Abstract

Structural and physicochemical properties of two types of bacterial cellulose (BC) produced by Komagateibacter sucrofermentans strain DSM 15973T after 7 days through either immobilized bacteria (solid inoculum) forming BCS7 or free bacteria (liquid inoculum) forming BCL7, followed by a water-based purification as a chem-free alternative treatment, were investigated in this study. SEM verifies the effectiveness of the water-based purification on BC network and reveals the insufficient interfibrillar space of BCS7 compared to BCL7. BCL7 was generally proved to be superior to BCS7 regarding degree of purification, BC yield, overall higher porosity, water swell ability, and water holding capacity (WHC), exhibiting higher hydrophilicity. However, thermally resistant BCS7 reveals a 35% residual up to 800 ºC compared to BCL7 (15%) and prevailed in terms of water retention rate. Both water-treated BC7 were proved to be Iα-rich cellulose type and exhibited a typical type IV(a) isotherm with an H3 type of hysteresis loop, a similar pore distribution, crystallinity index (~77%), crystallite size (~7.5 cm), same levels of moisture content (~98%) and the same poor levels of rehydration after the freeze-drying process. During BCL kinetics in 20 mL of HS medium over 7 days, K. sucrofermentans, 2D pellicle formation was observed until day 3 and then 3D. The highest WHC was obtained on day 4 (116 g water/g cellulose), while the lowest on day 1 (19 g water/g cellulose). Overall, we discussed the preparation and characterization of two different BCs water-treated for purification as an eco-friendly alternative method towards functional, and sustainable application.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC) stands out as nanocellulose's "gold standard" since it is purely composed of cellulose and does not contain hemicellulose, lignin, or other impurities that are ubiquitously found in plant-derived cellulose. This abundant natural biopolymer was synthesized by some cellulose-producing bacteria such as those in the genera of Komagateibacter (former Acetobacter and Gluconacetobacter) Agrobacterium, Achromobacter, Aerobacter, Azotobacter, Sarcina ventriculi, Salmonella, Escherichia, and Rhizobium, as extracellular cellulose fibrils and can be used as a promising renewable resource or an eco-friendly alternative to petroleum-based products (Wan et al. 2009; Chen et al. 2017; Suwanmajo and Taokaew 2022). The most common and highest BC producers among the acetic bacteria species of the Komagataeibacter genus were reported Komagateibacter sucrofermentans, Komagateibacter xylinus and Komagateibacter hansenii (Sheykhnazari et al. 2011; Brugnoli et al. 2021; Almeida et al. 2021).

BC shows high crystallinity, water holding capacity, degree of polymerization, finer web-like network, purity and mechanical strength (i.e., extensibility, stiffness, viscoelasticity and poroelasticity) (Wan et al. 2009; Castro et al. 2011; Sheykhnazari et al. 2011; Li et al. 2021). Additionally, the United States Food and Drug Administration (FDA) was reported that BC is “generally recognized as safe” (GRAS) and the European Food Safety Authority (EFSA) Scientific Panel on Biological Hazards (BIOHAZ), recently, included the species K. sucrofermentans in the list of QPS-recommended biological agents, intentionally added to food (Bourdichon et al. 2012; Shi et al. 2014; Bolton et al. 2019).

BC is new era in Green Chemistry products, providing unique properties, remarkable versatility and sustainable functionalization with applications in various fields. In the field of White Biotechnology for instance, BC has been used as proper support carrier for cells and enzymes attachment, providing BC composites with enhanced mechanical and physicochemical properties (Fijałkowski et al. 2016; Bayazidi et al. 2018; Żywicka et al. 2019; Drosos et al. 2021, 2023). In food industry, where the highest water-holding capacity and biocompatibility of BC makes it an ideal biomaterial for smart food packaging, which prolonging its freshness with moisture preservation and thereby extending the shelf life of food by preventing changes in aroma, taste, texture, and appearance. In addition, BC used as a thickening agent in some types of dietary supplements and functional foods or as a stabilizer in cheese and yogurt production, improving their shelf life and texture (Montoya et al. 2019; Cazón and Vázquez 2021; Liu et al. 2021). In the field of electronics, BC is used as a binder for display devices, improving interaction and facilitating homogeneous color change, while, in the paper industry, BC's high water-retention capacity, superior to that of commercial available α-cellulose, provides new possibilities for papermaking technologies (Choi et al. 2022; Revin et al. 2022). Even though, cellulose is not extensively used in the biomedical industrial field, due to the limited clinical trials, BC has shown promise in regenerative medicine due to its biocompatibility, biodegradability, and ability to mimic the extracellular matrix. These cellulose-based biomaterials are a potential substrate for the 3D bioprinting, where the tissues and organs can be designed as prototype production. Additionally, BC’s excellent water-holding and oil-holding capacities make it an attractive material for wound dressing applications (Gorgieva and Trček 2019; Hasanin 2022; Popa et al. 2022).

Most important parameters of BC preparation include a plethora of cellulose-producing microorganisms, the wide variety of cultivation media, purification treatment, drying processes, types of bioreactor and co-incubation with other polysaccharides and surfactants, which all of the above could be affect the structural characteristics of BC and ultimately to determine the quality and application of the biomaterial (Watanabe et al. 1998; Sani and Dahman 2010; Chen et al. 2017, 2021; Fernandes et al. 2020).

The difficulty of industrializing BC and its high costs are two major issues with direct implications for BC production. Even though BC production is easy in a laboratory, industrialization and commercialization of BC at large scale is limited by the chemicals in the medium and its low production capacity (Hussain et al. 2019; Avcioglu 2023). For that reason, sustainable strategies are being tested, such as optimizing the production process, varying the media content, and using additives to improve BC production. In the quest for cost-effective BC production, considering of evaluating industrial wastes and preventing environmental pollution, researchers have been exploring the use of low-cost carbon and nitrogen sources, avoiding commercial media like the HS medium. Thus, the focus has been on the use of various plants, herbal extracts and agricultural by-products, as these resources are abundant, easily accessible and relatively cheap (Tsouko et al. 2015; Islam et al. 2017; Velásquez-Riaño and Bojacá 2017; Lotfy et al. 2021). Typically, these sources are not defined media, so they require pretreatment, which makes it imperative to carefully manage their selection to achieve optimal BC yields and quality. A pretreatment process changes the size, structure and chemical properties of the biomass in order to optimize the conditions for efficient hydrolysis, improve sugar yield or the ability to convert sugars by enzymatic hydrolysis, eliminating carbohydrate degradation and provide economic efficiency (Sperotto et al. 2021; El-Gendi et al. 2022).

Aim of this work is to present a comparative study that focusses on investigation of culture parameters, structural modifications, and physicochemical properties of two-type BC preparation, called BCS or BCL, which produced after 7 days of polymerization at 30 °C in commercial HS medium under static conditions by immobilized bacteria (solid inoculum) or free bacteria (liquid inoculum) of K. sucrofermentans DSM 15973T strain, respectively, and their water-based purification as eco-friendly alternative. Additionally, in this study evaluated BCL production over seven days in 20 mL fermentation volume using a kinetic model. It is important to emphasize that it was developed an eco-friendly and sustainable water-based purification method to the formed biomaterials avoiding: (i) costly purification processes that introduce hazardous chemicals to remove impurities for BC and (ii) damaged BC microfibers by the common alkali solution treatment or surfactants using concentrated solutions, which negatively affects BC's mechanical properties (Cazón and Vázquez 2021).

Considering the effect of water-based purification and freeze-drying on physiochemical, morphological, and structural properties of as-produced bacterial cellulose, a completely characterization of the water-treated biomaterials was evaluated using thermogravimetric/differential thermogravimetric analysis (TG/DTA), Fourier transform infrared spectroscopy (FTIR), x-ray diffraction (XRD), field emission scanning electron microscopy (SEM), energy dispersive x-ray spectroscopy (EDS), nitrogen adsorption-desorption isotherms based on Brunauer–Emmett–Teller (BET) equation and Barrett–Joyner–Halenda (BJH) and calculation of hydrophilic properties such as water holding capacity (WHC), moisture content (MC), water retention rate (WRR), rehydration ratio (RR) and water swell ability (WSA). By evaluating of the significant properties of water-treated BCL or BCS, this comparative study provides information for combining efforts toward more suitable, functional, and sustainable applications.

Materials and methods

Materials

The stock culture medium of the K. sucrofermentans strain DSM (Deutsche Sammlung von Mikroorganismen) 15973T starter culture was prepared based on the method that was reported by Drosos et al. (Drosos et al. 2021).

