Abstract

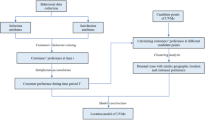

The optimization of replenishment and delivery problem (RDP) for unmanned vending machines supply chain network (UVM-SCN) is challenging due to frequent service interruptions and supply–demand mismatches in operations. Many studies adopt proactive resilience strategies to solve those challenges. However, since most proactive resilience strategies are weak in providing dynamic redundancy towards frequent interruptions, we propose a two-stage resilience strategy to optimize the RDP for UVM-SCN, which redesigns the structure of UVM-SCN and allocates appropriate suppliers for different customers. The first stage focuses on the optimization of UVM-SCN structure. Based on the analysis of customers’ preferences, UVMs with similar geographic locations and customer preferences are clustered into closely related demand zones through the improved fuzzy C-means algorithm. The mutual rescue strategy is applied in each demand zone when interruptions occur to achieve quick transfer of products and customers. In the second stage, the dynamic matching mechanism, which integrates suppliers’ capabilities and customers’ requirements, is proposed to guarantee the provision of various products. On this basis, a scheduling model is established to optimize the RDP of UVM-SCN considering total cost, completion time and customers’ satisfaction, and solved by the genetic algorithm. The numerical studies show that the optimal solution can guarantee service reliability and satisfy customers’ demands at a competitive cost under continuous uncertainties, thereby demonstrating the validity and effectiveness of the model and the corresponding algorithm. This work extends the research on SCN structural resilience under frequent interruptions and contributes to the UVM-SCN resilience management by integrating suppliers’ capability and customers’ multi-dimensional requirements into one research framework.

Similar content being viewed by others

References

Zhong, X., Lee, H. K., & Li, J. (2017). From production systems to health care delivery systems: A retrospective look on similarities, difficulties and opportunities. International Journal of Production Research, 55(14), 4212–4227. https://doi.org/10.1080/00207543.2016.1277276

Grzybowska, H., Kerferd, B. B., Gretton, C., & Waller, S. T. (2020). A simulation optimisation genetic algorithm approach to product allocation in vending machine systems. Expert Systems with Applications, 145, 113110. https://doi.org/10.1016/j.eswa.2019.113110

Zhang, H., Li, D., Ji, Y., Zhou, H., Wu, W., & Liu, K. (2019). Towards new retail: A benchmark dataset for smart unmanned vending machines. IEEE Transactions on Industrial Informatics, 16(12), 7722–7731. https://doi.org/10.1109/tii.2019.2954956

Li, J., Blumenfeld, D. E., Huang, N., & Alden, J. M. (2009). Throughput analysis of production systems: Recent advances and future topics. International Journal of Production Research, 47(14), 3823–3851. https://doi.org/10.1080/00207540701829752

Tan, W. J., Zhang, A. N., & Cai, W. (2019). A graph-based model to measure structural redundancy for supply chain resilience. International Journal of Production Research, 57(20), 6385–6404. https://doi.org/10.1080/00207543.2019.1566666

Hosseini, S., Ivanov, D., & Dolgui, A. (2019). Review of quantitative methods for supply chain resilience analysis. Transportation Research: Part E, 125, 285–307. https://doi.org/10.1016/j.tre.2019.03.001

Yoon, J., Talluri, S., Yildiz, H., & Ho, W. (2018). Models for supplier selection and risk mitigation: A holistic approach. International Journal of Production Research, 56(10), 3636–3661. https://doi.org/10.1080/00207543.2017.1403056

Ivanov, D., & Dolgui, A. (2020). Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research, 58(10), 2904–2915. https://doi.org/10.1080/00207543.2020.1750727

Yu, W., Jacobs, M. A., Chavez, R., & Yang, J. (2019). Dynamism, disruption orientation, and resilience in the supply chain and the impacts on financial performance: A dynamic capabilities perspective. International Journal of Production Economics, 218, 352–362. https://doi.org/10.1016/j.ijpe.2019.07.013

Wang, J., Dou, R., Muddada, R. R., & Zhang, W. (2017). Management of a holistic supply chain network for proactive resilience: Theory and case study. Computers & Industrial Engineering, 125, 668–677. https://doi.org/10.1016/j.cie.2017.12.021

