Abstract

The present study provides a simplified closed-form solution for the deposition flux of atmospheric Particulate Matter on electrical insulators. Due to the lack of experimental data on deposition over this type of solid bodies, the mathematical model is closed by means of a 4D regression procedure on obstacle-scale numerical data. This dataset is obtained with the Lagrangian Stochastic Model SPRAY-WEB (Università del Piemonte Orientale et al., 2021). The code was already validated on Particulate Matter dispersion and deposition on solid obstacles (Amicarelli et al. in Environ Fluid Mech 21(2): 433–463, 2021) and is here applied to a XP-70 porcelain-disk electrical insulator. A published tutorial is associated with this numerical dataset (SPRAY-WEB, 2021). The verification metrics on the performance of the closed-form solution show that the errors lie below the guideline thresholds for air-quality numerical simulations (Chang and Hanna in Meteorol Atmos Phys 87:167–196, 2004) and are limited by a Maximum Gross Error of ca.24% for an external verification. Although they cannot be used to close any mathematical model or to represent any specific event, the long-term averaged deposition fluxes of Zhang et al. (IEEE Trans Dielectr Electr Insulat 21(4):1901–1909, 2014. 10.1109/TDEI.2014.004343) are associated with the same insulator used for this study. With respect to the full-scale experiment mentioned above, the present solution provides an overestimation of 13%. The closed-form solution can be used for instantaneous preliminary estimates or be integrated within air-quality numerical codes for fast assessments of contamination maps for electrical insulators. Such applications aim to quantify the insulator functional damage (i.e., flashovers, short-circuits). The closed-form solution can be also generalized any time new data are available.

Similar content being viewed by others

References

Zhang Z, Zhang D, Jiang X, Liu X (2014) Study on natural contamination performance of typical types of insulators. IEEE Trans Dielectr Electr Insul 21(4):1901–1909

Amicarelli A, Alessandrini S, Agate G, Ferrero E, Pirovano G, Tinarelli GL, Trini Castelli S (2021) A dry deposition scheme for particulate matter coupled with a well-known Lagrangian Stochastic Model for pollutant dispersion. Environ Fluid Mech 21(2):433–463

Dawson M, Borman D, Hammond B, Lesnic D, Rhodes D (2014) Moving boundary models for the growth of crystalline deposits from undetected leakages of industrial process liquors. Comput Chem Eng 71:331–346

D’Agostino D, Congedo P, Cataldo R (2014) Computational fluid dynamics (CFD) modeling of microclimate for salts crystallization control and artworks conservation. J Cult Herit 15(4):448–457

Ansys Fluent. [Online]. Available: https://www.ansys.com/products/fluids/ansys-fluent. [Accessed 15 November 2019]

DePaSITIA v.1.0 (RSE SpA), 2019. [Online]. Available: https://github.com/AndreaAmicarelliRSE/DePaSITIA

SPRAY-WEB (Università del Piemonte Orientale et al. [Online]. Available: http://sprayweb.isac.cnr.it/. [Accessed 2021]

Ould-Dada Z (2002) Dry deposition profile of small particles within a model spruce canopy. Sci Total Environ 286:83–96

Andronopoulos S, Grigoriadis D, Robins A, Venetsanos A, Rafailidis S, Bartzis J (2001) Three-dimensional modelling of concentration fluctuations in complicated geometry. Environ Fluid Mech 1(4):415–440

Mavroidis I, Andronopoulos S, Venetsanos A, Bartzis J (2015) Numerical investigation of concentrations and concentration fluctuations around isolated obstacles of different shapes. Comparison with wind tunnel results. Environ Fluid Mech 15(5):999–1034

CFX (Ansys). [Online]. Available: http://www.ansys.com/products/fluids/ansys-cfx. [Accessed 2020]

Tebbal A, Saidi F, Noureddine B, Imine B, Hamoudi B (2016) Numerical study of the roughness influence on NACA 63–430 profile aerodynamic performance. Int Rev Mech Eng 10(4):231–238

Krepper E, Ruyer P, Beyer M, Lucas D (2009) CFD simulation of polydispersed bubbly two-phase flow around an obstacle. Sci Technol Nuclear Install. https://doi.org/10.1155/2009/320738

