Abstract

Cotton is one of the most important cellulose fibers, but the absence of antimicrobial capacity along with the self-cleaning, UV protection and electric conductivity often frustrates its wider applications in many fields. Nanotechnology has provided new insights into the development of functional nanomaterials with unique chemical and physical properties. Silver has been effectively incorporated into the cotton fabrics as the antimicrobial agents due to the strong inhibitory and antimicrobial effects on a broad spectrum of bacteria, fungi and virus with low toxicity to human being. In this review, a variety of strategies have been summarized to load silver on cotton fabrics in situ or ex situ and to fabricate high performance value-added cotton fabrics with self-cleaning, UV protection, electric conductivity and antimicrobial capability depending on the synthesis of silver coating or silver-based nanocomposite coating.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cellulose, consisted by thousands of glucose units, is the most abundant natural polysaccharide. As one of the most important cellulose fibers, cotton is widely used as sportswear, healthcare and medical textiles due to its excellent properties including biodegradability, hygroscopicity, flexibility, breathability, good skin affinity and low cost. However it is easily wrinkled and soiled with other characteristics such as low strength and UV-protective capability. More importantly, cotton is a favorable media for microbial growth under certain humidity and temperature, causing discoloration, mechanical strength loss, foul odor and even negative health effects to human body. Modification of cotton fabrics with antimicrobial agents has become a popular way to produce high performance value-added textiles (Nadi et al. 2018; Morais et al. 2016).

Organic antibacterial agents, such as quaternary ammonium salts and N-halamines (Liu et al. 2013), polypyrrole (Varesano et al. 2009), tetramethylcyclosiloxyl-piperazin tetra guanidine (Wei et al. 2019), ketoconazole (Hedayati et al. 2020) and phenolic compounds (Hong 2015), have been used to modify cotton fabrics through a pad-dry-cure process. The modified cotton possessed high sterilization ability and good color fastness, however some antimicrobial agents showed poor heat and hydrolysis resistance. Antimicrobial peptide is a novel antimicrobial agent with higher specific activity and good biocompatibility. Incorporating these peptides into polyelectrolyte multilayer coating provided the decorated gauzes with strong antimicrobial activity for both S. aureus and K. pneumonia (Gomes et al. 2015). Antimicrobial peptides were immobilized on alkyl ketene dimer-modified cellulose nanofibers via a immersion process, producing an antimicrobial surface against B. subtilis (Gonzalez et al. 2017). This physical method would avoid the structural destruction of the peptides to protect their antimicrobial activity, but the weak binding strength often leads to their rapid release, which is a main concern for fabricating durable antimicrobial cotton fabrics. High cost of the antimicrobial peptides would limit their use to medical applications either.

Recent advances in nanotechnology have provided new insights into antimicrobial agents, and led to the development of functional nanomaterials with unique chemical and physical properties. Antimicrobial nanoparticles (NPs) have been effectively incorporated into the fabrics (Zhang et al. 2016; Shahid-ul-Islam et al. 2016; Emam 2019), among which silver (Ag) has attracted great attention because of its low toxicity and surface plasmon resonance features along with the strong inhibitory and antimicrobial effects on a broad spectrum of bacteria (Liao et al. 2019; Burduşel et al. 2018). Ag, AgX (X = Cl or Br) or Ag/Cu nanocomposite coated fabric have been reported to present good antifungal properties against C. albicans or Aspergillus niger (Ilic et al. 2009a, b; Rehan et al. 2018; Paszkiewicz et al. 2016; Klemencic et al. 2014). In 2020, Coronavirus disease 2019 spread quickly around the world and has been infecting tens of millions of people. As therapeutic antiviral agents, Ag or Ag-based nanocomposites fight the drug-resistant types of virus, and their potential interaction with virus (e.g. coronavirus) has been summarized by Han D et al. (2020). Ag NPs possessed inhibiting effect on influenza A virus H1N1 (Miao and Zheng 2010), and their nanocomposites with chitosan exhibited antiviral activity against H1N1 either (Mori et al. 2013). Ag NPs presented the lethal concentration 50 and 90 of 34.88 and 64.56 mg/ml, respectively against fourth instar mosquito larvae of the Zika virus vector Aedes aegypti (Ishwarya et al. 2017). Ag2O/AgO NPs indicated a reduction rate of 49.23% in cytopathic effect against Herpes Simplex virus (El-Sheekh et al. 2020). Ag/chitin sheets showed much stronger antimicrobial properties against influenza A virus, and the antiviral capability enhanced with the increase in Ag NPs content (Nguyen et al. 2014). Yacaman MJ et al. have demonstrated that Ag NPs undergo a size-dependent interaction with HIV-1, for nanoparticles exclusively in the range of 1 ~ 10 nm attached to the virus. Ag NPs interacted with the HIV-1 virus via preferential binding to the gp120 glycoprotein knobs, thus inhibiting the virus from binding to host cells (Elechiguerra et al. 2005). More studies have been focused on the antimicrobial capability of Ag or Ag-based nanocomposites, and the number will increase dramatically with the urgent demand on antimicrobial medical supplies.

It is postulated that the antimicrobial activity is derived from the adhesion to the microbial cells and experiences a series events: alters the structure and function of microbial membrane, generates reactive oxygen species and free-radicals, and inactivates the essential proteins and genes. The microbial signal-transduction pathways are finally changed by the microorganisms. Generally, the antimicrobial activity of AgNPs was mainly influenced by their morphology, size, surface charge, concentration and colloidal states (Akter et al. 2018; Durán et al. 2016). Cotton should immobilize more antimicrobial agents to ensure bactericidal effect throughout the life of the fabrics, however, large quantities of the leached silver may exert serious risk to the environment. Acquisition of an ideal antimicrobial durability with a small loading of silver and a minor damage to the bulk properties of fabrics is a substantial challenge.

High performance value-added fabrics have been designed to endow multi-functionalities to cotton fabrics including self-cleaning, UV protection, electric conductivity, and antimicrobial capability as well. Self-cleaning feature has two meanings: superhydrophobic property and photo superhydrophilic property. The former route is to fabricate superhydrophobic surfaces to repel water so that spherical water droplets can clean dirt particles by an easy roll-off mechanism; the latter focuses on photocatalytic degradation of dyes. A sequential deposition of branched poly(ethylenimine), Ag NPs and fluorinated decylpolyhedral oligomeric silsesquioxane (F-POSS) was applied on cotton fabrics to obtain antibacterial and superhydrophobic surface with a water contact angle of ~169° and a sliding angle of ~3°. The superhydrophobic coating prevented AgNPs leaching during laundry because water cannot seep through the coating, while F-POSS allowed the release of Ag+ (Wu et al. 2016). Ag NPs decorating cotton are sensitive to light, but their low quantum yields due to the high rate of the electron-hole recombination and low visible-light activity hinder the practical application for self-cleaning fabrics. Ag NPs coating possessed UV protective properties due to absorption and reflection of UV radiation (Rehan et al. 2015). Ag deposition on cotton fabrics endows a conductive and high electromagnetic interference (EMI) shielding coating. Ag coated carbon fabric with a compact and continuous layer via an electroless plating method using glucose as a reducing reagent presented a volume resistivity of 8.99 × 10−4 Ω.cm (Chen et al. 2017). Ag-based nanocomposites with ZnO, TiO2 and reduced graphene oxides have shown great promise to fabricate high performance value-added fabrics with enhanced self-cleaning, UV protection, electric conductivity and antimicrobial capability.

In this work, a variety of strategies have been reported to immobilize Ag on cotton to fabricate antimicrobial fabrics in situ or ex situ, depending on whether the nanoparticles are synthesized and deposited simultaneously on the fabric or not. Factors that influence the loading efficiency of nanoparticles and their binding fastness with textiles were discussed in order to achieve durable antimicrobial cotton fabrics without sacrifice the bulk properties. High performance value-added fabrics with other multi-functionalities such as self-cleaning, UV protection and electric conductivity via immobilization of Ag or Ag-bearing nanocomposites were also been reviewed briefly.

Silver decorated cotton fabric via ex situ route

Decoration of silver ex situ on cotton fabrics is an easy approach via incorporating silver salts, silver nanoparticles and even monomeric silver-organic compound complexes directly (Table 1). Thanks to the weak adhesion of antimicrobial agents to the fabric, the antimicrobial cotton presents a rapid release with increasing number of washing cycles, thus resulting in unsatisfied laundering durability. Moreover, silver releasing from the antimicrobial cotton has potential risks to the environment and human health, since its toxicity strongly depends on the accumulated concentration (Gaillet and Rouanet 2015). The fabrics are usually pre-modified to introduce reactive groups via chemical and physical treatment to achieve stable silver immobilization. For example, the bleached cotton or mercerized cotton having negative functional groups could anchor Ag NPs, though such modification often weakens the strength of the fibers.

Silver salts

Inorganic silver salts such as silver nitrate have already been used as the antimicrobial agents since ancient Roman times, and often applied for treating cotton fabrics via sorption process (Fig. 1, Bulk sorption). Since the absorption capacity will determine the final antimicrobial activity, high dosage of silver salts is a key point for fabricating antimicrobial cotton fabric. β-cyclodextin, an eco-friendly hosting compound, increases the absorption of silver salts by its hydrophobic cavities. The cotton fabrics being grafted with monochlorotriazinyl β-cyclodextin showed an inhibition zone reducing from 27.5 mm (S. aureus) and 24.5 mm (E. coli) to 21.0 mm and 18.0 mm after 10 washings (Ibrahim et al. 2018). The inclusion of Ag ions increased with the increasing concentration of AgNO3 in the finishing bath, so that the modified cotton fabrics possessed an enhanced antibacterial capability thanks to the rapid release of Ag ions.

