Abstract

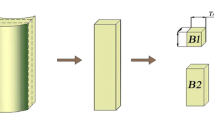

The development of the use of flax fibre as reinforcement of eco-friendly composite materials requires a good knowledge of its hydrothermal and mechanical behaviours. To this end the fibre internal structure must be finely investigated. Transmission electron microscopy was used to analyse the morphology of the fibre cell walls in terms of the arrangement of the layers and their thickness. Thus, an alternative eco-friendly staining method, based on oolong tea extract was successfully implemented. The results reveal an arrangement at the nanoscale slightly different from the classical four layer model encountered in the literature: the inner layer includes three to four sub-layers. The cell walls comprises two outer layers of relative thickness of about 10 %, a middle layer of about 70 % and a group of thinner layers (called sub-layers) that are contiguous to the lumen with relative thickness of about 20 %.

Similar content being viewed by others

References

Baley C (2002) Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos A Appl Sci Manuf 33:939–948

Baley C, Morvan C, Grohens Y (2005) Influence of the absorbed water on the tensile strength of flax fibers. Macromol Symp 222:195–202

Barbulée A, Jernot J-P, Bréard J, Gomina M (2014) Damage to flax fibre slivers under monotonic uniaxial tensile loading. Compos A Appl Sci Manuf 64:107–114

Batra SK (1998). Handbook of fiber chemistry—other long vegetable fibers. In: Lewin M, Pearce EM

Beukers A, van Hinte E (2005) Lightness: the inevitable renaissance of minimum energy structures (010 Publishers)

Bos HL, Donald AM (1999) In situ ESEM study of the deformation of elementary flax fibres. J Mater Sci 34:3029–3034

Brett CT, Waldron KW (1996) Physiology and biochemistry of plant cell walls. Chapman and Hall, Londres

Carpentier A, Abreu S, Trichet M, Satiat-Jeunemaitre B (2012) Microwaves and tea: new tools to process plant tissue for transmission electron microscopy. J Microsc 247:94–105

Chakravarty A, Hearle JWS (1967) Observations of the tensile properties of ultimate cells of some plant fibres. J Text Inst 58:651–656

Charlet K, Baley C, Morvan C, Jernot JP, Gomina M, Bréard J (2007) Characteristics of Hermès flax fibres as a function of their location in the stem and properties of the derived unidirectional composites. Compos A Appl Sci Manuf 38:1912–1921

Charlet K, Jernot JP, Gomina M, Bréard J, Morvan C, Baley C (2009) Influence of an Agatha flax fibre location in a stem on its mechanical, chemical and morphological properties. Compos Sci Technol 69:1399–1403

Chernova T, Gorshkova T (2007) Biogenesis of plant fibers. Russ J Dev Biol 38:221–232

Davies GC, Bruce DM (1998) Effect of environmental relative humidity and damage on the tensile properties of flax and nettle fibers. Text Res J 68:623–629

Dittenber DB, GangaRao HV (2012) Critical review of recent publications on use of natural composites in infrastructure. Compos A Appl Sci Manuf 43:1419–1429

Doblin MS, Kurek I, Jacob-Wilk D, Delmer DP (2002) Cellulose biosynthesis in plants: from genes to rosettes. Plant Cell Physiol 43:1407

Domenges B, Charlet K (2010) Direct insights on flax fiber structure by focused ion beam microscopy. Microsc Microanal 16:175–182

Le Duigou A, Bourmaud A, Baley C (2015) In-situ evaluation of flax fibre degradation during water ageing. Ind Crops Prod 70:204–210

Fink HP, Walenta E, Kunze J (1999) The structure of natural cellulosic fibres-Part 2. The supermolecular structure of bast fibres and their changes by mercerization as revealed by X-ray diffraction and C-13-NMR-spectroscopy. Papier 9:534–542

Fromm J, Rockel B, Lautner S, Windeisen E, Wanner G (2003) Lignin distribution in wood cell walls determined by TEM and backscattered SEM techniques. J Struct Biol 143:77–84

Ganster J, Fink HP (1999) Physical constants of cellulose. Polymer Handbook Immergut EH, Grulke

Gassan J, Chate A, Bledzki AK (2001) Calculation of elastic properties of natural fibers. J Mater Sci 36:3715–3720

Godin B, Agneessens R, Gofflot S, Lamaudière S, Sinnaeve G, Gerin PA, Delcarte J (2011) Revue bibliographique sur les méthodes d’analyse des polysaccharides structuraux des biomasses lignocellulosiques. Biotechnol Agron Soc Environ 15:165–182