Methods

BC pellicle preparation process from solid inoculum (BCS)

For the solid inoculum preparation, as reported in the method by Drosos et al. (Drosos et al. 2021), 10% v/v (106 cells/mL) of the starter culture was combined with 20 mL fresh Hestrin and Schramm (HS) medium in 50 mL flasks and new cultures allowed to grow for 4 days at 30 °C to result in the formation of the first cellulose layer (pellicle) on the top surface of the culture medium. The initial bacterial pellicles were used as the solid inoculum of K. sucrofermentans. For the microbial synthesis of BCS, an amount of initial solid bacterial pellicles of 1, 5, 20 and 50 g was added proportionally in flasks of 50, 250, 500 and 2000 mL containing 20, 100, 400 or 1000 mL of fresh HS culture medium and the flasks were stoppered with cotton plug. Then, aerobic cultivation was carried out under static conditions at 30°C for 7 days and the final formed pellicle was called BCS7. A water treatment was applied to remove bacterial cells, proteins, and other medium fermentation residues and the depigmentation of the gelatinous BCS pellicles happened gradually till the gelatinous BCS pellicle became translucent. Water treatment compromise the following steps: (i) immersing BC pellicles into distilled water with stirring at 100 °C, (ii) changing the water after 30 min for 3 times (total: 1.5 h) and finally (iii) extra rinsing of the BC pellicles with sterile distilled boiled water until the pH level become neutral. Finally, the wet water-treated BCS7 that was remained, dried at room temperature (RT-dried) or freeze-dried (by cooling to −45 °C and with an exposure (48 h) to vacuum (5–15 × 10−3 bar at −45 °C) on a freeze dryer system, Freezone 4.5 (Labconco Corp., Kansas, MO, USA), for further physicochemical analysis.

BC pellicle preparation process from liquid inoculum (BCL)

For the microbial synthesis of BCL, the synthesized bacterial pellicle, as described in section "BC pellicle preparation process from solid inoculum (BCS)", was removed and the remaining bacterial liquid was used as liquid inoculum. For this process, different volumes (5, 25, 100, and 250 mL) of the liquid inoculum (20%, v/v) were added proportionally in flasks of 50, 250, 500, and 2000 mL containing 20, 100, 400 and 1000 mL of fresh HS medium, respectively, so that the final concentration of bacterium to be ca 107 cells/ mL. Aerobic cultivation was carried out under static conditions at 30 °C for 7 days and the flasks were stoppered with cotton plug. The produced BC were isolated each different day for 7 days. The final formed pellicle was called BCL7. As described in section "BC pellicle preparation process from solid inoculum (BCS)", the produced wet BCL pellicles were treated with distilled water for bacterial cell removing and the water-treated BCL1-7 were remained wet or RT-dried or freeze-dried for further physicochemical analysis.

Characterization and study of water-treated bacterial cellulose (BC)

BC yield and BC to glucose conversion efficiency

To measure the BC (BCL and BCS) yield by K. sucrofermentans in different cultivation volumes, BC were water-treated, freeze-dried, and then weighed on an analytical balance. All concentrations of the BC were converted into g of the freeze-dried BCS per Liter of the total cultivation volumes for comparison reasons. Also, the BC to glucose conversion efficiency, defined as the ratio of BC yield to the consuming glucose (residual glucose determination reported in section "Residual Sugar (RS) Determination") based on modified method by Zhou et al. (Zhou et al. 2023) and was determined by using Eq. (1):

where the Initial glucose in this study is 20 g/L.

Morphological properties

Scanning Electron Microscopy/Energy Dispersive X-ray Spectroscopy (SEM/EDS) was performed to analyze the microstructure and the elemental composition of BCL1-720mL and BCS720mL pellicles. The assessment of the morphology, surface area and the cross section of the pellicles were analyzed by SEM imaging. Prior to the analysis, the pellicles were dried by a freeze-dryer (Labconco Corp., Kansas, MO, USA), cut into small pieces, coated with a thin layer of sputtered gold for 2 min (BALTEC, MED 020) and examined in a Scanning Electron Microscope (JSM6300LV, JEOL, Japan), operating at an accelerating voltage of 30 kV/SEI, W.D. = 8 mm, and discretionary limit of 3.5 nm. In addition, EDS was carried out by SEM equipped with Link ISIS 300, which can perform elemental analysis of the material by detecting characteristic X-rays generated from a specimen to determine the C/O molar ratio from BCL720mL and BCS720mL pellicles. SEM/EDS images were analyzed at magnification of 2000x and bar of 20 μm.

Hydrophilic properties

After BCL1-720mL and BCS720mL production, BC pellicles were water-treated and used in different forms (wet, RT-dried, and freeze-dried) for the determination of their hydrophilic properties according to the following modified methods. After BC production, BCL and BCS pellicles were isolated, water-treated, shaken twice quickly to eliminate the surface water, and then weighed (mwet). These pellicles were RT-dried for 24 to 96 h and their weights (mRT-dry) were measured at different time intervals. As described in section "Methods", BC pellicles were freeze-dried for complete water removal. Finally, they were transferred quickly to the balance for weighing (mFD-dry) to determine moisture content (%), water holding capacity and water retention rate. After freeze-drying process and weighing, BC pellicles were immersed in deionized water (w/v = 1:2) for 48 to 96 h and then weighted (mrwet) to determine the rehydration ratio (%) and the water swell ability (%) of the cellulose pellicles. The standard deviation of the all the values of the following parameters were calculated based on three measurements.

Moisture Content (MC) method

Based on the modified method by Fang and Catchmark (Fang and Catchmark 2014), the Moisture Content (MC) was calculated as follows Eq. (2):

where mwet is the weight after washing, shaking twice for surface water removal and mFD-dry is the freeze-dried weight.

Water Holding Capacity (WHC) method

Based on the modified method by Shezad et al. (Shezad et al. 2010), the Water Holding Capacity (WHC) was calculated as follows Eq. (3):

where mwet is the weight after washing, shaking twice for surface water removal, mRT-dry is the RT-dried weight at 48 to 96 h and mFD-dry is the freeze-dried weight.

Water Retention Rate (WRR) method

Based on the modified method by Shezad et al. (Shezad et al. 2010), the Water Retention Rate (WRR) was determined, calculating the water content during RT-drying up to 96 h as follows Eq. (4):

where mRT-dry is the RT-dried weight for 48 to 96 h and mFD-dry is the freeze-dried weight.

Rehydration Ratio (RR) method

Based on the method by Chang and Chen (Chang and Chen 2016), the Rehydration Ratio (RR) was calculated as follows Eq. (5):

where mFD-dry is the freeze-dried weight and mrwet is the weight after immersion in deionized water for 48 to 96 h.

Water Swell Ability (WSA) method

Based on the method by Chang and Chen (Chang and Chen 2016), the Water Swell Ability (WSA) was calculated as follows Eq. (6):

where mFD-dry is the freeze-dried weight and mrwet is the weight after immersion in deionized water for 48 to 96 h.

Nitrogen Adsorption-Desorption Isotherms

Nitrogen adsorption-desorption isotherms of the water-treated and freeze-dried BCL1-720mL/BCS720mL pellicles were recorded in a Micromeritics apparatus (Tristar 3000 porosimeter). Specific Surface Area (SSA), Pore Volume (PV), and Pore Size (PS) distributions of produced water-treated BC pellicles were determined by measuring the amount of N2 adsorbed on and desorbed from the material surface over a wide range of relative pressures. Freeze-dried BCL1-7 and BCS7 pellicles were degassed using N2 flow at 90 °C for 3 h to remove any gases adsorbed in the pellicles’ surface. SSA and PS distribution calculation was based on Brunauer–Emmett–Teller (BET) equation using adsorption data. PV distribution was determined using the Barrett–Joyner–Halenda (BJH) method and the N2 desorption curve.

X-ray Diffraction (XRD)

The crystal structure of the water-treated BCL1-720mL/BCS720mL pellicles was investigated using XRD patterns. These were recorded in an X-Ray diffractometer (Bruker D8 Advance, Billerica, MA, USA) equipped with nickel filtered CuKα (λ=0.15418 nm) radiation source. The operating voltage and current were 40 kV and 40 mA, respectively. The step size and the time per step were respectively fixed at 0.02° and 0.5 s in the range of 10° ≤ 2θ ≤ 40°. All pellicles, prior to the measurement, were slightly ground in order to achieve a random order.

The crystallinity index (CI) was calculated following an approach described below. The formulas used to compute the amorphousness and crystallinity percentages are as follows:

where Global area corresponds to the whole area of the pattern whereas Crystal area corresponds to the area of the crystal peaks, after reducing the area of the background. For the calculation of these areas, the methodology described in supplementary information by Leonarski et al. (Leonarski et al. 2022) was followed. GSAS software (Larson and Von Dreele 2004) was used for the Rietveld refinement method (Rietveld 2014), for obtaining the crystallographic parameters from the XRD patterns. The peak profile analysis of the crystalline material was performed adopting a pseudo-Voigt shape. Background was fitted with Chebyshev polynomials, using 16 coefficients. The .cif used for the Rietveld refinement was obtained from the COD (Crystallography Open Database), number COD-4114382 (X-Ray diffraction .cif file) from the work of (Nishiyama et al. 2003) A representative example for the BCL7 pellicles is illustrated in Fig. S1.

The crystallite size (CS) was calculated using Scherrer´s equation (Scherrer 1918; French and Santiago Cintrón 2013), as shown in Eq. (9):

where K is a crystal shape constant (0.94), λ is the wavelength of the CuKα X-ray radiation (λ = 0.15418 nm), θ is the diffraction angle (Bragg’s angle), and β is the full width of the peak in 2θ degrees expressed in radians measured at half of the maximum peak height (FWHM).

The interplanar distances (d-spacing) and the Z value were calculated according to Bragg’s law Eq. (10) and the Z discriminant equation (Eq. 11) (Wada et al. 2001), as shown below:

where λ is the wavelength of the CuKα X-ray radiation (λ=0.15418 nm), and θ is the angle between the plane and the diffracted.

where d1 is the d-spacing peak (100), and d2 is the d-spacing peak (010).