Wang, J. W., Liu, D., Ip, W. H., Zhang, W. J., & Deters, R. (2014). Integration of system dynamics, aspect-programming, and objective-orientation in system information modeling. IEEE Transactions on Industrial Informatics, 10(2), 847–853. https://doi.org/10.1109/tii.2014.2300703

Wang, J. W., Ip, W. H., Muddada, R. R., Huang, J. L., & Zhang, W. J. (2013). On petri net implementation of proactive resilient holistic supply chain networks. International Journal of Advanced Manufacturing Technology, 69(1–4), 427–437. https://doi.org/10.1007/s00170-013-5022-x

Blackhurst, J., Craighead, C. W., Elkins, D., & Handfield, R. B. (2005). An empirically derived agenda of critical research issues for managing supply-chain disruptions. International Journal of Production Research, 43(19), 4067–4081. https://doi.org/10.1080/00207540500151549

Wagner, S. M., & Bode, C. (2006). An empirical investigation into supply chain vulnerability. Journal of Purchasing and Supply Management, 12(6), 301–312. https://doi.org/10.1016/j.pursup.2007.01.004

Christopher, M., & Holweg, M. (2011). Supply chain 2.0: Managing supply chains in the era of turbulence. International Journal of Physical Distribution & Logistics Management, 41(1), 63–82. https://doi.org/10.1108/09600031111101439

Stefanovic, D., Stefanovic, N., & Radenkovic, B. (2009). Supply network modelling and simulation methodology. Simulation Modelling Practice and Theory, 17(4), 743–766. https://doi.org/10.1016/j.simpat.2009.01.001

Ghadge, A., Dani, S., & Kalawsky, R. S. (2012). Supply chain risk management: Present and future scope. The International Journal of Logistics Management, 23(3), 313–339. https://doi.org/10.1108/09574091211289200

Pereira, C. R., Christopher, M., & Silva, A. L. D. (2014). Achieving supply chain resilience: The role of procurement. Supply Chain Management, 19, 626–642. https://doi.org/10.1108/scm-09-2013-0346

Simangunsong, E., Hendry, L. C., & Stevenson, M. (2012). Supply-chain uncertainty: A review and theoretical foundation for future research. International Journal of Production Research, 50(16), 4493–4523. https://doi.org/10.1080/00207543.2011.613864

Park, K., Min, H., & Min, S. (2016). Inter-relationship among risk taking propensity, supply chain security practices, and supply chain disruption occurrence. Journal of Purchasing and Supply Management, 22(2), 120–130. https://doi.org/10.1016/j.pursup.2015.12.001

Manuj, I., & Mentzer, J. T. (2008). Global supply chain risk management. Journal of business logistics., 29(1), 133–155. https://doi.org/10.1002/j.2158-1592.2008.tb00072.x

Xu, J., Hu, Z., Zou, Z., Zou, J., Hu, X., Liu, L., & Zheng, L. (2020). Design of smart unstaffed retail shop based on IOT and artificial intelligence. IEEE Access, 8, 147728–147737. https://doi.org/10.1109/ACCESS.2020.3014047

Liu, L., Zhou, B., Zou, Z., Yeh, S. C., & Zheng, L. (2018). A smart unstaffed retail shop based on artificial intelligence and IoT. In 2018 23rd International workshop on computer aided modeling and design of communication links and networks (CAMAD) (pp. 1–4). https://doi.org/10.1109/CAMAD.2018.8514988

Zheng, Y., & Li, Y. (2018). Unmanned retail’s distribution strategy based on sales forecasting. In 2018 8th International conference on logistics, informatics and service sciences (LISS) (pp. 1–5). https://doi.org/10.1109/LISS.2018.8593273

Sibanda, V., Munetsi, L., Mpofu, K., Murena, E., & Trimble, J. (2020). Design of a high-tech vending machine. Procedia CIRP, 91, 678–683. https://doi.org/10.1016/j.procir.2020.04.133

Murena, E., Sibanda, V., Sibanda, S., & Mpofu, K. (2020). Design of a control system for a vending machine. Procedia CIRP, 91, 758–763. https://doi.org/10.1016/j.procir.2020.04.136