Loganathan R, Hunt G (2019) Analytical solutions for flow induced by a vertically distributed turbulent plume. Environ Fluid Mech 19:801–818

Violeau D (2017) A comprehensive presentation of the turbulent plane jet theory with passive scalar. Math Probl Eng, pp 1–11, Article ID 4369895

Gnuplot (Williams & Kelley), “http://www.gnuplot.info/,” 2021. [Online]

Morrison F (2013) An introduction to fluid mechanics. Cambridge University Press, New York

Davies C (1945) Definitive equations for the fluid resistance of spheres. In: Proceedings of the Physical Society, vol 57, p 259

Leuzzi G, Amicarelli A, Monti P, Thomson D (2012) The 3D Lagrangian micromixing dispersion model LAGFLUM and its validation with a wind tunnel experiment. Atmos Environ 54:117–126

Chang J, Hanna S (2004) Air quality model performance evaluation. Meteorol Atmos Phys 87:167–196

Efthimiou G, Andronopoulos S, Tolias I, Venetsanos A (2016) Prediction of the upper tail of concentration distributions of a continuous point source release in urban environments. Environ Fluid Mech 16(5):899–921

Hertwig D, Soulhac L, Fuka V, Auerswald T, Carpentieri M, Hayden P, Robins A, Xie Z-T, Coceal O (2018) Evaluation of fast atmospheric dispersion models in a regular street network. Environ Fluid Mech 18:1007–1044

Di Bernardino A, Monti P, Leuzzi G, Querzoli G (2018) Pollutant fluxes in two-dimensional street canyons. Urban Clim 24:80–93

Li S, Flynn M (2021) Cooling tower plume abatement and plume modeling: a review. Environ Fluid Mech 21:521–559

Viccione G, Evangelista S, Armenante A, Ricciardi V (2020) Clogging process and related pressure drops in wire-wound filters: laboratory evidence. Environ Sci Pollut Res 27(19):23464–23476

Tinarelli G, Anfossi D, Brusasca G, Ferrero E, Giostra U, Morselli M, Moussafir J, Tampieri F, Trombetti F (1994) Lagrangian particle simulation of tracer dispersion in the lee of a schematic twodimensional hill. J Appl Meteorol 33:744–756

Alessandrini S, Ferrero E (2011) A Lagrangian particle model with chemical reactions: application in real atmosphere. Int J Environ Pollut 47:97–107

Bisignano A, Mortarini L, Ferrero E, Alessandrini S (2017) Model chain for buoyant plume dispersion. Int J Environ Pollut 62(2):200–213

Thomson D (1987) Criteria for the selection of the stochastic models of particle trajectories in turbulent flows. J Fluid Mech 180:529–556

Minier J-P, Chibbaro S, Pope S (2014) Guidelines for the formulation of Lagrangian stochastic models for particle simulations of single-phase and dispersed two-phase turbulent flows. Phys Fluids 26(11):113303. https://doi.org/10.1063/1.4901315

Marro M, Salizzoni P, Cierco F, Korsakiss I (2014) Plume rise and spread in buoyant releases from elevated sources in the lower atmosphere. Environ Fluid Mech 14(1):201–219

Bahlali M, Dupont E, Carissimo B (2019) Atmospheric dispersion using a Lagrangian stochastic approach: application to an idealized urban area under neutral and stable meteorological conditions. J Wind Eng Ind Aerodyn. https://doi.org/10.1016/j.jweia.2019.103976

Litschke T, Kuttler W (2008) On the reduction of urban particle concentration by vegetation—a review. Meteorol Z 17:229–240

Contini D, Robins A, Hayden P (2014) Statistical properties of concentration fluctuations in two merging plumes. Environ Fluid Mech 14(4):919–942

Lo Iacono G (2009) Application of Rice’s theory to recurrence statistics of concentration fluctuations in dispersing plumes. Environ Fluid Mech 9(3):341–357

Cassiani M, Franzese P, Albertson JD (2009) A coupled Eulerian and Lagrangian mixing model for intermittent concentration time series. Phys Fluids 21(8):085105

Brancher M, Hieden A, Baumann-Stanzer K, Schauberger G, Piringer M (2020) Performance evaluation of approaches to predict sub-hourly peak odour concentrations. Atmos Environ X. 7:100076

