Abstract

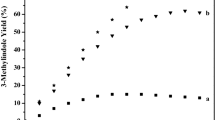

TS-1 with different Ti/Si molar ratios (0.02 for TS-1a, 0.025 for TS-1b, 0.03 for TS-1c), and Ti–K (TiO2-SiO2) catalysts were prepared through a hydrothermal procedure and characterized by the XRD, BET, SEM/TEM, XPS/ICP, Raman, UV–Vis, FT-IR/Py–IR, and NH3–TPD for gas-glycerol value-added conversion. The acidic [(Ti, Si)O4] sites were considered to be the reactive centers for acetaldehyde production with the selectivity closely related to the concentration of [(Ti, Si)O4] and Smicro/SBET values but not the PyB/PyL value or surface acid density. The [(Ti, Si)O4] in MFI micro-structure promoted acetaldehyde production by 1–2 dehydration and subsequent cracking of gas-glycerol, better than the [(Ti, Si)O4] without MFI micro-structure. Over the TS-1c, gas-glycerol conversion reached 91.5%, with the selectivity towards acetaldehyde and acrolein reaching 34.4% and 29.5%, respectively. Significantly, the catalytic stability of the TS-1c can be obviously improved by using liquid feed of a glycerol-methanol solution.

Graphical Abstract

TS-1c (3.3%) showed glycerol catalytic conversion reached 91.5 % with the selectivity of acetaldehyde and acrolein reaching about 34.4 %, and 29.5 %, respectively. The acidic [(Ti, Si)O4] was confirmed to be the reactive centers for acetaldehyde production, especially for the [(Ti, Si)O4] in MFI micro-structure (with b-axis 300 nm, micro-pores 5.8 Å) promoted acetaldehyde production from 1 to 2 and 1–3 dehydration of glycerol. It was new found the catalytic stability of TS-1c can be obviously improved as using liquid feed of glycerol-methanol solution.

Similar content being viewed by others

References

Lei LJ, Wang YH, Zhang ZX et al (2020) Transformations of biomass its derivatives, and downstream chemicals over ceria catalysts. ACS Catal 10(15):8788–8814

Chen BL, Peng ZQ, Li C et al (2021) Catalytic conversion of biomass to furanic derivatives with deep eutectic solvents. Chemsuschem 14:1496–1506

Mardiana ST, Azhari NJ, Ilmi T et al (2022) Hierarchical zeolite for biomass conversion to biofuel: a review. Fuel 309:122119

Zhang TJ, Liu CH, Gu YL et al (2021) Glycerol in energy transportation: a state-of-the-art review. Green Chem 23:7865–7889

Sun D, Yamada Y, Sato S (2016) Glycerol hydrogenolysis into useful C3 chemicals. Appl Catal B 19:75–92

Jin X, Meng KX, YZhang G et al (2021) Interfacial catalysts for sustainable chemistry: advances on atom and energy efficient glycerol conversion to acrylic acid. Green Chem 23:51–76

Tran NH, Kannangara GSK (2013) Conversion of glycerol to hydrogen rich gas. Chem Soc Rev 42(24):9454–9479

Zhou CHC, Beltramini JN, Fan YX (2008) Chemoselective catalytic conversion of glycerol as a biorenewable source to valuable commodity chemicals. Chem Soc Rev 37:527–549

Dodekatos G, Schünemann S, Tüysüz H (2018) Recent advances in thermo-, photo-, and electrocatalytic glycerol oxidation. ACS Catal 8:6301–6333

NPCS, Board of Consultants & Engineers (2010) Industrial alcohol technology handbook. Asia Pacific Business Press Inc.