Weak absorption of silver salts is a huge obstacle to fabricate antibacterial cotton fabrics via sorption process, therefore surface modification is required to improve the loading efficiency and stability of silver salts. For example, plasma-treatment of the fabric was reported to enhance the absorption of silver nitrate, and silver particles showed a decreasing size of 250 nm compared with 800 nm for the untreated cotton. Moreover, the quantity of silver particles on N2 plasma-treated fabric was greater than that on O2 plasma-treated one. The silver decorated fabrics showed 95% and 100% bacterial reduction, and the values maintained 92% and 99% after 10 consecutive home laundering for O2 and N2 plasma treated fabrics, respectively (Shahidi et al. 2010).

Coating with silver salts-polymer networks would endow antibacterial capability to the cotton fabrics without impact their bulk properties (Fig. 1, Coating). A silver nitrate-carboxymethylcellulose hydrogel using fumaric acid as a crosslinking agent was padded on the cotton, where Ag ions formed electrostatic bindings with negative groups of the hydrogels to produce uniformly distributed silver particles. When the padding time increased, the tensile strength of the fabrics decreased due to the acid treatment, but the whiteness did not alter substantially. The coated cotton fabrics demonstrated 99.9% reduction for both S. aureus and K. pneumonia, but only a reduction of 67.4% for S. aureus and 60.6% for K. pneumonia after 10 cycles washings for polymer solution containing 2 × 10−3 M silver, probably due to partial removal of silver nitrate (Bozaci et al. 2015).

In addition to the electrostatic bonds, coordination bonds between Ag ions and polymer chains enhance the stability of silver salts on cotton surface. Cao et al. (2013) modified cotton fabrics with acryloyl sulfadiazine-methyl methacrylate copolymers using ethylene glycol diglycidyl ether as a bifunctional binder (Fig. 1, Binding). The immobilized sulfadiazine moieties onto cotton formed coordination complexes with silver cations to produce polymeric silver sulfadiazines. The modified fabrics provided a 6-log reduction of 108 CFU/mL of S. aureus, E. coli, methicillin-resistant S. aureus (MRSA) and vancomycin-resistant E. (VRE) in 30−60 min. More importantly, the sulfadiazine moieties on the modified cellulose would be transformed into silver-sulfadiazine coordination complexes again after exposure to aqueous silver nitrate. The silver content decreased from 0.58 wt% to 0.10 wt% after 50 washing, but could be recharged to 0.53 wt%. This refreshable function avoided the depletion of antimicrobial agents, providing the cotton fabrics with durable antimicrobial ability.

It should be mentioned that silver nitrate is often limited for the application to textile materials because of its black-brown staining when exposed to the light, air or other uncontrolled reduction processes and of its low durability. Most studies performed only 10 washings for durable antibacterial tests, therefore more washing cycle is needed to evaluate the antimicrobial capability.

Silver Nanoparticles

Ag NPs are among the earliest investigated inorganic nanoparticles for their antibacterial and wound healing properties, and several such products have been already commercialized. Functioned as multifunctional agents, they impart coloration and antimicrobial properties to cotton fabrics via chemical reductants or plant extracts (Parashar et al. 2009; Kaviya et al. 2012; Bankara et al. 2010; Dipankar and Murugan 2012; Augustine et al. 2014). The latter route is cost-effectiveness and eco-friendliness without using high pressure, energy, temperature or toxic chemicals. For example, cotton fabrics being treated with Ag colloid for 4 h showed antifungal activity against F. oxysporum and A. brassicicola, where Ag NPs were obtained by using aqueous extract of lemon leaves (Citrus limon) which acted as reducing agent and encapsulating cage for the nanoparticles (Vankar and Shukla 2012).

Nanoparticles agglomeration is one of the most widely acknowledged challenges compromised with macroscopic properties. Ultrasound irradiation has proven as a successful method to weaken this effect. It activated the cotton surface and facilitated the deposition and dispersion of small Ag NPs, thereby providing an enhanced antibacterial activity against E. coli and S. aureus (Perelshtein et al. 2008). Reliable finishing methodologies such as composite finishes were also employed to reduce the agglomeration of Ag NPs. Biodegradable gum tragacanth/Ag NPs (~20 nm) composites were applied to fabricate an antibacterial coating (Fig. 1, Coating) by a simple pad-dry-cure method, where the gum tragacanth functioned as the chelating polymer for Ag NPs. The nanoparticles were distributed completely and uniformly in the gum tragacanth coating, but the authors did not show the content of Ag NPs. The strength and strain of the gum tragacanth-modified cotton increased to 45 MPa and 91%, compared with 38 MPa and 67% of the raw cotton fabric. However, immobilization of Ag NPs did not influence the mechanical properties of the fabrics significantly (Ranjbar-Mohammadi 2018).

Nanoparticles stabilization on cotton fabric is another major concern because Ag NPs are lack of reactivity to form chemical bonds with cotton. A crosslinking agent or a binder (Fig. 1, Binding) that contains at least two functional groups bonded with Ag NPs and the cellulose chains has been employed to achieve the stable immobilization. The reaction of carboxylic acids with cellulose is the most common process to decorate a variety of cellulose fibre, for example, 1,2,3,4-butanetetracarboxylic acid. It bonded with cotton fabrics and provided high affinity towards the positive Ag NPs via hydroxyl and carboxyl groups. Ag NPs (~60 nm) colloidal treated cotton fabric showed higher bacterial reduction (>90%) than Ag NPs trapped one (~60%) after 30 washing cycles, though the silver content of the former fabric decreased from 1.63 to 0.89%. The treated cotton fabric had higher wrinkle recovery without yellowing, and the wrinkle recovery angle increased to 150.7° compared with 108.1° of the untreated cotton (Montazer et al. 2012a). β-cyclodextrin grafted polyacrylic acid can serve as reducing and capping agents for Ag NPs to control the reduction reaction. It protected the silver atoms from overgrowth and agglomeration, and obtained spherical Ag NPs with a mean size of 3 ~ 22 nm. Cyclodextrin-g-polyacrylic acid treatment was reported to enhance Ag NPs content (~50 mg) on fiber surface in the presence of ephichlorphydrin (crosslinker), and the growth of S. aureus and E. coli was inhibited (Hebeish et al. 2011). Water soluble polysaccharides being extracted from marinemacro-algae were functioned as reducing and stabilizing agents to form spherical AgNPs with the maximum diameter of 7 ~ 20 nm, and the cotton fabrics were treated with the Ag NPs colloidal solution at a concentration of 108 ppm using citric acid (crosslinker) via pad/dry technique. The bacterial reduction of Ag-NPs decorated cotton fabrics reached to 100% against S. aureus and E. coli, but decreased to 87% and 83% after 10 washing, respectively (El-Rafie et al. 2013). Biomass filtrate of fungus F. solani was applied to prepare Ag NPs colloid with a size range of 3 ~ 8 nm. Incorporation of 1% binder in AgNPs colloid finishing bath increased the bacterial reduction up to 97% and 91% for S. aureus and E. coli in very minute Ag NPs amount of 54 ppm, and remained at 94% and 85% after 20 laundering cycles, respectively, compared with 53% and 48.7% for the fabrics without the binder (El-Rafie et al. 2010). It should be noted that the application of crosslinker or binder may lead to undesirable effects for cotton fabrics or make them associated with toxicity.

Ag NPs adhesion on fabrics has been challenged due to their low charge density. Surface modification via introducing cotton with reactive functional groups would enhance the affinity of Ag NPs to the fabric through covalent bonds, electrostatic attraction or hydrogen bonds. Cotton fabrics being padded with Ag/carboxymethyl chitosan composite presented bacterial reduction rates of over 94% against both S. aureus and E. coli even after 50 consecutive laundering tests, where the primary amine groups of carboxymethyl chitosan formed a coordination bond with Ag ions and the carboxylic acid groups were linked covalently to cotton via an esterification with the cellulose hydroxyl groups at high temperature of 180°. Ag NPs (63.9 ~ 68.2 nm) adhered strongly to the surface so that the fabric with 12.5% loss of Ag still possessed similar vapor permeability, water absorbability, tensile breaking strength and flexibility after 50 washing tests (Xu et al. 2018b).

