Abstract

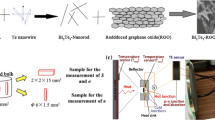

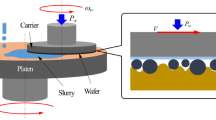

For the first time, a review of microheater design and its implementation for nanowire synthesis has been investigated. The recent developments on the effect of temperature, precursor flow rate, and synthesis time on the size and size distribution of nanowires have been studied. The essential components of the microheater include a substrate, insulating layer(s), and microheater area. A guide for material selection associated with different components of the device including the heating element, conducting pads, membrane, substrate, and oxidation layer has been addressed. The current progress on electrode patterns and microheater fabrication methods has been evaluated. The insights into microheater calibration curves have been reviewed. Finally, the economic aspects including the microheater market and fabrication costs have been presented.

Similar content being viewed by others

References

Ahmed MG, Dennis J, Khir MM, Rabih AA (2018) Characterization of micro-heater and temperature sensor in micro-electromechanical system device for gas detection. In: International Conference on Computer, Control, Electrical, and Electronics Engineering (ICCCEEE), IEEE, 1–6, 2018.

Ali SZ, Udrea F, Milne WI, Gardner JW (2008) Tungsten-based SOI microhotplates for smart gas sensors. J Microelectromech Syst 17(6):1408–1417

An T, Zhu B, Ling Y, Gong S, Cheng W (2019) A Janus gold nanowire electrode for stretchable micro-supercapacitors with distinct capacitances. J Mater Chem A 7:14233–14238

Ashby MF, Shercliff H, Cebon D (2018) Materials: engineering, science, processing and design. Butterworth-Heinemann

Astié S, Gue A, Scheid E, Guillemet J (2000) Design of a low power SnO2 gas sensor integrated on silicon oxynitride membrane. Sens Actu B Chem 67(1–2):84–88

Avramescu V, De Luca A, Brezeanu M, Zeeshan Ali S, Udrea F, Buiu O, Cobianu C, Serban B, Gardner J, Dumitru V, Stratulat A (2016) CMOS-compatible SOI micro-hotplate-based oxygen sensor. In: 46th European Solid-State Device Research Conference (ESSDERC), IEEE, 280–283, 2016.

Bai Y, Tian J, Lin Z, You M, Liu J, Wang X (2020) Development of a high throughput micro-heater array with controllable temperature for each heating unit. Microsyst Technol 26(3):787–792

Balakrishnan V et al (2017) Steady-state analytical model of suspended p-type 3C-SiC bridges under consideration of Joule heating. J Micromech Microeng 27(7):075008

Basu S, Werneke B, Peles Y, Jensen MK (2015) Transient microscale flow boiling heat transfer characteristics of HFE-7000. Int J Heat Mass Transfer 90:396

Bauer MJ, Wen X, Tiwari P, Arnold DP, Andrew JS (2018) Magnetic field sensors using arrays of electrospun magnetoelectric. Janus Nanow Microsyst Nanoeng 4:37

Beckel D, Briand D, Bieberle-Hütter A, Courbat J, De Rooij NF, Gauckler LJ (2007) Micro-hotplates-A platform for micro-solid oxide fuel cells. J Power Sour 166(1):143–148

Beeby S, Ensel G, White NM, Kraft M (2004) MEMS mechanical sensors. Artech House: 828–831

Bel’skaya EA, Kulyamina EY, (2007) Electrical resistivity of titanium in the temperature range from 290 to 1800 K. High Temp 45(6):785–796

Benn GGS (2001) Design of a silicon carbide micro-hotplate geometry for high temperature chemical sensing. Massachusetts Institute of Technology

Bergman TL, Incropera FP, De Witt DP, Lavine AS (2011) Fundamentals of heat and mass transfer. Wiley

Berlicki T, Murawski E, Osadnik S, Prociòw E (1989) Thermoresistive thin film flow sensor. Act Passive Electron Compond 13(3):161–173

Bhattacharyya P (2014a) Technological journey towards reliable microheater development for mems gas sensors: a review. IEEE Trans Device Mater Reliable 14:589

Bhattacharyya P (2014b) “Technological journey towards reliable microheater development for MEMS gas sensors: a review. IEEE Trans Device Mater Reliab 14(2):589–599

Bhattacharyya P, Basu P, Mondal B, Saha H (2008) A low power MEMS gas sensor based on nanocrystalline ZnO thin films for sensing methane. Microelectron Reliab 48(11–12):1772–1779

Bhowmick S (2017) investigation of pyroelectric effect generated by lithium niobate crystals induced by integrated microheaters, Ph. D. Thesis.