Ali, A., Mahfouz, A., & Arisha, A. (2017). Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Management, 22(1), 16–39. https://doi.org/10.1108/scm-06-2016-0197

Ribeiro, J. P., & Barbosa-Póvoa, A. P. F. D. (2018). Supply chain resilience: Definitions and quantitative modelling approaches: A literature review. Computers & Industrial Engineering, 115, 109–122. https://doi.org/10.1016/j.cie.2017.11.006

Fattahi, M., Govindan, K., & Maihami, R. (2020). Stochastic optimization of disruption-driven supply chain network design with a new resilience metric. International Journal of Production Economics, 230, 107755. https://doi.org/10.1016/j.ijpe.2020.107755

Spiegler, V., Naim, M., & Wikner, J. (2012). A control engineering approach to the assessment of supply chain resilience. International Journal of Production Research, 50, 6162–6187. https://doi.org/10.1080/00207543.2012.710764

Ponomarov, S. Y., & Holcomb, M. C. (2009). Understanding the concept of supply chain resilience. International Journal of Logistics Management, 20(1), 124–143. https://doi.org/10.1108/09574090910954873

Kamalahmadi, M., & Parast, M. M. (2017). An assessment of supply chain disruption mitigation strategies. International Journal of Production Economics, 184, 210–230. https://doi.org/10.1016/j.ijpe.2016.12.011

Behzadi, G., O’Sullivan, M. J., & Olsen, T. L. (2020). On metrics for supply chain resilience. European Journal of Operational Research, 287(1), 145–158. https://doi.org/10.1016/j.ejor.2020.04.040

Kamalahmadi, M., & Parast, M. M. (2016). A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. International Journal of Production Economics, 171, 116–133. https://doi.org/10.1016/j.ijpe.2015.10.023

Dolgui, A., Ivanov, D., & Sokolov, B. (2020). Reconfigurable supply chain: The X-network. International Journal of Production Research, 58(13), 4138–4163. https://doi.org/10.1080/00207543.2020.1774679

Hohenstein, N. O., Feisel, E., Hartmann, E., & Giunipero, L. (2015). Research on the phenomenon of supply chain resilience: A systematic review and paths for further investigation. International Journal of Physical Distribution & Logistics Management, 45(1/2), 90–117. https://doi.org/10.1108/ijpdlm-05-2013-0128

Hosseini, S., & Barker, K. (2016). A Bayesian network model for resilience-based supplier selection. International Journal of Production Economics, 180, 68–87. https://doi.org/10.1016/j.ijpe.2016.07.007

Yildiz, H., Yoon, J., Talluri, S., & Ho, W. (2016). Reliable supply chain network design. Decision Sciences, 47(4), 661–698. https://doi.org/10.1111/deci.12160

Chopra, S., & Sodhi, M. S. (2004). Supply-chain breakdown. MIT Sloan Management Review, 46(1), 53–61.

Turnquist, M., & Vugrin, E. (2013). Design for resilience in infrastructure distribution networks. Environment Systems & Decisions, 33(1), 104–120. https://doi.org/10.1007/s10669-012-9428-z

Khalili, S. M., Jolai, F., & Torabi, S. A. (2017). Integrated production–distribution planning in two-echelon systems: A resilience view. International Journal of Production Research, 55(4), 1040–1064. https://doi.org/10.1080/00207543.2016.1213446

Jabbarzadeh, A., Fahimnia, B., & Sabouhi, F. (2018). Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. International Journal of Production Research, 56(17), 5945–5968. https://doi.org/10.1080/00207543.2018.1461950

Tomlin, B. (2006). On the value of mitigation and contingency strategies for managing supply chain disruption risks. Management science, 52(5), 639–657. https://doi.org/10.1287/mnsc.1060.0515

Wang, X., Herty, M., & Zhao, L. (2016). Contingent rerouting for enhancing supply chain resilience from supplier behavior perspective. International Transactions in Operational Research, 23(4), 775–796. https://doi.org/10.1111/itor.12151

Khaled, A. A., Jin, M., Clarke, D. B., & Hoque, M. A. (2015). Train design and routing optimization for evaluating criticality of freight railroad infrastructures. Transportation Research Part B: Methodological, 71, 71–84. https://doi.org/10.1016/j.trb.2014.10.002

