Abstract

The use of waste activated sludge (WAS) as a biocatalyst to produce polyhydroxyalkanoates (PHA) from waste streams may help promote the beneficial use of WAS for low-carbon, sustainable wastewater treatment. However, it remains unclear which types of substrates can be used for efficient PHA production, and how the PHA production can be maximized. This study aimed to assess the substrate versatility of mixed microbial cultures (MMCs) constructed from WAS by enriching PHA-accumulating bacteria using an aerobic dynamic discharge (ADD) process fed with acetate. Twelve different substrates, including organic acids, saccharides, and alcohols, were selected as the test substrates. In single-batch assays, the highest PHA production (583–680 mg/L) was achieved using butyrate, acetate, and pyruvate. In fed-batch assays, > 30 wt% PHA content was achieved using acetate, butyrate, propionate, lactate, and ethanol, with the highest content (60.3 wt%) using acetate. These results indicate that acetate-fed MMC by the ADD process could efficiently produce PHA from volatile fatty acids, lactate, pyruvate, and ethanol. Polyhydroxybutyrate was preferentially produced from acetate, butyrate, pyruvate, lactate, and ethanol, whereas polyhydroxyvalerate was notably produced from propionate. The results suggest that PHA can be efficiently produced from a wide range of substrates using MMCs enriched on a single substrate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biological treatments using activated sludge (AS) are widely used in municipal wastewater treatment plants (WWTPs). Wastewater treatment using AS inevitably generates large amounts of waste activated sludge (WAS), resulting in substantial financial and energy costs associated with its disposal [1]. The use of WAS as an energy source and value-added material may help solve this problem while helping establish low-carbon, sustainable wastewater treatment.

The utilization of WAS as a biocatalyst for polyhydroxyalkanoates (PHAs) production from local waste streams has been proposed as a promising strategy and previously examined [2,3,4]. PHAs are a group of polyesters synthesized by microorganisms. They are biodegradable and biocompatible thermoplastic materials that can be used in various applications as alternatives to conventional petroleum-based plastics [5, 6]. The realization of this concept would innovate wastewater treatment plants into biorefinery facilities capable of producing valuable products such as PHA. This would help reduce WAS volume as well as other local waste streams, some of which could be upcycled for use in urban activities.

However, it remains unclear which substrates in the waste stream can be used as feedstock for PHA production and how to maximize the PHA production. The PHA production by WAS has been extensively studied using simple organic acids (e.g., acetate) or a mixture of volatile fatty acids (VFAs) as substrates, which are generated from organic waste streams via acidogenesis [7,8,9]. A few studies have explored PHA production from WAS using carbon sources beyond VFAs, such as saccharides [10] and ethanol [11]. These efforts demonstrate the potential of WAS to produce PHA from different categories of carbon sources, probably owing to the presence of a variety of microorganisms in WAS.

However, this process remains challenging. In general, when WAS is directly used as a PHA production catalyst, the PHA concentration produced is low, and a long reaction time is required [8, 12]. Therefore, attempts to improve the PHA production capability of WAS have involved constructing efficient PHA-producing mixed microbial cultures (MMCs) through the enrichment of talented PHA-accumulating bacteria [13,14,15]. Previous studies have succeeded in the construction of MMCs with highly efficient PHA production abilities using specific carbon sources [16, 17]. However, most studies have used the same or similar substrates, such as acetate and other VFAs singly or in combination, in both the enrichment and PHA accumulation steps [18, 19]. Only a few studies have applied different substrates for the enrichment and PHA accumulation steps. For example, Moralejo-Gárate et al. [20] constructed a MMC from WAS using glycerol and evaluated its ability to produce PHA from glycerol, acetate, lactate, and glucose. Another study established a MMC using acetate and evaluated its PHA production ability using acetate, glucose, and starch as substrates [21]. These studies have suggested that MMC constructed using a specific substrate has the potential to produce PHA from other substrates. However, given the limited available evidence, further studies to determine the substrate range of WAS-derived MMCs for PHA production are desirable.