Billat S, Storz M, Ashauer H, Hedrich F, Kattinger G, Lust L, Ashauer M, Zengerle R (2009) Thermal flow sensors for harsh environment applications. Procedia Chem 1(1):1459–1462

Birk JP, Ronan M, Bennett I, Kinney C, Chem J (1991) Reactivity of nickel. ACS Publ 68:48

Bontempi A, Thiery L, Teyssieux D, Briand D, Vairac P (2013) Quantitative thermal microscopy using thermoelectric probe in passive mode. Rev Sci Instrum 84(10):103703

Bontempi A, Thiery L, Teyssieux D, Briand D, Vairac P (2014) DC and AC scanning thermal microscopy using micro-thermoelectric probe. High Temp High Press 43:321–332

Botau A, Bonfert D, Negrea C, Svasta P, Ionescu C (2015) Electro-thermal analysis of flexible micro-heater. In: 38th Int. Spring Seminar on Electronics Technology, 358–363.

Bouznit Y, Henni A (2019) Characterization of Sb doped SnO2 films prepared by spray technique and their application to photocurrent generation. Mater Chem Phys 233:242–248

Briand D, Heimgartner S, Gretillat M-A, van der Schoot B, de Rooij NF (2002) Thermal optimization of micro-hotplates that have a silicon island. J Micromech Microeng 12(6):971

Bruschi P, Piotto M (2012) Design issues for low power integrated thermal flow sensors with ultra-wide dynamic range and low insertion loss. Micromachines 3(2):295–314

Buchner R, Bhargava P, Sosna C, Benecke W, Lang W (2007) Thermoelectric flow sensors with monolithically integrated channel structures for measurements of very small flow rates. Sensors

Cai ZX, Zeng XY, Duan J (2011) Fabrication of platinum microheater on alumina substrate by micro-pen and laser sintering. Thin Solid Films 519:3893–3896

Casady J, Johnson RW (1996) Status of silicon carbide (SiC) as a wide-bandgap semiconductor for high-temperature applications: a review. Solid State Electron 39(10):1409–1422

Chang W-Y, Hsihe Y-S (2016) Multilayer microheater based on glass substrate using MEMS technology. Microelectron Eng 149:25–30

Chen Q, Xin Y, Zhu X (2015) Au-Pd nanoparticles-decorated TiO2 nanobelts for photocatalytic degradation of antibiotic levofloxacin in aqueous solution. Electrochim Acta 186:34–42

Cheng M, Yang S, Chen R, Zhu X, Liao Q, Huang Y (2017) Copper-decorated TiO2 nanorod thin films in optofluidic planar reactors for efficient photocatalytic reduction of CO2. Int J Hydrogen Energy 42:9722–9732

Chiba A (1992) Development of the TGS gas sensor. In: Yamauchi S (ed) Chemical Sensor Technology, vol 4, pp 1–18

Chiou J-C, Tsai S-W, Lin C-Y (2013) Liquid phase deposition based SnO2 gas sensor integrated With TaN heater on a micro-hotplate. IEEE Sens J 13(6):2466–2473

Choi H-J, Choi S-J, Choo S, Kim I-D, Lee H (2016) Hierarchical ZnO nanowires-loaded Sb-doped SnO2–ZnO micrograting pattern via direct imprinting-assisted hydrothermal growth and its selective detection of acetone molecules. Sci Rep 6:18731

Chung G-S, Jeong J-M (2010) Fabrication of micro heaters on polycrystalline 3C-SiC suspended membranes for gas sensors and their characteristics. Microelectron Eng 87:2348–2352

Creemer J et al (2008) Microhotplates with TiN heaters. Sens Actu A 148(2):416–421

Dai C-L, Liu M-C, Chen F-S, Chyan-Chyi Wu, Chang M-W (2007) A nanowire WO3 humidity sensor integrated with micro-heater and inverting amplifier circuit on chip manufactured using CMOS-MEMS technique. Sens Actu B 123:896–901

