Abstract

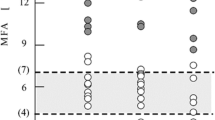

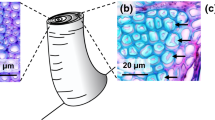

Many woody eudicot plants form a secondary xylem composed of gelatinous fibers (G-fibers) called "tension wood" (TW) along the upper side of the tilted stem or branch. TW generates a large tensile growth stress in the longitudinal direction, allowing the tilted stem or a branch to develop negative-gravitropism in response to the strong gravitational stimulus. This is because the G-fiber tends to contract in the longitudinal direction as it matures. The matured G-fiber also contracts upon boiling in water (= hygrothermal treatment, i.e., HT-treatment), and moisture desorption (= drying treatment). These contractions occur in the cellulose-rich gelatinous layer (G-layer) as an innermost layer of the G-fiber. It is still an unsolved mystery how the G-layer, which is composed of highly crystallized and longitudinally oriented cellulose microfibrils (CMFs), contracts during maturation, boiling, and drying. In the present study, TW specimen of Konara oak (Quercus serrata L.) was subjected to HT-treatment under different temperature and time conditions, and strain due to treatment was followed. Besides, the mass loss due to HT-treatment was also followed. Obtained results are summarized as follows. (1) Green TW specimen of Konara oak contracted in the longitudinal direction when subjected to the HT-treatment at a treatment temperature higher than 40 °C, which eventually converged to a constant value according to each treatment temperature. Magnitude of the longitudinal HTR-strain in the TW specimen was positively correlated with the treatment temperature in the range from 40 to 120 °C, whereas in the normal wood (NW) specimen, it does not occur explicitly when the temperature is less than 100 °C. (2) Both TW and NW specimens showed mass loss when subjected to the HT-treatment. The mass loss rate increased rapidly by the HT-treatment at 120 °C, while it was only slight below 100 °C. There was no significant difference between the mass loss behavior of TW and NW by the HT-treatment. From analyzing those results, physical behavior of CMF and other non-cellulosic matrix components in the G-layer during the HT-treatment was estimated. The discussion was further developed to associate HT-contraction with microscopic mechanisms of the other two characteristic contractions of the G-fiber, i.e., maturation strain and drying shrinkage.

Graphical abstract

Similar content being viewed by others

Abbreviations

- TW:

-

Tension wood

- NW:

-

Normal wood

- OW:

-

Opposite wood

- LW:

-

Lateral wood

- G-fiber:

-

Gelatinous fiber

- N-fiber:

-

Normal fiber

- G-layer:

-

Gelatinous layer

- L-layer:

-

Lignified layer

- CMF:

-

Cellulose microfibril

- MFA:

-

Microfibril angle

- HTR:

-

Hygrothermal recovery

- HTR-strain:

-

Hygrothermal recovery strain

- HT-treatment:

-

Hygrothermal treatment

- HTR-behavior:

-

Hygrothermal recovery behavior

- XRD:

-

X-ray diffraction

- WAXS:

-

Wide angle X-ray scattering

- FWHM β :

-

Full width at half maximum of central peak in β-profile

- FWHM 200 :

-

Full width at half maximum of 200 peak in WAXS-profile

- O.I.:

-

Orientation index of CMF in the secondary wall of wood fiber, equivalent to FWHMβ in β-profile

- C.I. :

-

Crystallinity index of CMF in the secondary wall of wood fiber, calculated by Eq. 3

- WSC :

-

Width of single crystallite of cellulose, calculated by Eq. 4

References

Abe K, Yamamoto H (2007) The influence of boiling and drying treatments on the behaviors of tension wood with gelatinous layers in Zelkova serrata. J Wood Sci 53:5–10

Agarwal UP, Ralph SA, Baez C, Reiner RS, Verrill SP (2017) Effect of sample moisture content on XRD-estimated cellulose crystallinity index and crystallite size. Cellulose 24:1971–1984

Alméras T, Clair B (2016) Critical review on the mechanisms of maturation stress generation in trees. J R Soc Interface 13: Article number 20160550

Araki N, Fujita M, Saiki H, Harada H (1982) Transition of the fiber wall structure from normal wood to tension wood in Robinia pseudoacacia L. and Populus euramericana Guinier. Mokuzai Gakkaishi 28:267–273

Baba K, Parka YW, Kaku T, Kaida R, Takeuchi M, Yoshida M, Hosoo Y, Ojio Y, Okuyama T, Taniguchi T, Ohmiya Y, Kondo T, Shani Z, Shoseyov O, Awano T, Serada S, Norioka N, Norioka S, Hayashi T (2009) Xyloglucan for generating tensile stress to bend tree stem. Mol Plant 2:893–903