Thermal properties

The thermogravimetric (TG) and differential thermogravimetric (DTG) analysis was carried out in a Labsys TM TG apparatus of Setaram controlled by Applications SetSoft 2000 software. The water-treated and freeze-dried BCL1-720mL/BCS720mL pellicles (ca. 8 mg) were placed in an aluminum crucible and heated at 50 °C until their weight was stabilized. Afterwards, the temperature was increased up to 800 °C (rate 10 °C/min) under nitrogen purge (40 mL/min), so the weight loss and derivative weight graphs were obtained. The activation energy (Ea) was calculated according to literature (Coats and Redfern 1964; Basta 1998; Gao et al. 2003).

Fourier Transformation Infrared Spectroscopy (FT-IR)

FT-IR measurements of water-treated and freeze-dried BCL1-720mL/BCS720mL pellicles were obtained in KBr discs on a Nicolet™ iS20 FT-IR Spectrometer (Thermo Fisher Scientific Inc.) equipped with DTGS KBr detector. Spectra were recorded in the spectral range of 4000 to 400 cm−1 at 4 cm−1 spectral resolution, 1 sample gain, and 36 sample/background scans using OMNIC 9.11.721 software (Thermo Fisher Scientific Inc.).

Analytical methods

Residual Sugar (RS) Determination

Residual Sugar (RS) (g/L) determination during the BCL1-720mL/BCS720mL production, was carried out by high performance liquid chromatography, using a chromatograph (SHIMADZU, HPLC-RID) equipped with a column (Nucleogel ION 300 OA, 300×7,8 mm i.d., particle size of 10 μm), a degassing unit (DGU-2A), a pump (LC-9 A), an oven (CTO-10 A set at 33 ºC), a refractive index detector (RID-6 A) and a integrator (C-R6A). As a mobile phase, 0.008 N H2SO4 was used at a flow rate of 500 μL/min and 1% (v/v) propanol-2 was used as an internal standard. For the dilutions, ultra-pure water obtained by a Milli-Q water purifying system with a resistivity of 18.2 MΩ cm−1, was used. A volume of 100 μL of sample and 100 μL of propanol-2 solution were diluted up to 25 mL by ultra-pure water. Disposable syringe cellulose acetate filters (pore size of 0.22 µm) were used for samples filtering and injecting the final solution of 20 µL directly to the column. The determination of RS was achieved by comparing every retention time with authentic known D-glucose for analyses (purity: ≥99.5%). Glucose calibration curves were prepared in concentration range of 1 to 250 mg glucose/mL water and residual glucose quantitation in samples was based on automatically measured peak areas and corresponding standard curves.

Acidity analysis and Measurement of pH

Volatile acidity (VA) was estimated by titration of distillate that was obtained by steam distillation of the culture HS medium samples during the BCL1-720mL/BCS720mL production by K. sucrofermentans (1-7 days), using standard 0.1 N NaOH solution with phenolphthalein as indicator, expressing the results as g acetic acid per liter of the culture medium (Bodily 1956).

Titratable acidity (TA) was determined by titration of 10 mL of the culture HS medium samples during the BCL1-720mL/BCS720mL production by K. sucrofermentans (1-7 days), using standard 0.1 N NaOH solution with phenolphthalein as indicator, expressing the results as milliequivalents per liter of the culture medium.

A commercial pH-meter (HANNA HI98100, with accuracy of ±0.01 pH and resolution of 0.01 pH) was used for the pH estimation during the BCL1-720mL/BCS720mL production by K. sucrofermentans (1-7 days). For instrument calibration, which was performed before each measurement series, 2 buffers, one with an acidic pH of 4.0 and one with an alkaline pH of 7.0 were used.

Results and discussion

Aim of the comparative study

The comparative study focuses on the production of two-type of BC called BCS or BCL, which produced by the immobilized bacteria (solid inoculum) or free bacteria (liquid inoculum) of K. sucrofermentans DSM 15973T strain, respectively, and their eco-friendly purification using hot water. Initially, in the present research was examined various bioprocess parameters that affect the BC features. This involves the determination of residual glucose, pH, BC yield, bacteria cells viability, volatile acidity, and total acidity. The second part of the research will explore the eco-friendly water-based purification of BC. As already mentioned, unlike plant cellulose, which requires harsh chemicals for purification, BC purification can be a low-energy and chem-free process (Shi et al. 2014). However, the specific mechanisms and efficiency of water-based purification for BC remain underexplored. The study investigates how water can effectively purify BC, considering factors such as temperature, pH, repeatability, intensity, and duration of water treatment. Completely characterization of the water-treated biomaterials using material methods (TG/DTA, FTIR, XRD, SEM, EDS, nitrogen adsorption-desorption isotherms) and determination of their hydrophilic properties (WHC, MC, WRR, RR, WSA) were carried out. Briefly, the research aims to provide a comprehensive understanding of BCL/BCS feature difference and their purification using an environmentally friendly process. The outcomes of this research could contribute to the development of sustainable methods for BC production and purification, which could then be suitably applied to various industries, from food to biomedical applications, in accordance with the features of biomaterials.

Kinetic evaluation of Glucose, pH, Cell viability, Acidity and Yield during BCL/BCS production by K. sucrofermentans

Biosynthesis of cellulose involves two steps catalyzed by cellulose synthase. Following the polymerization of glucose units into β-1,4-glucan units, the cellulose chain is assembled and crystallized (Tajima et al. 2022). A range of parameters (nutrient sources, dissolved oxygen, initial pH, acidity, temperature, and static or agitated cultivation) could induce the formation of products and changes in the medium composition may affect BC yield directly or indirectly. Based on relative studies, the best parameters for the optimum cultivation of a Komagataeibacter strain are: temperature of 30 °C, initial pH of 6.0, glucose source, low agitation rate and an adequate supply of oxygen (10% saturation of dissolved oxygen provides the highest yield of BC. Among all above, glucose is the main nutrient source of carbon, which is remarkably consumed by bacterial cells to attain the metabolic demands and high energy yield (Lahiri et al. 2021). Additionally, HS glucose-medium is the most recommended for Komagataeibacter strains and the most appropriate without any significant loss of their production performance (Schramm and Hestrin 1954; Chen et al. 2017). Thus, for production of BC pellicles, was used in HS glucose-medium under static cultivation mode at 30 °C for 1 up to 7 days, cotton on the top of the flasks to adequate oxygen supply, initial pH value of 5.5-6.0, using liquid (as free bacterium cells, BCL) or solid (as immobilized bacterium cells on a preculture pellicle, BCS) inoculum K. sucrofermentans, as reported in subsections "BC pellicle preparation process from solid inoculum (BCS)" and "BC pellicle preparation process from liquid inoculum (BCL)".

Based on the results presented in Table 1 for two production processes of BCL720mL and BCS720mL by K. sucrofermentans, the residual glucose (g/L) of culture medium reached out the 1.3 and 5.2, respectively, via a 4-fold times higher glucose remaining concentration in BCS720mL than BCL720mL. In addition, according to Table 2, increasing the volume (5 to 25 to 100 up to 250 mL) of the 20% v/v bacterium liquid inoculum in the case of BCL720mL, BCL7100mL, BCL7400mL and BCL71000mL pellicles or increasing the amount (5 to 25 to 100 up to 250 g) of the bacterium solid inoculum in the case of the BCS720mL, BCS7100mL, BCS7400mL and BCS71000mL proportionally in HS-glucose medium, the residual glucose (g/L) was ranged from 2.4-3.2 and 5.2-6.4, respectively. We assumed that it happens because in the case of BCL production, the liquid inoculum of K. sucrofermentans is dispersed throughout the HS medium and consumes more glucose units which were subtracted from the glucose capital which would be polymerized into the BC pellicle, while in the case of solid method (BCS preparation) the glucose units’ consumption is confined around the preculture pellicle used as solid inoculum.

It is worth mentioning that the BCL20mL pellicle was starting synthesized in the first 20-22 hours by the free cells of K. sucrofermentans whereas using the immobilized bacterium cells as inoculum makes the process more time-consuming and as a result BCS20mL pellicle is formed after a 2.5-fold times higher time (50-52 hours). Consequently, this lag phase affects the BC20mL yield of each method. Thus, the BCL7 was generally proved to be superior to BCS7 regarding the higher produced pellicle mass in lower fermentation volumes (20 and 100 mL), and consequently the higher BC yield, while in higher fermentation volumes (400 and 1000 mL) this is reversed. In addition to the rate of glucose consumption, the overall increase in cultivation days can increase the yield of BC (Lahiri et al. 2021). To be more specific, in our findings arose that in the 7th production day of BCL720mL, BC yield was 6-fold times higher than the 1st cultivation day of K. sucrofermentans. As recorded in Table 1, the BCL yield obtained by the effect of the cultivation time (1-7 days) was decreased as follows (g freeze-dried/L): BCL720mL (2.65) > BCL620mL (2.40) > BCL520mL (1.90) > BCL420mL (1.35) > BCL320mL (0.80) > BCL220mL (0.75) > BCL120mL (0.45). Considering the above descending order, the highest BC yield rate was obtained from day 1 to day 2 of bacterial cultivation, ranging from 40-45 % per day, while the lowest BC yield rate of 6% was obtained at day 2 to day 3. Comparing to related studies about BC yields by Komagataeibacter strains, Brugnoli et al., added 5% (v/v) inoculum of the same strain of K. sucrofermentans (DSM 15973T) in HS medium with static cultivation mode at 28 °C, providing a maximum BC yield of 0.81 g dried/L (Brugnoli et al. 2021), while in our study, 20% (v/v) inoculum of the bacterium was used in HS medium under static cultivation mode at 30 °C, achieving a maximum BC yield of 4.67 g freeze-dried/L after 7 days. Chen et al. (Chen et al. 2017), were used 10% (v/v) of different K. sucrofermentans strains (ATCC 700178, ATCC 10245, ATCC 23769, KTH 5655, NBRC 13693, ATCC 53524) in HS medium under static cultivation mode at 30 °C, providing various BC yields of 1.90-10.39 g dried/L after 9 days.