Sip V, Benes L (2017) Dry deposition model for a microscale aerosol dispersion solver based on the moment method. J Aerosol Sci 107:107–122

Monin A, Obukhov A (1954) Basic laws of turbulent mixing in the surface layer of the atmosphere. Tr Akad Nauk SSSR Geophiz Inst 24(151):163–187

Pelliccioni A, Monti P, Gariazzo C, Leuzzi G (2012) Some characteristics of the urban boundary layer above Rome, Italy, and applicability of Monin–Obukhov similarity. Environ Fluid Mech 12(5):405–428

Cassiani M, Radicchi A, Albertson J (2007) Modelling of concentration fluctuations in canopy turbulence. Bound-Layer Meteorol 122:655–681

Amicarelli A, Leuzzi G, Monti P (2012) Lagrangian micromixing models for concentration fluctuations: an overview. Am J Environ Sci 8:577–590

Acknowledgements

We acknowledge the CINECA award under the ISCRA initiative, for the availability of High Performance Computing resources and support”. In fact, most of the SPRAY-WEB simulations of this document are executed on ISCRA machines (HPC projects: HSPHER21, HSPHER22)

Funding

The contributions of the RSE authors have been financed by the Research Fund for the Italian Electrical System (for ‘‘Ricerca di Sistema -RdS-’’), in compliance with the Decree of Minister of Economic Development April 16, 2018. The software library DePaSITIA (RSE SpA) has been financed by the Research Fund for the Italian Electrical System (for ‘‘Ricerca di Sistema -RdS-’’) under the Contract Agreements between RSE SpA and the Italian Ministry of Economic Development, in compliance with the Decree of Minister of Economic Development April 16, 2018 (and analogous following agreements). The RSE contributions to SPRAY-WEB (Università del Piemonte Orientale et al.) were realised thanks to the funding “Fondo di Ricerca per il Sistema Elettrico” within the frame of Program Agreements between RSE SpA and the Italian Ministry of Economic Development (Ministero dello Sviluppo Economico).

Author information

Authors and Affiliations

Contributions

Andrea Amicarelli (all the paper sections but section “Numerical simulations for the airflow and geometry reconstruction” and the introduction to section “The code SPRAY-WEB”); Giordano Agate (section “Numerical simulations for the airflow and geometry reconstruction”); Enrico Ferrero (software supervision of SPRAY-WEB as Software Manager of the code); Antonella Frigerio (paper supervision). The mention to the code SPRAY-WEB in the introduction to section “The code SPRAY-WEB” is extracted and adapted from the code guide.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Using the Lagrangian stochastic model SPRAY-WEB to simulate PM deposition

The Lagrangian Stochastic Model SPRAY-WEB ([7]; section “The code SPRAY-WEB”), including the PM deposition library DePaSITIA ([6]; section “Using the Lagrangian stochastic model spray-web to simulate PM deposition”), have been used to simulate the PM dispersion and deposition on an electrical insulator (section “A numerical dataset to close the mathematical model”), after some minor improvements to deal with PM deposition at the obstacle-scale (section “Minor improvements to SPRAY-WEB for PM deposition at the obstacle-scale”).

1.1 The code SPRAY-WEB

SPRAY-WEB v.1.0 [7, 26,27,28] is a Lagrangian Stochastic Model (LSM) for the dispersion of atmospheric pollutants, based on the Langevin equation [29] to assess the concentration Reynolds’ ensemble means. The numerical particles of a generic LSM code represent the motion of a polluted fluid flow during N experimental realizations of the same turbulent phenomenon, under the hypotheses of Reynolds’ decomposition (e.g., [30,31,32]). Any LSM code might be also interpreted as a Lagrangian CFD turbulence scheme based on the Finite Difference Method (FDM) to close the Reynolds’ Average (RA) of the balance equation for the pollutant mass.

