Abstract

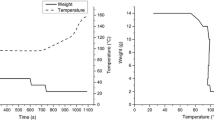

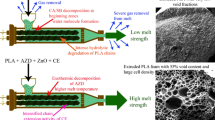

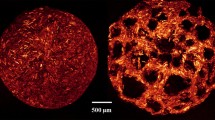

Foamed materials are gaining an increased interest due to their good mechanical properties in relation to their low densities and an increased industrial demand can be expected. A few less attractive issues can however be associated with commodity foamed products. For instance the raw-material often originates from non-renewable, fossil-based, sources. Furthermore, degradation in nature is slow, therefor the disposed product is burned or end up in landfills. One possibility to reduce the impact on nature could be to produce foams from natural polymers such as starch or cellulose. In this study the possibility to produce foams from hydroxypropyl methylcellulose (HPMC) with water as blowing agent, by continuous extrusion, was investigated. A pre-study using a capillary viscometer, batch-extruder, was conducted to evaluate the foamability of HPMC. Due to promising results further experiments were conducted with a single-screw extruder. The goal was to find an adequate processing window for foaming. It was concluded that HPMC could successfully be foamed by continuous extrusion, although a careful tailoring of the processing parameters was required. Crucial parameters were here the temperature, pressure and residence time distribution in the extruder. Regions of the extruded foams were examined using optical and scanning electron microscopy and HPMC foams with a density in the range of that of fossil-based polymeric foams could be produced.

Similar content being viewed by others

References

Ali ZM, Gibson LJ (2013) The structure and mechanics of nanofibrillar cellulose foams. Soft Matter 9:1580–1588

Biron M (2013) Detailed accounts of thermoplastic resins. In: Biron M (ed) Thermoplastics and thermoplastic composites. William Andrew, Boston, p 326

Calvert K, Trumble K, Webster T, Kirkpatrick L (2010) Characterization of commercial rigid polyurethane foams used as bone analogs for implant testing. J Mater Sci Mater Med 21(5):1453–1461

Clasen C, Kulicke W (2001) Determination of viscoelastic and rheo-optical material functions of water-soluble cellulose derivatives. Prog Polym Sci 26(9):1839–1919

da Silva A et al (2013) Cassava starch-based foams reinforced with bacterial cellulose. J Appl Polym Sci 130(5):3043–3049

Defonseka C (2013) Practical guide to flexible polyurethane foams, 1st edn. Smithers Rapra Technology, Shawbury

Eichhorn SJ et al (2001) Review: current international research into cellulosic fibres and composites. J Mater Sci 36(9):2107–2131

Guan J, Hanna MA (2006) Selected morphological and functional properties of extruded acetylated starch–cellulose foams. Bioresour Technol 97(14):1716–1726

Karlsson K, Schuster E, Stading M, Rigdahl M (2015) Foaming behavior of water-soluble cellulose derivatives: hydroxypropyl methylcellulose and ethyl hydroxyethyl cellulose. Cellulose 22(4):2651–2664

Katsanevakis S (2008) Marine debris, a growing problem: sources, distribution, composition, and impacts, in marine. In: Hofer TN (ed) Marine pollution: new research. Nova Science Publishers, New York, p 59

Klemm D et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466

Kumar Das A (2007) Application of multivariate analysis to increase the yield of dry cell batteries. J Appl Stat 34(3):239–248

Lee S-T (2008) History and trends of polymeric foams. In: Lee S, Scholz D (eds) Polymeric foams-technology and developments in regulation, process, and products. CRC Press, Boca Raton, p 27

Lee S.-T., Pontiff T, (2014) Chapter 1 and 13. In: Lee S, Park CB (eds) Foam extrusion: principles and practice, 2nd edn. CRC Press, Boca Raton, pp. 1–17; 419–433

Robledo-Ortiz J et al (2008) Non-isothermal decomposition kinetics of azodicarbonamide in high density polyethylene using a capillary rheometer. Polym Test 27(6):730–735

Samper M, Garcia-Sanoguera D, Parres F, Lopez J (2010) Recycling of expanded polystyrene from packaging. Prog Rubber Plast Recycl Technol 26(2):83–92

Sauceau M et al (2011) New challenges in polymer foaming: a review of extrusion processes assisted by supercritical carbon dioxide. Prog Polym Sci 36(6):749–766

Svagan AJ, Berglund LA, Jensen P (2011) Cellulose nanocomposite biopolymer foam—hierarchical structure effects on energy absorption. ACS Appl Mater Interfaces 3:1411–1417

Acknowledgments

The funding from the Swedish Research Council Formas is gratefully acknowledged. Thanks to Anette Larsson, Gunnar Westman, Linda Härdelin, Mikaela Börjesson, Filip Nylander and all other members within the SmartFoam project for interesting, helpful discussions on laboratory equipment and interpretation of results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karlsson, K., Kádár, R., Stading, M. et al. Processing window for extrusion foaming of hydroxypropyl methylcellulose. Cellulose 23, 1675–1685 (2016). https://doi.org/10.1007/s10570-016-0924-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0924-z