Additionally, the influence of medium volume (20, 100, 400 and 1000 mL) on the dynamics of the BCL7 and BCS7 pellicles are presented in Table 2. It seems that increasing the medium volume, the pellicle diameter, and the mass (wet and freeze-dried) were increased. However, the higher BC yields were achieved in different medium volume for each different BC production process, as resulted as BCL7100mL and BCS7400mL were proved the superior per process. To be more specific, in Table 2 were recorded the maximum BC7 yields obtained by the combined effect of (1) BC production process and (2) medium volume that were decreased as follows (g freeze-dried/L): BCL7100mL (4.67) > BCL7400mL (3.88) > BCS7400mL (3.81) > BCS71000mL (3.46) > BCS7100mL (3.40) > BCL71000mL (2.69) > BCL720mL (2.65) > BCS720mL (2.40). Considering the above results, we presumed that in the case of BCL: (i) the dispersed free cells of K. sucrofermentans in the liquid inoculum and (ii) the proper adjustment of the medium volume, could increase the metabolic system of the bacterial cultures and maximize the BC production pathway. This could occur due to increasing: (1) the rate of bacterial multiplication, (2) the consumption of glucose and nutrients, (3) the consumption of dissolved oxygen, and (4) the production of gluconic acid by the units’ glucose, in the whole HS-glucose medium batch. In contrast to the immobilized cells of K. sucrofermentans in the case of the solid method (BCS) that restricts the above parameters (1-4) to the area around the preculture pellicle, which used as inoculum.

BC yield and residual glucose content in the HS medium were also determined to calculate glucose to BC conversion efficiency (%), a key economic parameter for industrializing BC production. Thus, a more cost-effective method for BC production is to find a less expensive alternative medium, as BC production is an expensive process to industrialize. However, to make the above even more feasible, it is essential to along with it with the optimal combination of medium volume and preparation method, as we studied. As reported in Table 1, during the BCL1-720mL production, the percentage of glucose consumed decreased from 91.0 % (day 1) to 6.5% (day 7) by K. sucrofermentans, whereas the diminished glucose resulted in a noticeable descent in BC to glucose conversion efficiency from 25.0% (day 1) to 14.0% (day 7). The glucose conversion efficiency in BCS after 7 days reached at 16%. Regarding the influence of medium volume (20, 100, 400 and 1000 mL) on the BC to glucose conversion efficiency is shown in Table 2, where reported the maximum values of 27% for BC produced with the liquid method after 7 days in 100 mL of HS medium (BCL7100mL) and 25% for BC produced with the solid method after 7 days in 400 mL of HS medium (BCS7400mL).

To provide a better view of the different factors' effect on 2 BC production processes, determined the bacterial cell viability in HS culture media, where the free cells of K. sucrofermentans were counted out by a hemocytometer. The initial concentration of free K. sucrofermentans cells in the HS culture medium after liquid inoculum and solid inoculum added, were measured at 1x107 and 1x106 cell/mL, respectively. Analogously to the other bacterial strains, BC-producing strains have identical growth curve patterns with lag, log, stationary, and death phases (Lahiri et al. 2021). Thus, based on our findings during the BCL1-720mL production, the lag phase lasts 1 day, the log phase lasts 2 days, the stationary phase lasts 2-3 days and the death phase lasts 2 days (Table 1). According to Table 2, when producing the BCL720mL, BCL7100mL, BCL7400mL and BCL71000mL pellicles, the free bacterial cells in HS culture media were reaching out the concentration of ca. 107 cell/mL, while when producing BCS720mL, BCS7100mL, BCS7400mL and BCS71000mL pellicles the free bacterial cells were counted about ca. 106 cell/mL, pointing out that in the case of BCL, the increased free cells could maximizing BC yield by enhancing the total metabolic system of them in lower fermentation volumes however not in the larger ones. Therefore, free cells are adaptable to smaller fermentation volumes while immobilized cells is more effective in achieving a fermentation batch with a larger volume which is a major aspect to industrialize BC production.

Additionally, to study better the cultivation of an acid-producing bacterium as K. sucrofermentans had to indicate the total acidity of the culture media, accordingly the important parameters of titratable acidity (TA), volatile acidity (VA) and pH were estimated. Acid-producing bacteria often increase the environmental acidity to inhibit the growth of local competitors (He et al. 2020b). In most cases, a culture medium may contain the full complement of Krebs cycle acids (and their derivatives), fatty acids, and amino acids, depending on the bacterial strain. Although, inorganic acids such as phosphoric and carbonic (arising from carbon dioxide in solution) acids often play an important and even predominant role in culture medium acidulation (Sadler and Murphy 2010). Worthy to mention that the pH decrease associated with the cultivation of the genus Komagataeibacter is correlated with a distinctive metabolic feature of excessive gluconic acid synthesis once the cells begin to assimilate glucose residues, hence the culture pH turns more acidic (Al-Hagar and Abol-Fotouh 2022). Also, change in pH is inevitable as acetic acid, formic acid, lactic acids are produced when glucose, sucrose and fructose are utilized as carbon source by Komagataeibacter strains (Gupte et al. 2021).

The TA (as mEq/L) in BCL720mL and BCS720mL production was determined, reaching out the 0.88±0.04 and 1.16±0.05 levels of acidity, respectively (Table 1). During the BCL1-720mL production, the TA was increasing day by day and was ranged from 0.32 to 0.88 mEq/L. In the case of K. sucrofermentans as acetic acid bacteria, it is often desirable to know how much acidity comes from the acetic acid and how much is contributed naturally by other acids in the culture medium. This can be achieved by measuring the volatile acidity (VA). As recorded in Table 1, it can be observed that the two production methods of BC, by free bacterial cells (liquid method, BCL) or immobilized bacterial cells (solid method, BCS), can produce volatile acids (as g acetic acid/L) with 0.45±0.03 and 0.52±0.03 levels of acidity (Table 1). During BCL1-720mL production, the VA (as g acetic acid/L) was increasing day by day (1-7 days) and was ranged from 0.12 to 0.52. By all the TA and VA measurements, it is observed that in the case of immobilized bacterial cells (solid method), a more acidic character in the culture medium was resulted.

Since pH is a combined function of titratable acid and conjugate base, the TA is not a good predictor of pH (Sadler and Murphy 2010). Thus, the pH variation was evaluated by a pH-meter during BCL1-720mL production (1-7 days) by K. sucrofermentans. After the liquid and solid inoculation, the pH value of the HS-glucose media with liquid inoculum and HS-glucose media with solid one was 5.5 and 6.0, respectively. The lower pH in liquid process was due to the more acidic character of the pre-culture liquid (pH=3.95) than pre-culture solid pellicle. During BCL1-720mL production, the most significant drop in pH occurred in 3 days of the cultivation, decreasing to 3.86 and the pH remained practically constant (3.72-3.76) after the 4th day till the 7th day of cultivation in HS culture medium (Table 1). Comparing to the solid method (BCS720mL), the pH value in the HS culture medium after 7 days reaching at 3.73. He et al., also, was verified a higher drop in the pH value in 2 days of Komagataeibacter rhaeticus cultivation and the pH value in the HS medium after 7 days reached at 3.6 (He et al. 2020b). According to Leonarski et al., the higher drop in the pH value was in 2 days of Komagataeibacter strain cultivation and the pH value in the HS medium after 7 days reached around 3.5 (Leonarski et al. 2022). Additionally, increasing the volume of the liquid inoculum or the amount of the solid inoculum of K. sucrofermentans proportionally in HS the medium, pH was ranged at 3.53-3.71 and 3.68-3.70, respectively (Table 2).

Characterization of bacterial cellulose (BC)

Morphological properties of BC

The comparative study focused on BCL1-720mL and BCS720mL pellicles production using an eco-friendly water treatment without any chemical alkali purification although is essential and improves the BC properties (Chen et al. 2021; Sari et al. 2021).The appearances of BCL1-7 pellicles in (a) wet, (b) RT-dried, (c) rehydrated, and (d) freeze-dried form are shown in Fig. 1. It seems that the gelatinous properties of the wet BCL1-7 pellicles were similar to a bacterial cellulosic material. At RT-dried and rehydrated status of BCLs, on day 1 to 3 the pellicles were thinner and translucent, while from day 4 to 7 were thicker and opaque. Finally, all freeze-dried BCL pellicles were white opaque, like-cotton fabric.