Dennis JO, Yousif A, Mohamad MN (2010) Design simulation and modeling of a micromachined high temperature microhotplate for application in trace gas detection. Int J Eng Technol IJET-IJENS 10(02):89–96

Dong K-Y, Choi J-K, Hwang I-S, Lee J-W, Kang BH, Ham D-J, Lee J-H, Byeong-Kwon J (2011) Enhanced H2S sensing characteristics of Pt doped SnO2 nanofibers sensors with micro heater. Sens Actu B 157:154–161

Dufour N, Chapelle A, Mesnilgrente F, Conédéra V, Menini P (2014) Technological improvements of a metal oxide gas multi-sensor based on a micro-hotplate structure and inkjet deposition for an automotive air quality sensor application

Duvigneau J, Schonherr H, Vancso GJ (2010) Nanoscale thermal AFM of polymers: transient heat flow effects. ACS Nano 4(11):6932–6940

Eynon B, Wu B (2005) Photomask fabrication technology. McGraw-Hill, Inc.

Franssila S (2010) Introduction to microfabrication. Wiley

Fries DP (2006) Maskless photolithography for etching and deposition. US Patent 6(998): 219. https://scholarcommons.usf.edu/usf_patents/647/

Froehner BK, Sosna C, Benecke W, Lang W (2008) Toward flexible thermoelectric flow sensors: a new technological approach. J Microelectromech Syst 17(5):1114–1119

Ghodssi R, Lin P (2011) MEMS materials and processes handbook. Springer

Gottfried K, Kriz J, Leibelt J, Kaufmann C, Gessner T (1998) High temperature stable metallization schemes for SiC-technology operating in air. In: 1998 High-Temperature Electronic Materials, Devices and Sensors Conference (Cat. No. 98EX132), IEEE, 153–158

Hamdan S, Dumke JC, El-Zahab B, Das S, Boldor D, Baker GA, Warner IM (2015) Strategies for controlled synthesis of nanoparticles derived from a group of uniform materials based on organic salts. J Colloid Interface Sci 446:163–169

Harris GL (1995) Properties of silicon carbide (no. 13). Iet

Higuchi Y, Kanki T, Tanaka H (2017) Joule-heat-driven high-efficiency electronic-phase switching in freestanding VO2/TiO2 nanowires. Appl Phys Express 10:033201

Hodgkinson J, Tatam RP (2013) Meas Sci Technol 24: 012004

Hodgson DE, Wu MH, Biermann RJ (1990) ASM handbook, properties and selection, nonferrous alloys and special-purpose materials. ASM Handbook Committee (Materials Park: ASM International)

Holt N, Marques LG, Van Horn A, Montazeri M, Zhou W (2018) Fabrication and control of a microheater array for microheater array powder sintering. Int J Adv Manufact Technol 95(1–4):1369–1376

Horade M, Kojima M, Kamiyama K, Mae Y (2016) Tatsuo Arai1, development of a novel 2-dimensional micro-heater array device with regional selective heating. Mech Eng Res 6:66–74

Hsueh TJ, Peng CH, Chen WS (2020) A Transparent ZnO nanowire MEMS Gas Sensor prepared by an ITO Micro-Heater. Sens Actu B Chem 304:127319

http://mmt-co.com/views/home.php. Accessed June 16, 2020.

http://nanosniff.com. Accessed June13, 2020.

https://www.advanceheaters.com. Accessed June 13, 2020.

https://www.okazaki-mfg.com. Accessed June 13, 2020.

Huang Z, Wu L (2018) Phase equilibria diagrams of high-temperature non-oxide ceramics. Springer

Hutagalung SD, Lee BY (2007) Surface profile and optical properties of Sb-doped SnO2 thin films. In: 2007 2nd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, IEEE, 219–222

Hwang I-S, Lee E-B, Kim S-J, Choi J-K, Cha J-H, Lee H-J, Byeong-Kwon Ju, Lee J-H (2011) Gas sensing properties of SnO2 nanowires on micro-heater. Sens Actu B 154:295–300

Imai M, Maehara A, Fukunaga Y (2006) Mask for photolithography, method of forming thin film, liquid crystal display device, and method of producing the liquid crystal display device. US Patent 7(153): 614. https://patents.google.com/patent/US7153614B2/en.

