Abstract

Objectives

Microbial production of biopolymers is typically associated with high viscosity and suitable mixing plays an important role in their production. Due to the nature of Streptococcus strains in high production of lactic acid and consequently high consumption of NaOH, which is associated with increased viscosity and reduced mixing caused by hyaluronic acid production, the injected NaOH accumulates and causes cells loss, and decreases in quantity and quality of the produced hyaluronic acid.

Results

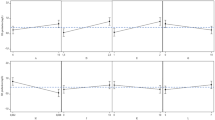

In this study, the effect of increasing dilution of media culture of Streptococcus zooepidemicus fed-batch culture during pH control by NaOH on mixing time, volumetric oxygen transfer coefficient, and increasing hyaluronic acid production in a 2-L fermenter were studied. The results showed that significant increasing dilution causes reduction mixing time, remarkable improvement volumetric oxygen transfer coefficient, hyaluronic acid production enhancement from 6.6 to 8.4 g/L, and diminution the consumption of NaOH.

Conclusion

Dilution of media culture of S. zooepidemicus fed-batch culture by the pH controlling agent achieved one of the highest amounts of hyaluronic acid that was reported recently. This method does not require any automatic control and can be used at a low cost to produce other soluble extracellular biopolymers.

Similar content being viewed by others

References

Amado IR, Vázquez JA, Pastrana L, Teixeira JA (2017) Microbial production of hyaluronic acid from agro-industrial by-products: molasses and corn steep liquor. Biochem Eng J 117:181–187

Chong BF, Nielsen LK (2003) Aerobic cultivation of Streptococcus zooepidemicus and the role of NADH oxidase. Biochem Eng J 16:153–162

Duan XJ, Yang L, Zhang X, Tan WS (2008) Effect of oxygen and shear stress on molecular weight of hyaluronic acid produced by Streptococcus zooepidemicus. J Microbiol Biotechnol 18(4):718–724

Huang G, Chen J (2019) Preparation and applications of hyaluronic acid and its derivatives. Int J Biol Macromol 125:478–484

Izawa N, Hanamizu T, Sone T, Chiba K (2010) Effects of fermentation conditions and soybean peptide supplementation on hyaluronic acid production by Streptococcus thermophilus strain YIT 2084 in milk. J Biosci Bioeng 109(4):356–360

Lai Z, Abdul Rahim R, Arbakariya B, Rosfarizan M (2012) Biosynthesis of high molecular weight hyaluronic acid by Streptococcus zooepidemicus using oxygen vector and optimum impeller tip speed. J Biosci Bioeng 114(3):286–291

Liu L, Du G, Chen J, Wang M, Sun J (2009) Comparative study on the influence of dissolved oxygen control approaches on the microbial hyaluronic acid production of Streptococcus zooepidemicus. Bioprocess Biosyst Eng 32(6):755–763

Liu L, Yang HQ, Zhang DX, Du GC, Chen J, Wang M, Sun J (2009) Enhancement of hyaluronic acid production by batch culture of Streptococcus zooepidemicus via the addition of n-dodecane as an oxygen vector. J Microbiol Biotechnol 19(6):596–603

Long L, Guocheng D, Jian C, Yang Z, Miao W, Jun S (2009) Microbial production of low molecular weight hyaluronic acid by adding hydrogen peroxide and ascorbate in batch culture of Streptococcus zooepidemicus. Biores Technol 100:362–367

Schügerl K (1981) Oxygen transfer into highly viscous media in reactors and reactions. Springer, Berlin, Heidelberg, pp 71–174

Seviour RJ, McNeil B, Fazenda ML, Harvey LM (2011) Operating bioreactors for microbial exopolysaccharide production. Crit Rev Biotechnol 31:170–185

Vázquez J, Pastrana L, Piñeiro C, Teixeira J, Pérez-Martín R, Amado I (2015) Production of hyaluronic acid by Streptococcus zooepidemicus on protein substrates obtained from Scyliorhinus canicula discards. Mar Drugs 13(10):6537–6549

Viloria AC, Ardila KS, Mendez DA, Rojas IC, Moreno NC (2017) Volumetric oxygen mass transfer coefficient determination and hydrodynamic optimization of polyhydroxyalkanoate production with vegetal oil as carbon source. Chem Eng Trans 57:1303–1308

Zakeri A, Rasaee MJ (2016) Identification of wild type Streptococcus zooepidemicus and optimization of culture medium and fermentation conditions for production of hyaluronic acid. Biosci Biotechnol Res Asia 13(1):189–198

Zakeri A, Rasaee MJ, Pourzardosht N (2017) Enhanced hyaluronic acid production in Streptococcus zooepidemicus by over expressing HasA and molecular weight control with niscin and glucose. Biotechnol Rep 16:65–70

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saharkhiz, S., Babaeipour, V. The dilution effect of media culture on mixing time, Kla O2, and hyaluronic acid production in S. zooepidemicus fed-batch culture. Biotechnol Lett 43, 2217–2222 (2021). https://doi.org/10.1007/s10529-021-03192-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-021-03192-0