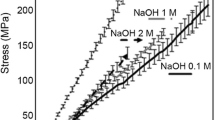

Thus, the water-treated biomaterial morphology (surficial or cross sectional) was assessed by SEM (Fig. 2) to demonstrate an equally valuable treatment method as an alkali. The gradual depigmentation of the gelatinous pellicles of BCL7 and corresponding surface SEM images before the water treatment (native BCL7), after the water treatment for 30 min, and finally after the water treatment for 90 min, at magnification of 2000x and bar of 20 µm illustrated in Fig. S2. In SEM imaging seems that K. sucrofermentans produce fine sub-elementary cellulose fibrils during cultivation, which are extruded into the culture medium by the enzyme complexes. The sub-elementary cellulose fibrils, which are exhibiting an extraordinarily high surface area, are assembled into microfibrils and then these microfibrils are then bundled to form ribbon-shaped fibrils (Cai and Kim 2010). As seen in Fig. 2 (a, b, c, d, e, f, g, i), the ribbon-shaped fibrils can be observed on the surface of BC. In Fig. 2h illustrated a cross-sectional SEM photo of the water-treated BCL720mL, revealing repeating thin layering structures. From the surface SEM images, we can observe that BCL720mL and BCS720mL revealed a denser structure and uniform fibrils with almost non-existent interfibrillar space compared to BCL1-620mL pellicles. It can be observed that a similar morphological microstructure of the BCL1-620mL produced by K. sucrofermentans and a denser fibrous structure day by day, too. In the cross-sectional SEM image of BCL7 (Fig. 2h), fibrils in the sheets appear to constitute a pile of thin layers. It can be observed that a well-organized three-dimensional (3D) network structure formed, and these fibrils assemble to form porous structures as interconnected slit-like pores. The advantageous aspect of the eco-friendly and chem-free process of water treatment, which was applied to the produced BC pellicles, is its simplicity and effectiveness in purifying the BC network since it was used for the entire bacterial cell removing and SEM images verified the clear BC nanofibril networks. Thus, there was no difference of SEM morphology in produced BC pellicles by K. sucrofermentans strains in HS medium or other wastes, in which was applied water (Chen et al. 2018; Souza et al. 2021) or chemical alkali-treatments such as NaOH (Tsouko et al. 2015; Fan et al. 2016; Chen et al. 2017; Vigentini et al. 2019; Souza et al. 2021), Na2CO3 (George et al. 2008) and KOH (Castro et al. 2011; Ashrafi et al. 2019).

The elemental mapping was carried out via EDS spectra (Fig. S3) in order to better differentiate between the water-treated BCL720mL and BCS720mL pellicles, determining their total (%, w/w) elemental composition and comparing their C/O molar ratio. The surface elemental (C, O, Na, K and Cl) analysis (%, w/w) composition data of water treated BCL720mL and BCS720mL are provided in Table S1. The C/O ratio, that was calculated by the elemental mass percent, for the BCL720mL pellicle was at 1.32, compared to the BCS720mL which was determined at 1.40 (Table S1), when in the study of Alonso et al. was found a molar C/O ratio of 1.46 in an alkali-treated and freeze-dried BC pellicle (Alonso et al. 2018). EDS analysis of water-treated BCL720mL and BCS720mL pellicles (Fig. S3) shows the presence of elements like sodium, potassium, and chloride, which are commonly present in biological samples like proteins and nucleic acids along with carbon and oxygen elements of a cellulosic material. Specifically, as tabulated in Table S1, in the case of water-treated BCL720mL, the total (%, w/w) elemental composition of biological impurities is about 2.7, compared to water-treated BCS720mL that is about 3.45. This occurs as a result of the denser structure of BCS720mL than BCL720mL, in which the water-treatment method may not have worked so penetratingly into the biomaterial. As a result, the enhancement of water-based purification is a promising future prospect since it is known that BC does not require chemicals to remove impurities, such as plant-cellulose. While have generally removed the elements corresponding to biological impurities from BC, they also confirm that alkali treatments are effective for obtaining a relatively pure form of bacterial cellulose (George et al. 2008; Alonso et al. 2018), however, this may not be necessarily be a requirement for most BC applications.

Nitrogen adsorption – desorption isotherms

BC porosity can vary depending on its biosynthesis conditions, which can ultimately influence its application. This 3D porous structure of BC can enhance the mobility or entrapment of cells, enzymes and other active agents in the tissue engineering, nanomedicine, and white biotechnology fields. Related studies have demonstrated that the microporous and nanoporous scaffolds are suitable for cell growth and tissue formation (Zaborowska et al. 2010; Carvalho et al. 2019), while the lack of macropores in BC restricts its broad applications in the biomedical field (Wahid et al. 2021). Further, in our related studies, we have noted that the deeper pores in nanocellulose provide better enzymes or cells attachment, making them better protected for reusing bioprocessing within a circular bioeconomy (Drosos et al. 2021, 2023). Due to the widely applied alkali treatments of BC can decrease its porosity (Al-Shamary and Darwash 2013), N2 physisorption at liquid N2 temperature experiments were conducted to investigate how the combination of water treatment and lyophilization affect the porosity of BCS720mL and BCL1-720mL. In addition, investigating how enzyme complexes of K. sucrofermentans affect porosity over time (1-7 days) is a key to understanding the production time for the highest-pore-count biomaterials.

The isotherms and pore distribution of all the BCS720mL and BCL1-720mL pellicles under studied are presented in Fig. 3. As showed in the Fig. 3 (right), the isotherms are a typical type IV(a) with an H3 type of hysteresis loop (Kondor et al. 2021). The latter indicates cellulosic biomaterials with very broad pore size distribution, as illustrated in Fig. 3 (left). All BC20mL pellicles show the presence of pores with a broad range of pore width (2-100 nm), as suggested from the isotherms, which certifies that all the structures can be characterized as bacterial nanocellulose (nanosized cellulose fibers with a diameter <100 nm). Notably, BCL120mL shows the formation of a few pores with pore width ~ 2-10 nm (micropores) and mainly larger than 10 nm (mesopores and macropores). Microporosity is enhanced, moving to later stages of the synthesis process (BCL2-720mL), showing more values at 0-10 nm than BCL120mL. Also, BCL2-720mL structures show the formation of more mesopores (10-50 nm) and macropores (50-100 nm) than BCL120mL. Thus, the more cultivating time of K. sucrofermentans, the more pores can form in the cellulosic material. Specifically, it can be observed a decrease in macroporosity during the 2nd, 4th, 5th day and a consequent increase during the 3rd, 6th, and 7th day. Overall, the total pore distribution of the BCL20mL pellicles could range in decreasing size order: micro > meso > macro, confirming the microstructure features of the bacterial cellulosic material synthesized by the K. sucrofermentans strain. According to our findings, BCS720mL and BCL720mL exhibit similar nanostructure in terms of the pore distribution with more micropores than macro- or mesopores.

Based on the porosimetric data in Table 3, fluctuations in the specific surface area (SSA), pore volume (PV) and pore size (PS) values were observed during the preparation process of BCL20mL per day. According to the BET method, the SSA of resultant BCL1-720mL pellicles were determined in the relative pressure ranging from 2 to 32 m2/g. As shown in Table 3, it is observed a very low SSA (2 m2/g), on the first day of the formulation process. BCL320mL showed a sharp increase in SSA, thus the highest value is recorded at 32 m2/g. However, an overall decrease was recorded in the following days while a relative increase was measured for the 6th and 7th day. This might be attributed to the biosynthesis mechanism of the pellicle. As expected, similar trends are noticed for the PV measurements. Regarding the PV distribution of the biomaterials is presented in Fig. 3 (up and left). Specifically, the highest SSA and PV of 32 m2/g and 0.19 cm3/g, respectively, indicated that K. sucrofermentans cells were polymerized forming the 2D pellicle synthesis till the 3rd day. Subsequently, the 3D pellicle synthesis was achieved causing a decrease in the aforementioned parameters. As for the two different preparation methods of BC20mL, the BCL720mL exhibited overall higher SSA, PV, and PS values than BCS720mL (Table 3). As mentioned in section "Kinetic evaluation of Glucose, pH, Cell viability, Acidity and Yield during BCL/BCS production by K. sucrofermentans", the initial formation time of BCL (20-22 hours) is less than BCS (50-52 hours), that affect the porosity of the biomaterial, since it seems that enzyme complexes produced by free K. sucrofermentans provides more pores in the earlier produced cellulosic substrate than the enzymes produced by the immobilized bacterium. In summary, BCL seems a primary choice among biomaterials due to its higher porosity for application in the diverse fields of tissue engineering, nanomedicine, and white biotechnology but overall, both BC exhibit similar nanostructure in terms of the pore distribution with more micropores than macro- or mesopores that both may affecting positively in the motility or entrapment of cells, enzymes, and other active agents. both BC exhibit similar nanostructure in terms of the pore distribution with more micropores than macro- or mesopores that both may affect positively in the motility or entrapment of cells, enzymes, and other active agents.