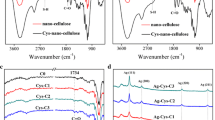

Grafts with thiol groups that provide the cellulose with a strong metal-sulfur bond are very effective for immobilizing Ag NPs onto the cotton surface, resulting in high deposition efficiency and low nanoparticle release. Thiol-modified cotton was achieved via dipping the fabric in acidic mixture including mercaptoacetic acid, acetic anhydride, acetic acid and concentrated sulfuric acid (Thiol-cotton), and then immersed into Ag NPs colloids via simple impregnation (Ag-thiol-cotton) where spherical Ag NPs (10 ~ 20 nm) were positioned at the exterior fiber via a covalent bond. The treated fabric was dark yellow while the raw cotton fabric did not show a change in color even after immersion in Ag NPs colloids (Ag-cotton). Ag NPs loading of Ag-cotton was 302 mg/kg, 120 times lower than that of Ag-thiol-cotton. Silver release from Ag-thiol-cotton was 0.008 ~ 0.024%, 0.012 ~ 0.027% and 0.097 ~ 0.186% respectively for an acidic, neutral and basic washing, much lower than 1.98 ~ 10.9%, 5.95 ~ 8.93% and 0.99 ~ 4.96% for Ag-cotton, demonstrating its higher durability in various pH ranges. Generally, thiol-modified fabric showed over 99.9% growth inhibition of the microorganism (Park et al. 2012). Liu XD et al. (Xu et al. 2018a) employed a “mist” procedure to introduce Ag NPs on one side of fabrics (Fig. 2): Cotton fabric was first exposed to a cysteine mist steam (Cys-cotton) and then exposed successively to a silver nitrate mist steam and a sodium borohydride mist steam (Ag-Cys-cotton), where cysteine was linked covalently to cotton via esterification with cellulose hydroxyl groups and to Ag NPs via coordination bonds. The content of Ag NPs enhanced from 0.74 to 1.46 mg/g as the concentration of cysteine increased. Ag-Cys-cotton with silver loss of ~15% still possessed bacterial reduction rates of 94% against both S. aureus and E. coli after 90 consecutive laundering. The authors confirmed the strong binding between Ag NPs and cysteine against abrasion forces because the size reduction of Ag NPs was consistent with the loss of silver. The vapor permeability and water absorbability of Ag-Cys-cotton decreased respectively by 10.5 and 2.8% compared with raw cotton fabrics, however the breaking strength and the elongation did not change significantly. Different from the pad-dry-cure technique, this mist procedure provided a route for fabricating single-sided antibacterial coating for cotton fabric. More importantly, the tailored thickness may decrease the release of silver without sacrifice the durable antibacterial ability.

Modification of AgNPs is another way to introduce strong bonding with cotton fabrics to enhance laundering durability. AgNPs (~27 nm in diameter) being produced by reducing silver nitrate with sodium citrate were decorated with chitosan via a simple immersion method (CS-Ag), where chitosan was functioned as chelating agents for numerous metal ions to increase total positive charge density, resulting an increase in destruction of cell membranes negatively charged. An aqueous solution containing CS-Ag and other auxiliaries was then padded onto the cotton fabrics (CS-Ag-cotton). The modified cotton possessed the bacterial reduction rates of 99.01% and 98.78% for S. aureus and E. coli, and reduced to 98.95% and 85.82% after 20 washes. CS-Ag-cotton presented an increased tensile strength in warp direction but a decrease in weft direction, and there was no significant difference on the whiteness and absorbency between CS-Ag-cotton and raw cotton fabrics (Arif et al. 2015). Dendrimers and hyperbranched polymers with numerous interior cavities as well as inward and outward oriented functional groups have also be utilized as templates to control the synthesis of Ag NPs with small size, good monodispersity and stability. Amino-terminated hyperbranched polymer was an effective self-reducing and stabilizing agent to produce Ag NPs (10 ~ 30 nm) without agglomeration, and the colloids could be stored steadily more than two months because of a large amount of polymer being adsorbed on Ag NPs. The cotton fabric was immersed in Ag NPs colloids with silver content ranging from 20 mg/l to 200 mg/l, where amino-terminated hyperbranched polymer served as a binder to fix Ag NPs on the fabrics to provide durable antimicrobial properties. The bacterial reduction of the treated cotton fabric reached to 99.0% (S. aureus) and 99.3% (E. coli) at silver content of ~88 mg/kg, and maintained over 98.8% after 20 consecutive home laundering (Zhang et al. 2009).

Strong and stable bonding between Ag NPs and fabric is essential to ensuring the high-efficient deposition and durability without unwanted release of nanoparticles to deteriorate the fabric, therefore modification of Ag NPs along with fabrics is regarded as an effective route to strengthen the bonding greatly. For example, amino-terminated hyperbranched polymer as a reducer was used to generate stable Ag NPs colloids with an average size of ~10.8 nm without any other stabilizer. Meanwhile, cotton fabrics was periodate-oxidized to produce aldehyde groups that would react with amino-terminated hyperbranched polymer being absorbed on Ag NPs in mild condition to provide durable antibacterial fabric. It was believed that the concentration of Ag NPs colloids was the most important factor to determine Ag NPs content on fabrics. After the cotton fabrics were treated with 10 mg/L Ag NPs colloid, the bacterial reduction rates of the modified fabrics having Ag content of 149.88 mg/kg were 99.43% and 99.45% respectively for S. aureus and E. coli, and maintained over 96% after 50 washings with Ag content of 116.08 mg/kg. Oxidization treatment lowered the breaking strength of cotton fabrics, and the breaking strength deceased slightly with the increasing concentration of Ag NPs. The color of Ag NPs treated cotton fabric became darker with the increase in Ag NPs content due to their surface plasmon absorption (Zhang et al. 2013). Biocompatible sericin was functioned as a reducing and dispersing agent to produce a stable Ag NPS-sericin colloid with no obvious precipitation and color change even after one month at ambient temperature. The hybrid colloid (~18 nm) was employed to finish the sodium periodate-modified cotton fabrics, where a cross-linking network was formed between sericin and oxidized cellulose. Ag NPs on Ag-sericin cotton was larger than that of Ag-sericin colloids, perhaps owing to Ag NPs aggregation during the finishing treatment. Ag-sericin cotton showed bacterial reduction rates of above 99%, and still reached over 95% against S. aureus and E. coli after 20 washings. Sericin endowed cotton fabrics relatively smooth surface and good wear ability. The whiteness of the cotton decreased from 89.70 to 78.65 after finishing. Finishing treatment did not change the breaking strength of the fabric significantly, though the breaking strength of oxidized cotton showed a declining trend with the increasing concentration of oxidant due to the degradation of cellulose (Yue et al. 2014).

Finishing treatment with an encapsulating system would enhance the stability of Ag NPs on the cotton and realize a controlled release of Ag ions (Fig. 1, Encapsulation). For example, polystyrene-b-polyacrylic acid copolymer (encapsulating polymer) being synthesized by the atom transfer free radical polymerization could form reverse micelles in toluene, among which Ag NPs around 20 nm were located within the cores regardless of the silver precursor ratio. Ag-copolymer encapsulation padded fabrics provided stable attachment of Ag NPs onto the cotton, where an esterification reaction took place between polyacrylic acid (corona) and hydroxyl groups of cellulose. The antibacterial activity remained up to 5 washings against E. coli and 20 washings against S. aureus (Budama et al. 2013). DNA from salmon milt was used as templates to produce spherical Ag NPs (< 10 nm) and formed a thin layer around Ag NPs core. Ag-DNA encapsulation was further immobilized onto the polycationic-modified cotton to produce antibacterial fabrics (Ag-DNA cotton), showing no colonies after 18 h incubation with E. coli for Ag-DNA cotton having Ag NPs of 30 ppm (Takeshima et al. 2015). Encapsulation protected Ag NPs from interacting directly with fabrics physically and chemically, however, the antimicrobial activity was thus decreased at some extent.

Generally, antimicrobial activity of Ag NPs deposited fabrics is more preferable than silver salt immobilized fabrics due to its high surface area to volume ratio and the lower release of silver. Direct impregnation of Ag NPs into the fabrics is a typical route for fabricating Ag-cotton hybrids, but usually frustrated with the nanoparticles aggregation, low deposition efficiency and low adhesion affinity. Silver released rapidly from the fabric due to the weak adhesive force between silver and the cotton surface, resulting in unsatisfied laundering durability.

Silver decorated cotton fabric via in situ route

Direct immobilization of Ag NPs is often ineffective and raises environmental concerns because Ag NPs are prone to leach out during washing. Non-leaching and stable Ag/cotton fabric is therefore proposed via in situ route, where silver ions are firstly loaded onto the cotton fabric and then reduced to Ag NPs. The production of AgNPs consists of consecutive steps of classical nucleation and growth, aggregative nucleation and growth, and Ostwald ripening. In situ method promotes the stabilization efficiency of nanoparticles to lower the tendency to agglomerate and controls the size in nano scale (Table 1). Except argon glow discharge treatment (Li et al. 2017a, b) and electron beam irradiation (Chmielewska and Sartowska 2012), Ag NPs can be synthesized in situ on the fabrics by using chemical reducing agents to reduce AgNO3 in a one-bath process, such as sodium borohydride, butylamine, L-ascorbic and glucose (Lee et al. 2007; Bacciarelli-Ulacha et al. 2014; El-Shishtawy et al. 2011).

Cotton fabrics are often modified before chemical reducing reaction to achieve stable immobilization of Ag NPs. A grafted cysteine on cotton via esterification between its carboxylic acid groups and cellulose hydroxyl groups can form coordinate bonds between its thiol groups with Ag NPs (~63.9 nm) in situ reduced by sodium borohydride, producing an antimicrobial fabric with bacterial reduction rates of 100% for E. coli and S. aureus and maintaining over 97% after 50 consecutive laundering cycles. Ag decorated cotton became darker while Cys-cotton showed no color change compare with the raw cotton, and presented similar vapor permeability (1140 g/m2/d), water absorption (270%) and tensile breaking strength to the raw cotton, illustrating that immobilization of Ag NPs did not alter the bulk properties of the fabrics significantly (Xu et al. 2017a).