Bowling AJ, Vaughn KC (2008) Immunocytochemical characterization of tension wood: gelatinous fibers contain more than just cellulose. Am J Bot 95:655–663

Capron M, Bardet S, Sujan KC, Matsuo UM, Yamamoto H (2018) Viscoelastic modelling of wood in the process of formation to clarify the hygrothermal recovery behavior of tension wood. J Mater Sci 53:1487–1496

Cave ID (1966) Theory of X-ray measurement of microfibril angle. For Prod J 16:37–42

Chen S, Matsuo-Ueda M, Yoshida M, Yamamoto H (2021) Hygrothermal recovery behavior of cellulose-rich gelatinous layer in tension wood studied by viscoelastic vibration measurement. Cellulose 28:5793–5805

Clair B (2012) Evidence that release of internal stress contributes to drying strains of wood. Holzforschung 66:349–353

Clair B, Thibaut B (2001) Shrinkage of the gelatinous layer of poplar and beech tension wood. IAWA J 22:121–131

Clair B, Ruelle J, Thibaut B (2003) Relationship between growth stress, mechanical-physical properties and proportion of fibre with gelatinous layer in chestnut (Castanea Sativa Mill.). Holzforshung 57:189–195

Clair B, Gril J, Di Renzo F, Yamamoto H, Quignard F (2008) Characterization of a gel in the cell wall to elucidate the paradoxical shrinkage of tension wood. Biomacromol 9:494–498

Conley K, Whitehead MA, van de Ven TGM (2017) Probing the structural chirality of crystalline cellulose with induced circular dichroism. Cellulose 24:479–486

Cȏté WA Jr, Day AC (1962) The G-layer in gelatinous fibers - electron microscopic studies. For Prod J 17:333–339

Fang L, Catchmark JM (2014) Structure characterization of native cellulose during dehydration and rehydration. Cellulose 21:3951–3963

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, and reactions. De Gruyter, Berlin

Fernandes AN, Thomas LH, Altaner CM, Callowd P, Forsythd VT, Apperley DC, Kennedy CJ, Jarvish MC (2011) Nanostructure of cellulose microfibrils in spruce wood. PNAS 108:E1195–E1203

Fourcaud T, Lac P (2003) Numerical modelling of shape regulation and growth stresses in trees I. An incremental static finite element formulation. Trees 17:23–30

Garrote G, Dominguez H, Parajo JC (2001) Study on the deacetylation of hemicelluloses during the hydrothermal processing of Eucalyptus wood. Holz Roh Werkst 59:53–59

Goring DAI (1963) Thermal softening of lignin, hemicellulose and cellulose. Pulp Paper Mag Can 64:T517-527

Gorshkova T, Mokshina N, Chernova T, Ibragimova N, Salnikov V, Mikshina P, Tryfona T, Banasiak A, Immerzeel P, Dupree P, Mellerowicz EJ (2015) Aspen tension wood fibers contain beta-(1→4)- galactans and acidic arabinogalactans retained by cellulose microfibrils in gelatinous walls. Plant Physiol 169:2048–2063

Goswami L, Dunlop JWC, Jungnikl K, Eder M, Gierlinger N, Coutand C, Jeronimidis G, Fratzl P, Burgert I (2009) Stress generation in the tension wood of poplar is based on the lateral swelling power of the G-layer. Plant J 56:531–538

Gril J, Berrada E, Thibaut B (1993) Recouvrance hygrothermique du bois vert II. Variations dans le plan transverse chez le Châtaignier et l’Epicéa et modélisation de la fissuration à coeur induite par l’étuvage (in French with English summary). Ann Sci for 50:487–508

Gril J, Thibaut B (1994) Tree mechanics and wood mechanics. Relating hygrothermal recovery of green wood to the maturation process. Ann Sci for 51:329–338

Gril J, Bardet S, Julien D, Yamamoto H (2017) Tree growth stress and its problems. J Wood Sci 63:411–432

Guedes FTP, Laurans F, Quemener B, Asso C, Lainé-Prade V, Boizot N, Vigouroux J, Lesage-Descauses MC, Jean-Charles Leplé JC, Déjardin A, Pilate G (2017) Non-cellulosic polysaccharide distribution during G-layer formation in poplar tension wood fibers: abundance of rhamnogalacturonan I and arabinogalactan proteins but no evidence of xyloglucan. Planta 246:857–878

Joseleau JP, Imai T, Kuroda K, Ruel K (2004) Detection in situ and characterization of lignin in the G-layer of tension wood fibres of Populus deltoides. Planta 219:338–345

Kang KY, Bradic S, Avramidis S, Mansfield SD (2007) Kiln-drying lumber quality of hybrid poplar clones. Holzforschung 61:65–73