Hydrophilic properties of BC

Highly hydrated BC pellicles are a proper biomaterial for many applications e.g. biomedical applications of BC as a dressing material accelerating the wound healing process, protecting it against contamination, facilitating the penetration of active substances into the wound and the change without damage to the new-formed skin (Shezad et al. 2010; Ul-Islam et al. 2012). Therefore, the evaluation of the effect of the water treatment on the BC microstructure through the determination of its hydrophilic properties such as WHC, MC, WRR and RR was the major aim of the present study.

WHC is highly dependent on the BC microstructural features, especially the textural parameters, such as porosity (SSA, PS and PV), due to the water molecules are captured naturally on the surface of the fibrous BC matrix and escape to the environment through the arrangement of its microfibrils (Shezad et al. 2010; Ul-Islam et al. 2012). Consequently, the WHC values of BC pellicles varied according to the data in Table 1. It is known that, the combination of the larger SSA and the larger PS of a BC pellicle, promotes the higher WHC since if there are many voids between the BC fibrils, then more water can penetrate and adsorb onto the material (Guo and Catchmark 2012; Ul-Islam et al. 2012), which was confirmed by the highest SSA and PS of BCL320mL and BCL420mL among the other BCL pellicles. Following the above confirmation based on our findings, the BCL720mL having a 2-fold higher SSA, a 0.8-fold higher PS and a 0.9-fold higher mass than that of BCL720mL which means that BCL720mL can accumulate more water, increasing the WHC of the pellicle (Table 3). In addition, the water removal, as also WHC from BCL pellicles, depends on the pellicle thickness, diameter and mass (Rebelo et al. 2018). By comparing the two methods of BC production, the water-treated BCL720mL pellicle was generally proved to be a more suitable material about the above applications compare to water-treated BCS720mL yielding a higher WHC (Table 1). As reported in Table 1, the highest WHC value obtained in the BCL420mL (116 g water/g cellulose), while the lowest is in the BCL120mL (19 g water/g cellulose). Additionally, calculating the ratio of WHC/freeze dried mass illustrates a better view of BC's high hydrophilicity: the WHC of BCL720mL and BCS720mL is about 1,600 times their freeze-dried mass, while using WHC/freeze dried mass per day of produced BCL, the following sequence is obtained (x times): 6,062 (BCL320mL) > 4,296 (BCL420mL) > 2,867 (BCL220mL) > 2,184 (BCL520mL) > 2,111 (BCL120mL) > 1,687 (BCL620mL) > 1,679 (BCL720mL).

Regarding to moisture parameter, both BCL and BCS water-treated pellicles exhibited a high MC of 98.8% due to the high hydroscopic nature of BC characterized by inter and intramolecular hydroxyl groups (Torgbo and Sukyai 2020). By using the process of BCL production in different volumes, the MC was high ranged from 95.5 to 99%, while the process of BCs production in different volumes gave a same-level range of 95.1 to 98.7% (Table 2).

In Fig. S4 illustrated the RT-drying effect on the BC which after 96 hours the BCL71000mL retained about 5 g higher water content than those of lower volume (BCL720mL, BCL7100mL and BCL7400mL), while the BCS71000mL retained about 10 g higher water content than BCS720mL, BCS7100mL and BCS7400mL, due to the higher wet mass of BCS71000mL compared to BCL71000mL. The absorbed water completely evaporated at 48 h of RT-drying from the BCL20mL, BCL100mL, BCS20mL and BCS100mL pellicles while the total water was released after 96 h in the case of BCL7400mL and BCS7400mL. The BCL71000mL and BCS71000mL contained a reasonable amount of water at this period, retaining about 6 and 11 g water, respectively. Overall, the total BCS pellicles having a slower WRR than BCL. As mentioned above, the micro-fibrils of BCS720mL are more crowded and denser than BCL20mL (section "Morphological properties of BC") which leads to a smaller PV and PS (section "Nitrogen adsorption – desorption isotherms"). This means that the microstructure of BCS720mL can protect the water molecules more efficiently from evaporation regarding to BCL20mL.

In Fig. S5 are shown the results about the RR property of the water-treated and freeze-dried BCL and BCS pellicles. The RR of BC7 in the different medium volumes followed the downward order BCL71000mL (42 %) > BCL7400mL (38 %) > BCL7100mL (28 %) > BCL720mL (10 %) and BCS71000mL (36 %) > BCS7400mL (35 %) > BCS7100mL (27 %) > BCSL720mL (11 %) during the forty-eight hours rehydration process. Additionally, during the BCL1-720mL pellicles production method, the RR was following the descending order: BCL120mL (81 %) > BCL220mL (24 %) > BCL320mL (20 %) > BCL420mL (16 %) > BCL520mL (13 %) > BCL620mL (11 %) > BCL720mL (10 %). Considering the above results, BC exhibits poor rehydration after freeze-drying, due to the high stability, high crystallinity level or high porosity of the biomaterial (Chang and Chen 2016; González-García et al. 2022), emphasizing the lowest stability, crystallinity index and porosity of BCL120mL.

To determine the sensitivity to water, an important property of packaging, was investigated by means of WSA (Jipa et al. 2012). Thus, in Fig. S6 are resulted the WSA of the BCL and BCS pellicles. The WSA of BC7 in the different medium volumes followed the downward order: BCL7400mL (108 %) > BCL71000mL (94 %) > BCL7100mL (92 %) > BCL720mL (49 %) and BCS71000mL = BCS7400mL (84 %) > BCS7100mL (76%) > BCS720mL (42 %) during the swelling process (48 h). Additionally, during the BCL1-720mL pellicles production method, the WSA was following the descending order: BCL120mL (172 %) > BCL220mL (157 %) > BCL320mL (93 %) > BCL420mL (72 %) > BCL520mL (62 %) > BCL620mL = BCL720mL (49 %). Considering the above results, BC exhibits high shellability in most of the cases. However, to prove adequate barrier properties, if not designed as edible coatings, films must exhibit low swelling ability (Jipa et al. 2012), such as BCL620mL, BCL720mL and BCS720mL produced in lower medium volumes.

Overall, the BCS exhibited lower hydrophilicity since WHC, WRR, RR and WSA were determined in lower ratios than BCL pellicles, whereas MC remained at the same levels. BCS pellicles, however, exhibit a higher WRR than BCL, as BCL has a combination of fine and loose microfibrils (section "Morphological properties of BC") and a higher PV and PS (section "Nitrogen adsorption – desorption isotherms"). It means that the microstructure of BCS can protect the water molecules more efficiently from evaporation regarding to BCL, providing BCS as a more appropriate biomaterials for wound dressings and packaging than BCL. Also, in the paper industry, BCS’s higher water-retention capacity provides new possibilities for papermaking technologies. Notably, both the WHC and WRR are highly dependent on the structural features of BC, especially the pore size and total pore volume. BC with smaller pore sizes can retain water in the matrix for longer times (BCS), but a high pore volume means that BC can accumulate more water, increasing its WHC (BCL). Therefore, the lower swelling ability of BCS compared to BCL, prove its adequate barrier properties, vital for packaging materials.

Crystallinity analysis

In terms of the properties of cellulosic materials, their processing, and their final use, cellulose crystallinity significantly influences their physical, mechanical, and chemical properties. Therefore, for an in-depth characterization of the water-treated BCL1-7 and BCS7 pellicles, their crystal structure of the water-treated BCL1-7 and BCS7 pellicles were investigated by X-ray diffractometry. Cellulose is described as a two-region combination: crystalline (ordered) and amorphous (less ordered) regions, due to its supramolecular structure. In addition, cellulose can be considered as semicrystalline polymer that in its original or ‘‘native” state presents a combination of two allomorphs Iα and Iβ and Iα/Iβ ratio which varies according to the biological source and culture methodology (Trache et al. 2016; Leonarski et al. 2022). The data about Z values, interplanar distances (d-spacing), crystallite size (CS), and crystallinity index (CI) are shown in Table 3.

Fig.e 4 represents a comparison of the BCL1-7 and BCS7 X-ray diffraction patterns after Rietveld refinement with background subtracted (crystallographic parameters after Rietveld refinement for a representative sample are given in table S2). The patterns show the characteristic diffraction profile of cellulose I, including three main peaks at 2θ = 14.3°, 16.7° and 22.5°. The three major reflections for the Iα one-chain triclinic unit cell have diffraction planes of (100), (010) and (110) (which are the counterparts to the (1 \(\overline{1 }\) 0), (110) and (200) peaks of the cellulose Iβ pattern), respectively (Illa et al. 2019; Anwar et al. 2021). Notably, there are small signs of peaks at around 20.0° and 34.1°, referring to the (11 \(\overline{2 }\)) and (11 \(\overline{4 }\)) diffraction planes in Iα and (012) and (004) in Iβ, respectively. The moderate peak at 34.1° is seen to be a composite of several reflections and (11 \(\overline{4 }\)) is not the dominant contributor (French 2014).