SPRAY-WEB [7] assumes the following hypotheses: the probability density function of the components of the Eulerian velocity are independent Gaussian distributions; the one-point covariance matrix of the components of the Eulerian velocity is diagonal; the motion regime is stationary; the gradient of a generic statistic of the Eulerian velocity is aligned with the same component (1D variability of the Eulerian velocity statistics). The main governing equation rules the increments of the Lagrangian velocity U (m/s) [7]:

where a (m/s2) is an acceleration which guarantees the so-called “well-mixed condition” (i.e., the Reynolds’ statistics of the Lagrangian velocities are consistent with the Reynolds’ statistics of the Eulerian velocities at any time and point), dt (s) is the (macromixing) time step, B0 (m/s2) is a scalar acceleration constrained to the definition of the auto-correlation function for \(dt \to 0\) (according to the Kolmogorov theory) and dμ (m0.5/s0.5) is an incremental Wiener process with null mean and variance equal to the unity. Starting from the particle trajectories and pollutant masses, the field of the Reynolds’ mean concentration are computed. Further details are reported in SPRAY-WEB [7], which is available as an Open-Source Software.

1.1.1 The numerical coupling of the code SPRAY-WEB with the library DePaSITIA

The coupling of the Lagrangian Stochastic Model SPRAY-WEB [7] with the library DePaSITIA v.1.0 [6] for PM deposition, reproduces the height-dependent dry-deposition flux for solid and liquid atmospheric PM. This solution is based on recent formulations for each deposition mechanism. Beyond the adhesion process, the following dry deposition mechanisms are represented: sedimentation, inertial impaction, turbulent impaction, interception. Deposition is sensitive to meteorological quantities (local RA speed, friction velocity), land-use or geometric parameters (Leaf/obstacle Area Density; leaf equivalent diameter or travel characteristic length of the obstacle; geometric leaf/obstacle ratios) and PM properties (local mean concentration, median diameter and density). No tuning parameters is mandatory for deposition. The coupled solution SPRAY-WEB—DePaSITIA permits the simultaneous deposition of multiple PM species by means of the sectional method.

SPRAY-WEB (including DePaSITIA) provides several advantages in representing PM dispersion and deposition with respect to the best micro-scale Reynolds-Averaged Eulerian models for pollutant dispersion: higher accuracy in simulating turbulence (e.g., representation of the velocity auto-correlation); potential application to any type of obstacle (e.g., not only needle-leaf canopies); minimum truncation errors on time integration for both the deposited particle mass and the deposition flux; the sectional method to represent PM species is more accurate than the moment method; the adhesion process is represented. At the same time, the following drawbacks can be listed: the sectional method is computationally more expensive than the moment method; the transporting fluid is fixed (i.e., the ABL air, DePaSITIA does not work for water quality); no deposition mechanism is associated with molecular Brownian Diffusion (BD) although it could be neglected in the ABL for d50 > 1 × 10−7 m [33],concentration turbulent fluctuations (e.g., [34,35,36,37])are neglected.

When deposition is the only PM transformation process, the Reynolds-Averaged balance equation for the pollutant mass can be written as follows:

where t (s) is time. Fd,v (kg × s−1 × m−2) is the RA deposition flux per unit of leaf/obstacle area, whereas the RA specific deposition flux Fd (kg × s−1 × m−2) refers to the unit of horizontal area:

where Δz (m) is the cell depth (Eq. 2.5 in [2], is only an approximated formula not used by DePaSITIA). The deposition velocity ud (m/s) is defined as the following ratio (e.g., [38]):

When DePaSITIA is active, SPRAY-WEB also produces the following output quantities for each pollutant: the 2D horizontal field for the local \(M_{d,*}^{{}} = M_{d,3D} \Delta z\)(kg/m2) and depth-cumulated Md,2D (kg/m2) values of the Reynolds-averaged time-cumulated deposition mass per unit of horizontal area, where Md,3D (kg/m3) is the Reynolds-averaged time-cumulated deposition mass per unit of volume. They can be expressed as follows:

where zc (m) is a generic height associated with the presence of obstacles (e.g., a canopy).

The sum of the Md,* values over the nz,c cells of the same grid column equals Md,2D:

DePaSITIA [6] is Free/Libre & Open-Source Software (FOSS) and might be coupled with any micro-scale and meso-scale air quality model. Further details on the coupling of SPRAY-WEB [7] with DePaSITIA [6] are available in [2].

1.2 Minor improvements to SPRAY-WEB for PM deposition at the obstacle-scale

SPRAY-WEB [7], including DePaSITIA [6], was used to represent the PM deposition at the scale of the obstacle matrix [2]. Hereafter the numerical developments to the code to simulate the PM deposition at the obstacle-scale are presented. These improvements have been mandatory for the numerical results used in Sects. 3 and 4.