Intelligent micro patterning (2009) llc and maskless photolithography, http://www.intelligentmp.com/index.htm.

Jang B, Wang W, Wiget S, Petruska AJ, Chen X, Chengzhi Hu, Hong A, Folio D, Ferreira A, Pane S, Nelson BJ (2016) Catalytic locomotion of core−shell nanowire motors. ACS Nano 10:9983–9991

Janssen L, Warmoeskerken M (1987) Transport phenomena data companion. E. Arnold

Jiang L, Cheung R (2009) A review of silicon carbide development in MEMS applications. Int J Nanomanuf 2(3/4):225–240

Ke M-T, Lee M-T, Lee C-Y, Lung-Ming Fu (2009) A MEMS-based benzene gas sensor with a self-heating WO3 sensing layer. Sensors 9:2895–2906

Keng Xu, Tang Q, Zhao W, Xing Yu, Yang Y, Ting Yu, Yuan C (2020) In situ growth of Co3O4@NiMoO4composite arrays on alumina substratewith improved triethylamine sensing performance. Sens Actu B 302:127–154

Kien N, Hung CM, Ngoc TM, Le DTT, Hoa ND, Van Duy N, Van Hieu N (2017) Low-temperature prototype hydrogen sensors using Pd-decorated SnO2 nanowires for exhaled breath applications. Sens Actu B 253:156–163

Kim J, Li Z, Park I (2011) Direct synthesis and integration of functional nanostructures in microfluidic devices. Lab Chip 11:1946–1954

Kim J, Kim G, Bahk J-H, Noh J-S, Lee W (2017) Enhanced thermoelectric properties in Bi/Te core/shell heterostructure nanowires through strain and interface engineering. Nano Energy 32:520–525

Kohl F, Fasching R, Keplinger F, Chabicovsky R, Jachimowicz A, Urban G (2003) Development of miniaturized semiconductor flow sensors. Measurement 33(2):109–119

Kou X, Wang C, Ding M, Feng C, Ma XLJ, Zhang H, Yanfeng Sun Geyu Lu (2016) Synthesis of Co-doped SnO2 nanofibers and their enhanced gas-sensing properties. Sens Actu B 236:425–432

Kumar N, Pourrezaei K, Fissel M, Begley T, Lee B, Douglas E (1987) Growth and properties of radio frequency reactively sputtered titanium nitride thin films. J Vac Sci Technol A Vac Surf Films 5(4):1778–1782

Kwon J, Hong S, Kim G, Suh YD, Lee H, Choo S-Y, Lee D, Kong H, Yeo J, Ko SH (2018) Digitally patterned resistive micro heater as a platform for zinc oxide nanowire based micro sensor. Appl Surf Sci 447:1–7

Laconte J, Dupont C, Flandre D, Raskin J-P (2004) SOI CMOS compatible low-power microheater optimization for the fabrication of smart gas sensors. IEEE Sens J 4(5):670–680

LaLonde AD, Pei Y, Wang H, Snyder GJ (2011) Lead telluride alloy thermoelectrics. Mater Today 14(11):526–532

Laocharoensuk R, Palaniappan K, Smith NA, Dickerson RM, Werder DJ, Baldwin JK, Hollingsworth JA (2013) Flow-based solution–liquid–solid nanowire synthesis. Nat Nanotechnol 8:660–666

Li W, Gao X, Wang X, Xiong D, Huang P-P, Song W-G, Bao X, Liu L (2016) From water reduction to oxidation: janus Co-Ni-P nanowires as high-efficiency and ultrastable electrocatalysts for over 3000 h water splitting. J Power Sour 330:156–166

Li T, Xu L, Wang Y, Huang Q (2017) Micro-heater-based gas sensors. Micro Electro Mech Syst 2:1–37

Liang H-W, Liu S, Shu-Hong Yu (2010) Controlled synthesis of one-dimensional inorganic nanostructures using pre-existing one-dimensional nanostructures as templates. Adv Mater 22:3925–3937