Therefore, in this study, we aimed to assess the ability of MMC, which was constructed from AS using acetate as the enrichment substrate, to produce PHA from various substrate categories, including VFAs, saccharides, and alcohols. A short-term enrichment method of PHA-accumulating bacteria, called the aerobic dynamic discharge (ADD) method [22], was applied to establish the MMC in this study. The ADD method applies an ecological selective pressure based on the feast-famine regime and physical selective pressure by short-term settling after the feast phase. Consequently, the ADD method enables efficient enrichment of PHA-accumulating bacteria within a shorter period (specifically within 2 days [22]) as compared to the widely applied aerobic dynamic feeding method that employs only the ecological selective pressure [18, 20, 21], and has a clear benefit in using WAS generated continuously in WWTPs as the biocatalyst for PHA production from local waste streams.

Materials and methods

Activated sludge sample

The AS samples were collected from the sludge-returning line after the final settling tanks at a municipal WWTP in Osaka Prefecture, Japan. The WWTP employs the conventional activated sludge process and step-feed multistage denitrification–nitrification process and AS after the final settling tanks is returned through the same sludge-returning line. Also, the WWTP mainly receives domestic wastewater and a small amount of industrial discharge, with a maximum inflow volume of 73,500 m3/d. The collected samples were washed twice with nitrogen- and phosphorus-deficient basal salt medium (BSM) [23] without pH adjustment, resuspended in fresh medium, and used to enrich PHA-accumulating bacteria and evaluate their inherent PHA accumulation capability.

Enrichment of PHA-accumulating bacteria

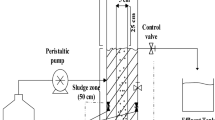

The enrichment of PHA-accumulating bacteria was conducted in a sequencing batch reactor (SBR) using an ADD process [22]. Cylindrical reactors with a height/diameter ratio of 10:1 and a working volume of 4 L with internal aeration using an XP-40 air pump (Techno Takatsuki, Osaka, Japan) through a ceramic diffuser were used for the SBR operation.

The SBR was operated for four cycles with a cycle duration of 12 h under conditions optimized in our previous study [22]. One SBR cycle consisted of the following phases: the first feeding phase (15 min), first reaction phase (feast period), first settling phase (10 min), first 2-L effluent withdrawal phase (10 min), second feeding phase (15 min), second reaction phase (famine period), second settling phase (30 min), and second 2-L effluent withdrawal phase (10 min). Using consecutive periods of availability (feast phase) and scarcity (famine phase) of the external substrate induces the selection of PHA-accumulating bacteria over microorganisms that are less capable of persisting under famine conditions due to their inability to accumulate PHAs [18]. During each SBR cycle, the feast-to-famine (F/F) ratio was calculated by dividing the length of the feast phase by that of the famine phase. The F/F ratio, an indicator of substrate consumption, has been applied to assess the enrichment status of PHA-accumulating bacteria [24].

At the beginning of the SBR operation, 2 L of the washed AS sample with a final mixed liquor suspended solids (MLSS) concentration of 8000 mg/L was inoculated into each SBR. During the first feeding phase, 2 L of nitrogen- and phosphorus-deficient BSM and 1297 mg-C sodium acetate were added. In the second feeding phase, 2-L BSM containing 189 mg-N NH4Cl and 154 mg-P KH2PO4 was added. During the first and second reaction phases, air was continuously supplied, and the dissolved oxygen (DO) concentration and pH were measured using a water quality meter (WQC-24; DKK-TOA, Tokyo, Japan) at a 5-min interval. When the DO concentration sharply rose from around 1.0 mg/L to above 5.0 mg/L, the aeration was halted, and the first settling phase was initiated. The time for the first reaction phase (from the start of aeration to the halting of aeration due to the sharp increase in DO) was recorded as the feast-phase length. The time for the second reaction phase (from the start of aeration after the second feeding phase to the end of aeration before the start of the final settling phase) was recorded as the famine-phase length. As the time of initiation of DO increase varies, the duration of both the first and second reaction phases (i.e., the F/F ratio) also varies for each SBR. The temperature of the SBR was maintained at 22 ± 1 °C in a water bath, and the pH was not controlled during the process. The MLSS concentrations were determined at the beginning of each cycle. The MMC was established and collected after the four-cycle SBR operation; then, it was washed and resuspended using the same procedures as those used for AS sample preparation in the PHA accumulation experiments. The SBR was operated four times under the same operating procedures using the sludge samples collected on different dates (with the operation designated SBR1–4) to obtain sufficient MMCs for use in evaluating PHA accumulation ability.

