of the structure compared to the front. This phenomenon likely results from heated smoke traveling along the ceiling, impacting the relatively cool vertical obstruction at the back of the structure, and then descending onto the instructor. If SCBA are worn throughout the training evolution, these changes in gas concentration should have no impact on firefighter health and safety. However, if the SCBA facepiece is dislodged or the regulator is temporarily removed (which is strongly discouraged but anecdotally may occur during instruction), these high CO and low \(\hbox {O}_2\) concentrations can create an acute risk.

3.1.3 Thermal Class Analysis

The mean and peak values of thermal conditions in the structure provide useful comparisons between fuel loads, but further insight into safety risks for firefighters and instructors can be gained through analyzing this data using established thermal class analyses. A variety of classification systems have been developed and utilized by researchers to provide insight into the potential hazard of thermal exposures that could be experienced by firefighters in a fire environment [22,23,24,25,26,27]. Based on Utech’s categories of a firefighter’s environment as ‘Routine’, ‘Ordinary’, or ‘Emergency’, Madrzykowski modified the temperature and heat flux ranges as shown in Table 5 [26, 27]. A Routine environment is slightly more intense than what would be encountered on a hot summer day. In an Ordinary environment, firefighters can be expected to function effectively with proper PPE for 10–20 min dependent on the heat absorbed by the PPE prior to Ordinary exposure. If the PPE is exposed to conditions near the upper bounds of the Ordinary exposure, the safe operational time will be reduced. Firefighters should only be expected to operate in Emergency exposures for 60 s or less prior to degradation of the PPE or an injury occurs. These categories were applied to data from estimated firefighter head height (0.9 m above the floor) to characterize the thermal exposures risks at each location with each fuel package (Table 6). It should be noted that a firefighter’s PPE will be preheated by exposure to conditions classified as Ordinary prior to reaching Emergency conditions. The suggested time thresholds are useful for comparison purposes, but the impact of preheating the gear should be carefully considered when applying these thermal class criteria. However, the amount of time firefighters would be working in conditions characterized as “Emergency” or “Ordinary” following this classification scheme provides a useful metric to compare thermal exposure risk.

For fire instructors and students at the front and middle locations, the thermal exposure hazard from radiated heat was consistently classified as more severe than the hazard from the gas temperature, reinforcing a finding reported by Willi et al. [28] and Madrzykowski [27]. At the front location, conditions based on the heat flux data were characterized as Emergency for an average of 3 % (pallets) to 22 % (OSB) of the exposure duration during the cycling period, while the Emergency threshold was never exceeded by the gas temperature 0.9 m above the floor. At both the front and middle locations, gas temperature hazards were more often Routine than the heat flux hazard. The OSB experiments resulted in the largest time in Emergency conditions based on heat flux criteria, while the fiberboard experiments resulted in the longest average duration in the Ordinary classification for both the heat flux and temperature hazard.

The longest average duration in Emergency conditions was slightly over 2.5 min for the OSB fuel package. It is important to note that firefighters would not be working in these conditions in a continuous manner as this exposure was typically experienced at isolated times during peak conditions just prior to the vents being closed for each cycle (see Fig. 7). None of these experiments resulted in continuous exposure in Emergency conditions longer than 60 s. However, for all fuel packages other than pallets, there was at least one experiment where continuous exposure in Emergency conditions lasted longer than 15 s after sustained exposure to Ordinary conditions. The longest single sustained exposure in Emergency conditions was 58 s during a fiberboard experiment. Fire instructors who operate at the front location can employ strategies to reduce this risk through time, distance, and shielding (see below), though some of these techniques may be less effective at reducing the impact of elevated gas temperatures. While gas temperature hazard levels were regularly considered in the Ordinary hazard range, none of the experiments exceeded the 20 min upper limit [26] at 0.9 m above the floor for any location or any fuel package.

At the rear instructor location, the thermal hazard levels were dramatically reduced and most often considered Routine for both gas temperature and heat flux. At this location, the hazard due to gas temperature was consistently higher than that from heat flux due to the extended distance from the flaming materials. As previously mentioned, two OSB experiments did produce brief flashes of fire that reached beyond the baffle in the observation area, which resulted in quick excursions into Emergency conditions (< 5 s each) at the rear instructor location.