Liao J-Y, Lei B-X, Chen H-Y, Kuang D-B, Cheng-Yong Su (2012) Oriented hierarchical single crystalline anatase TiO2 nanowire arrays on Ti-foil substrate for efficient flexible dye-sensitized solar cells. Energy Environ Sci 5:5750

Lin B (2011) Microfluidics: technologies and applications. Springer

Lin W-C, Yang Y-J, Hsieh G-W, Tsai C-H, Chen C-C, Liang C-C (2006) Selective local synthesis of nanowires on a microreactor chip. Sens Actu A 130–131:625–632

Lin W-C, Shih C-J, Ching-Chen Wu, Seshia AA (2013) Synthesis of zinc oxide nanostructures by microheaters in the ambient environment. IEEE Trans Nanotechnol 12:21–28

Lin W-C, Lin Y-C, Esashi M, Seshia AA (2015) In-situ hydrothermal synthesis of zinc oxide nanostructures using microheaters. IEEE Trans Nanotechnol 14:1046–1053

Liu G, Lowy DA, Kahrim A, Wang C, Dilli Z, Kratzmeier N, Zhao W, Peckerar M (2014) A low cost micro-heater for aerosol generation applications. Microelectron Eng 129:46–52

Liu G et al (2017) Self-gauged fiber-optic micro-heater with an operation temperature above 1000 °C. Opt Lett 42(7):1412–1415

Long H, Harley-Trochimczyk A, Cheng S, Hao H, Chi WS, Carraro C, Shi T, Tang Z, Maboudian R (2016) Nanowire-assembled hierarchical ZnCo2O4 microstructure integrated with low power microheater for highly sensitive formaldehyde detection. ACS Appl Mater Interfaces 8:31764–31771

Long H et al (2017) 3D MoS2 aerogel for ultrasensitive NO2 detection and its tunable sensing behavior. Adv Mater Interf 4(16):1700217

A. De Luca, G. Longobardi, F. Udrea, SOI multidirectional thermoelectric flow sensor for harsh environment applications, International Semiconductor Conference (CAS), IEEE, 95–98, 2015.

Lucklum F, Schwaiger A, Jakoby B (2013) High temperature micro-hotplates on porous silicon substrates. In: 2013 Transducers and Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems: IEEE, 1907–1910

Lupan O, Postica V, Labat F, Ciofini I, Pauporte T, Adelung R (2018) Ultra-sensitive and selective hydrogen nanosensor with fast response at room temperature based on a single Pd/ZnO nanowire. Sens Actu B 254:1259–1270

Ma H, Wang W, Liu X (2014) Methane detection with high temperature all-silicon microheater, IEEE Sens J: 186–189

Mahmood A, Reger R (2010) Microfabrication process cost calculator, US 978–1–4244–4732–9/10/$25.00 © IEEE

Marasso SL, Tommasi A, Perrone D, Cocuzza M, Mosca R, Villani M, Zappettini A, Calestani D (2016) A new method to integrate ZnO nano-tetrapods on MEMS micro-hotplates for large scale gas sensor production. Nanotechnology 27(38):385503

Martinek J et al (2019) Large area scanning thermal microscopy and infrared imaging system. Measur Sci Technol 30(3):035010

Mele L et al (2012) A molybdenum MEMS microhotplate for high-temperature operation. Sens Actu A 188:173–180

Mele L et al (2016) A MEMS-based heating holder for the direct imaging of simultaneous in-situ heating and biasing experiments in scanning/transmission electron microscopes. Microsc Res Tech 79(4):239–250

Miralles V, Huerre A, Malloggi F, Jullien M-C (2013) A review of heating and temperature control in microfluidic systems: techniques and applications. Diagnostics 3:33

Mo Y, Okawa Y, Tajima M, Nakai T, Yoshiike N, Natukawa K (2001) Micro-machined gas sensor array based on metal film micro-heater. Sens Actu B Chem 79(2–3):175–181

Mo Y, Okawa Y, Inoue K, Natukawa K (2002) Low-voltage and low-power optimization of micro-heater and its on-chip drive circuitry for gas sensor array. Sens Actu A 100(1):94–101

Mondal B, Maity S, Das S, Panda D, Saha H, Kundu A (2015) Fabrication and packaging of MEMS based platform for hydrogen sensor using ZnO–SnO