Kim DY, Nishiyama Y, Wada M, Kuga S, Okano T (2001) Thermal decomposition of cellulose crystallites in wood. Holzforschung 55:521–524

Kim YS, Wi SG, Grunwald C, Schmitt U (2002) Immuno electron microscopic localization of peroxidases in the differentiating xylem of Populus spp. Holzforschung 56:355–359

Klement I, Vilkovská T, Uhrín M, Barański J, Konopka A (2019) Impact of high temperature drying process on beech wood containing tension wood. Open Eng 9:428–433

Kübler H (1959) Studien über wachstumsspannungen des holzes III. Längenänderungen bei der wärmebehandlung frischen holzes (in German). Holz Roh Werkst 17:77–86

Kübler H, Chen T (1974) How to cut tree disks without formation of checks. For Prod J 24:57–59

Leppanen K, Bjurhager I, Peura M, Kallonen A, Suuronen JP, Penttila P, Love J, Fagerstedt K, Serimaa R (2011) X-ray scattering and microtomography study on the structural changes of never-dried silver birch, European aspen and hybrid aspen during drying. Holzforschung 65:865–873

Matsuo MU, Niimi G, Sujan KC, Yoshida M, Yamamoto H (2016) Hygrothermal recovery of compression wood in relation to elastic growth stress and its physicochemical characteristics. J Mater Sci 51:7956–7965

Mellerowicz EJ, Gorshkova TA (2012) Tensional stress generation in gelatinous fibres: a review and possible mechanism based on cell wall structure and composition. J Exp Bot 63:551–565

Mellerowicz EJ, Immerzeer P, Hayashi T (2008) Xyloglucan: the molecular muscle of trees. Ann Bot 102:659–665

Meylan BA (1967) Measurement of microfibril angle by X-ray diffraction. For Prod J 17:51–58

Müller M, Burghammer M, Sugiyama J (2006) Direct investigation of the structural properties of tension wood cellulose microfibrils using microbeam X-ray fibre diffraction. Holzforschung 60:474–479

Nishikubo N, Awano T, Banasiak A, Bourquin V, Ibatullin F, Funada R, Brumer H, Teeri TT, Hayashi T, Sundberg B, Mellerowicz EJ (2007) Xyloglucan endo-transglycosylase (XET) functions in gelatinous layers of tension wood fibers in poplar—a glimpse into the mechanism of the balancing cct of trees. Plant Cell Physiol 48:843–855

Okuyama T, Sasaki Y, Kikata Y, Kawai N (1981) The seasonal change in growth stress in the tree trunk. Mokuzai Gakkaishi 27:351–355

Okuyama T, Yamamoto H, Iguchi M, Yoshida M (1990) Generation process of growth stresses in cell walls. II. Growth stress in tension wood. Mokuzai Gakkaishi 36:797–803

Okuyama T, Yamamoto H, Yoshida M, Hattori Y, Archer RR (1994) Growth stresses in tension wood. Role of microfibrils and lignification. Ann Sci for 51:291–300

Okuyama T, Doldan J, Yamamoto H, Ona T (2004) Heart splitting at crosscutting of Eucalyptus grandis logs. J Wood Sci 50:1–6

Olsson AM, Salmen L (2004) The softening behavior of hemicelluloses related to moisture. Hemicelluloses: science and technology, vol 864. Am Chem Soc, Washington, pp 184–197

Onaka F (1949) Studies on compression and tension wood (in Japanese). Wood Res (Bul Wood Res Inst Kyoto Univ) 1:1–88

Paavilainen S, Tomasz R, Vattulainen I (2011) Analysis of twisting of cellulose nanofibrils in atomistic molecular dynamics simulations. J Phys Chem 115:3747–3755

Placet V, Passard J, Perre P (2007) Viscoelastic properties of green wood across the grain measured by harmonic tests in the range 0–95°C: hardwood vs. softwood and normal wood vs. reaction wood. Holzforschung 61:548–557

Sandquist D, Filonova L, von Schantz L, Ohlin M, Daniel J (2010) Microdistribution of xyloglucan in differentiating poplar cells. BioResources 5:796–807

Sasaki Y, Okuyama T (1983) Residual stress and dimensional change on heating green wood. Mokuzai Gakkaishi 29:302–307

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sujan KC, Yamamoto H, Matsuo M, Yoshida M, Naito K, Shirai T (2015) Continuum contraction of tension wood fiber induced by repetitive hygrothermal treatment. Wood Sci Technol 49:1157–1169

Sujan KC, Yamamoto H, Matsuo M, Yoshida M, Naito K, Suzuki Y, Yamashita N, Yamaji FM (2016) Is hygrothermal recovery of tension wood temperature-dependent? Wood Sci Technol 50:759–772