Mancheri, N. A., Sprecher, B., Deetman, S., Young, S. B., Bleischwitz, R., Dong, L., & Tukker, A. (2018). Resilience in the tantalum supply chain. Resources, Conservation and Recycling, 129, 56–69. https://doi.org/10.1016/j.resconrec.2017.10.018

Rezapour, S., Farahani, R. Z., & Pourakbar, M. (2017). Resilient supply chain network design under competition: A case study. European Journal of Operational Research, 259(3), 1017–1035. https://doi.org/10.1016/j.ejor.2016.11.041

Namdar, J., Li, X., Sawhney, R., & Pradhan, N. (2018). Supply chain resilience for single and multiple sourcing in the presence of disruption risks. International Journal of Production Research, 56(6), 2339–2360. https://doi.org/10.1080/00207543.2017.1370149

Sabouhi, F., Pishvaee, M. S., & Jabalameli, M. S. (2018). Resilient supply chain design under operational and disruption risks considering quantity discount: A case study of pharmaceutical supply chain. Computers & Industrial Engineering, 126, 657–672. https://doi.org/10.1016/j.cie.2018.10.001

Bode, C., & Wagner, S. M. (2015). Structural drivers of upstream supply chain complexity and the frequency of supply chain disruptions. Journal of Operations Management, 36, 215–228. https://doi.org/10.1016/j.jom.2014.12.004

Tan, W. J., Cai, W., & Zhang, A. N. (2020). Structural-aware simulation analysis of supply chain resilience. International Journal of Production Research, 58(17), 5175–5195. https://doi.org/10.1080/00207543.2019.1705421

Liu, R., Tao, Y., Hu, Q., & Xie, X. (2017). Simulation-based optimisation approach for the stochastic two-echelon logistics problem. International Journal of Production Research, 55(1), 187–201. https://doi.org/10.1080/00207543.2016.1201221

Hosseini, S., & Ivanov, D. (2020). Bayesian networks for supply chain risk, resilience and ripple effect analysis: A literature review. Expert Systems With Applications, 161, 113649. https://doi.org/10.1108/ijpdlm-05-2013-0128

Dubey, R., Gunasekaran, A., Childe, S. J., Wamba, S. F., Roubaud, D., & Foropon, C. (2019). Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. International Journal of Production Research, 59(1), 110–128. https://doi.org/10.1080/00207543.2019.1582820

Rusdiansyah, A., & Tsao, D. (2005). An integrated model of the periodic delivery problems for vending-machine supply chains. Journal of Food Engineering, 70(3), 421–434. https://doi.org/10.1016/j.jfoodeng.2004.05.073

Poon, T. C., Choy, K. L., Cheng, C. K., & Lao, S. I. (2010). A real-time replenishment system for vending machine industry. In 2010 8th IEEE International conference on industrial informatics (pp. 209–213). https://doi.org/10.1109/INDIN.2010.5549432

Park, Y.-B., & Yoo, J.-S. (2012). A heuristic for the inventory management of smart vending machine systems. Journal of Industrial Engineering and Management, 5(2), 354–363. https://doi.org/10.3926/jiem.587

Grzybowska, H., Kerferd, B., Gretton, C., & Waller, S. T. (2020). A simulation-optimisation genetic algorithm approach to product allocation in vending machine systems. Expert Systems with Applications, 145, 113110. https://doi.org/10.1016/j.eswa.2019.113110

Anupindi, R., Dada, M., & Gupta, S. (1998). Estimation of consumer demand with stock-out based substitution: An application to vending machine products. Marketing Science, 17(4), 406–423. https://doi.org/10.1287/mksc.17.4.406

Pan, J. N., & Nguyen, H. T. N. (2015). Achieving customer satisfaction through product–service systems. European Journal of Operational Research, 247(1), 179–190. https://doi.org/10.1016/j.ejor.2015.05.018

Simon, F., & Usunier, J. C. (2007). Cognitive, demographic, and situational determinants of service customer preference for personnel-in-contact over self-service technology. International Journal of Research in Marketing, 24(2), 163–173. https://doi.org/10.1016/j.ijresmar.2006.11.004