Morisot F, Zuliani C, Luque J, Ali Z, Mouis M, Nguyen VH, Muñoz-Rojas D, Lourhzal O, Texier M, Cornelius TW, Ternon C (2019) ZnO based nanowire network for gas sensing applications. Mater Res Express 6:8

Naimon E, Weston W, Ledbetter H (1974) Elastic properties of two titanium alloys at low temperatures. Cryogenics 14(5):246–249

Nordin AN, Voiculescu I, Zaghloul M (2009) Micro-hotplate based temperature stabilization system for CMOS SAW resonators. Microsyst Technol 15(8):1187–1193

Pachauri V, Vlandas A, Kern K, Balasubramanian K (2010) Site-specific self-assembled liquid-gated ZnO nanowire transistors for sensing applications. Small 6:589–594

Penmetsa S, Nagrajan K, Gong Z, Mills D, Que L (2010) Biological cell controllable patch-clamp microchip. Appl Phys Lett 97:263702

Pérez-Garza HH, et al. (2016) The “Climate” system: Nano-Reactor for in-situ analysis of solid-gas interactions inside the TEM. In: 2016 IEEE 11th Annual International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), IEEE, 85–90

. Phatthanakun R, Deekla P, Pummara W, Sriphung C, Pantong C, Chomnawang N (2011) Fabrication and control of thin-film aluminum microheater and nickel temperature sensor. In: the 8th Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI) Association of Thailand-Conference, IEEE, 14–17, 2011.

Phatthanakun R, Deekla P, Pummara W, Sriphung C, Pantong C, Chomnawang N (2012) Design and fabrication of thin-film aluminum microheater and nickel temperature sensor. In: 7th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), IEEE, 112–115

Phatthanakun R, Deelda P, Pummara W, Sriphung C, Pantong C, Chomnawang N (2012) Design and fabrication of thin-film aluminum microheater and nickel temperature sensor. In: NEMS, Kyoto, Japan, pp 5–8

Pike A, Gardner JW (1997) Thermal modelling and characterisation of micropower chemoresistive silicon sensors. Sens Actu B Chem 45(1):19–26

Prasad M, Dutta PS (2018) Development of micro-hotplate and its reliability for gas sensing applications. Appl Phys A 124(11):788

Prasad M, Arya DS, Khanna VK (2015) Fabrication and reliability study of a double spiral platinum-based MEMS hotplate. J Micro/nanolithogr MEMS MOEMS 14(2):025003

Micro pg101-heidelberg instruments (2009) https://www.yumpu.com/en/document/view/2981062/aupg-101-heidelberg-instruments, print

Puigcorbé J et al (2003) High temperature degradation of Pt/Ti electrodes in micro-hotplate gas sensors. J Micromech Microeng 13(4):S119

Rackauskas S, Shandakov SD, Jiang H, Wagner JB, Nasibulin AG (2017) Direct observation of nanowire growth and decomposition. Sci Rep 7:12310

Roy S, Sarkar C, Bhattacharyya P (2012a) A highly sensitive methane sensor with nickel alloy microheater on micromachined Si substrate. Sol State Electron 76:84–90

Roy S, Sarkar C, Bhattacharyya P (2012b) Low temperature fabrication of a highly sensitive methane sensor with embedded co-planar nickel alloy microheater on MEMS platform. Sens Lett 10(3–4):760–769

Roy J, Chandra S, Das S, Maitra S (2014) Oxidation behaviour of silicon carbide-a review. Rev Adv Mater Sci 38:1

Samaeifar F, Hajghassem H, Afifi A, Abdollahi H (2015) Implementation of high-performance MEMS platinum micro-hotplate. Sens Rev.

Savage NO, Roberson S, Gillen G, Tarlov MJ, Semancik S (2003) Thermolithographic patterning of sol-gel metal oxides on micro hot plate sensing arrays using organosilanes. Anal Chem 75(17):4360–4367

Semancik S, Cavicchi RE, Wheeler MC, Tiffany JE, Poirier GE, Walton RM, Suehle JS, Panchapakesan B, DeVoe DL (2001) Microhotplate platforms for chemical sensor research. Sens Actu B Chem 77(1–2):579–591

Shackelford JF, Alexander W (2001) Thermal properties of materials. Materials science and engineering handbook vol 5.