The difference between two celluloses (Iα or Iβ) can be identified with the help of the Z values. More analytically, the Z value is a parameter used to discriminate whether BC is enriched in Iα or in Iβ type in which Z >0 means BC is a Iα-rich type (a triclinic structure with all angles of unit cell different than 90o and with the three axes of unequal length) and Z < 0 a Iß-dominant type (a monoclinic structure with two of the unit cell angles equal to 90° and different length of all axes) (Leonarski et al. 2022). According to the results in Table 3, where the value of Z is greater than 0, all BC pellicles (BCL1-7 and BCS7) are Iα-rich type. Likewise, the d-spacing values (interplanar distances refers to the difference in Bragg angle) of peak (\(100\)) and peak (010) in the X-ray diffraction curve could determine the difference between the Iα and Iβ-dominant type, inducing the irreversible crystal transformation from cellulose Iα to cellulose Ιβ accompanying the decrease mostly in d-spacing of peak (100) (Watanabe et al. 1998; Leonarski et al. 2022). Table 3 presents the interplanar space (d-pacing) of all BC pellicles (BCL1-7 and BCS7) between planes in crystallites, reporting close to 0.62, 0.53, and 0.40 nm at 2θ = 14.3, 16.7° and 22.5°, respectively. In previous studies, characterizing BC was produced by Komagataeibacter strains, have reported similar values to above reported (Dubey et al. 2017; Zhou et al. 2023). Notably, during the BCL production method, the d-spacing and Z values remain constant for the most pellicles, except for BCL120mL and BCL520mL which are lower than the others. In the light of all the above, it is confirmed that BCL120mL and BCL520mL pellicles are also enriched in Iα-type cellulose, but they have a lower percentage than the other ones.

The fluctuations in crystallinity are due to the change of intermolecular hydrogen bonds during the preparation of the BCL1-7. Specifically, comparing the two preparations (BCS and BCL), no significant differences were observed for the CI and CS of both the water-treated BC7 samples (CI: 78.1 and 77.3%, CS: 7.65 and7.19 nm, respectively). It seems that water-based treatment as chemical-alkali treatments neither affect the CI of BC pellicles, since it is similar to that reported in previous studies for BC obtained in the same conditions, nor the CS of BC pellicles which is close to that reported in those studies (Castro et al. 2011; Sheykhnazari et al. 2011; Al-Hagar and Abol-Fotouh 2022). In contrast to alkali, water-based treatment avoids the breaking of many hydrogen bonds between molecules (mercerization), maintaining the highest mechanical properties as well as the highest axial elastic modulus of type I cellulose, so it prevents the structure from changing into type II (Vazquez et al. 2013; Bandyopadhyay et al. 2018).

Thermal properties

In the field of biomedicine, thermal stability is a key property enabling the use of BC as a drug-delivery system and as antiseptic dressings for periodontal applications. In addition, higher resistance to thermal decomposition leading to minimization of levoglucosan formation, control of smoke production and combustion toxicity is a key prerequisite in the papermaking industry while the higher thermal stability properties, makes cellulosic biomaterials promising candidates for use in polymer composites (Chen et al. 2011; Campano et al. 2016; Torgbo and Sukyai 2020). Thus, the thermal stability and degradation profile of the water-treated and freeze-dried BCL1-7 and BCS7 were assessed to evaluate potential use of the synthesized material in high-temperature applications such as thermal processing by thermogravimetric/ differential thermogravimetric (TG/DTG) analysis. The activation energy (Ea), the thermal degradation onset temperatures (Ton), maximum thermal degradation temperatures (Td), weight loss (WL) at different temperature range of 3 thermal regions, residual ash amount (RAA) at 800ºC, and temperatures at the half of the weight loss of all BC pellicles are listed in Table 3. The TG and DTG curves are shown in Fig. 5, appearing a same trend of BC thermograms and confirming the 3 literature-known stages of cellulose degradation: (1) the dehydration of cellulose, an endothermic process known as dehydrocellulose, (2) the depolymerization into levoglucosan (1,6-anhydro-β-D-glucopyranose) as an essential intermediate, and (3) the produced dehydrocellulose then results into gaseous products (CO, CO2) and residual char (Mohite and Patil 2014; Pacheco et al. 2017). Notably, the most weight loss (%) and structural change is mostly observed during the above stage (2), where series of degradation reactions occurs between 200-400 ºC (Torgbo and Sukyai 2020). The above stages are more clearly depicted in Fig. S7, where we plotted the thermal analysis separately for each BC pellicle. Concerning the Ea found to increase steadily which can be attributed to degradation of cellulose in stage (2) (George et al. 2008). The determination of the Ea for the most important degradation stage was attempted for BCL1-7 and BCS7, based on literature (Coats and Redfern 1964; Basta 1998; Gao et al. 2003). The results are summarized in Table 3, together with the temperature range used for the determination of Ea. With the exemption of BCL1, similar activation energies were determined for all other BCL, taking values within the range 77-110 kJ/mol (most of them being around 100 kJ/mol). For BCL1, it was not possible to clearly define the limits of each degradation step and, thus, the Ea was determined within the whole temperature range. The Ea for the degradation of this sample is much lower (of the order of 10 kJ/mol), indicating that degradation now is much easier, as also supported by the fact that the degradation of this sample takes place at a much lower temperature range, as compared to the other samples. In addition, BCS7 exhibited much lower Ea compared to BCL7.

The outcomes of the TG analysis plotted in Fig. 5 (up) and showed that the BC pellicles except of BCL1 exhibited almost the same decomposition pattern throughout the scanned temperature range. It is worth noting that all BC pellicles (except BCL1) had initial weak weight loss (about 6-8%) at temperatures below 100 °C and this was attributed to the evaporation of absorbed water onto the cellulose surfaces, whereas the more thermally unstable BCL1 appears an initial weight loss of 13%. Notably, the thermogram of all the BC pellicles reveals the one step decomposition ranged from 256 to 266 °C whereas BCL1 exhibits a two-stages of degradation at 100 and 247 °C. The lower degree of polymerization could probably contribute to the different decomposition temperature of BCL1 (Unger et al. 2010; Mamun et al. 2018). The end of this process is usually BC pyrolysis (Tomé et al. 2010). The DTG analysis, plotted in Fig. 5 (down) and listed in Table 1 as Td, declares that the decay temperature degrees for all the produced BC pellicles ranged from 311.3 to 330.6 ℃, whereas BCL1 exhibits a two-stages of decay at 141.9 and 313.7 °C, confirming that is a less stable pellicle. In addition, the weight loss of approximately 50% (T50%) for all BC pellicles (except BCL1) was reported at 320.2-340.3 °C when T50%=292.1 for BCL1. Data in Table 3 confirm that BCL5 is the most thermally resistant pellicle, exhibiting the maximum residue (RAA) percentage of ~30% as compared to all BCL (RAA < 20%). In addition, the most weight loss (%) of all pellicles, except BCL1, obtained at thermal region II (200-400 ºC).

According to Table 3, BCS7 reveals a residue (RAA) of approximately 32.7% upon heating up to 800 °C under nitrogen when RAA=15.1% for BCL7 due to the different polymerization conditions and the molecular weight gain. The result indicated that the BCS have a higher thermal resistance stability and had good flame retardancy, which is due to its dense network structure comparing to the BCLs as reported earlier in SEM analysis, since the thermal stability of any material is intrinsically dependent of fiber orientation (Chandrasekaran et al. 2017). Also, the hypothesis of its higher thermal stability enhances since the BCS exhibited lower hydrophilicity as reported earlier via hydrophilic properties. Also, it could be verified that the immobilized K. sucrofermentans inoculum (solid method) may have a major impact on the BC structural bonds responsible for fastening the cellulosic nano-, and microfibrils to each other, keeping them tightly attached to grant the BC better mechanical properties than the free bacteria inoculum (liquid method). Considering the above, BCS appear to be more suitable candidates for polymer composites regarding papermaking, drug-delivery, and antiseptic dressings compared to BCL.

Fourier Transform Infrared Spectroscopy (FT-IR)

FT-IR spectroscopy is an important technic to determine the functional groups and nature of chemical bonds in a molecule (Ul-Islam et al. 2013). The FT-IR spectra of the water-treated BCL1-720mL during production are shown in Fig. 6. During production of BCL, the first observation of these pellicles showed similar FT-IR profiles. The absorption bands are observed in two areas at of 3660-2800 cm−1 and 1650-400 cm−1. To be more specific, the characteristic broad absorption band centered at 3404 cm−1 is due to stretching of O-H groups in polysaccharides. Additionally, this peak includes inter- and intra-molecular hydrogen bond vibrations in cellulose (Popescu et al. 2011; Hospodarova et al. 2018). However, it should be noted that has been mentioned that absorption in this area could be due to contamination by biological impurities present in bacterial cellulose (N-H stretching vibration of amide groups) (George et al. 2008). The absorption at 2922 cm−1 is related to C-H groups, in agreement with previous observations (Jahan et al. 2011; Trovatti et al. 2011; Ul-Islam et al. 2013; Du et al. 2018; Barshan et al. 2019). The absorption at 1645 cm−1 is indicative of absorbed water (BC is being hydrophilic in nature). Based on other studies, this band is related to the bending modes of water molecules due to a strong interaction between cellulose and water (Günister et al. 2007; Rosa et al. 2012; Johar et al. 2012).