Plasma is very effective to introduce functional groups or produce radicals to induce graft polymerization. The cotton fabric being grafted with polyacrylic acid attracted silver nitrate through the electrostatic interaction, and Ag NPs with an average size of 17 nm were then formed on cotton fabrics without visible aggregation via in situ reduction by sodium borohydride (M-Ag). Plasma treatment increased capillary flow height of the fabrics, and plasma induced graft polymerization on fabrics endowed much higher capillary flow height than only plasma treatment. Different from light brown of Ag NPs loading cotton without plasma treatment (C-Ag), the color of M-Ag cotton changed to dark yellow, indicating higher Ag NPs deposition than C-Ag cotton. The degradation rate of methylene blue of M-Ag cotton was higher than that of C-Ag cotton, and did not decrease significantly even after 3 cycles, indicating durable self-cleaning activity of M-Ag cotton under visible light. M-Ag cotton showed good antibacterial activity, and only 5.4% reduction of the inhibition zone was shown after 30 washings. The weight loss of M-Ag cotton was a little greater than that of the control and C-Ag cotton fabrics (Wang et al. 2017a, b). Maleic anhydride was plasma polymerized and hydrolyzed to produce carboxylic groups on the cotton fabrics. Ag ions were bonded with the fabrics and reduced by NaBH4 to form spherical Ag NPs (~8 nm) dispersed homogeneously. A distinct inhibition zones of Ag-cotton against E. coli was nearly 41% of the sample surface (Airoudj et al. 2015).

Carboxymethyl chitosan grafted cotton could form coordination bonds between the amine groups and Ag NPs being reduced in situ by trisodium citrate through a mist process (mist-cotton, 45.9 nm) or an immersion process (immersion-cotton, 52.8 nm). Immersion-cotton possessed a more smooth and darker surface than mist-cotton thanks to the higher loading of Ag NPs. The bacterial reduction rates of mist-cotton against both S. aureus and E. coli remained over 95%. Mist-cotton had a good vapor permeability of 1138 g/m2/d, close to the raw cotton (1140 g/m2/d), but much higher than immersion-cotton (785 g/m2/d); a good water absorption of 265.5%, almost equal to that of the raw cotton (272.5%), much higher than immersion-cotton (165.6%). The tensile breaking strength of mist-cotton was about 17.5 MPa, almost equal to the raw cotton, but much lower than that of immersion-cotton (22.8 MPa). It should be mentioned that mist process is very complex and might not be suitable for industrial production (Xu et al. 2017b).

Hydrophilic polymers having reductive groups were effective reducing agents for in situ synthesis of Ag NPs on cotton fabric and their hydrophilic chains also prevented proteins deposition and bacterial adhesion. For example, Ag-cotton was prepared via immersing the fabric into Ag NPs colloids being reduced by alkali hydrolyzed alginate. The silver content increased with the increasing concentration of Ag NPs colloids in the presence of binder, and the maximum content of 114.17 mg/kg decreased to 61.03 mg/kg after 20 washing cycles. It was found that the finishing process using 50 ppm AgNPs colloids without a binder was sufficient to exhibit good antibacterial activity against E. coli, P. aeruginosa and S. aureus, and the bacterial reduction was retained 90% even after 20 washing cycles (Zahran et al. 2014). Dopamine can self-polymerize to form a uniform film on cotton fabric under alkaline condition, and its remaining catechol groups can reduce Ag+ to Ag°. Monodispersed Ag NPs as well as some aggregated Ag particles with diameter of 100 ~ 300 nm were distributed uniformly on the fabric surface. The bacterial reduction of Ag NPs decorated cotton reached to 99.99%, and did not alter remarkably after 30 consecutive laundering cycles, with a final Ag content decreasing to 15 mg/g. In the meantime, the aggregated silver particles disappeared and only some Ag NPs with diameter of 80 ~ 90 nm remained (Xu et al. 2011). A pomegranate-shaped polymer structure wrapping Ag aggregations were synthesized via the coincident growth of Ag NPs and polymer chains, and the size of pomegranates structure was therefore determined by the reaction ratio of the reduction and graft polymerization. The photografted poly(2-aminoethyl methacrylate) was used as a reducing agent to form Ag nanoparticle aggregations up to 500 nm thanks to the coordination forces between amino groups and silver, and the grafting degree of Ag and poly(2-aminoethyl methacrylate) were 0.54% and 14.6%, respectively. The pomegranates structure endowed the fabrics with an enhanced whiteness and superhydrophilicity as water drops spread out within 0.2 s. The bacterial reduction maintained 90% after 50 accelerated laundering cycles that was equivalent to 250 instances of home laundering, with the total loss of silver below 10% (Liu et al. 2014).

More interestingly, cellulose can be used as the reducing agent to support and synthesize nano silver, and the reactivity of its hydroxyl groups and reducing ends enhanced greatly at high temperature. Ag NPs with an average size of 40 nm was uniformly decorated on the cotton surface when the deposition time was 10 and 30 min, but the size increased to 100 nm when the deposition time prolonged to 50 min. The modified fabrics having silver content of 0.6890 ~ 1.3561 mg/g retained the bacterial reduction of 98.5% and 94.3% against E. coli and S. aureus after 20 washings, respectively. The antibacterial activity increased slightly with the increasing concentration of AgNO3, but enhanced significantly from 23.93 to 99.99% as the temperature increased. The color difference values of Ag NPs decorated fabrics were 9.25–18.32 compared with the raw cotton as the reaction time increased from 10 to 50 min (Jiang et al. 2011). Tollens’ reagent is a mild oxidizing agent and can reduce to nano silver particles using cellulosic chains as reducing and stabilizing agents. Spherical Ag NPs with an average size of 88 nm were loaded directly on the fabrics to endow over 96% of bacterial reduction rates against S. aureus and E. coli after 30 washing, where cellulose chains were oxidized to oxycellulose (Montazer et al. 2012b).

Mercerization finishing can convert crystalline structures of cotton from cellulose I to cellulose II. Under basic condition, cellulose hydroxyl groups were supposed to be activated and the silver ions were reduced to Ag NPs bound to cotton. Color strength of Ag-mercerized cotton was higher than Ag-cotton without mercerization because there were a few aggregates on Ag-cotton while Ag NPs on the mercerized cotton were uniformly distributed. As pH value of solution increased, silver contents of cotton did not increase, but color strength of cotton with Ag NPs enhanced and the value was twice after heating treatment. Ag NPs decorated cotton completely inhibited bacterial growth even after 7 laundering cycles no matter mercerized or not (Tang et al. 2013). Pre-alkalization treatment produced alcoholic and aldehydic groups on cotton, which reduced in situ silver ions to AgNPs with size majority (70%) of less than 80 nm without any other reducing agent. As the concentration of AgNO3 increased, Ag content increased from 48.7 to 2391.5 mg/kg and the lightness decreased. The color strength reached to 10.32 when the concentration of silver ions was 400 mg/L. The modified fabric exhibited an inhibition zone of 12 mm against S. aureus at low Ag content (66.8 mg/kg) and no difference in water absorption from the raw cotton (Emam et al. 2015). Two solventless techniques, sorption (S-Ag) and padding (P-Ag), were studied carefully to determine their effect on Ag-mercerized cotton. S-Ag cotton exhibited higher Ag content (69.3 ~ 6094.8 mg/kg) than P-Ag cotton (33.8 ~ 609.3 mg/kg) because the fabrics swelled in sodium hydroxide to expose more hydroxyl groups to absorb silver ions. When the temperature elevated from 70 to 95 °C, Ag contents increased by factor of 2 ~ 3 for P-Ag cotton, but did not change for S-Ag cotton. The increase in reaction temperature had no serious effects on the color of fabrics for both techniques. Bacterial reduction and UV protection factor (UPF) reached to 99% and 12.59 for fabric with Ag content of 5912.3 mg/kg, and reduced to 90% and 10.19 after 20 washings (Emam et al. 2016).

Keliab, natural ashes containing sodium and potassium carbonate, provides an alkali environment with pH value of 13, where the hydroxyl groups are oxidized to ketone, aldehyde or carboxylate to reduce Ag ions to Ag° simultaneously on the fabrics. Absorption of carbonate ions restrained the agglomeration of nanoparticles, therefore Ag NPs decorated cotton showed high bacterial reduction over 99%. The color change value increased with the increasing concentration of AgNO3, but decreased slightly with the increasing concentration of Keliab because more Ag NPs were supposed to form in solution. The concentration of AgNO3 or Keliab did not influence the tensile strength and tensile strains significantly (Aladpoosh et al. 2014).

Silver decoration on cotton fabrics whenever ex situ or in situ has achieved significant improvement on antibacterial capability. Various capping agents have been employed to stabilize Ag NPs on cotton fabrics to avoid agglomeration. Polymers having strong interactions with the fabric and Ag NPs can serve as the dispersion medium and binder to achieve stable immobilization. Polymeric capping agents can also be tailored to introduce diverse functionalities such as amine or thiol groups that enable tremendous possibilities with respect to the surface functionalization of Ag NPs or fabrics. In addition, metal-fabric hybrids via electrostatic-assembly using direct impregnation or in situ reduction technique led to an efficient deposition of Ag NPs to the cellulose fabric, but nanoparticles could be easily released from the fabric under acidic or basic environments because ionic charges and bond strength were influenced by pH value.