Guo LL, Yu J, Wang WW et al (2021) Small-sized cuprous oxide species on silica boost acrolein formation via selective oxidation of propylene. Chinese J Catal 42:320–333

Zhang QT, Goldbach A, Ta N et al (2021) Selective oxidation of propylene to acrolein over silver-promoted hexagonal molybdates and derivative Ag/Ag2Mo4O13/α-MoO3 composites. Appl Catal A Gen 623:118275

Jiang XC, Zhou CH, Tesser R et al (2018) Coking of catalysts in catalytic glycerol dehydration to acrolein. Ind Eng Chem Res 57:10736–10753

Cespi D, Passarini G, Mastragostino VL et al (2015) Glycerol as feedstock in the synthesis of chemicals: a life cycle analysis for acrolein production. Green Chem 17:343–355

García-Sancho C, Moreno-Tost R, Mérida-Robles J et al (2012) Zirconium doped mesoporous silica catalysts for dehydration of glycerol to high added-value products. Appl Catal A 433–434:179–187

Zhang HB, Hu ZJ, Huang L et al (2015) Dehydration of glycerol to acrolein over hierarchical ZSM-5 zeolites: effects of mesoporosity and acidity. ACS Catal 5:2548–2558

Liu R, Wang TF, Liu C et al (2013) Highly selective and stable CsPW/Nb2O5 catalysts for dehydration of glycerol to acrolein. Chinese J Catal 34:2174–2182

Filhoa RAL, Possatob LG, Santistebana OAN et al (2020) Synthesis and characterization of chromium silicate catalyst and its application in the gas phase glycerol transformation into acetaldehyde. Inorg Chem Commun 112:107710

Kiakalaieh AT, Amin NAS (2017) Coke-tolerant SiW20-Al/Zr10 catalyst for glycerol dehydration to acrolein, Chinese. J Catal 38:1697–1710

García-Sancho C, Cecilia JA, Mérida-Robles JM et al (2018) Effect of the treatment with H3PO4 on the catalytic activity of Nb2O5 supported on Zr-doped mesoporous silica catalyst. Case study: glycerol dehydration. Appl Catal B 221:158–168

Ren X, Zhang F, Sudhakar M et al (2019) Gas-phase dehydration of glycerol to acrolein catalyzed by hybrid acid sites derived from transition metal hydrogen phosphate and meso-HZSM-5. Catal Today 332:20–27

Chai SH, Wang HP, Liang Y et al (2007) Sustainable production of acrolein: investigation of solid acid-base catalysts for gas-phase dehydration of glycerol. Green Chem 9:1130–1136

Foo GS, Wei D, Sholl DS et al (2014) Role of lewis and brønsted acid sites in the dehydration of glycerol over niobia. ACS Catal 4:3180–3192

Carriço CS, Cruz FT, dos Santos MB et al (2016) MWW-type catalysts for gas phase glycerol dehydration to acrolein. J Catal 334:34–41

Wang F, Dubois JL, Ueda W (2009) Catalytic dehydration of glycerol over vanadium phosphate oxides in the presence of molecular oxygen. J Catal 268:260–267

Ma TL, Ding JF, Liu XL et al (2020) Gas-phase dehydration of glycerol to acrolein over different metal phosphate catalysts. Korean J Chem Eng 37(6):955–960

Zhao SF, Wang W, Wang LZ et al (2020) Cooperation of hierarchical pores with strong Brønsted acid sites on SAPO-34 catalysts for the glycerol dehydration to acrolein. J Catal 389:166–175

Lan H, Xiao X, Yuan SL et al (2017) Synergistic effect of Mo-Fe bimetal oxides promoting catalytic conversion of glycerol to allyl alcohol. Catal Lett 147:2187–2199

Lan H, Yao Q, Zhou YB et al (2020) Direct conversion of gas-glycerol to allyl alcohol over V, Ti or Nb modified MoFe/KIT-6 oxide catalysts. Mol Catal 498:111279

Tang CM, Zhai ZJ, Li XL et al (2016) Sustainable production of acetaldehyde from lactic acid over the magnesium aluminate spinel. J Taiwan Inst Chem Eng 58:97–106

Filho RAL, Possato LG, Santisteban OAN et al (2020) Synthesis and characterization of chromium silicate catalyst and its application in the gas phase glycerol transformation into acetaldehyde. Inorganic Chem Commun 112:107710

Khomane RB, Kulkarni BD, Paraskar A et al (2002) Synthesis, characterization and catalytic performance of titanium silicalite-1 prepared in micellar media. Mater Chem Phys 76:99–103

