Abstract

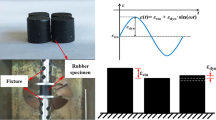

This paper establishes an empirical formula to predict the strain amplitude effect. A viscoelastic constitutive model—the superposition of a hyperelastic model and a viscoelastic model—is constructed based on the laws of thermodynamics. The Mooney–Rivlin model and the Prony series are employed for uniaxial tension testing. The empirical formula is derived using a hysteresis loop; it obtains results that are in agreement with the experimental results of dynamic mechanical analysis (DMA). The empirical formula proposed in this paper has certain accuracy in predicting the dynamic modulus under different strain amplitudes.

Similar content being viewed by others

References

Dai W, Moroni MO, Roesset JM, et al. Effect of isolation pads and their stiffness on the dynamic characteristics of bridges. Eng Struct. 2006;28(9):1298–306.

Siqueira GH, Tavares DH, Paultre P, et al. Performance evaluation of natural rubber seismic isolators as a retrofit measure for typical multi-span concrete bridges in eastern Canada. Eng Struct. 2014;74:300–10.

Yuan Y, Wei W, Tan P, et al. A rate-dependent constitutive model of high damping rubber bearings: modeling and experimental verification. Earthq Eng Struct Dyn. 2016;45(11):1875–92.

Xiang N, Li J. Experimental and numerical study on seismic sliding mechanism of laminated-rubber bearings. Eng Struct. 2017;141:159–74.

Ahmadipour M, Alam MS. Sensitivity analysis on mechanical characteristics of lead-core steel-reinforced elastomeric bearings under cyclic loading. Eng Struct. 2017;140:39–50.

Tinard V, Brinster M, Francois P, et al. Experimental assessment of sound velocity and bulk modulus in high damping rubber bearings under compressive loading. Polym Test. 2018;65:331–8.

Mullins L. Effect of stretching on the properties of rubber. Rubber Chem Technol. 1948;21(2):281–300.

Diani J, Brieu M, Batzler K, et al. Effect of the Mullins softening on mode I fracture of carbon-black filled rubbers. Int J Fract. 2015;194(1):11–8.

Sokolov AK, Svistkov AL, Shadrin VV, et al. Influence of the Mullins effect on the stress-strain state of design at the example of calculation of deformation field in tyre. Int J Nonlinear Mech. 2018;104:67–74.

Payne AR. The dynamic properties of carbon black—natural rubber vulcanizates. Part I. J Appl Polym Sci. 1963;6(19):57–63.

Kraus G. Mechanical losses in carbon-black-filled rubbers. J Appl Polym Symp. 1984;39:75–92.

Luo W, Hu X, Wang C, et al. Frequency-and strain-amplitude-dependent dynamical mechanical properties and hysteresis loss of CB-filled vulcanized natural rubber. Int J Mech Sci. 2010;52(2):168–74.

Lion A, Kardelky C, Haupt P. On the frequency and amplitude dependence of the Payne effect: theory and experiments. Rubber Chem Technol. 2003;76(2):533–47.

Lion A, Kardelky C. The Payne effect in finite viscoelasticity: constitutive modelling based on fractional derivatives and intrinsic time scales. Int J Plast. 2004;20(7):1313–45.

Hofer P, Lion A. Modelling of frequency- and amplitude-dependent material properties of filler-reinforced rubber. J Mech Phys Solids. 2009;57:500–20.

Kim BK, Youn K. A viscoelastic constitutive model of rubber under small oscillatory load superimposed on large static deformation. Arch Appl Mech. 2001;71(11):748–63.

Tomita Y, Azuma K, Naito M. Computational evaluation of strain-rate dependent deformation behavior of rubber and carbon-black-filled rubber under monotonic and cyclic straining. Int J Mech Sci. 2008;50:856–68.

Kar KR, Bhowmick AK. Effect of holding time on high strain hysteresis loss of carbon black filled rubber vulcanizates. Polym Eng Sci. 1998;38(12):1927–45.

Kar KK, Bhowmick AK. Medium strain hysteresis loss of natural rubber and styrene-butadiene rubber vulcanizates: a predictive model. Polymer. 1999;40(3):683–94.

Park DM, Hong WH, Kim SG, et al. Heat generation of filled rubber vulcanizates and its relationship with vulcanizate network structures. Eur Polym J. 2000;36(11):2429–36.

Ismail H, Osman H, Ariffin A. Curing characteristics, fatigue and hysteresis behaviour of feldspar filled natural rubber vulcanizates. J Macromol Sci Part D Rev Polym Process. 2007;46(6):6.

Yang R, Song Y, Zheng Q. Payne effect of silica-filled styrene-butadiene rubber. Polymer. 2017;116:304–13.

Acknowledgements

The project was financially supported by the National Natural Science Foundation of China (No. 51708433) and the Fundamental Research Funds. We would like to thank Editage (www.editage.cn) for English language editing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, L., Li, Z. & Li, Y. Strain Amplitude Effect on the Viscoelastic Mechanics of Chloroprene Rubber. Acta Mech. Solida Sin. 33, 392–402 (2020). https://doi.org/10.1007/s10338-019-00154-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-019-00154-y