In Amicarelli et al. [2], the following constraints were assumed:

-

1)

implicitness of the obstacles as in the porous-model approaches;

-

2)

the geometric properties of the obstacles are homogeneous within the same cell;

-

3)

every obstacle has to be contained within a single cell;

-

4)

the obstacles have to be delimited by closed surfaces;

-

5)

the cells containing obstacles have to be permeable.

To satisfy the constraint 1) on the obstacle implicitness, the numerical domain is partitioned in four sub-domains, depending on the fluid and solid volume fractions (εf, εs), and LAD. Figure 4 shows a 2D sketch of the domain partitioning of SPRAYWEB at the obstacle-scale. Those numerical cells of the concentration grid of SPRAY-WEB which contain a portion of the fluid–solid interface of the obstacle belong to the porous sub-domain. Here deposition is simulated by DePaSITIA, with 0 < εf < 1, 0 < εs < 1 and 0 < LAD < 1 × 1015 m−1. The cells without solid elements belong to the fluid sub-domain, where deposition does not act (εf = 1, εs = 0, LAD = 0). The cells without fluid elements belong to the solid sub-domain (εf = 0, εs = 1 and formally LAD ≥ 1 × 1015 m−1), which is in turn split as described in the following. Those solid cells close to the porous sub-domain represent the outer solid sub-domain: the pollutant mass of the numerical LSM particles impacting these cells is instantaneously zeroed, as explained later. The other solid cells belong to the inner solid sub-domain, where deposition does not apply, and the approaching LSM particles already have null pollutant mass. Deposition occurs only in the porous sub-domain and the outer solid sub-domain, so that the depth of the deposition layer is locally equal to ca. 2 cells.

To remove the constraint 3) on the relationship between the obstacle size and the concentration grid cells, the definition of some input variables of DePaSITIA [6] has been generalized: the 3D field of the friction velocity is replaced with a 2D field or a scalar field (section “A numerical dataset to close the mathematical model”), the 3D field of kx refers to the direction of the mean velocity of the undisturbed upstream flow, whereas the 3D local mean speed is still used as the reference mean speed.

To satisfy the constraint 5) on the cell permeability, SPRAY-WEB has been improved as follows. The pollutant mass of the LSM particles reaching the outer solid sub-domain is completely and instantaneously removed. This procedure represents the contribution of the turbulent impaction deposition mechanism intrinsically assessed by means of the Lagrangian instantaneous-like trajectories of the macro-mixing scheme of SPRAY-WEB [7]. This is more accurate than the homologous deposition mechanism of DePaSITIA [6] acting in the porous sub-domain. Further, this pollutant removal allows to roughly represent the deposition mechanisms in the porous sub-domain during the missed departing stage of the numerical LSM particles from the deposition zone. Furthermore, this numerical assumption allows to avoid any explicit scheme for the bouncing of the LSM particles on the 3D complex surfaces of the obstacles. Such a scheme would appreciably increase the computational time and violate the constraint on the implicitness of the obstacles. In the solid sub-domain, the adhesion coefficient is so approximated by the unity (Ra = 1.00). This can be interpreted by the simplifying hypothesis that the PM particles in the solid sub-domain have intruded so deeply the inner influence region of the obstacle that they cannot exit this zone: given time, the pollutant removal would be complete, even if non-instantaneous.

Under the generalizations above, the constraints 2) and 4) are not violated. This solution also takes advantage from assessing the Lagrangian mean concentration, which is a more accurate choice than relying on the Eulerian mean concentration at the micro-scale. The SPRAY-WEB procedures for deposition have been parallelized by means of the OMP (Open Multi Processing) technique.