Ag-based nanocomposites for multi-functional coating

Many attempts have been conducted to endow cotton fabrics with multifunctionalities, including self-cleaning, UV protection, electric conductivity and antimicrobial capability. Ag-based nanocomposites with other metal or metal oxide have been designed to fabricate high performance value-added cotton fabrics, such as antimicrobial ZnO (El-Nahhal et al. 2013, 2020; Selvam et al. 2012; Gao et al. 2019) or TiO2 (Doganli et al. 2016; Chitichotpanya et al. 2019; Yuranova et al. 2006). CuO (Ma et al. 2013; Perelshtein et al. 2013), Cu2O (Sing et al. 2013; Sedighi et al. 2014b; Montazer et al. 2015) or Cu NPs (Xu et al. 2018c; Sedighi et al. 2014a) has also been immobilized onto the fabric to offer durable antimicrobial properties with or without binders. It has been reported that Ag/Cu hybrid coating showed good antibacterial and antifungal activity against E. coli, S. aureus, MRSA, A. baumanii, P. aeruginosa, P. vulgaris and C. albicans (Paszkiewicz et al. 2016; Slamborova et al. 2013). Ag/Cu nanoparticles on cotton fabric possessed a localized surface plasmon resonance (Anderson et al. 2016), and bimetallic coating with low concentration of Ag/Cu (0.015 ~ 0.13 wt%) had antimicrobial properties against a wide range of multidrug-resistant bacteria and fungi (Eremenko et al. 2016). Ag/Cu coated cotton showed higher adsorption rate of tryptophan than Ag coated cotton, but the complexation of tryptophan and Ag/Cu NPs did not reduce their bactericidal capability against a number of microorganisms (Petrik et al. 2020). Ag/graphene or Ag/graphene oxide nanocomposites were doped in hydrogels using 1-hexyl-3-methyl-imidazolium as dispersant to achieve the antimicrobial hybrid coating (Espinoza-Ibarra et al. 2019). Special core/shell SiO2@Ag NPs coating provided cotton fabrics with bacterial reduction of 97.49% (Mohamed et al. 2017).

Self-cleaning coatings

Self-cleaning cotton is classified as one of the intelligent fabrics because it is resource (water and chemicals) savings on cleaning and prolongs the lifetime of the fabrics. Self-cleaning feature is generally based on Lotus leaf effect (superhydrophobic property) or photo superhydrophilic property. Self-cleaning coatings of Ag-based nanocomposites on cotton fabrics were summarized in Table 2.

Superhydrophobic surfaces with water contact angles above 150° and sliding angles below 10° can been fabricated via tuning the surface roughness and chemical composition. Due to high water repellency of the superhydrophobic surfaces, water droplets in spherical shapes can clean dirt particles by an easy roll-off mechanism. Since fabrics possess a micrometer-scale roughness originating naturally from the fibers and the corresponding woven structure, a single-scale nanostructure needs to be formed to lower the surface free energy with an aim at reducing bacterial colonization and introducing self-cleaning properties simultaneously. Therefore, nanoparticles coating on the fabrics with a micro/nano-scale structure is an effective way to produce superhydrophobic surfaces. For example, AgBr/TiO2 nanocomposites coating on cotton fabrics using silane coupling agents exhibited a contact angle of 145.8° similar to the silane coated cotton and showed bacterial reduction of 99.87% against E. Coli (Rana et al. 2016). Superhydrophobic fabrics have also been designed via in situ growth of both metallic nanocrystals and transition-metal oxides through neutralization reaction and oxidation-reduction reaction. The coating with nanocrystals (such as Fe, Co, Ni, Cu and Ag) not only presented multiscale roughness but also coordinated with n-octadecyl thiol on the cotton fabrics, producing a superhydrophobic surface with a water contact angle of ~150° (Wang et al. 2013). Aligned nanoneedles of copper hydroxide on Ag-dopamine hydrochloride decorating cotton created a hydrophobic surface with a water contact angle of 168°, where the doped Ag NPs prevented the formation of CuO. Cu NPs being formed on the fabrics were successively oxidized into nanoneedles by persulfate in the alkaline medium (Belal et al. 2020).

Photocatalytic self-cleaning coating via Ag-based nanocomposites has attracted much attention for fabricating multifunctional cotton fabrics. Photocatalysts such as TiO2 and ZnO NPs possess photocatalytic activity thanks to their sensitivity to UV radiation, but the photogenerated electron-hole pairs are likely to recombine. Based on the surface plasmon resonance of Ag NPs, Ag/TiO2 or Ag/ZnO heterostructure lowers the recombination of the electron-hole pairs along with enhancing sensitivity to visible-light. Ag/TiO2 decorated fabrics that were formed via depositing TiO2 film and Ag NPs alternatively via ultrasonic treatment degraded Rhodamine 6G completely within 180 min under UV light (Ge et al. 2019). TiO2 nanowires were reported to be more efficient in photodegradation than TiO2 nanoparticles. Methylene blue stain on TiO2 nanowires/Ag/polyvinylpyrrolidone treated cotton fabric was completely disappeared after 12 h exposure to sunlight. Moreover, 2% TiO2 nanowires/Ag nanocomposites showed inhibition zones of 24, 18, 19, 24 and 16 mm against P. aeruginosa, S. aureus, E. coli, B. cereus and C. albicans, respectively (Hebeish et al. 2013). Ag/ZnO coating was prepared via reducing zinc salt on cotton fabrics using polyallylamine, followed by the immobilization of Ag NPs. The modified fabrics degraded rhodamine B completely within 2.5 h under visible light, and maintained almost similar photocatalytic activities up to 5 cycles. Color stain on Ag/ZnO coated fabric removed completely after sunlight exposure for 15 h, while the stain on the raw fabric did not change. Ag/ZnO decorated fabrics showed a 100% reduction for S. aureus and P. aeruginosa after 4 and 6 h, respectively (Manna et al. 2015). Cotton fabric being loaded with Ag/ZnO nanocomposites that were prepared by photo-reduction of Ag+ on ZnO nanoparticles decolorized safranin O within 225 min. Photocatalytic degradation was found to be dependent on light intensity, concentration and initial pH value of dye solution (Oda et al. 2016). A simple exhaustion method based on zinc acetate dehydrate, AgNO3 and Keliab was employed to synthesize nanocomposites coating on cotton fabric, followed by dehydrolysis of Ag2O on ZnO surface to produce star-like Ag/ZnO. Ag/ZnO coating showed the degradation factor △E of 53.6 for methylene blue, and bacterial reduction of 93.5% and 99.7%, respectively for S. aureus and E. coli (Aladpoosh and Montazer 2016). It is well known that Ag/ZnO heterostructure enhances the photodegradation activity under visible-light, but Ag NPs can be easily oxidized by ZnO due to their high chemical reactivity. Ag/ZnO modified cotton fabric was formed via radiation-induced graft polymerization of γ-methacryloxypropyl trimethoxysilane, followed by in-situ formation of ZnO and Ag NPs simultaneously. The grafted chains formed Zn-O-Si in the interfacial layer to increase the bonding strength of fabrics with Ag/ZnO NPs, thus enhancing the near-field amplitudes of the localized surface plasmon resonance. The photocatalytic degradation rate of the modified cotton was up to 98% and remained approximately 97.6% after 5 photocatalytic test cycles, illustrating its photocorrosion resistance, photostability and laundering durability (Wang et al. 2019).

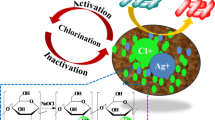

Ag/AgX (X = Cl or Br) heterostructure is a valuable visible-light-response photocatalyst. Upon light irradiation, the photocatalyst absorbs a photon that is separated efficiently into an electron and a hole. The electrons are transferred to the surface of Ag NP farthest away from the Ag/AgCl interface. The holes are shifted to the surface of AgCl particle to oxidize Cl− ions to Cl° atoms, the powerful oxidizing agents to decompose methyl orange (MO) dye into CO2 and H2O (Fig. 3). AgCl coating can be synthesized simply by exposing the fabrics to silver nitrate and sodium chloride successively (Potiyaraj et al. 2007), and an AgCl-based hybrid coating showed a 94% bacterial reduction even after 10 washings (Tomsic et al. 2009; Klemencic et al. 2012). Ag/AgCl modified cotton via using polydopamine as adhesive agent and reducing agent displayed a photocatalytic activity of 95% for C.I. RB-19 dye within 180 min, approximately 31 times higher than those of the raw cotton, where O2− and h+ were confirmed to be the active species in the photo-degradation process (Ding et al. 2018). Combination of TiO2 and plasmonic Ag/AgX junction is a promising approach to boost the photocatalytic activity by extending the response to the visible domain and decreasing the recombination of electron-hole pairs. Ag/AgCl was introduced on TiO2 coated cotton by immersed the fabric in silver nitrate/HCl, followed by UV irradiation. MO stains on Ag/AgCl/TiO2 coated fabric was almost removed after 60 min irradiation under visible light, while the photodegradation over TiO2 coating was very weak (Wu et al. 2013). Cotton fabric being modified with TiO2/Ag/AgBr layer via sol-gel route degraded Rhodamine completely in 1.5 h and 95.5% dimethyl methylphosphonate in 2 h of irradiation under visible light (Boufi et al. 2019).

Many photocatalysts have been integrated to form heterostructures to enhance the photocatalytic self-cleaning properties. ZIF-8, one of metal-organic framework materials, possesses characteristics of large pore size, high surface area and good thermal stability, and has be employed as a UV photocatalyst with low efficiency of exciton generation. Nanocomposites integrating Ag/AgCl and TiO2 with ZIF-8 were decorated on the cotton fabric to enhance absorption capacity both in ultraviolet region and visible region. The degradation rate of methylene blue by Ag/AgCl/ZIF-8/TiO2 decorated fabric reached to 98.5% within 105 min irradiation under visible light, and the degradation capacity maintained approximately 85% after 3 cycles. Moreover, the first-order kinetic constant of photocatalytic degradation was 0.0332 min−1. It was suggested that .OH and .O2− were the main active species for the degradation of methylene blue in the presence of Ag/AgCl/ZIF-8/TiO2 decorated cotton (Guan et al. 2019).