3.1.4 PPE Damage Risk

In addition to the thermal risk to firefighters operating in these environments, long duration exposures to elevated thermal conditions can increase the risk of damage to firefighting PPE. Anecdotally, the Fire Behavior Lab has been known to create an environment where damage to firefighting helmets and facepieces can occur. In 2016, Willi et al. published results from experiments that aimed to characterize a firefighter’s thermal environment in a variety of training environments [28], two of which were training evolutions in a Fire Behavior Lab. During one of these experiments, it was reported that the firefighter’s SCBA facepiece began to show visible signs of degradation (i.e., bubbling) after an exposure with an average heat flux of 1.1 kW/m\(^2\) for approximately 9 min followed by an average heat flux of 5.0 kW/m\(^2\) for less than 9 min. The exposure was also characterized by moderate temperatures that averaged less than 40 \(^\circ\)C and never exceeded 150 \(^\circ\)C. It should be noted that the SCBA facepiece worn by the firefighter in the Willi et al. experiment was tested to an earlier standard of NFPA 1981. However, even with PPE tested to the latest standard, firefighters should still be cognizant of the potential for PPE damage from the prolonged exposures experienced in the Fire Behavior Lab.

The heat flux exposures summarized in Tables 3 and 4, particularly those at the front and middle positions, were generally more severe than those described by Willi et al. and could increase risk for damage to firefighter PPE. Firefighting SCBA facepiece damage and failure has been studied in depth over the past decade, including damage ranging from microcracking to hole formation for SCBA facepieces certified to different editions of NFPA 1981: Standard on Open-Circuit Self-Contained Breathing Apparatus (SCBA) for Emergency Services) [29]. These results are summarized in Table 7 [30,31,32]. The magnitude of the heat flux experienced at the front (and potentially middle) location over the duration recorded in these experiments can increase the risk for damage to SCBA facepieces—particularly those certified prior to the 2013 edition of NFPA 1981—unless control measures are taken to mitigate the thermal risk.

3.1.5 Firefighters Thermal Exposure Control Options

Due to the elevated thermal risk when conducting training in the Fire Behavior Lab, firefighters should consider important control measures to reduce opportunity for PPE damage and skin burns. As shown above, training fuel selection can impact the thermal risk, particularly at the front locations. Pallet fuels produced training environments that reduced the amount of time in Emergency operating conditions compared to the particle board and OSB fuel packages. However, the pallet fuel load also requires the longest overall exposure time within the training structure (fire development and cycling periods) and such substitutions may not always be possible depending on the training objectives that are to be achieved (see next section). The fuels selected for this study were commercially available in eastern Pennsylvania (USA), yet other options may be utilized with differences in density (and overall fuel load), exposed surface area (particularly related to pallet design), and properties such as heat of combustion. Each of these factors, along with ambient environmental conditions, can impact thermal risk and should be considered with any fuel package selection.

Firefighters can control their exposure to radiant heat through time, distance, and shielding. Completing the same training objective in a shorter time frame can reduce exposure to elevated thermal conditions. Fuel packages that typically had shortest overall exposure times (e.g. OSB, particle board, plywood—Tables 1, 2) also tended to expose fire instructors and students to the highest peak heat fluxes. However, with increased efficiency during instruction or smaller groups of students, it may be possible to achieve training objectives with three to four ventilation cycles as opposed to six cycles, which may reduce the time in Emergency conditions after PPE has already been pre-heated. Additionally, instructors and students can reduce the amount of time that PPE components are impacted by radiant heating by simply moving around, such as turning away from the fire (to better protect their SCBA facepiece) or by rotating their orientation relative to the fire area (to minimize heating of PPE on a given side). Shielding can also be effective and may be most easily employed by instructors at the front location by ducking below the structural offset between the fire area and observation area (see Fig. 2) to shield from horizontal components of radiation.

Finally, the impact of distance from the fire area was demonstrated by the marked reduction of time in Emergency conditions when moving from the front to middle to rear locations. Moving instructors or students as far back from the fire area as possible while still achieving training objectives can reduce the exposure risk—particularly to Emergency thermal conditions. In addition to the horizontal distance from the fire, changing the vertical distance from the fire area floor can also provide additional levels of control. The primary analysis of gas temperature focused on measurements from 0.9 m above the floor as an approximation of a firefighter’s head height while crouching or kneeling. Small perturbations in vertical location can have a dramatic effect on thermal risk. Temperatures at ± 0.3 m from this assumed vertical location are summarized in Table 8 along with relative times in each thermal class (Table 9) at each measurement location.