Appendix 2: A numerical dataset to close the mathematical model

The closure of the mathematical model of Sect. 2 needs the numerical results of this section, obtained by means of the Lagrangian Stochastic Model SPRAY-WEB ([7]; section “Using the Lagrangian stochastic model spray-web to simulate PM deposition”). The reference test case is the sub-horizontal airflow around the XP-70 porcelain disk insulator “Type A” described in Zhang et al. [1]. It is an electrical insulator made of a string of three cap-and-pin disk insulator units, similar to those of Fig. 1 (centre and right panels). A sequence of scenario analyses is here reproduced. The reconstruction of the obstacle geometry and the airflow simulations, which adopts the ABL similarity profiles [39, 40] in pre-processing and post-processing procedures, are presented in section “Numerical simulations for the airflow and geometry reconstruction”. The configurations of the LSM simulations are described in section “Numerical configuration of the LSM simulations”. Some examples of the 3D fields of the PM mean concentration, deposition flux and cumulated deposition mass are shown in section “Simulated PM mean concentration, mean deposition flux, cumulated deposition mass”.

2.1 Numerical simulations for the airflow and geometry reconstruction

ANSYS/CFX v16.0 [11] is a general-purpose commercial CFD code. It is based on the FVM to solve the RANS equations in 3D geometries. The CFD2SprayWEB interface (RSE S.p.A.) has been developed to use the CFX results as input for the code SPRAY-WEB. The interface provides the complete input meteorological file required. The mean velocity \(\underline{{\overline{u} }}\) is directly assessed by CFX, whereas the following quantities are post-processed from the CFX output: the velocity standard deviations are approximately reconstructed by partitioning the turbulent kinetic energy q along the Cartesian directions according to the ratios between the velocity standard deviations in the Monin and Obukhov [39] theory for the surface neutral boundary layer. The same theory is adopted to compute the friction velocity \(u_{*}\) The integral Lagrangian time scale TL (s) is expressed as function of e and the velocity standard deviations. The mean speed \(\left| {\underline{{\overline{u} }} } \right|\) is the absolute value of the mean velocity vector.

The geometry taken into consideration for the application is that relating to the Type-A insulator, reported in Zhang et al. [1]. It consists of three sections with three superimposed porcelain discs with a diameter of 0.255 m and a height of 0.146 m. The computational domain that inscribes the insulator, has the shape of a parallelepiped of dimensions Ldom,CFX × Wdom,CFX × Hdom,CFX = 0.6 m × 1.0 m × 0.8 m. The final grid, optimized by refining the elements near the solid surfaces of the insulator with prismatic elements, is composed of 5,382,837 3D elements and 1,421,999 nodes. Figure 5 shows the considered domain, an insulator detail and the grid in a vertical section across the insulator.

ANSYS/CFX simulations. Left. Vertical longitudinal section along the air flow located in the centre of the insulator: speed field and vector velocity field (test#10 of Table 6). Right. ANSYS/CFX interface for SPRAY-WEB. Speed field on vertical sections transversal and longitudinal to the air flow, located in the centre of the insulator (test#10 of Table 6). The cells on the insulator, inside the insulator and near the bottom are highlighted

The boundary conditions imposed are:

-

inlet speed, temperature (20 °C), turbulence intensity and CFX turbulence scale (LCFX = 0.07Ri where Ri is the hydraulic radius of the computational domain) are consistent with Table 6;

-

at outlet side atmospheric pressure condition;

-

at bottom of the domain no-slip condition;

-

at upper surface and at lateral walls with free slip condition;

-

at surfaces of the insulator walls zero speed is assigned, with a wall roughness corresponding to a material like glass/porcelain or ceramic with roughness characteristic length of 0.01 mm.

Initial conditions are assigned as zero velocity and temperature at 20 °C. The stationary-regime calculations adopt the RNG (ReNormalization Group) k-ε turbulence scheme.

Figure 6 (left panel) shows some fields of the speed and the vector velocity in the longitudinal vertical section along the air flow and placed in the centre of the insulator, obtained with the simulation described. In Fig. 6 (right panel) an example of vertical sections of the speed field computed by means of the CFD2SprayWEB interface (RSE S.p.A.) on the SPRAY-WEB grid is shown; in the same figure the solid, the porous and the bottom cells are highlighted, while the fluid cells are not displayed for readability of the figure.

2.2 Numerical configuration of the LSM simulations

The configurations of the SPRAY-WEB simulations of Sects. 3.1 and 3.3 are described.