UV protective coatings

UV protective coating on the fabrics can prevent bodies from UV radiation via absorption and reflection (Table 3). Many inorganic UV absorbers, such as ZnO or TiO2, have been employed to fabricate UV protective coating. High reflection of UV radiation provided Ag coated fabrics with strong UV protective properties (Rehan et al. 2015), and the UV blocking capability was influenced by size and morphology of the nanoparticles (Fig. 4). Carboxymethyl cellulose-Ag NPs (~18.2 nm) composite coating was reported to decreased the UV transmission radiation to 7-10% after applying ten composite layers (Ahmed and Emam 2016). Macromolecules in nanocomposites coating facilitated the dispersion of UV blocking nanoparticles and reduced the total reflection of UV light because the irregular and multiple reflection of UV light on the macromolecule-Ag interface enhanced the photons absorption greatly.

ZnO NPs has an excellent UV blocking property over a board range of UV wavelengths with a wide direct band gap (3.37 eV) and large excitation binding energy (60 meV). Cotton fabric being loaded with Ag/ZnO that spherical Ag (~15 nm) was doped on rod-like ZnO (Φ30 nm×170 nm) had a lower UV transmittance than the raw fabric (~99%), and the UV transmission decreased with the increasing dosage of nanocomposites. Water contact angle of Ag/ZnO laden fabric was 139° higher than 103° of ZnO laden fabric. 3% Ag/ZnO modified fabrics promoted the antibacterial rates to 91%, 96% and 98%, respectively against S. aureus, E. coil and C. albicans, and presented anti-mildew effect of 0 grade against A. flavus (Gao et al. 2020). Ag/ZnO coating with different color possessed higher UPF values of 267 (yellow), 269 (scarlet) and 274 (blue) than 179 of ZnO coating. As far as the antimicrobial activity, Ag/ZnO treated fabrics exhibited 100% reduction for both S. aureus and E. coli, while ZnO treated fabric exhibited 75% reduction of S. aureus and 90% reduction for E. coli (Avazpour et al. 2017). Ag/ZnO nanocomposites (10 ~ 35 nm) being modified with 3-glycidyloxypropyltrimethoxysilane (GPTMS) and tetraethoxysilane (TEOS) could form an organic/inorganic hybrid sol with chitosan via hydrolysis and condensation, where Si-OH of TEOS and GPTMS reacted with hydroxyl at C-6 position of chitosan and condensation of two Si-OH groups formed Si-O-Si network. This hybrid sol coating provided cotton fabrics with high UV absorption (Fig. 4) and antimicrobial activity (Busila et al. 2015). A uniform and continuous Ag/ZnO layer containing Ag, ZnO and Ag/ZnO NPs was formed on cotton fabric via in situ reduction of zinc 2-ethylhexylcarbamate and silver 2-ethylhexylcarbamate by 3-mercaptopropyl triethoxysilane and 3-aminopropyl triethoxysilane, and presented UV blocking properties and antibacterial performance against S. aureus and E. coli (Kim et al. 2018). The cotton fabrics being deposited with Ag and ZnO nanoparticles (30 ~ 120 nm) simultaneously by an amino terminated hyperbranched polymer (reducer) under microwave irradiation enhanced UPF value to 60 compared to that of 4.79 for the raw fabric. The bacterial reduction rates against S. aureus and E. coli reached to 99.99%, however Ag content decreased from 0.389 mg/g to 0.213 mg/g after 30 consecutive laundering tests (Zhang et al. 2014).

Ag/TiO2 loaded cotton that was produced by successive deposition of flower-like TiO2 micro-nanoparticles via hydrothermal method and in situ reduction of AgNO3 exhibited UPF value of 56.39 and bacterial inhibition rates higher than 99% against S. aureus and E. coli (Li et al. 2017a, b). Ag/TiO2 coating on cotton fabric being formed in the presence of alanine and methyl alcohol presented bacterial reduction of 99.9% and UPF rating of 50+ after 10 washings, where alanine on the surface of TiO2 NPs was bound with Ag ions (Milosevic et al. 2014). Ag doped TiO2 coating on cotton fabric with very low silver concentration (<100 ppm) via a hydrothermal deposition approach did not cause color change but developed good UV protection (UPF>60) and antibacterial activity against S. aureus and E. coli (Mishra and Butola 2017). The cotton fabrics being colored with yellow, red and blue reactive dyes were reported to increase the adhesion of Ag/TiO2 nanocomposite, and the silver content on the dyed fabrics ranged from 65.67 to 142.24 mg/kg compared with blank fabrics of 35.05 mg/kg. Ag/TiO2 decorated fabrics showed an enhanced UPF with the increasing concentration of reactive dye, and remained UV protective properties even after repetitive washings (Gorjanc and Sala 2016). Ag/SiO2 doped TiO2 coating via a solvothermal method achieved UPF rating of 50+ even after 5 washings and presented low transmission values of 0.1% and 0.3% at UVA region from 315 to 400 nm before and after washing, respectively (Onar et al. 2011).

Conductive coatings

Conductive textiles has elicited considerable attention in biomedical devices, energy conversion, storage and electromagnetic interference shielding. High conductivity is usually related to high absorption and reflection of electromagnetic wave, therefore, optimizing the distribution of conductive fillers is a key point to achieve high conductive and electromagnetic attenuation coating. Modification of cotton fabrics is often required to enhance the binding strength of coatings, more importantly, hydrophobic treatment is essential to fabricating conductive coating of metal and metal oxide nanoparticles because the electrical properties are influenced by relative humidity. Conductive coatings of Ag-based nanocomposites on cotton fabrics were summarized in Table 4.

A conductive fabric was prepared via padding 3-mercaptopropyltriethoxysilane modified cotton with silver 2-ethylhexylcarbamate/methanol, followed by a thermal reduction process at 130 °C. Ag NPs with a size of 20 ~ 100 nm endowed the fabrics with electric resistance as low as 3.92 Ω and inhibition zones of 22.0 mm and 21.2 mm against E. coli and S. aureus, respectively (Kwak et al. 2015). Ag-epoxy coating had the shielding effectiveness (SE) of 50-69 dB in the frequency of 60-15000 MHz, and the concentration of precursor (silver nitrate) had a significant effect on the electromagnetic shielding effectiveness of fabrics (Perumalraj et al. 2011). Ag coated cotton with the conductivity of ~3333 S/m via a wet electroless deposition method possessed EMI SE of ~111 dB at the plating time of 3 min, far more than that of 30 dB for commercial fabrics. Moreover, Ag plating fabrics maintained high EMI SE by suffering dozens of washing times or one thousands of bending times (Tan et al. 2018). Core-shell yarns with conductive copper as core and cotton fiber as sheath were weaved into conductive fabrics, and spherical Ag NPs (30 ~ 50 nm) were coated onto the fabrics. Ag-modified fabric presented a 20 ~ 55% increase of electromagnetic shielding in 500-12000 MHz to that of the untreated copper core yarn fabrics (Perumalraj and Narayanan 2014).

Bimetallic deposition of Cu and Ag over cotton fabric was a simple method for fabricating superhydrophobic textiles with electrical conductivity and antibacterial activity. Cu plating Ag-deposited fabrics (Cu/Ag) possessed good electrical conductivity and EMI SE to make lightweight and flexible smart electronic fabric, where Ag-coated fabrics were treated with the electroless Cu plating bath containing CuSO4, glyoxylic acid (reducing agent), ethylene diamine tetraacetic acid (complexing agent) and bipyridyl (stabilizer). Surface resistivity of Ag-deposited fabrics was ~620 Ω and decreased to 20 Ω after Cu electroless plating while the value of the fabric by conventional Cu electroless plating (control sample) was 62 Ω, and EMI SE of Cu/Ag cotton was recorded as 75.53 dB compared with 47.43 dB of control sample. Regarding Joule heating behavior, the surface temperature of Cu/Ag cotton was 83.1 °C, higher than control sample of 69.6 °C. Inhibition zones of Cu/Ag cotton were 16.5 mm (S. aureus) and 13 mm (E. coli) and decreased to 14 mm and 11 mm after a standard washing, while those of control sample were 12 mm (S. aureus) and 9 mm (E. coli) and decreased to 10.5 mm and 8 mm. Cu/Ag cotton showed good retention of the metal layer without significant loss of electrical conductivity or antibacterial properties (Ali et al. 2020). Ag over Cu-coated cotton fabric by electroless deposition had a sheet resistance of 0.15 Ω/sq, lower than Cu-coated cotton fabric of 1.15 Ω/sq. Electrical conductivity of Ag/Cu coated cotton did not change significantly after two weeks, demonstrating that the bimetallic coating suppressed the oxidation of Ag or Cu, and the sheet resistance remained constant during 10 washings. This bimetallic layer showed an enhanced surface roughness with water contact angles increased to 160.9° and inhibition zones of 14 mm (S. aureus) and 17 mm (E. Coli) (Suryaprabha and Sethuraman 2017). Electroless plating has been used to deposit continuous and uniform coatings on cotton with complex shapes, but there is still some key points needed to be handled such as controllable plating rate and interface bonding strength.