Sujan KC, Yamamoto H, Matsuo-Ueda M, Yoshida M, Asaka K (2018) Delayed recovery of growth stress in tension wood induced by drying and subsequent wetting treatment. Wood Sci Technol 52:1049–1060

Tanaka M, Yamamoto H, Kojima M, Yoshida M, Matsuo M, Lahjie AM, Hongo I, Arizono T (2014) The interrelation between microfibril angle (MFA) and hygrothermal recovery in compression wood and normal wood of Sugi and Agathis. Holzforschung 68:823–830

Tarmian A, Sepeher A, Rahimi S (2009) Drying stress and strain in tension wood: a conventional kiln schedule to efficiently dry mixed tension/normal wood boards in poplar. Drying Technol 27:1033–1040

Toba K, Yamamoto H, Yoshida M (2013) Crystallization of cellulose microfibrils in wood cell wall by repeated dry-and-wet treatment, using X-ray diffraction technique. Cellulose 20:633–643

Tejada A, Okuyama T, Yamamoto H, Yoshida M, Imai T, Ito T (1998) Studies on the softening point of wood powder as a basis for understanding the release of residual growth stresses in logs. For Prod J 48:84–90

Vilkovská T, Klement I, Čunderlík I (2019) Longitudinal contraction of reaction and opposite wood during drying process. Wood Res 64:903–912

Wada M, Okano T, Sugiyama J, Horii F (1995) Characterization of tension and normally lignified wood cellulose in Populus maximowiczii. Cellulose 2:223–233

Wardrop AB, Dadswell HE (1955) The nature of reaction wood IV: variations in cell wall organization of tension wood fibers. Austral J Bot 3:177–189

Willhammar T, Daicho K, Johnstone DN, Kobayashi K, Liu Y, Midgley PA, Bergström L, Saito T (2021) Local crystallinity in twisted cellulose nanofibers. ACS Nano 15:2730–2737

Wu X, Moon RJ, Martini A (2014) Tensile strength of Iβ crystalline cellulose predicted by molecular dynamics simulation. Cellulose 21:2233–2245

Yamamoto H, Okuyama T, Iguchi M (1989) Measurement of growth stresses on the surface of a leaning stem (in Japanese, with English summary). Mokuzai Gakkaishi 35:595–601

Yamamoto H, Okuyama T, Sugiyama K, Yoshida M (1992) Generation process of growth stresses in cell walls. IV. Action of the cellulose microfibril upon the generation of the tensile stresses. Mokuzai Gakkaishi 38:107–113

Yamamoto H, Okuyama T, Yoshida M (1993a) Generation process of growth stresses in cell walls. V. Model of tensile stress generation in gelatinous fibers. Mokuzai Gakkaishi 39:118–125

Yamamoto H, Okuyama T, Yoshida M (1993b) Method of determining the mean microfibril angle of wood over wide range by the improved Cave’s method. Mokuzai Gakkaishi 39:375–381

Yamamoto H, Yoshida M, Okuyama T (2002) Growth stress controls negative gravitropism in woody plant stems. Planta 216:280–292

Yamamoto H, Abe K, Arakawa Y, Okuyama T, Gril J (2005) Role of the gelatinous layer (G-layer) on the origin of the physical properties of the tension wood of Acer sieboldianum. J Wood Sci 51:222–233

Yamamoto H, Ruelle J, Arakawa Y, Yoshida M, Clair B, Gril J (2010) Origin of characteristic properties of gelatinous layer in tension wood from Kunugi Oak (Quercus acctissima). Wood Sci Technol 44:149–163

Yokota T, Tarkow H (1962) Changes in dimension on heating green wood. For Prod J 12:43–45

Yoshida M, Okuyama T (2002) Techniques for measuring growth stress on the xylem surface using strain and dial gauges. Holzforschung 56:461–467

Acknowledgments

We thank Mr. Naoki Takabe and Mr. Norio Yamaguchi of the Nagoya University Experimental Forest (Inabu-cho, Toyota-City, Aichi-Prefecture, Japan) for their technical cooperation in selecting and sampling the material trees. We would also like to thank the Isotope Research Center of Nagoya University (Chikusa-ku, Nagoya, Japan) for their cooperation in the XRD measurements.

Funding

This work was financially supported by the Graduate Program of Transformative Chem-Bio Research (GTR), Nagoya University (Chikusa-ku, Nagoya, Japan).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamamoto, H., Sujan, K.C., Matsuo-Ueda, M. et al. Microscopic mechanism of contraction of tension wood G-fiber due to boiling. Cellulose 29, 7935–7954 (2022). https://doi.org/10.1007/s10570-022-04742-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04742-z