The design of the obstacle geometry is reconstructed in section “Numerical simulations for the airflow and geometry reconstruction”, starting from the figures of Zhang et al. [1]. The travel characteristic length of the insulator string is the diameter of its disks: dv = 0.240 m. The deposition area Adep = 0.367 m2 and its projection area Av,x are limited to the three insulator disks (not to the whole insulator), as these components are the key targets whose contamination may trigger a flashover [1]. The area of the projection of a single disk on the inlet section is Av,x/3 = ca.0.25 m × 0.04 m = ca.0.010 m2 [1]. The three insulator disks share the same geometry: this condition is subjected to discrepancies due to both the geometry reconstruction and the following discretization of SPRAY-WEB.

The obstacle-scale meteorological input is provided by the CFX [11] simulations (section “Numerical simulations for the airflow and geometry reconstruction”).

The Kolmogorov constant is set to C0 = 2 [41]. The values of the following constants are assigned in DePaSITIA [6]: the average values of the kinematic viscosity n, the mean free path λ, the molecular mass mm and the temperature Te of the air in the atmospheric boundary layer [2].

The surface pollutant source is uniform and coincide with the inlet section of the LSM simulations.

The numerical domain of SPRAY-WEB [7] has the following dimensions: Ldom × Wdom × Hdom = 0.390 m × 0.790 m × 0.600 m. SPRAY-WEB already worked at similar spatial scales (Ldom × Wdom × Hdom = 6.000 m × 3.200 m × 1.260 m) in Amicarelli et al. [2].

The spatial resolution of the concentration grid along the Cartesian axes is defined by \(\Delta x\) = \(\Delta y\) = \(\Delta z\) = 0.010 m. The bouncing of the LSM particles at the domain bottom allows to assign symmetry conditions. The downstream boundary of the domain is an open section. The lateral and top frontiers are approximately represented by open sections.

The domain is initially empty of LSM particles. The simulations achieve stationary conditions dynamically at t = tsc (s), whose value depends on the simulation. The time lag to compute Reynolds’ mean concentration is dtRA = tsc/2 (s). The constant of the stability criteria is Cst = 0.05 [42]. The sampling time step dts (s) is set equal to the macromixing time step dt (s), the deposition time step dtd (s) and the emission time step dtem (s). The concentration grid is locally coincident with the meteorological grid (even if the first is slightly smaller). This grid is in SPRAY-WEB the computational mesh on which the velocity gradients are computed.

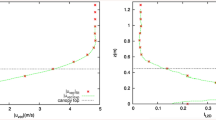

Table 6 reports the numerical configurations of the simulations of Sects. 3.1 and 3.3. The space-dependent quantities here refer to the undisturbed upstream flow. The 23 tests differ in terms of macromixing time step, mean concentration, mean speed and the non-dimensional numbers Re, It,\(\frac{{d_{50} }}{{d_{v} }}\) and \(\frac{{\rho_{PM} }}{{\rho_{air} }}\). In the 4D space of the independent non-dimensional numbers Re, It, \(\frac{{d_{50} }}{{d_{v} }}\) and \(\frac{{\rho_{PM} }}{{\rho_{air} }}\), the LSM simulations of Sect. 3.1 provide four dotted segments crossing at the point represented by the simulation n.10. This procedure has some advantages and drawbacks. This anisotropic sampling provides robust 1D regression curves (Sect. 3.1) and permit any further generalization. Further, a second set of LSM simulations (Sect. 3.3) enriches the sampling data for the final solution of Sect. 4.

2.3 Simulated PM mean concentration, mean deposition flux, cumulated deposition mass

The simulation n.10 of Table 6 differs from the other simulations of Sect. 3.1 only of one quantity among the non-dimensional numbers defined in Sect. 2. Some examples of the results of the reference LSM simulation are shown in the following. It is several 3D and 2D fields of the PM mean concentration, mean deposition flux and cumulated deposition mass.

Figure 7 reports some sections representative of the 3D stationary field of the mean concentration. Its field is quite uniform upstream the insulator and far from its centreline. The mean concentration is null in the solid sub-domain and shows local minima in the downward turbulent wakes of the insulator units due to the deposition processes at the obstacle surface. The deposition flux on the disks is the target variable and satisfies the convergence criterion.