Sharpe WN Jr (2001) Mechanical properties of MEMS materials. The MEMS Handbook 3:49–54

Sidek O, Ishak M, Khalid M, Bakar MA, Miskam M (2011) Effect of heater geometry on the high temperature distribution on a MEMS micro-hotplate. In: 2011 3rd Asia Symposium on Quality Electronic Design (ASQED), IEEE, 100–104

Siegele M, Gamauf C, Nemecek A, Mutinati GC, Steinhauer S, Köck A, Kraft J, Siezert J, Schrank F (2013) Optimized integrated micro-hotplates in CMOS technology. In: 11th International New Circuits and Systems Conference (NEWCAS), IEEE, 1–4, 2013.

Simon I, Bârsan N, Bauer M, Weimar U (2001) Micromachined metal oxide gas sensors: opportunities to improve sensor performance. Sens Actu B Chem 73(1):1–26

Singer F (2013) Industrial ceramics. Springer

Singh A, Sharma A, Dhull N, Arora A, Tomar M, Gupta V (2018a) MEMS-based microheaters integrated gas sensors. Integr Ferroelectr 193(1):72–87

Singh A, Sharma A, Dhull N, Arora A, Tomar M, Gupta V (2018b) MEMS-based microheaters integrated gas sensors. Integr Ferroelectr 193:72–87

Sohrabi S, Moraveji MK, Iranshahi D (2019) A review on the design and development of photocatalysts synthesis and application in microfluidic reactors challenges and opportunities. Rev Chem Eng. https://doi.org/10.1515/revce-2018-0013 (in press)

Song N-K, Yun J-I, Joo S-K (2008) A study on the electrical properties of Pb (Zr, Ti) O3 thin films crystallized by the electrical resistive heating of Pt thin film. Mater Res Bull 43(2):292–296

Spannhake J, Helwig A, Müller G, Faglia G, Sberveglieri G, DollcT T, Wassner ME (2007) SnO2: Sb-A new material for high-temperature MEMS heater applications: performance and limitations. Sens Actu B Chem 124(2):421–428

Spruit RG, Tijn van Omme J, Ghatkesar MK, Hugo Pérez Garza H (2017) A review on development and optimization of microheaters for high-temperature in situ studies. J Microelectromech Syst. https://doi.org/10.1109/JMEMS.2017.2757402

Steinhauer S, Chapelle A, Menini P, Sowwan M (2016) Local CuO nanowire growth on microhotplates. In situ electrical measurements and gas sensing application. ACS Sens 1:503–507

Thai NX, Van Duy N, Hung CM, Nguyen H, Hung TM, Van Hieu N, Hoa ND (2020) Realization of portable H2S sensing instrument based on SnO2 Nanowires. J Sci Adv Mater Devices 5:40–47

Tian W-C, Ho Y-H, Chen C-H, Kuo C-Y (2013) Sensing performance of precisely ordered TiO2 nanowire gas sensors fabricated by electron-beam lithography. Sensors 13:865–874

Tiggelaar RM (2004) Silicon-technology based microreactors for high-temperature heterogeneous partial oxidation reactions. Ph.D. Thesis, University of Twente

Tommasi A, Cocuzza M, Perrone D, Pirri CF, Mosca R, Villani M, Delmonte N, Zappettini A, Calestani D, Marasso SL (2017) Modeling, fabrication and testing of a customizable micromachined hotplate for sensor applications. Sensors 17(1):62

Toskov S, Glatz R, Miskovic G, Radosavljevic G (2013) Modeling and fabrication of pt micro-heaters built on alumina substrate. In: Proceedings of the 36th International Spring Seminar on Electronics Technology, IEEE, 47–52

Touloukian Y, Powell R, Ho C, Klemens P (1971) Thermophysical properties of matter-the tprc data series, thermal conductivity-nonmetallic solids. (reannouncement). Data book, Purdue Univ., Lafayette, IN (United States)

Tran V-T, Wei Y, Hejun Du (2020) On-substrate joule effect heating by printed micro-heater for the preparation of ZnO semiconductor thin film. Micromachines 11:490–501

Tsai Y-T, Chang S-J, Tang I-T, Hsiao Y-J, Ji L-W (2018) High density novel porous ZnO nanosheets based on a microheater chip for ozone sensors. IEEE Sens J 18(13):5559–5565