Graphene (G) and reduced graphene oxides (rGO) have characteristics of high surface area, conductivity, flexibility and stability towards thermal or chemical environment, and their composites with metal oxide or metal nanoparticles ameliorate the shielding efficiency synergistically. Hydrophobic Ag/rGO nanocomposites coating with a water contact angle of 135.1° on cotton fabric being produced via microwave irradiation presented a surface resistance of 5.61 Ω/sq, while Ag coated or rGO coated fabrics showed poor electrical conductivity, perhaps owing to the high nanoparticles deposition of Ag/rGO (3.20 mg/cm2) coating than Ag (1.92 mg/cm2) or rGO (0.08 mg/cm2) coating. Surface resistance of Ag/rGO coating increased to 33.60 Ω/sq after a washing, such high electrical conductivity made temperature of Ag/rGO coated cotton increase to 61.3 °C when exposed to a voltage of 4 V. Ag/rGO coated cotton possessed EMI SE of >40 dB at the frequencies from 1 to 18 GHz, and decreased to 18 ~ 24 dB after washings (Wang et al. 2017a, b). Ag/rGO coating on cotton fabric using PVP as non-ionic adhesive, where Ag was doped on rGO sheets through in situ reduction of AgNO3 and GO via a hydrothermal treatment, possessed EMI SE of 27.36 dB in 8.2 ~ 12.4 GHz and was conductive enough to light up a series of 57 LEDs with high intensity (Fig. 5). The inhibition zone of Ag/rGO decorated fabric was 1.0 cm against E. coli, compared with GO coated fabric of ~0.1 cm, confirming the suppression of E. coli growth (Ghosh et al. 2019).

Conductive fabrics have been widely used to prepare flexible electronic devices. For example, Ag/G coated cotton with a surface resistance of 2.71 Ω/sq was employed to fabricate a strain sensor to real-time monitor the finger rotation in strain range of 0 ~ 20%, showing its high sensitivity, fast response and great stability. Sheet resistance of Ag/G coated cotton increased from 13.6 Ω/sq to 2.58 kΩ/sq after 20 washings, much lower than G coated cotton from 33.8 to 240.0 kΩ/sq. It should be noted that the continuous Ag/G conductive network would be destroyed once the fabrics were deformed excessively (He et al. 2018). Novel inkjet-print technique is considered to be very promising for fabricating conductive coating due to its excellent processing and environmental benefits, but frustrating with poor ink stability at higher concentration of graphene derivatives. Since graphene possessed better electrical conductivity than GO and rGO, Ag/graphene nanocomposite as printing ink was designed to fabricate highly conductive coating with a sheet resistance lowered to ~2.11 Ω/sq. The sheet resistance was found to be depend on the number of print layers and Ag/graphene ratio in the formulation (Karim et al. 2019).

Nanocomposites coating have also been employed to other cellulose for fabricating multifunctional materials. ZnO doping on weakly ionised gaseous plasma modified cellulose fibre possessed high UPF values (50+) when the fibre was plasma-treated for 10 s (Gorjanc et al. 2014). Cellulose nanofiber with a TiO2 coating (~25 nm in thickness) via hydrolysis was positive charged and showed 100% efficiency of capturing negative Au NPs (~5 nm) through electrostatic interaction, demonstrating its high filtration efficiency for potential applications in filtration membrane areas (Zhang et al. 2019). Ag decorated cellulose nanocrystals having a percolated network upon solvent evaporation were electrically conductive with a high conductivity of 2.9 × 104 S/cm (Meulendijks et al. 2017). Ag doping nano-fibrillated cellulose through dopamine binding exhibited relatively high strength, flexibility and thermal conductivity. It formed a thermal conductive pathways and showed a high in-plane thermal conductivity of 6.0 W/(m.K) when Ag NPs content was 2.0%, 4 times that of the raw cellulose, illustrating potential applications as lateral heat spreaders in flexible electronic equipment (Shen and Feng 2018). Multi-walled carbon nanotube (MWCNT)/GO nanocomposites coating on cellulosic paper, where GO was used to improve MWCNTs dispersion in water media and nanocrystalline cellulose was employed as a binder for the nanocomposites, enhanced its mechanical properties and electro-conductivity up to 892 S/m (Tang et al. 2014). Bacterial cellulose being modified successively by Cu and ZnO NPs using direct current magnetron sputtering and radio frequency reactive sputter coating techniques illustrated good UV resistance (T.UVA% 0.16, T.UVB% 0.07, UPF 1850.33), antistatic behavior (S.H.P 51.50, I.E. V 349.33) and reduction rates of 98.45% against E. coli and 98.11% of S. aureus (Wasim et al. 2020). Spherical SiO2@TiO2 nanocomposites (~50 nm) decorating bacterial cellulose via sol-gel process showed high photocatalytic activity of methyl violet 2B dye in 30 min, demonstrating its good self-cleaning performance (Monteiro et al. 2019). Photocatalytic coating on bacterial cellulose membranes through hydrolysis-polycondensation of tetraethyl orthosilicate/titanium (IV) isopropoxide and hydrothermal treatment exhibited good TiO2 dependent self-cleaning activity towards crystal violet dye. The SiO2-TiO2/Ag doping membranes degraded 97% dye within 50 min under UV illumination. More importantly, it could be easily disinfected under UV irradiation from a lamp or natural sunlight and recycled (Rahman et al. 2021). Dopamine grafted cellulose acetate membranes showed high porosity, pore size and hydrophilicity, and water permeability reached to 181.2 L/m2h with protein rejection of 93.5%, showing its potential application in the field of separation (Guo et al. 2020). Cellulose carbamate containing 2.7 ~ 15.1% ZnO with a hexagonal wurtzite structure displayed UV-blocking properties and antibacterial activities against S. aureus and E. coli. A dramatic reduction in viable bacteria was observed within 3 h of exposure, while all of the bacteria were killed within 6 h (Fu et al. 2015).

Nanocomposites have been decorated on cellulose to produce high performance value-added fabrics for diverse applications, but several urgent problems remained. Uncontrollable thickness of the coatings influenced the softness and wearing comfort of the fabrics. A high degree of Ag-based nanocomposites coverage on fabric surface is also a prerequisite for obtaining durable multifunctional coatings, but their toxic breakdown products and the consequent risks to human health and environment arouse great concerns and have frustrated their application in biomedical areas. Ag-nanocomposites with other nanoparticles such as CuO (Karlsson et al. 2008) and TiO2 (Karlsson et al. 2009) have been demonstrated their potential toxicity to cause DNA damage. However, most studies neglected important parameters such as the real content of Ag on fabrics and its impact on the functionalization. Over excessive loading of Ag-based nanocomposites is undesirable due to their potential toxicity, therefore, surface decoration and doping/capping treatment would be reasonable solutions.

Conclusions

-

The desire for comfort, hygiene and high performance fabric has created a rapid development on multifunctional cotton. Ag-based nanocomposites endowed cotton fabrics with multifunctionalities and influenced bulk properties such as the decorative color, mechanical and comfort capability. Ag NPs presented a variety of brilliant colors because of their surface plasmon resonance, which can be tailored by changing the size and shape of AgNPs. Key decoration technologies should be mastered to balance multifunctionalities and bulk properties for developing high performance value-added cotton fabric.

-

Many loading routes of Ag nanoparticles and nanocomposites have been reviewed in this paper. These routes should be high efficiency, economical and practical without creating ecological hazard. Most decoration ex situ and in situ were performed by using harmful chemicals which contaminate water or induce mechanical hazards to the fabric. Upon the health and environmental protection priority, green synthesis approach using nontoxic chemicals, environmentally benign solvents or renewable materials is one of the key issues that worth much consideration.

-

Durable multifunctional cotton fabrics is urgently needed, and special interest is oriented toward enhancing the adherence of Ag NPs or Ag-based nanocomposites on fabrics in order to avoid low washing fastness of the coating and prevent leaching of nanocomposites into environment. Application of crosslinking agents, capping agents or binders as intermediates and pre-treatment of the fabrics or nanocomposites to increase the contents of functional groups have been summarized to improve the stability of AgNPs or Ag-based nanocomposites on cotton fabrics. However, the reported 20 ~ 50 washing cycles is insufficient for antimicrobial fabrics. Meanwhile, most studies lacked reliable data on the loading and/or releasing profile of Ag NPs or Ag-based nanocomposites. The durable antimicrobial capability and other multifunctionalities are still the biggest challenge and should be estimated accurately while taking into consideration the health and environmental problems.

Future development

Much effort has been devoted to the development of high performance value-added cotton based on nanocomposites containing Ag NPs in order to endow the fabrics with antimicrobial capacity and self-cleaning, UV protection or electric conductivity as well. As the key functional components, Ag-based nanocomposites were essential to the durable multifunctionalities. Many studies have been focused on durable antimicrobial capability during laundry and controlled release of nanoantimicrobial agents (Rubin et al. 2018). However, few research has been done on durable self-cleaning, UV protection or electric conductivity, especially in the case of simulating surface contamination and abrasion of wearing, washing, drying and ironing in actual situation. Therefore, anti-abrasion surface with low nonspecific adhesion is potentially the critical feature for future sustainable multifunctional fabrics. Another possible study is the production of rechargable fabrics that can be recycled to integrate Ag-based nanocomposites, even if the fabrics were contaminated by the absorbed target molecules. Regarding future developments, more effort should be devoted to provide the fabrics with intelligent responsiveness, for example, response to thermal, optical or pH modulations. Novel visible-light photocatalysts such as tungsten trioxide (Fan et al. 2019), Ag doped TiO2 nanotube (Van Viet et al. 2018), porphyrinic metal-organic frameworks (Nie et al. 2020), double-shell Ag/AgCl/G-ZnFe2O4 nanocube (Zhang et al. 2020) have been developed in recent years, and the potential application of these photocatalysts on cotton fabrics should also be the subject of future research. Another area of research not covered yet is the employment of multifunctional cellulose to fabricate flexible electronic device. These devices using thermal conductive or electrical conductive coatings to harvest energy from body or body movement will be explored in more depth. Flexible supercapacitors is predicated as the most applicable electronic textiles with different functional agents in future perspectives.