Gorshkova TA, Wyatt SE, Salnikov VV, Gibeaut DM, Ibragimov MR, Lozovaya VV, Carpita NC (1996) Cell-wall polysaccharides of developing flax plants. Plant Physiol 110:721–729

Gorshkova TA, Salnikov VV, Pogodina NM, Chemikosova SB, Yablokova EV, Ulanov AV, Ageeva MV, Van Dam JEG, Lozovaya VV (2000) Composition and distribution of cell wall phenolic compounds in flax (Linum usitatissimum L.) stem tissues. Ann Bot 85:477

Gorshkova TA, Sal’nikov VV, Chemikosova SB, Ageeva MV, Pavlencheva NV, van Dam JEG (2003) The snap point: a transition point in Linum usitatissimum bast fiber development. Ind Crops Prod 18:213–221

Hearle JWS (1963) The fine structure of fibers and crystalline polymers. III. Interpretation of the mechanical properties of fibers. J Appl Polym Sci 7:1207–1223

Juarez C, Duran A, Valdez P, Fajardo G (2007) Performance of “Agave lecheguilla” natural fiber in Portland cement composites exposed to severe environment conditions. Build Environ 42:1151–1157

Lehringer C, Daniel G, Schmitt U (2009) TEM/FE-SEM studies on tension wood fibres of Acer spp., Fagus sylvatica L. and Quercus robur L. Wood Sci Technol 43:691–702

Lennholm H, Larsson T, Iversen T (1994) Determination of cellulose I[alpha] and I[beta] in lignocellulosic materials. Carbohydr Res 261:119–131

Mark RE (1967) Cell wall mechanics of tracheids. Yale University Press, New Haven

Meredith J, Ebsworth R, Coles SR, Wood BM, Kirwan K (2012) Natural fibre composite energy absorption structures. Compos Sci Technol 72:211–217

Meredith J, Coles SR, Powe R, Collings E, Cozien-Cazuc S, Weager B, Müssig J, Kirwan K (2013) On the static and dynamic properties of flax and Cordenka epoxy composites. Compos Sci Technol 80:31–38

Morvan C, Andème-Onzighi C, Girault R, Himmelsbach DS, Driouich A, Akin DE (2003) Building flax fibres: more than one brick in the walls. Plant Physiol Biochem 41:935–944

Mukherjee PS, Satyanarayana KG (1986a) An empirical evaluation of structure-property relationships in natural fibres and their fracture behaviour. J Mater Sci 21:4162–4168

Mukherjee PS, Satyanarayana KG (1986b) Structure and properties of some vegetable fibers 2 Pineapple fiber (anannus-comosus). J Mater Sci 2:51–56

Näslund P, Vuong R, Chanzy H, Jésior JC (1988) Diffraction contrast transmission electron microscopy on flax fiber ultrathin cross sections. Text Res J 58:414–417

Nilsson T, Gustafsson PJ (2007) Influence of dislocations and plasticity on the tensile behaviour of flax and hemp fibres. Compos A Appl Sci Manuf 38:1722–1728

Van den Oever MJA, Bos HL, Van Kemenade M (2000) Influence of the physical structure of flax fibres on the mechanical properties of flax fibre reinforced polypropylene composites. Appl Compos Mater 7:387–402

Oksman K (2001) High quality flax fibre composites manufactured by the resin transfer moulding process. J Reinf Plast Compos 20:621

Olorunnisola AO (2008) Effects of pre-treatment of rattan (Laccosperma secundiflorum) on the hydration of Portland cement and the development of a new compatibility index. Cement Concr Compos 30:37–43

Pacheco-Torgal F, Jalali S (2011) Cementitious building materials reinforced with vegetable fibres: a review. Constr Build Mater 25:575–581

Preston RD (1974) The physical biology of plant cell walls. Chapman and Hall, Londres

Roe PJ, Ansell MP (1985) Jute-reinforced polyester composites. J Mater Sci 20:4015–4020

Roland J-C, Mosiniak M, Roland D (1995) Dynamique du positionnement de la cellulose dans les parois des fibres textiles du lin (Linum usitatissimum). Acta Bot Gallica 142:463–484

Sasaki Y, Sato S, Adachi A, Dan Y, Nishimura M (2001) Use of oolong tea extract staining of soft-tissue specimens in low-vacuum scanning electron microscope with a cooling stage. Med Electron Microsc 34:254–257