PHA accumulation assays

The PHA accumulation capabilities of both the AS sample and enriched MMC were evaluated using single-batch and fed-batch assays.

In single-batch assays, 12 different carbon sources, including acetate, butyrate, propionate, lactate, pyruvate, citrate, malate, glucose, sucrose, fructose, ethanol, and glycerol, were separately used as substrates for PHA production. For the single-batch assays, we used AS and MMC samples from SBR1–3, designating these as AS1–3 and MMC1–3, respectively; these were separately inoculated at a MLSS concentration of 2,000 mg/L into 500 mL Erlenmeyer flasks containing 300 mL of nitrogen- and phosphorus-deficient BSM supplemented with 600 mg-C of each substrate. The cultures were incubated at 22 ± 1 °C with rotary shaking at 120 rpm for 12 h. The pH was adjusted to 8.0 ± 0.1 using 1 M NaOH and 1 M HCl at the beginning of the experiments. The pH was left uncontrolled during the experiment. All experiments were repeated three times using AS samples collected on three different dates (i.e., SBR1-3 in Fig. 1) and conducted in duplicate each time. Substrate concentration (carbon moles per liter; C-mol/L), MLSS (mg/L), and the contents (wt%) of two PHAs, polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHV), were determined at the beginning (0 h) and the end (12 h) of the assays.

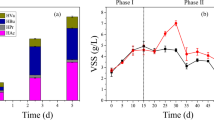

Variation in mixed liquor suspended solids (MLSS) concentration (a) and feast-to-famine (F/F) ratio (b) during enrichment of polyhydroxyalkanoate-accumulating bacteria from activated sludge using the aerobic dynamic discharge process with acetate as the substrate. Three mixed microbial cultures (MMCs) obtained from SBR1, SBR2, and SBR3 were used in the single-batch assays, whereas a MMC obtained from SBR4 was applied in the fed-batch assay

In the fed-batch assay, acetate, butyrate, propionate, lactate, glucose, and ethanol were used as sole substrates. For the fed-batch assays, we used AS and MMC samples from SBR4, designating these as AS4 and MMC4, respectively; they were used in the fed-batch assays. The AS sample and MMC were separately inoculated at a MLSS concentration of 3500 mg/L into a 2-L polymethylpentene beaker containing nitrogen- and phosphorus-deficient BSM supplemented with 3240 mg-C of each substrate at pH 8. During the assays with acetate, butyrate, propionate, and lactate, the pH of the culture changed in response to their consumption levels. Thus, the pH was continuously measured, and 1.5 M substrate solution was additionally supplied to maintain the pH at 8.0 ± 0.1 using a TDP-51 pH controller (Toko Chemical Laboratories, Tokyo, Japan). When glucose and ethanol were used as the substrates, 1.5 M glucose with a 1.5 M NaOH solution and 1.5 M ethanol with a 1.0 M HCl solution were added to control the pH in response to the pH change caused by substrate consumption. The culture was cultivated at 22 ± 1 °C with stirring at 360 rpm using a magnetic stirrer until 60 h. Changes in substrate concentration, MLSS concentration, and PHA content over time were monitored. The experiment was conducted without repetition using the AS-derived MMC4 (i.e., SBR4 in Fig. 1), and the substrates and PHA were analyzed in duplicate.

MLSS concentration (mg/L) was converted into C-mol/L, assuming a general biomass composition of CH1.8O0.5N0.2 with a formula weight of 24.6 g/C-mol [25]. Biomass concentration (C-mol/L) was then determined by subtracting PHA concentration (C-mol/L) from converted MLSS concentration (C-mol/L). Based on these data, the amount of PHA in the culture (mg/L), PHA accumulation rate (C-mol PHA/C-mol biomass/h), substrate consumption rate (C-mol substrate/C-mol biomass/h), and PHA yield (C-mol PHA/C-mol substrate) were calculated.