Song ZN, Feng X, Sheng N et al (2019) Cost-efficient core-shell TS-1/silicalite-1 supported Au catalysts: towards enhanced stability for propene epoxidation with H2 and O2. Chem Eng J 377:119927

Zhu QH, Liang MN, Yan WJ et al (2019) Effective hierarchization of TS-1 and its catalytic performance in propene epoxidation. Microporous Mesoporous Mater 278:307–313

Du Q, Guo YP, Wu P et al (2019) Facile synthesis of hierarchical TS-1 zeolite without using mesopore templates and its application in deep oxidative desulfurization. Microporous Mesoporous Mater 275:61–68

Kleitz F, Choi SH, Ryoo R (2003) Cubic Ia3d large mesoporous silica: synthesis and replication to platinum nanowires, carbon nanorods and carbon nanotubes. Chem Commun 17:2136–2137

Yan W, Ramanathan A, Patel PD (2016) Mechanistic insights for enhancing activity and stability of Nb-incorporated silicates for selective ethylene epoxidation. J Catal 336:75–84

Zhang TJ, Chen XX, Chen GR et al (2018) Synthesis of anatase-free nano-sized hierarchical TS-1 zeolites and their excellent catalytic performance in alkene epoxidation. J Mater Chem A 6:9473–9479

Pang CL, Xiong JH, Li GY et al (2018) Direct ring CAH bond activation to produce cresols from toluene and hydrogen peroxide catalyzed by framework titanium in TS-1. J Catal 366:37–49

Chen Z, Wang J, Shen K et al (2020) In-depth understanding the role of seeds in the synthesis of TS-1. Appl Catal A Gen 591:117403

Lu TL, Zou JP, Zhan YZ et al (2018) Highly efficient oxidation of ethyl lactate to ethyl pyruvate catalyzed by TS-1 under mild conditions. ACS Catal 8(2):1287–1296

Wroblewska A, Tołpa J, Kłosin D et al (2020) The application of TS-1 materials with different titanium contents as catalysts for the autoxidation of α-pinene. Microporous Mesoporous Mater 305:110384

Wang XL, Xiao CK, Zheng P et al (2020) Dendritic micro–mesoporous composites with center-radial pores assembled by TS-1 nanocrystals to enhance hydrodesulfurization activity of dibenzothiophene and 4, 6-dimethyldibenzothiophene. J Catal 384:136–146

Li JC, Li JM, Zhao Z et al (2017) Size effect of TS-1 supports on the catalytic performance of PtSn/TS-1catalysts for propane dehydrogenation. J Catal 352:361–370

Du Q, Guo YP, Duan HN et al (2017) Synthesis of hierarchical TS-1 zeolite via a novel three-step crystallization method and its excellent catalytic performance in oxidative desulfurization. Fuel 188:232–238

Dalil M, Carnevali D, Dubois JL (2015) Transient acrolein selectivity and carbon deposition study of glycerol dehydration over WO3/TiO2 catalyst. Chem Eng J 270:557–563

Nimlos MR, Blanksby SJ, Qian X (2006) Mechanisms of glycerol dehydration. J Phys Chem A 110(18):6145–6156

Lauriol PG, Millet JMM, Loridant S (2011) New efficient and long-life catalyst for gas-phase glycerol dehydration to acrolein. J catal 280(1):68–76

Acknowledgements

The work was financially supported by Natural Science Foundation project of Chongqing Science and Technology (CSTB2022NSCQ-MSX1497); Youth research project of science and technology of Chongqing municipal education commission (KJQN201800746); Sichuan Science and Technology Program (2021ZHCG0019); Research project of Chongqing Jiaotong University (19JDKJC-A017, XJ2021000901); Talent projects of Guangdong University of Petrochemical Technology (2019rc038); Featured Innovative Talents Project of Guangdong Education Department (2022KTSCX085) and Science and Technology Program of Maoming (2022038)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lan, H., Yao, Q., Liu, M. et al. TS-1 Molecular Sieves Facilitated Aldehyde Stable Production from Gas-Glycerol Dehydration: Using Liquid Feed of Glycerol-Methanol Solution. Catal Lett 153, 3480–3491 (2023). https://doi.org/10.1007/s10562-022-04246-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04246-2