Sato S, Adachi A, Satomura K (1996) The ultrastructure of spiralled collagen in liver fibrosis. Med Electron Microsc 29:153–158

Sato S, Sasaki Y, Adachi A, Dai W, Liu X-L, Namimatsu S (2003) Use of oolong tea extract (OTE) for elastin staining and enhancement in ultrathin sections. Med Electron Microsc 36:179–182

Sato S, Adachi A, Sasaki Y, Ghazizadeh M (2008) Oolong tea extract as a substitute for uranyl acetate in staining of ultrathin sections. J Microsc 229:17–20

Sawsen C, Fouzia K, Mohamed B, Moussa G (2014) Optimizing the formulation of flax fiber-reinforced cement composites. Constr Build Mater 54:659–664

Sawsen C, Fouzia K, Mohamed B, Moussa G (2015) Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr Build Mater 79:229–235

Saxena IM, Brown RM (2005) Cellulose biosynthesis: current views and evolving concepts. Ann Bot 96:9–21

Sridhar MK, Basavarajappa G, Kasturi SG, Balasubramanian N (1982) Evaluation of jute as a reinforcement in composites. Indian J Fibre Text Res 7:87–92

Stout HP, Jenkins JA (1955) Comparative strengths of some bast and leaf fibres. Ann Text Belges 4:231–251

Thuault A, Eve S, Bazin J, Charlet K, Destaing F, Gomina M, Bréard J (2011) Morphologie, biocomposition et comportement mécanique des fibres de lin. Matér Tech 99(3):275–280

Thuault A, Eve S, Blond D, Bréard J, Gomina M (2013a). Effects of the hygrothermal environment on the mechanical properties of flax fibres. J Compos Mater 0021998313490217

Thuault A, Eve S, Jouannot-Chesney P, Bréard J, Gomina M (2013b) Interrelation between the variety and the mechanical properties of flax fibres. J Biobased Mater Bioenergy 7(5):609–618

Thuault A, Bazin J, Eve S, Bréard J, Gomina M (2013c). Numerical study of the influence of structural and mechanical parameters on the tensile mechanical behaviour of flax fibres. J Indu Text 44(1):22–39

Tröger F, Wegener G, Seemann C (1998) Miscanthus and flax as raw material for reinforced particleboards. Ind Crops Prod 8:113–121

Van de Velde K, Kiekens P (2001) Thermoplastic pultrusion of natural fibre reinforced composites. Compos Struct 54:355–360

Wang HH, Drummond JG, Reath SM, Hunt K, Watson PA (2001) An improved fibril angle measurement method for wood fibres. Wood Sci Technol 34:493–503

Weimer PJ, Lopez-Guisa JM, French AD (1990) Effect of cellulose fine structure on kinetics of its digestion by mixed ruminal microorganisms in vitro. Appl Environ Microbiol 56:2421–2429

Yamaguchi K, Suzuki K, Tanaka K (2010) Examination of electron stains as a substitute for uranyl acetate for the ultrathin sections of bacterial cells. J Electron Microsc 59:113

Yan L, Chouw N (2013) Crashworthiness characteristics of flax fibre reinforced epoxy tubes for energy absorption application. Mater Des 51:629–640

Yan L, Chouw N, Jayaraman K (2014a) Flax fibre and its composites—a review. Compos B Eng 56:296–317

Yan L, Chouw N, Jayaraman K (2014b) Effect of triggering and polyurethane foam-filler on axial crushing of natural flax/epoxy composite tubes. Mater Des 56:528–541

Yan L, Chouw N, Jayaraman K (2014c) Lateral crushing of empty and polyurethane-foam filled natural flax fabric reinforced epoxy composite tubes. Compos B Eng 63:15–26

Yan L, Chouw N, Jayaraman K (2015) Effect of UV and water spraying on the mechanical properties of flax fabric reinforced polymer composites used for civil engineering applications. Mater Des 71:17–25

Acknowledgments

They are grateful to the French National Research Center (CNRS) and the Region of Lower Normandy for their financial support. Authors also want to thank Dr. B. Duchemin for his helpful advices.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thuault, A., Domengès, B., Hervas, I. et al. Investigation of the internal structure of flax fibre cell walls by transmission electron microscopy. Cellulose 22, 3521–3530 (2015). https://doi.org/10.1007/s10570-015-0744-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0744-6