Grigoroudis, E., & Siskos, Y. (2002). Preference disaggregation for measuring and analysing customer satisfaction: The MUSA method. European Journal of Operational Research, 143(1), 148–170. https://doi.org/10.1016/s0377-2217(01)00332-0

Kumar, A., Shankar, R., & Debnath, R. M. (2015). Analysing customer preference and measuring relative efficiency in telecom sector: A hybrid fuzzy AHP/DEA study. Telematics and Informatics, 32(3), 447–462. https://doi.org/10.1016/j.tele.2014.10.003

Cao, L., Ou, Y., & Yu, P. S. (2012). Coupled behavior analysis with applications. IEEE Transactions on Knowledge and Data Engineering, 24(8), 1378–1392. https://doi.org/10.1109/tkde.2011.129

Meo, P. D., Nocera, A., Terracina, G., & Ursino, D. (2011). Recommendation of similar users, resources and social networks in a social internetworking scenario. Information Sciences, 181(7), 1285–1305. https://doi.org/10.1016/j.ins.2010.12.001

Cao, L. (2010). In-depth behavior understanding and use: The behavior informatics approach. Information Sciences, 180(17), 3067–3085. https://doi.org/10.1016/j.ins.2010.03.025

Shokouhyar, S., Shokoohyar, S., & Safari, S. (2020). Research on the influence of after-sales service quality factors on customer satisfaction. Journal of Retailing and Consumer Services, 56, 102139. https://doi.org/10.1016/j.jretconser.2020.102139

Ahani, A., et al. (2019). Revealing customers’ satisfaction and preferences through online review analysis: The case of Canary Islands hotels. Journal of Retailing and Consumer Services, 51, 331–343. https://doi.org/10.1016/j.jretconser.2019.06.014

Qiu, J., Lin, Z., & Li, Y. (2015). Predicting customer purchase behavior in the E-commerce context. Electronic Commerce Research, 15(4), 427–452. https://doi.org/10.1007/s10660-015-9191-6

Zhou, L. (2020). Product advertising recommendation in E-commerce based on deep learning and distributed expression. Electronic Commerce Research, 20, 321–342. https://doi.org/10.1007/s10660-020-09411-6

Forsati, R., & Meybodi, M. R. (2010). Effective page recommendation algorithms based on distributed learning automata and weighted association rules. Expert Systems With Applications, 37(2), 1316–1330. https://doi.org/10.1016/j.eswa.2009.06.010

Azami, S. Z., Torabi, N., & Tanabian, M. (2004). Modeling the customer behavior in the mobile payment on a non-connected vending machine platform. In 2004 Canadian conference on electrical and computer engineering (Vol. 2, pp. 815–818). https://doi.org/10.1109/CCECE.2004.1345239

Kobsa, A. (2001). Generic user modeling systems. User Modeling and Use-adapted Interaction, 11(1–2), 49–63. https://doi.org/10.1023/A:1011187500863

Kwan, I., Fong, J., & Wong, H. (2005). An E-customer behavior model with online analytical mining for internet marketing planning. Decision Support System, 41(1), 189–204. https://doi.org/10.1016/j.dss.2004.11.012

Cao, P., Fan, M., & Liu, K. (2015). Optimal dynamic pricing problem considering patient and impatient customers’ purchasing behavior. International Journal of Production Research, 53(22), 6719–6735. https://doi.org/10.1080/00207543.2015.1056320

Cao, J., Jiang, Z., & Wang, K. (2016). Customer demand prediction of service-oriented manufacturing incorporating customer satisfaction. International Journal of Production Research, 54(5), 1303–1321. https://doi.org/10.1080/00207543.2015.1067377

Wu, X., Zhang, L., & Tian, S. (2019). Scenario-based E-commerce recommendation algorithm based on customer interest in Internet of Things environment. Electronic Commerce Research, 21, 689–705. https://doi.org/10.1007/s10660-019-09339-6

Cui, W., Huang, Y., & Liu, M. (2015). Influential factors of vending machine interface to enhance the interaction performance. In: 2015 8th International conference on intelligent computation technology and automation (ICICTA) (pp. 486–489). https://doi.org/10.1109/ICICTA.2015.285

Wang, M., & Yao, J. (2021). A reliable location design of unmanned vending machines based on customer satisfaction. Electronic Commerce Research. https://doi.org/10.1007/s10660-021-09479-8

Bezdek, J. C. (1981). Pattern recognition with fuzzy objective function algorithms. Kluwer Academic Publishers.