Figure 8 reports some sections representative of the 3D stationary field of the deposition flux per unit of volume Fd/Δz (kg/s/m3). The first panel shows the vertical section containing the vertical axis of the insulator and with the normal aligned with the undisturbed upstream mean velocity. The depth of the deposition region is locally equal to ca.2 cells (section “Minor improvements to SPRAY-WEB for PM deposition at the obstacle-scale”). This deposition layer might seem deeper if the graphical 3D effects are not taken into account: some cells of the solid sub-domain are close to the cells of the porous sub-domain, but they are not visible in the section. The cells of the inner solid sub-domain and the fluid sub-domain are featured by null deposition fluxes.

LSM example simulation (test n.10) for the obstacle-scale PM dispersion and deposition on the XP-70 porcelain disk insulator “Type A” defined in Zhang et al. [1]. 3D stationary field of the mean concentration. Left panel: vertical section containing the vertical axis of the insulator and with the normal aligned with the undisturbed upstream mean velocity. Centre panel: vertical section containing the vertical axis of the insulator and with the normal perpendicular to the undisturbed upstream mean velocity. Right panel: horizontal section passing for the barycentre of the central disk. Edges of the cells of the porous sub-domain (bold black). Edges of monitoring parallelepipeds (white)

LSM example simulation (test n.10) for the obstacle-scale PM dispersion and deposition on the XP-70 porcelain disk insulator “Type A” defined in Zhang et al. [1]. 3D stationary field of the deposition flux per unit of volume Fd/Δz and example of the 2D field of the cumulated deposition mass per unit of horizontal surface Md,2D. From left to right. Vertical section of the 3D field of Fd/Δz containing the vertical axis of the insulator and with the normal aligned with the undisturbed upstream mean velocity. As for the previous panel, but with the section normal perpendicular to the undisturbed upstream mean velocity. Horizontal section of the 3D field of Fd/Δz passing for the barycentre of the central disk. As for the previous panel, but with the section passing for the bottom of the central disk. 2D field of Md,2D (t = tsc). Edges of the cells of the porous sub-domain (bold black). Edges of the monitoring parallelepipeds (white). Graphic rendering of common use

The maximum values of Fd are recorded on the caps (and on the pin of the lower insulator unit). The asymmetries of the field of Fd with respect to the y-axis are associated with analogous asymmetries in the meteorological input fields and the input obstacle geometry. The influence of these asymmetries on the monitoring region of the insulator disks does not seem relevant. In the second panel, the normal section is perpendicular to the undisturbed upstream mean velocity. The deposition flux decreases towards downstream at the heights of the disks due to the reduction in the mean concentration along the LSM trajectories close to the fluid–solid interfaces. The third panel reports the horizontal section of the 3D field of Fd/Δz passing for the barycentre of the central disk. The portion of the porous sub-domain visible on the outer part of the disk includes the vertical lateral walls of the disk. The portion of the porous sub-domain at the disk centre contains part of the disk base, which is featured by a variable depth. The deposition flux averagely decreases towards downstream with local maxima where the Leaf/obstacle Area Index LAD is higher. The deposition flux at the disk level does not show relevant asymmetries with respect to the y-axis. The visible outer solid sub-domain is in contact with the porous sub-domain of the disk bottom, which is most invisible in the current section. The fourth panel reports an analogous field, but the section passes for the bottom of the central disk, where the fluid sub-domain separates the pin from the lateral and inferior edges of the disk and the solid sub-domain is not intercepted by this section. Figure 8 (last panel) also reports the 2D field of the cumulated deposition mass per unit of horizontal area Md,2D at t = tsc. It is the integral along time and the vertical of Fd/Δz. The deposited mass averagely decreases from the leading edges (where the mean concentration is higher) to the trailing edges of the insulator with local maxima recorded where the local LAI is higher. The absolute maximum is located close to the vertical axis of the string, where the solid–fluid interfaces of both the caps and pins are present. Once integrated along the vertical, the local asymmetries in the field of the deposited mass (not associated with the disks) are much reduced. The graphic rendering permits to better appreciate the spatial evolution of the fields and is responsible for a light graphic over-estimation of the depth of the deposition layer.

Rights and permissions

About this article

Cite this article

Amicarelli, A., Agate, G., Ferrero, E. et al. A closed-form solution for the deposition of atmospheric particulate matter on electrical insulators. Environ Fluid Mech 22, 891–920 (2022). https://doi.org/10.1007/s10652-022-09862-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10652-022-09862-5