Changing a firefighters head height by as little as 0.3 m can have important impacts on thermal exposure risk. Total exposure duration in the lowest risk, Routine, conditions increased by 8–15 % at the front position and 28–40 % at the middle position at 0.6 m above the floor compared to 0.9 m. Conversely, raising a firefighter’s head height from 0.9 m to 1.2 m above the floor increases thermal risk. Gas temperatures 0.9 m above the floor never reached Emergency conditions at any of the three locations. However, at 1.2 m above the floor, the time spent in Emergency conditions averaged between 3–5 min at the front and middle locations, or between 22–42 % of the ventilation cycling. Additionally, there was an increase in the average time in Emergency conditions at the rear position with gas temperatures from 1.2 m above the floor. This analysis is of particular importance for those training organizations who use benches in the observation area for students to sit on. Although the benches may be more comfortable for twenty plus minutes of instruction, they can increase thermal hazards by orienting firefighters higher in the observation area.

Finally, the design of the training structure may be modified to reduce thermal exposure risk for future construction. The observation area may be constructed out of a taller container, lowering the floor relative to the fire area (though consideration should be given to other possible risks, such as larger potential fall distances from the fire area to the observation area). Newer structure design modifications have included a wider observation area and a fully opened observation compartment.

3.2 Training Fire Environment Presentation with Different Fuel Packages

To confidently employ substitution control measures such as replacing one training fuel with another, it is important to understand potential impacts on the objectives of the fire training evolution. Eleven members of the project team, including individuals from training organizations around the United States, reviewed video footage of the 25 experiments in randomized order and without knowledge of the fuel package employed. For each of the six ventilation cycles and each of the five different training fuels, eleven individuals reviewed up to five repetitions, resulting in up to 55 observations per cycle/fuel combination (though some individuals did not complete observations of all five replicates of each fuel). For each fuel, up to 330 total observations were possible over the six ventilation cycles (55 observations per cycle x 6 cycles), though the total number completed varied between 304 and 324. The percentage of responses that identified the fire dynamics presented in each cycle as either ‘Flashover’, ‘Localized Rollover’, or ‘Surface Burning’ (see Fig. 5) were calculated for all five training fuels at each of the six ventilation cycles (Table 10).

Overall, the fire dynamics environment created by both OSB and particle board were identified by training experts as achieving the training objectives (flashover and/or localized rollover) more consistently than other fuel types. In fact, only 6 % of the responses for both fuels indicated surface burning compared to 24–45 % for the other fuel packages. The plywood fuel package produced similarly consistent flashover or localized rollover conditions for the first four cycles, but the material was consumed more completely than the other fuel loads and lost its consistency in the fifth and particularly the sixth cycles. Fire dynamics produced by fiberboard and pallet fuel packages were markedly less consistent than the other fuels. It is possible that the burning characteristics of these materials may be more impacted by transient variations in ambient moisture than the other wood-based products that incorporate formaldehyde- and/or isocyanate-based resins. The pallet fuel load also has additional mass and different area and orientation of exposed surfaces compared to the sheet goods, which may have impacted time to produce appropriate amounts of combustible smoke. Fire dynamics from the fiberboard fuel load were identified as surface burning in more than half of the response at the fourth cycle and more than 90 % for the fifth and sixth cycle. This change in fire dynamics could not be attributed to complete consumption of the material as the sheets were doubled up (as is common for those who use this material due to its light weight). Previous research has identified challenges when using this fuel to create training fire environments [33]. Anecdotally, some training organizations have overcome these challenges with fiberboard by combining pallets with the panels on the ceiling to provide a longer, more consistent cycling period. This study concentrated on a single fuel type along the walls and ceiling, but future work should address hybrid fuel packages.