Analytical procedures

The MLSS concentrations in the SBR and fed-batch assays were measured using a portable MLSS meter (ML-30N; Kasahara Chemical Instruments, Saitama, Japan). The MLSS concentrations in the single-batch assays were measured according to the Standard Methods (APHA, 1998), which address the difficulties in using the portable MLSS meter. The MLSS meter was calibrated following the manufacturer’s instructions before use. For each series of experiments, one measurement method was used.

Samples were centrifuged at 2500×g for 10 min at 4 °C for liquid/solid separation. The supernatant was filtered through a 0.45 μm cellulose acetate filter (Advantec, Tokyo, Japan) and subjected to substrate concentration analysis. The pellets were washed twice with ultrapure water, frozen for 24 h, and dried using an FDU-1200 freeze dryer (EYELA, Tokyo, Japan) for PHA content analysis.

The substrate concentrations were determined using high-performance liquid chromatography (HPLC) with a Shimadzu LC-10Avp system (Shimadzu, Kyoto, Japan), equipped with a refractive index detector and an Aminex HPX-87H or HPX-87P column (300 × 7.8 mm; Bio-Rad, Hercules, CA) according to the conditions described previously [10].

In the single-batch assays, the contents of PHB and PHV were analyzed by the alkaline digestion–HPLC method developed by Satoh et al. [26], with minor modifications: since the sludge samples were freeze-dried, they were first collected in a 2-mL plastic centrifuge tube, followed by the addition of 0.8-mL chloroform; the tube was then placed in a 55 °C incubator until the chloroform had evaporated, which was the procedure applied for the analysis of the standard PHA particles. Subsequent steps were proceeded following the original method. In the fed-batch assays, the sludge samples were pretreated by methanolysis decomposition and subjected to PHA analysis using a GC2014 gas chromatograph (Shimadzu) equipped with a flame ionization detector and an InertCap WAX-HT capillary column (30 m × 0.25 mm i.d., film thickness 0.25 μm; GL Science, Tokyo, Japan) according to the conditions described previously [27, 28].

Statistical analysis

In single-batch assays, Duncan’s multiple range test was conducted to compare the PHA accumulation capability of MMC from different substrates. The Student’s t-test was used to verify whether there was a significant difference in the PHA accumulation capabilities between the AS and MMC. Statistical significance was set at p-values of < 0.05 for both tests. All statistical analyses were conducted using the R software v4.2.0 (https://www.r-project.org/).

Results

Establishment of acetate-enriched mixed microbial culture

The acetate-enriched MMCs, used to evaluate the substrate versatility, were established from AS using the ADD process four times on different dates. During the enrichment process, the MLSS concentration, which was initially 6950–8500 mg/L, declined drastically during the initial cycle and gradually thereafter, eventually reaching 1570–2280 mg/L (Fig. 1a). The F/F ratio, which is used to assess the enrichment status of PHA-accumulating bacteria, also declined steadily during the enrichment process, reaching 0.22–0.34 in the last cycle (Fig. 1b). The F/F ratio in the final cycle was confirmed to be similar to that obtained under the same enrichment conditions [22] and within a range sufficient for MMCs demonstrating a robust PHA accumulation ability established through the aerobic dynamic feeding process [24, 29].

To confirm whether PHA-accumulating bacteria were enriched, PHA accumulation from acetate was examined using single-batch assays. Although the PHA production of the seed AS was 294 mg/L with an average yield of 0.36 C-mol PHA/C-mol substrate, the AS-derived MMC produced 663 mg/L PHA with a yield of 0.60 C-mol PHA/C-mol substrate (Fig. 2). In addition, the PHA contents of AS1–4 and MMC1–4 were 16.9 ± 3.2 wt% and 34.4 ± 3.1 wt%, respectively. The significant improvement in PHA productivity and yield from AS to MMC (p < 0.05) (Fig. 2) indicates that MMCs enriched with efficient PHA-accumulating bacteria on acetate could be established reproducibly within a short period by the ADD process under previously optimized conditions. In previous studies, the activated sludge-derived MMCs enriched by the ADD or aerobic dynamic feeding process using acetate showed the maximum PHA content ranging from 50 to 67.5 wt% with the yield from 0.60 to 0.83 C-mol PHA/C-mol substrate [23, 25, 30]. The slightly lower PHA content achieved by the MMC established in this study may reflect the shorter reaction time (12 h) of the batch test compared to that used in previous studies.