Tsamis C, Nassiopoulou A, Tserepi A (2003) Thermal properties of suspended porous silicon micro-hotplates for sensor applications. Sens Actu B Chem 95(1–3):78–82

Udrea F et al (2001) Design and simulations of SOI CMOS micro-hotplate gas sensors. Sens Actu B Chem 78(1–3):180–190

VanHorn A, Zhou W (2016) Design and optimization of a high temperature microheater for inkjet deposition. Int J Adv Manufact Technol 86(9–12):3101–3111

Wang X, Hai Wang Y, Zhou YL, Li B, Zhou X, Shen H (2015) Confined-space synthesis of single crystal TiO2 nanowires in atmospheric vessel at low temperature: a generalized approach. Sci Rep 5:8129–8135

Werner MR, Fahrner WR (2001) Review on materials, microsensors, systems and devices for high-temperature and harsh-environment applications. IEEE Trans Industr Electron 48(2):249–257

Wiche G, Berns A, Steffes H, Obermeier E (2005) Thermal analysis of silicon carbide based micro hotplates for metal oxide gas sensors. Sens Actu A 123:12–17

Yang D, Cho I, Kim D, Lim MA, Li Z, Ok JG, Lee M, Park I (2019) Gas sensor by direct growth and functionalization of metal oxide/metal sulfide core−shell nanowires on flexible substrates. ACS Appl Mater Interfaces 11:24298–24307

Yeom J, Field CR, Bae B, Masel RI, Shannon MA (2018) The design, fabrication and characterization of a silicon microheater for an integrated MEMS gas preconcentrato. J Micromech Microeng 18:125001

Yu S, Wang S, Lu M, Zuo L (2017) A novel polyimide based micro heater with high temperature uniformity. Sens Actu A 257:58–64

Zhang X, Zhao L-D (2015) Thermoelectric materials: energy conversion between heat and electricity. J Materiom 1(2):92–105

Zhang D, Liu Z, Han S, Li C, Lei Bo, Stewart MP, Tour JM, Zhou C (2004) Magnetite (Fe3O4) core-shell nanowires: synthesis and magnetoresistance. Nano Lett 4:2150–2155

Zhang KL, Chou SK, Ang SS (2007) Fabrication, modeling and testing of a thin film Au/Ti microheater. Int J Therm Sci 46:580–588

Zhang K, Rossi C, Petrantoni M, Mauran N (2008) A nano initiator realized by integrating Al/CuO-based nanoenergetic materials with a Au/Pt/Cr microheater. J Microelectromech Syst 17(4):832–836

Zhang K, Yang Yang EYB, Pun RS (2010) Local and CMOS-compatible synthesis of CuO nanowires on a suspended microheater on a silicon substrate. Nanotechnology 21:235602–235608

Zhou X, Wang Y, Cheng Z, Ke X, Jiang W (2017) Facile preparation and energetic characteristics of core-shell Al/CuO metastable intermolecular composite thin film on a silicon substrate. Chem Eng J 328:585–590

Zhu XR, Wang CM, FubZ QB, Jiao WD, Wang GY, Qin JMX (2015) Preparation of Ag/Cu Janus nanowires: electrodeposition in track-etched polymer templates. Nucl Instrum Methods Phys Res Sect B 356–357:57–61

Zoysa MD, Asano T, Mochizuki K, Oskooi A, Inoue T, Noda S (2012) Conversion of broadband to narrowband thermal emission through energy recycling. Nat Photon 6:535

Phan HP, Dinh T, Kozeki T, Qamar A, Namazu T, Dimitrijev S, Nguyen NT, Dao DV (2016) Piezoresistive effect in p-type 3C-SiC at high temperatures characterized using Joule heating. Scientific Reports 6:28499. https://doi.org/10.1038/srep28499

Funding

The funding has been received from Amirkabir university of technology and Iran's national elites foundation with Grant no. 97.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sohrabi, S., Hajshahvaladi, L., Moraveji, M.K. et al. Patterned synthesis of nanowires in microheaters: design and operational aspects. Microfluid Nanofluid 26, 3 (2022). https://doi.org/10.1007/s10404-021-02506-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-021-02506-y