Each of these experiments were initiated with the Fire Behavior Lab at ambient temperature to allow consistent comparison across each fuel. The structure heats up during the first cycle, which likely contributes to the relatively low identification of flashover conditions during this ventilation cycle. Cycles 2–4 were the most consistent in producing flashover and/or rollover conditions regardless of the fuel package. Cycles 5 and 6 experienced reduced flashover conditions across all fuel packages. Although the typical fire dynamics demonstrations are well suited to the earlier cycles, instructors may also find value instructing students using the surface burning conditions. Alternatively, limiting training scenarios to the first three or four ventilation cycles compared to six cycles would reduce the total time exposed to elevated thermal conditions, and focus training during the time when the objectives of fire dynamics lessons are more likely to be accurately conveyed.

When utilized as part of a live-fire fire dynamics demonstration, fuel choice should balance fire dynamics fidelity with risk posed to the firefighting students and instructors. OSB and the particle board fuels resulted in training environments with the highest fire dynamics fidelity followed by plywood, pallets and then fiberboard. However, OSB and fiberboard produced elevated thermal conditions, followed by pallets, particle board, and plywood (Tables 3 and 4). Additional training considerations might include the accessibility and cost of the fuel, challenges in preparing and loading the fuels [33] and relative chemical exposure risks posed by the different training fire environments created [13]. While this study focused on wood-based training fuels that are commonly employed in the United States, other training fuel options with differences in total fuel weight, exposed surface area, resistance to ambient moisture absorption, and material properties can impact fire dynamics and should be considered with any fuel package selection.

4 Summary and Conclusions

To address questions from the NFPA 1403 Technical Committee regarding the impact of different fuels on training fire environments, the fire dynamics within the Fire Behavior Lab produced by five different commonly available training fuels were characterized. The time to complete each training evolution varied more between replicates with the pallets and fiberboard fuels than between those with other fuels. As expected, temperatures and heat fluxes were highest at the front position. The fuel load utilized had minimal impact on the range of gas temperatures recorded, though median thermal conditions were typically the highest for OSB and fiberboard, while plywood resulted in the lowest median temperature. Peak heat fluxes, however, were notably higher for the OSB experiments while pallet fuels loads produced the lowest median heat flux exposures. Using gas temperature and heat flux data from approximate firefighter head height (0.9 m above the floor), exposures were characterized as ‘Routine’, ‘Ordinary’, or ‘Emergency’. At the front instructor location, heat flux exposures measured 0.9 m above the floor were categorized, on average, as Ordinary for 75–93 % of the cycling duration and as Emergency for 3–22 % of the cycling duration for the five different fuel loads. Thermal classifications based on gas temperatures from the same height were much less severe—the temperatures measured during the 25 experiments were always below the Emergency threshold and thus characterized as either Routine or Ordinary. However, if the approximated head height of a firefighter was raised from 0.9 m to 1.2 m above the floor, conditions based on gas temperature from the front location were categorized as Emergency for an average 27–42 % of the cycling duration with the different fuel types. The most consistent fire dynamics were demonstrated with the OSB and particle board fuels, while the fiberboard and pallets resulted in much less repeatable flashover or rollover demonstrations. Overall, fuel substitutions can impact thermal risk for firefighters but also have important impact on the consistency of the fire dynamics being presented to the firefighting students. Thermal risks during live-fire training cannot be completely eliminated, but may be controlled to some extent by locating instructors and students lower in the observation area, farther from the fire, and by reducing the exposure time through fewer ventilation cycles when appropriate.

Data Availability

Data can be made available upon request.

Notes

NFPA 1403 definition of Flashover: “A transition phase in the development of a compartment fire in which surfaces exposed to thermal radiation reach ignition temperature more or less simultaneously and fire spreads rapidly throughout the space, resulting in full room involvement or total involvement of the compartment or enclosed space.”

NFPA 1403 definition of Flameover (Rollover): “The condition in which unburned fuel (pyrolysate) from the originating fire has accumulated in the ceiling layer to a sufficient concentration (i.e., at or above the lower flammable limit) that it ignites and burns. Flameover can occur without ignition of or prior to the ignition of other fuels separate from the origin.”

References

NFPA 1403 (2018) Standard on live fire training evolutions. National Fire Protection Association, Quincy, Massachusetts. National Fire Protection Association

IAFF Division of Occupational Health, Safety and Medicine (2018) Dangers of OSB Burning Summary. Technical report, International Association of Firefighters, Department of Occupational Health, Safety and Medicine, Washington, D.C.

