Abstract

A non-local variational model for the evolution of plastic deformation and fracture in tensile bars is proposed. The model is based on an energy functional, sum of an elastic bulk energy, a non-convex dissipative inelastic energy, and a quadratic non-local gradient term, as in (Del Piero et al. in J. Mech. Mater. Struct. 8(2–4):109–151, 2013). The non-local energy is enriched, by assuming a dependence on both the inelastic deformation and its gradient, in order to improve the description of fracture, and bars with varying cross-section are considered, to accurately reproduce the geometry of samples which are commonly used in tensile tests. The evolution of the deformation is described by a two-field incremental minimization problem, where the longitudinal displacement and the plastic part of the deformation are assumed as independent variables. The problem is discretized by finite elements, and the resulting sequence of constrained quadratic programming problems is solved numerically.

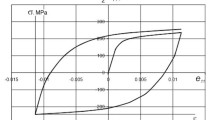

Different simulations are proposed, reproducing the results of experiments on smooth and notched bone-shaped steel samples. The numerical tests provide accurate response curves, and they capture the distinct phases of the evolution observed in experiments: from the initial yielding phase, in which inelastic deformations form, and propagate as slow plastic waves, to the final rupture, which constitutes the ending stage of a strain-localization process.

Similar content being viewed by others

Notes

From here on, a subscript is used to indicate dependence on time.

First-order energy minimization was used in [1] to determine the steepest descent configuration rates.

Proof. If \(\dot{\gamma}=0\) in some interval of (0,l), from (30)2, \(\dot{\sigma}\leq0\). But, integrating (30)3 over (0,l), we get \(l\dot{\sigma}\bar {\dot{\gamma}}=\int_{0}^{l} (\theta''\dot{\gamma}^{2}+\alpha\dot {\gamma }'^{2} )\,dx>0\), and thus \(\dot{\sigma}>0\), in contradiction with the above result. Thus \(\dot{\gamma}\) cannot be null in some subinterval of the bar. □

Necessary and sufficient conditions for the eigenvalue non-negativeness are proposed in Sect. 3.4 of [1].

It is the area of the triangle defined by θ″ in the interval 0<γ<γ 1 (see Fig. 6).

In not-reported simulations, it appears in the middle, and in the left extremity.

In particular, it is very similar to the Aifantis model [8], where the Laplacian of the cumulated plastic strain is introduced in the yield condition.

References

Del Piero, G., Lancioni, G., March, R.: A diffuse cohesive energy approach to fracture and plasticity: the one-dimensional case. J. Mech. Mater. Struct. 8(2–4), 109–151 (2013)

Del Piero, G., Truskinovsky, L.: Elastic bars with cohesive energy. Contin. Mech. Thermodyn. 21, 141–171 (2009)

Del Piero, G.: A variational approach to fracture and other inelastic phenomena. J. Elast. 112, 3–73 (2013)

Yalcinkaya, T., Brekelmans, W.A.M., Geers, M.G.D.: Deformation patterning driven by rate dependent non-convex strain gradient plasticity. J. Mech. Phys. Solids 59, 1–17 (2011)

Yalcinkaya, T., Brekelmans, W.A.M., Geers, M.G.D.: Non-convex rate dependent strain gradient crystal plasticity and deformation patterning. Int. J. Solids Struct. 49, 2625–2636 (2012)

Yalcinkaya, T.: Multi-scale modeling of microstructure evolution induced anysotropy in metals. Key Eng. Mater. 554–557, 2388–2399 (2013)

Bažant, Z.P., Jirásek, M.: Nonlocal integral formulations of plasticity and damage: survey of progress. J. Eng. Mech. 128, 1119–1149 (2002)

Aifantis, E.C.: On the microstructural origin of certain inelastic models. J. Eng. Mater. Technol. 106, 326–330 (1984)

Jirásek, M., Rolshoven, S.: Localization properties of strain-softening gradient plasticity models. Part I. Strain-gradient theories. Int. J. Solids Struct. 46, 2225–2238 (2009)

Jirásek, M., Rolshoven, S.: Localization properties of strain-softening gradient plasticity models. Part II. Theories with gradients of internal variables. Int. J. Solids Struct. 46, 2239–2254 (2009)

de Borst, R., Pamin, J., Peerlings, R.H.J., Sluys, L.J.: On gradient-enhanced damage and plasticity models for failure in quasi-brittle and frictional materials. Comput. Mech. 17, 130–141 (1995)

Bourdin, B., Francfort, G., Marigo, J.J.: The variational approach to fracture. J. Elast. 91(1–3), 1–148 (2008)

Freddi, F., Royer Carfagni, G.: Regularized variational theories of fracture: a unified approach. J. Mech. Phys. Solids 58, 1154–1174 (2010)

Pham, K., Amor, H., Marigo, J.J., Maurini, C.: Gradient damage models and their use to approximate brittle fracture. Int. J. Damage Mech. 20, 618–652 (2011)

Bourdin, B., Francfort, G., Marigo, J.J.: Numerical experiments in revisited brittle fracture. J. Mech. Phys. Solids 48, 797–826 (2000)

Del Piero, G., Lancioni, G., March, R.: A variational model for fracture mechanics: numerical experiments. J. Mech. Phys. Solids 55, 2513–2537 (2007)

Amor, H., Marigo, J.J., Maurini, C.: Regularized formulation of the variational brittle fracture with unilateral contact: numerical experiments. J. Mech. Phys. Solids 57, 1209–1229 (2009)