The presence of the band at 1546 cm−1 at water-treated pellicles compared to alkali-treated pellicles, corresponded to the amide bond and are associated with proteins and residual biomass that are biological impurities likely originated from the bacteria or compounds in the culture medium that may have remained attached to the cellulose layers (George et al. 2008). In our previous study, this band appeared in the water-treated BCS (without chemical treatment) and was used successfully for the BC-cell-factory preparation, which was used for the consolidated bioprocessing of starch to ethanol (Drosos et al. 2021). The appearance of a several peaks at 1450-1300 cm-1 was further supported the presence of the CH (stretching and bending vibrations of CH group of glucose units). The bands at 1426, 1376, 1337 and 1317 cm-1 are attributed to CH2, in-plane CH deformation, in-plane OH bending and CH2 wagging, respectively (Marchessault and Sundararajan 1983; de Menezes et al. 2009; Poletto et al. 2011; Vieira et al. 2012). The absorptions at 1161, 1111, 1060 and 1034 cm−1 are associated with the asymmetric stretching vibration of glycosidic C-O-C of pyranose rings (Marchessault and Sundararajan 1983), the anhydro-glucose ring (Gomes et al. 2013), C-OR stretching (de Menezes et al. 2009; Poletto et al. 2011; Ul-Islam et al. 2011), C-O-C pyranose ring skeletal vibration (de Menezes et al. 2009; Poletto et al. 2011; Ul-Islam et al. 2011), respectively. In addition, the peak at 899 cm−1 is associated to C1-H rock vibration (anomeric vibration that is specific for β-1,4-glycosidic linkages between glucopyranose units) (Li et al. 2009; Fahma et al. 2010). The fingerprint peaks of BCL1-7 pellicles can confirm the structure such as that of cellulose, the curve of peaks may vary, depending on the origin of cellulose.

The combined spectra of BCS (Drosos et al. 2021) and BCL along with the respective peak position assignments of them are shown in Fig. 6. The FT-IR spectra of the water-treated BCL and BCS pellicles contained similar peaks, thereby confirming the basic structure of pure cellulose. As you may observe, the spectra show the same structural characteristics. This suggests a preliminary qualitative analysis where the BCL and BCS pellicles are similar in terms of composition.

Comparison of BC formed by different cellulose-producing bacterial strains

A comparison of BC formed by different cellulose-producing bacterial strains in HS-glucose media without additives as reported in related studies, represented in Table 4. Based on the results in this study, K. sucrofermentans appears to be superior to other cellulose-producing bacteria with a yield in range 3.8-4.7g/L compared to others (2-4 g/L). The highest yield of produced cellulose was observed at 4.7 g/L in the case of BCL, while in case of BCS reached out 3.8 g/L, exhibiting, also, a high value based on literature. According to Table 4, the crystallinity was 77% for BCL and 78% for BCS, in agreement with the average crystallinity value (79%) for other bacterial celluloses. Specific surface areas (SSA) were in range of 3-60 m2/g, BCL’s SSA ranked in the middle (26 m2/g), while BCL’s (13 m2/g) at the bottom. In addition, the pore sizes of these BC pellicles (BCL: 18 nm and BCS: 14 nm) are quite satisfactory and close to the highest values based on the values (4-22 nm) in Table 4. The residual weights at 600 ºC comparatively with other literature BC's (1-35%), was found that BCS’s was the most thermally resistant (35%), and in the middle level ranked the BCL’s (21%). Regarding the purification of BC's, comparing with alkali- and water-treatment, in the case of water-treatment did not appear to negatively affect the physicochemical structure of BC, providing a significant aspect for a sustainable and chem-free alternative treatment.

Conclusions

A part of the remaining bacterial liquid from the preculture production at 4th day was added in HS medium as liquid inoculum for the preparation of BCL1-7 statically at 30ºC for 1 to 7 days. BCS7 was produced by the preculture pellicle of the 4th day which was used as a solid inoculum. Purification of all BC was achieved by treatment with hot water. A simple, chem-free, and environmentally friendly method was verified by the surface and cross SEM images of the pellicles. BCS7 and BCL7 presented similarities and differences regarding several structural and physicochemical properties, but BCL7 was proved to be superior to BCS7 regarding the degree of purification, BC yield, overall higher porosity, and higher hydrophilicity based on the water holding capacity (WHC) and water swell ability. On the other hand, BCS7 prevailed in terms of water retention rate and flame retardancy. Based on the BCL kinetics over 7 days, was observed the formation of 2D pellicle till the 3rd day and then 3D was achieved. Regarding the WHC, the highest level was obtained on day 4, and the lowest on day 1.

To sum up, we discussed the preparation and characterization of two different BCs water-treated for purification as an eco-friendly method. The results of this alternative method can be used for different applications (Ullah et al. 2016; Cazón and Vázquez 2021; Choi et al. 2022; Hasanin 2022) towards future perspectives that are functional and sustainable.

Data availability

All data generated or analyzed in this study are included in this published article.

References

Al-Hagar OEA, Abol-Fotouh D (2022) A turning point in the bacterial nanocellulose production employing low doses of gamma radiation. Sci Rep 12:1–14. https://doi.org/10.1038/s41598-022-11010-4

Almeida T, Silvestre AJD, Vilela C, Freire CSR (2021) Bacterial Nanocellulose toward Green Cosmetics : Recent Progresses andChallenges. Int J Mol Sci 22:2836. https://doi.org/10.3390/ijms22062836

Alonso E, Faria M, Mohammadkazemi F et al (2018) Conductive bacterial cellulose-polyaniline blends: Influence of the matrix and synthesis conditions. Carbohydr Polym 183:254–262. https://doi.org/10.1016/j.carbpol.2017.12.025

Al-ShamaryDarwash EEAKA (2013) Influence of Fermentation Condition and Alkali Treatment on the Porosity and Thickness of Bacterial Cellulose Membranes. Online J Sci Technol 3:194–203

Anwar B, Bundjali B, Sunarya Y, Arcana IM (2021) Properties of Bacterial Cellulose and Its Nanocrystalline Obtained from Pineapple Peel Waste Juice. Fibers Polym 22:1228–1236. https://doi.org/10.1007/s12221-021-0765-8

Ashrafi Z, Lucia L, Krause W (2019) Bioengineering tunable porosity in bacterial nanocellulose matrices. Soft Matter 15:9359–9367. https://doi.org/10.1039/c9sm01895f

Avcioglu NH (2023) Eco-friendly Production of Bacterial Cellulose with Komagataeibacter intermedius Strain by Using Jasminum sambac and Camellia sinensis Plants. J Polym Environ. https://doi.org/10.1007/s10924-023-03081-9

Bandyopadhyay S, Saha N, Saha P (2018) Characterization of Bacterial Cellulose Produced using Media Containing Waste Apple Juice. Appl Biochem Microbiol 54:649–657. https://doi.org/10.1134/S0003683818060042

Barshan S, Rezazadeh-Bari M, Almasi H, Amiri S (2019) Optimization and characterization of bacterial cellulose produced by Komagatacibacter xylinus PTCC 1734 using vinasse as a cheap cultivation medium. Int J Biol Macromol 136:1188–1195. https://doi.org/10.1016/j.ijbiomac.2019.06.192

Basta AH (1998) Preparation, characterization and properties of paper sheets made from chemically modified wood pulp treated with metal salts. Int J Polym Mater Polym Biomater 42:1–26. https://doi.org/10.1080/00914039808041056

Bayazidi P, Almasi H, Asl AK (2018) Immobilization of lysozyme on bacterial cellulose nanofibers: Characteristics, antimicrobial activity and morphological properties. Int J Biol Macromol 107:2544–2551. https://doi.org/10.1016/j.ijbiomac.2017.10.137

Bodily HL (1956) Official Methods of Analysis of the Association of Official Agricultural Chemists. Am J Public Heal. Nations Heal. 46:916–916

Bolton D, Bover-cid S, Koutsoumanis K et al (2019) Update of the list of QPS-recommended biological agents intentionally added to food or feed as noti fi ed to EFSA 9 : suitability of taxonomic units noti fi ed to EFSA until September 2018. 17:1–46. https://doi.org/10.2903/j.efsa.2019.5555

Bourdichon F, Casaregola S, Farrokh C et al (2012) International Journal of Food Microbiology Food fermentations: Microorganisms with technological bene fi cial use. Int J Food Microbiol 154:87–97. https://doi.org/10.1016/j.ijfoodmicro.2011.12.030

Brugnoli M, Robotti F, La China S et al (2021) Assessing effectiveness of Komagataeibacter strains for producing surface-microstructured cellulose via guided assembly-based biolithography. Sci Rep 11:1–8. https://doi.org/10.1038/s41598-021-98705-2

Cai Z, Kim J (2010) Bacterial cellulose/poly(ethylene glycol) composite: Characterization and first evaluation of biocompatibility. Cellulose 17:83–91. https://doi.org/10.1007/s10570-009-9362-5

Campano C, Balea A, Blanco A, Negro C (2016) Enhancement of the fermentation process and properties of bacterial cellulose: a review. Cellulose 23:57–91. https://doi.org/10.1007/s10570-015-0802-0

Carvalho T, Guedes G, Sousa FL et al (2019) Latest Advances on Bacterial Cellulose-Based Materials for Wound Healing, Delivery Systems, and Tissue Engineering. Biotechnol J 14. https://doi.org/10.1002/biot.201900059

Castro C, Zuluaga R, Putaux JL et al (2011) Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr Polym 84:96–102. https://doi.org/10.1016/j.carbpol.2010.10.072