Regan JW (2021) Heat release rate characterization of NFPA 1403 compliant training fuels. Fire Technol 57:1847–1867

Horn GP, Stewart JW, Kesler RM, DeBlois JP, Kerber S, Fent KW, Scott WS, Fernhall B, Smith DL (2019) Firefighter and fire instructor’s physiological responses and safety in various training fire environments. Saf Sci 116:287–294

Petrakis JG (2003) Firefighter learning styles and training: beyond the slide presentation. Fire Eng 156(10):132–6

Madrzykowski D (2007) Fatal training fires: fire analysis for the fire service. In: INTERFLAM 2007 Proceedings. Interscience Communications Ltd, London

Tarley J, Messanotte T (2001) Volunteer fire fighter dies and two others are injured during live-burn training—New York. Technical Report NIOSH F2001-38, National Institute for Occupational Safety and Health, Division of Physical Sciences and Engineering, Cincinnati, Ohio

Romano N, Tarley J (2002) Career lieutenant and fire fighter die in a flashover during a live-fire training evolution—Florida. NIOSH F2002-34, National Institute for Occupational Safety and Health, Division of Physical Sciences and Engineering, Cincinnati, Ohio

Tarley J (2007) Career probationary fire fighter dies while participating in a live-fire training evolution at an acquired structure—Maryland. NIOSH F2007-09, National Institute for Occupational Safety and Health, Division of Physical Sciences and Engineering, Cincinnati, Ohio

Fisher G (2015) Conducting NFPA 1403-compliant live burn training in acquired structures. Fire Eng. https://www.fireengineering.com/fire-prevention-protection/conducting-nfpa-1403-compliant-live-burn-training-in-acquired-structures-p1. Accessed 22 May 2023

Reeder F (2013) The NFPA 1403 debate. Fire Rescue. https://www.firefighternation.com/firerescue/the-nfpa-1403-debate. Accessed 22 May 2023

Garcia K, Kauffman R (2009) Realistic live burn training you can afford. Fire Eng 162(5):89

Horn, GP, Stakes, K, Neumann, DL, Madrzykowski D, Fent KW (2023) Exposure risks and potential control measures for a fire behavior lab training structure: Part B—chemical gas concentrations. Fire Technol submitted for review

Loikkanen P, Mangs J (1991) Flash over simulator, function and safe use. FOU Report P21-069/91, Technical Research Centre of Finland, Espoo

Blevins LG (1999) Behavior of bare and aspirated thermocouples in compartment fires. In: National Heat Transfer Conference, 33rd Proceedings, pp. 15–17

Pitts WM, Braun E, Peacock R, Mitler H, Johnson E, Reneke P, Blevins LG (2003) Temperature uncertainties for bare-bead and aspirated thermocouple measurements in fire environments. ASTM Special Techn Pub 1427:3–15

Pitts WM, Murthy AV, de Ris JL, Filtz J, Nygård K, Smith D, Wetterlund I (2006) Round robin study of total heat flux gauge calibration at fire laboratories. Fire Saf J 41(6):459–475

Kerber S, Madrzykowski D (2008) Evaluating positive pressure ventilation in large structures: school pressure and fire experiments. NIST Technical Note 1498, National Institute of Standards and Technology, Gaithersburg, MD

Bundy M, Hamins A, Johnsson EL, Kim SC, Ko GH, Lenhart DB (2007) Measurements of heat and combustion products in reduced-scale ventilated-limited compartment fires. NIST Technical Note 1483, National Institute of Standards and Technology, Gaithersburg, MD

Lock A, Bundy M, Johnsson EL, Hamins A, Ko GH, Hwang C, Fuss P, Harris R (2008) Experimental study of the effects of fuel type, fuel distribution, and vent size on full-scale underventilated compartment fires in an ISO 9705 room. NIST Technical Note 1603, National Institute of Standards and Technology, Gaithersburg, MD

Mayer AC, Fent KW, Wilkinson A, Chen I, Kerber S, Smith DL, Kesler RM, Horn GP (2022) Characterizing exposure to benzene, toluene, and naphthalene in firefighters wearing different types of new or laundered PPE. Int J Hyg Environ Health. https://doi.org/10.1016/j.ijheh.2021.113900

Duffy RM, Sawicki JC, Beer AR (1985) Project fires: firefighters integrated response equipment system—The Final Report. Technical report, International Association of Firefighters, Department of Occupational Health and Safety, Washington, D.C.