Lancioni, G., Royer-Carfagni, G.: The variational approach to fracture mechanics: a practical application to the French Panthéon in Paris. J. Elast. 95, 1–30 (2009)

Nucedal, J., Wright, S.: Numerical Optimization, 2nd edn. Springer, Berlin (2006)

Rice, J.R.: The initiation and growth of shear bands. In: Palmer, A.C. (ed.) Plasticity and Soil Mechanics, pp. 263–274. Cambridge University Press, Cambridge (1973)

Sun, H.B., Yoshida, F., Ma, X., Kamei, T., Ohmori, M.: Finite element simulation on the propagation of Lüders band and effect of stress concentration. Mater. Lett. 57, 3206–3210 (2003)

Froli, M., Royer-Carfagni, G.: Discontinous deformation of tensile steel bars: experimental results. J. Eng. Mech. 125, 1243–1250 (1999)

Froli, M., Royer-Carfagni, G.: A mechanical model for the elastic±plastic behavior of metallic bars. Int. J. Solids Struct. 37, 3901–3918 (2000)

Devillers-Guerville, L., Besson, J., Pineau, A.: Notch fracture toughness of a cast duplex stainless steel: modelling of experimental scatter and size effect. Nucl. Eng. Des. 168, 211–225 (1997)

Decamp, K., Bauvineau, L., Besson, J., Pineau, A.: Size and geometry effects on ductile rupture of notched bars in a CMn steel: experiments and modelling. Int. J. Fract. 88, 1–18 (1997)

Lancioni, G., Yalcinkaya, T.: Plastic slip patterns through rate-independent and rate-dependent plasticity. Key Eng. Mater. 611–612, 1777–1786 (2014)

Alessi, R., Marigo, J.-J., Vidoli, S.: Gradient damage models coupled with plasticity and nucleation of cohesive cracks. Arch. Rational Mech. Anal. 214, 575–615 (2014)

Alessi, R., Marigo, J.-J., Vidoli, S.: Gradient damage models coupled with plasticity: variational formulation and main properties. Mech. Mater. 80, 351–367 (2015)

Gill, P.E., Murray, W., Wright, M.H.: Practical Optimization. Academic Press, San Diego (1981)

Polak, E.: Computational Methods in Optimization. Academic Press, San Diego (1971)

Nadai, A.: Theory of Flow and Fracture of Solids. McGraw-Hill, New York (1950)

Miklowitz, J.: The influence of the dimensional factors on the mode of yielding and fracture in medium-carbon steel. II. The size of the round tensile bar. Proc. J. Appl. Mech 17, 159–168 (1950)

Yuan, H., Chen, J., Krompholz, K., Wittmann, F.H.: Investigations of size effects in tensile tests based on a nonlocal micro-mechanical damage model. Comput. Mater. Sci. 26, 230–243 (2003)

Yuan, H., Chen, J.: Comparison of computational predictions of material failure using nonlocal damage models. Int. J. Solids Struct. 41, 1021–1037 (2004)

Gurson, A.L.: Continuum theory of ductile rupture by void nucleation and growth. Part I. Yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99, 2–15 (1977)

Tvergaard, V., Needleman, A.: Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 32, 157–169 (1984)

Chen, J., Yuan, H.: A micro-mechanical damage model based on gradient plasticity: algorithms and applications. Int. J. Numer. Methods Eng. 54, 399–420 (2002)

Acknowledgements

The author gratefully acknowledges the valuable comments and suggestions of Prof. Gianpietro Del Piero.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was partially supported by the Italian Ministry of Education, Universities and Research (MIUR) by the PRIN funded Program “Dynamics, stability and control of flexible structures”, 2010/11N. 2010MBJK5B.

Appendices

Appendix A: Finite Elements Discretization

In the finite element discretization, two-points linear elements are considered for γ, and three-points quadratic elements for u. This allows to approximate both u′ and γ with linear functions, within each element. In the arbitrary e-th element (x e ,x e+1), the approximated solution is

where \(\mathbf{u}^{e}_{t}=[u_{t}(x_{e}),u_{t}((x_{e}+x_{e+1})/2),u_{t}(x_{e+1})]^{T}\), and \(\boldsymbol {\gamma}^{e}_{t}=[\gamma_{t}(x_{e}),\gamma_{t}(x_{e+1})]^{T}\) are the nodal vectors of displacement and inelastic deformation, respectively, and \(\boldsymbol {\varphi}^{e}(x)=[\varphi^{e}_{1}(x),\varphi^{e}_{2}(x),\varphi ^{e}_{3}(x)]^{T}\) and \(\boldsymbol {\psi}^{e}(x)=[\psi^{e}_{1}(x),\psi^{e}_{2}(x)]^{T}\) are the vectors of the quadratic and linear shape functions, respectively. Substituting (56) in the functional (21), restricted to the e-th element, we obtain the discrete quadratic form

where \(u_{t}=\boldsymbol {\varphi}^{e}\cdot{\mathbf{u}}_{t}^{e}\) and \(\gamma =\boldsymbol {\psi}^{e}\cdot{ \boldsymbol {\gamma}}_{t}^{e}\), and

Integrals are evaluated by means of two-point Gaussian quadrature. The dimension of the discretized problem is 3n e +2, with n e the number of elements.

Appendix B: Coefficients c h and c s of Formula (46)

Case θ″>0.

Case θ″=0.

Case θ″<0.

Rights and permissions

About this article

Cite this article

Lancioni, G. Modeling the Response of Tensile Steel Bars by Means of Incremental Energy Minimization. J Elast 121, 25–54 (2015). https://doi.org/10.1007/s10659-015-9515-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10659-015-9515-8