References

Ahmed HB, Emam HE (2016) Layer by layer assembly of nanosilver for high performance cotton fabrics. Fiber Polym 17:418–426. https://doi.org/10.1007/s12221-016-5814-3

Airoudj A, Ploux L, Roucoules V (2015) Effect of plasma duty cycle on silver nanoparticles loading of cotton fabrics for durable antibacterial properties. J Appl Polym Sci 132:41279. https://doi.org/10.1002/APP.41279

Akter M, Sikder MT, Rahman MM, Ullah AKMA, Hossain KFB, Banik S, Hosokawa T, Saito T, Kurasaki M (2018) A systematic review on silver nanoparticles-induced cytotoxicity: Physicochemical properties and perspectives. J Adv Res 9:1–16. https://doi.org/10.1016/j.jare.2017.10.008

Aladpoosh R, Montazer M, Samadi N (2014) In situ green synthesis of silver nanoparticles on cotton fabric using Seidlitzia rosmarinus ashes. Cellulose 21:3755–3766. https://doi.org/10.1007/s10570-014-0369-1

Aladpoosh R, Montazer M (2016) Nano-photo active cellulosic fabric through in situ phytosynthesis of star-like Ag/ZnO nanocomposites: Investigation and optimization of attributes associated with photocatalytic activity. Carbohyd Polym 141:116–125. https://doi.org/10.1016/j.carbpol.2016.01.005

Ali A, Baheti V, Vik M, Militky J (2020) Copper electroless plating of cotton fabrics after surface activation with deposition of silver and copper nanoparticles. J Phy Chem Solids 137:109181. https://doi.org/10.1016/j.jpcs.2019.109181

Anderson SR, Mohammadtaheri M, Kumar D, O’Mullane AP, Field MR, Ramanathan R, Bansal V (2016) Robust nanostructured silver and copper fabrics with localized surface plasmon resonance property for effective visible light induced reductive catalysis. Adv Mater Interfaces 3:1500632. https://doi.org/10.1002/admi.201500632

Arif D, Niazi MBK, Ul-Haq N, Anwar MN, Hashmi E (2015) Preparation of antibacterial cotton fabric using chitosan-silver nanoparticles. Fiber Polym 16:1519–1526. https://doi.org/10.1007/s12221-015-5245-6

Augustine R, Kalarikkal N, Thomas S (2014) A facile and rapid method for the black pepper leaf mediated green synthesis of silver nanoparticles and the antimicrobial study. Appl Nanosci 4:809–818. https://doi.org/10.1007/s13204-013-0260-7

Avazpour S, Karimi L, Zohoori S (2017) Simultaneous coloration and functional finishing of cotton fabric using Ag/ZnO nanocomposite. Color Technol 133:423–430. https://doi.org/10.1111/cote.12296

Bacciarelli-Ulacha A, Rybicki E, Matyjas-Zgondek E, Pawlaczyk A, Szynkowska MI (2014) A new method of finishing of cotton fabric by in situ synthesis of silver nanoparticles. Ind Eng Chem Res 53:4147–4155. https://doi.org/10.1021/ie4011113

Bankara A, Joshi B, Kumar AR, Zinjardea S (2010) Banana peel extract mediated novel route for the synthesis of silver nanoparticles. Colloid Surface A 368:58–63. https://doi.org/10.1016/j.colsurfa.2010.07.024

Belal AS, Khalil MMA, Soliman M, Ebrahim S (2020) Novel superhydrophobic surface of cotton fabrics for removing oil or organic solvents from contaminated water. Cellulose 27:7703–7719. https://doi.org/10.1007/s10570-020-03316-1

Boufi S, Abid M, Bouattour S, Ferraria AM, Conceicao DS, Ferreira LFV, Corbel G, Neto PM, Lopes PA, Vilar MR, do Rego AMB (2019) Cotton functionalized with nanostructured TiO2-Ag-AgBr layer for solar photocatalytic degradation of dyes and toxic organophosphates. Int J Biol Macromol 128:902–910. https://doi.org/10.1016/j.ijbiomac.2019.01.218

Bozaci E, Akar E, Ozdogan E, Demir A, Altinisik A, Seki Y (2015) Application of carboxymethylcellulose hydrogel based silver nanocomposites on cotton fabrics for antibacterial property. Carbohyd Polym 134:128–135. https://doi.org/10.1016/j.carbpol.2015.07.036

Budama L, Cakır BA, Topel O, Hoda N (2013) A new strategy for producing antibacterial textile surfaces using silver nanoparticles. Chem Eng J 228:489–495. https://doi.org/10.1016/j.cej.2013.05.018

Burduşel AC, Gherasim O, Grumezescu AM, Mogoantă L, Ficai A, Andronescu E (2018) Biomedical applications of silver nanoparticles: An up-to-date overview. Nanomaterials 8:681. https://doi.org/10.3390/nano8090681

Busila M, Musat V, Textor T, Mahltig B (2015) Synthesis and characterization of antimicrobial textile finishing based on Ag:ZnO nanoparticles/chitosan biocomposites. RSC Adv 5:21562–21571. https://doi.org/10.1039/c4ra13918f

Cao ZB, Sun XB, Yao JR, Sun YY (2013) Silver sulfadiazine-immobilized celluloses as biocompatible polymeric biocides. J Bioact Compat Polym 28:398–410. https://doi.org/10.1177/0883911513490340

Chen HY, Liao F, Yuan ZY, Han XR, Xu CJ (2017) Simple and fast fabrication of conductive silver coatings on carbon fabrics via an electroless plating technique. Mater Lett 196:205–208. https://doi.org/10.1016/j.matlet.2017.03.070

Chitichotpanya P, Inprasit T, Chitichotpanya C (2019) In vitro assessment of antibacterial potential and mechanical properties of Ag-TiO2/WPU on medical cotton optimized with response surface methodology. J Nat Fibers 16:88–99. https://doi.org/10.1080/15440478.2017.1408520

Chmielewska D, Sartowska B (2012) Radiation synthesis of silver nanostructures in cotton matrix. Radiat Phys Chem 81:1244–1248. https://doi.org/10.1016/j.radphyschem.2011.11.067

Ding K, Wang W, Yu D, Wang W, Gao P, Liu BJ (2018) Facile formation of flexible Ag/AgCl/polydopamine/cotton fabric composite photocatalysts as an efficient visible-light photocatalysts. Appl Surf Sci 454:101–111. https://doi.org/10.1016/j.apsusc.2018.05.154

Dipankar C, Murugan S (2012) The green synthesis, characterization and evaluation of the biological activities of silver nanoparticles synthesized from Iresine herbstii leaf aqueous extracts. Colloid Surface B 98:112–119. https://doi.org/10.1016/j.colsurfb.2012.04.006

Doganli G, Yuzer B, Aydin I, Gultekin T, Con AH, Selcuk H, Palamutcu S (2016) Functionalization of cotton fabric with nanosized TiO2 coating for self-cleaning and antibacterial property enhancement. J Coat Technol Res 13:257–265. https://doi.org/10.1007/s11998-015-9743-7

Durán N, Durán M, de Jesus MB, Seabra AB, Fávaro WJ, Nakazato G (2016) Silver nanoparticles: A new view on mechanistic aspects on antimicrobial activity. Nanomed Nanotechnol Biol Med 12:789–799. https://doi.org/10.1016/j.nano.2015.11.016

Elechiguerra JL, Burt JL, Morones JR, Camacho-Bragado A, Gao XX, Lara HH, Yacaman MJ (2005) Interaction of silver nanoparticles with HIV-1. J Nanobiotechnol 3:6

El-Nahhal IM, Salem J, Anbar R, Kodeh FS, Elmanama A (2020) Preparation and antimicrobial activity of ZnO-NPs coated cotton/starch and their functionalized ZnO-Ag/cotton and Zn(II) curcumin/cotton materials. Sci Rep 10:5410. https://doi.org/10.1038/s41598-020-61306-6

El-Nahhal IM, Zourab SM, Kodeh FS, Elmanama AA, Selmane M, Genois I, Babonneau F (2013) Nano-structured zinc oxide-cotton fibers: Synthesis, characterization and applications. J Mater Sci-Mater El 24:3970–3975. https://doi.org/10.1007/s10854-013-1349-1

El-Rafie HM, El-Rafie MH, Zahran MK (2013) Green synthesis of silver nanoparticles using polysaccharides extracted from marine macro algae. Carbohyd Polym 96:403–410. https://doi.org/10.1016/j.carbpol.2013.03.071

El-Rafie MH, Mohamed AA, Shaheen TI, Hebeish A (2010) Antimicrobial effect of silver nanoparticles produced by fungal process on cotton fabrics. Carbohyd Polym 80:779–782. https://doi.org/10.1016/j.carbpol.2009.12.028

El-Sheekh MM, Shabaan MT, Hassan L, Morsi HH (2020) Antiviral activity of algae biosynthesized silver and gold nanoparticles against Herps Simplex (HSV-1) virus in vitro using cell-line culture technique. Int J Environ Heal R. https://doi.org/10.1080/09603123.2020.1789946

El-Shishtawy RM, Asiri AM, Abdelwahed NAM, Al-Otaibi MM (2011) In situ production of silver nanoparticle on cotton fabric and its antimicrobial evaluation. Cellulose 18:75–82. https://doi.org/10.1007/s10570-010-9455-1

Emam HE (2019) Generic strategies for functionalization of cellulosic textiles with metal salts. Cellulose 26:1431–1447. https://doi.org/10.1007/s10570-018-2185-5