Foster JA, Roberts GV (September 1995) Measurements of the firefighting environment—summary report. 61, Central Fire Brigades Advisory Council Research, United Kingdom

Colletta GC, Arons IJ, Ashley LE, Drennan AP (February 1976) The Development of Criteria for Firefighters’ Gloves Volume I: Glove Requirements. Technical report, U. S. Department of Health, Education, and Welfare, Public Health Service, Center for Disease Control, National Institute for Occupational Safety and Health, Division of Physical Sciences and Engineering, Cincinnati, Ohio

Donnelly MK, Davis WD, Lawson JR, Selepak MJ (January 2006) Thermal environment for electronic equipment used by first responders. NIST TN 1474, National Institute of Standards and Technology, Gaithersburg, MD

Utech H (1973) Status report on research programs for firefighters protective clothing. In: 45th Annual Fire Department Instructors Conference Proceedings, pp. 156–166. International Society of Fire Service Instructors, Kansas City, MO

Madrzykowski D (2017) Fire fighter equipment operational environment: evaluation of thermal conditions. NFPA Fire Protection Research Foundation, Quincy, Massachussets

Willi J, Horn G, Madrzykowski D (2016) Characterizing a firefighter’s immediate thermal environment in live-fire training scenarios. Fire Technol 52:1667–1696

NFPA 1981 (2019) Standard on Open-Circuit Self-Contained Breathing Apparatus (SCBA) for Emergency Services. National Fire Protection Association, Quincy, Massachusetts. National Fire Protection Association

Putorti A, Mensch A, Bryner N, Braga G (2013) Thermal performance of self-contained breathing apparatus facepiece lenses exposed to radiant heat flux. Technical Report NIST TN 1785, National Institute of Standards and Technology, Gaithersburg, MD

Horn G, Kesler R, Regan J, Madrzykowski D (2017) A study on the effect of repeat moderate intensity radiant exposures on SCBA facepiece properties. NISTGCR 17-014, National Institute of Standards and Technology

Kesler R, Mitsingas C, Quiat A, Lee T, Madrzykowski D, Horn G (2018) Mechanical properties and off-gassing characteristics of new and legacy facepieces. NISTGCR 18-019 Natl Inst Stand Technol. https://doi.org/10.6028/NIST.GCR.18-019

Randall GB (2020) Characterization of a Live-Fire Training Simulator for use in the Canadian Fire Service. Master’s thesis, University of Waterloo

Acknowledgements

The authors thank Sarah Huffman, Philip Gilman, Nick Dow, Matthew Didomizio, Brad Morrissey, John Culbertson, Sean DeCrane, and Ethan Crivaro for their hard work and dedication during data collection and/or manuscript review. Additionally the 18 project technical panel members from fire service organizations across the United States are thanked for their guidance, insight, direction, and feedback throughout the project.

Funding

This work was supported by the Department of Homeland Security Fire Prevention and Safety Grant EMW-2019-FP-00770.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

None of the authors have any commitments or funding that would cause a conflict of interest for the publication of this manuscript.

Ethical Approval

Not applicable

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Explanatory Material for Study Methods

1.1 Example Fuel Load Images

1.2 Detailed Training Protocol for Fire Behavior Lab Operation

The Fire Behavior Lab can be operated in a variety of different ways based on training objectives and manufacturer recommendations. In this study, a common protocol developed and taught by the manufacturer was adopted and are summarized here. Typical steps associated with the preparatory phase include the following:

-

Gathering of equipment needed including an interior hose line for primary safety and an exterior hose line for backup as per the water supply requirements from the National Fire Protection Association (NFPA) 1403 on Live Fire Training [1], portable propane torch for ignition of the source fuel, full personal protective equipment (PPE) and self-contained breathing apparatus (SCBA) for all instructors and students, and a thermal imaging camera (TIC).

-

Loading of the fire area with both source and exposure fuels. The source fuel is typically comprised of one and a half pallets cut or broken apart and stacked into a metal source fuel barrel along with a proportional amount of straw, hay, or excelsior. The exposure fuel is typically comprised of wood-based sheet goods on both side walls, each of the fire area’s door leafs, and the ceiling of the fire area. Depending on the jurisdiction, these wood sheet goods could be oriented strand board (OSB), low-density wood fiber board, particle board, medium density fiber board, plywood, while others may use wooden pallets or some combination thereof.