Leski, J. M. (2016). Fuzzy C-ordered-means clustering. Fuzzy Sets and Systems, 286, 114–133. https://doi.org/10.1016/j.fss.2014.12.007

Qamar, U. (2014). A dissimilarity measure based fuzzy C-means (FCM) clustering algorithm. Journal of Intelligent and Fuzzy Systems, 26(1), 229–238. https://doi.org/10.3233/ifs-120730

Groll, L., & Jakel, J. (2005). A new convergence proof of fuzzy C-means. IEEE Transactions on Fuzzy Systems, 13(5), 717–720. https://doi.org/10.1109/tfuzz.2005.856560

Karayiannis, N. B. (2000). Generalized fuzzy C-means algorithms. Journal of Intelligent and Fuzzy Systems, 8(1), 63–81. https://doi.org/10.1109/fuzzy.1996.552321

Havens, T. C., Bezdek, J. C., Leckie, C., Hall, L. O., & Palaniswam, M. (2012). Fuzzy C-means algorithms for very large data. IEEE Transactions on Fuzzy Systems, 20(6), 1130–1146. https://doi.org/10.1109/tfuzz.2012.2201485

Chen, L., Chen, C. L. P., & Lu, M. (2011). A multiple-kernel fuzzy C-means algorithm for image segmentation. IEEE Transactions on Systems, Man, and Cybernetics, 41(5), 1263–1274. https://doi.org/10.1109/tsmcb.2011.2124455

Zhu, L., Chung, F. L., & Wang, S. (2009). Generalized fuzzy C-means clustering algorithm with improved fuzzy partitions. IEEE Transactions on Systems, Man, and Cybernetics, 39, 578–591. https://doi.org/10.1109/tsmcb.2008.2004818

Askari, S. (2021). Fuzzy C-means clustering algorithm for data with unequal cluster sizes and contaminated with noise and outliers: Review and development. Expert Systems with Applications, 165, 113856. https://doi.org/10.1016/j.eswa.2020.113856

Liu, Y., & Whitt, W. (2011). A network of time-varying many-server fluid queues with customer abandonment. Operations Research, 59(4), 835–846. https://doi.org/10.1287/opre.1110.0942

Naso, D., Surico, M., Turchiano, B., & Kaymak, U. (2007). Genetic algorithms for supply-chain scheduling: A case study in the distribution of ready-mixed concrete. European Journal of Operational Research, 177(3), 2069–2099. https://doi.org/10.1016/j.ejor.2005.12.019

Brown, E. C., & Sumichrast, R. T. (2005). Evaluating performance advantages of grouping genetic algorithms. Engineering Applications of Artificial Intelligence, 18(1), 1–12. https://doi.org/10.1016/j.engappai.2004.08.024

Kumar, N., & Shanker, K. (2000). A genetic algorithm for FMS part type selection and machine loading. International Journal of Production Research, 38(16), 3861–3887. https://doi.org/10.1080/00207540050176058

Syarif, A., Yun, Y., & Gen, M. (2002). Study on multi-stage logistic chain network: A spanning tree-based genetic algorithm approach. Computers & Industrial Engineering, 43(1), 299–314. https://doi.org/10.1016/s0360-8352(02)00076-1

Cha, B. C., Moon, I. K., & Park, J. H. (2008). The joint replenishment and delivery scheduling of the one-warehouse, n-retailer system. Transportation Research Part E: Logistics and Transportation Review, 44(5), 720–730. https://doi.org/10.1016/j.tre.2007.05.010

Acknowledgements

The author would like to thank the anonymous reviewers and editors, whose valuable comments and corrections substantially improved this paper.

Funding

This work was supported by the National Natural Science Foundation of China [Grant Number 71872174].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, M., Yao, J. Replenishment and delivery optimization for unmanned vending machines service system based on fuzzy clustering. Electron Commer Res 23, 2419–2461 (2023). https://doi.org/10.1007/s10660-022-09544-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10660-022-09544-w