-

Hosting of a safety briefing prior to each burn evolution by the identified lead instructor and safety officer. The safety briefing identifies the training structure layout, entry and exit points, operation of the ventilation openings, fuel loading, expected fire behavior, and safety precautions in the event of problem such as an equipment malfunction. After the safety briefing and prior to entry into the training structure, a safety check is performed on each individual to ensure that there is no exposed skin and that the PPE and SCBA are donned appropriately.

Once the above steps have been completed, the instructors for the evolution will ensure that the students are in place inside the structure, the hose lines are in place, tested, and charged, and will prepare the vents for ignition. It is important to note that the initial vent position and subsequent vent sequence and operation may vary based on the specific training structure manufacturer recommendation and/or jurisdiction in question. At the start of the evolution, the fire area doors, utilized for the loading and unloading of fuel, are closed and latched. One of the doors in the observation area is typically closed with the other door positioned between one half to fully open. The ceiling baffle in the observation area will be closed once students are in position. The roof vent will be closed to allow for the initial build up of heat and fire gases within the fire area and forward section of the observation area (Fig. 12). At this point, the instructors will ignite the fuel in the source fuel barrel which is positioned to the front of the fire area, approximately 0.3 m off the front wall and could be located in the center or to either side of the compartment.

After the source fuel barrel is ignited, the ignition device is removed from the training structure and the evolution instruction begins. The first ventilation action is commonly the opening of the roof vent to increase the efficiency of ventilation in both the observation area and fire area (Fig. 13), leading to a transition of the space through flashover. The roof vent is actuated once the smoke layer in the fire area has descended to near the bottom of the air inlets located on the source fuel barrel (Fig. 14), or approximately 0.3 to 0.6 m above the floor in the fire area. Once the fire area transitions through flashover, flames rolling along the bottom of the smoke layer are evident in the observation area above the position of the front instructor and student locations. This fire behavior is due to the presence of fresh air to support fire growth, which enters in through the opened door of the observation area, mixes with the hot fuel gases at this interface, and exhausts upwards through the roof vent. The timing of this demonstration is intended to limit the students’ and instructors’ exposure to flaming combustion as this radiant energy increases the rate of heat transfer to firefighters’ PPE. Once the instructor completes instruction of the characteristics of rollover and flashover, the roof vent and observation area door are closed (Fig. 15). Closing these vents decreases the efficiency of burning in the compartment and flaming combustion returns to the source fuel barrel as the fire becomes further ventilation-limited. This action completes the first cycle of the given burn evolution. While the vents are closed and the fire is darkened down, with combustion largely limited to the source fuel barrel, the students rotate positions to ensure each has a different vantage point of the fire behavior within the training structure, for each cycle performed.

Once the students have reoriented, the rear instructor opens the roof vent and a single door of the observation area simultaneously. As discussed above, this increases the airflow within the training structure, subsequently increasing the efficiency of burning, and transitions the fire area through flashover once more. With flashover in the fire area and rollover evident into the observation area, all vents are again closed. A full ventilation cycle includes the time when the vents are both opened and closed, ending when the vents are opened for the next demonstration cycle. The number of students, the desired learning objectives, the training policies, and the local weather conditions will determine the number of cycles performed in a given live fire evolution within the Fire Behavior Lab.

For the purpose of these experiments, the Fire Behavior Lab was instrumented with both thermal and environmental exposure sensors in addition to both standard and infrared imaging cameras. As such, there were no students or instructors inside the structure during the experiments. The thermal data and video footage was monitored remotely and communication was made to position ventilation openings via radio to firefighters wearing full PPE located outside of the structure.

1.3 Isometric View of Instrumentation Layout

See Fig. 16.

Appendix 2: Pressure and Gas Concentrations (\(\hbox {O}_2\), CO) from the Fire Behavior Lab

See Fig. 18 and Tables 12, 13.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Stakes, K., Willi, J.M., Chaffer, R. et al. Exposure Risks and Potential Control Measures for a Fire Behavior Lab Training Structure: Part A—Fire Dynamics and Thermal Risk. Fire Technol 59, 2089–2125 (2023). https://doi.org/10.1007/s10694-023-01414-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-023-01414-7