Polyhydroxyalkanoate (PHA) production capability of activated sludge (AS) and acetate-enriched mixed microbial culture (MMC) from 12 different substrates in the 12-h single-batch PHA accumulation assay. a Productivity of polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHV); b substrate consumption amount; c PHA yield. Error bars represent standard deviations (n = 6). Significant differences in the Student’s t-test are indicated by asterisks (*), and those in Duncan’s multiple range test are represented by different letters (a, b, c, etc.)

PHA accumulation from various substrates in single-batch assays

The MMC established on acetate was evaluated for its PHA production capability on 11 other substrates, in a 12-h single-batch assay, to screen out potential substrates. The results are shown in Fig. 2, along with the results of PHA production using AS before enrichment for comparison.

Among the tested substrates, AS showed significant PHA production from certain fatty acids, including acetate, butyrate, lactate, and pyruvate. Even the highest production of PHA by AS was relatively low at 294 and 324 mg/L from acetate and butyrate, respectively. PHA production using other substrates was either very low or negligible.

Although MMC was constructed using acetate as the sole substrate, its PHA production ability using butyrate, lactate, pyruvate, and ethanol was also significantly improved compared with that of AS (Fig. 2a). Furthermore, the PHA-production ability of these five substrates was significantly higher than that of the other five substrates (p < 0.05; Duncan’s multiple range test). In particular, PHA production by MMC from butyrate and pyruvate was comparable to that from acetate, achieving the highest production of 583 and 680 mg/L, respectively. In addition, MMC showed slightly better PHA production from propionate and glucose than AS. The PHV ratio reached 62 mol% when propionate was used as the substrate, whereas it was less than 15 mol% for the rest of the substrates.

Among the substrates that showed an improvement in PHA production by MMC, lactate, ethanol, and propionate led to an increase in substrate consumption compared to AS, whereas the consumption of the remaining substrates by MMC and AS was not significantly different (Fig. 2b). However, the PHA yield from substrates showing improved PHA production, except for propionate, was significantly higher in MMC than in AS (Fig. 2c). In addition, the PHA yields from acetate and butyrate were significantly higher than those from the other substrates.

The results of the single-batch assays suggested that acetate-enriched MMC has the capability to utilize various substrates for PHA production. Thus, the PHA production potential of AS from various substrates can be improved by the ADD enrichment using a single substrate, namely acetate.

PHA production performance of MMC from selected substrates in fed-batch assays

The substrates on which MMC showed improvement in PHA production, as compared to AS in the single-batch assays, were further used for PHA production in the fed-batch assays, which aimed to eliminate the substrate-uptake inhibition effect caused by high substrate concentrations in the single-batch assay [31] and to maximize PHA production under the appropriate conditions. In the single-batch assays described above, butyrate, lactate, and ethanol showed considerable improvements in PHA accumulation. The MMC could also accumulate slightly higher PHA from propionate and glucose than AS. In addition, notably high PHV ratio was found in PHA production from propionate. Therefore, these substrates, in addition to acetate, which was used to construct the MMC, were applied as substrates in the fed-batch assays.

The results of the fed-batch assays are summarized in Table 1. MMC efficiently produced PHA from acetate, resulting in a final PHA content of 60.3 wt% with a yield of 0.63 C-mol PHA/C-mol substrate, which was within the range reported in previous studies [22, 25, 32]. The MMC also produced PHA efficiently from butyrate, with a yield comparable to that for acetate (PHA content 48.8 wt%; yield 0.62 C-mol PHA/C-mol substrate). Furthermore, lactate, propionate, and ethanol were utilized relatively efficiently for PHA production by MMC, with more than 30 wt% of the final PHA content. It should be noted that although propionate was not efficiently utilized for PHA production in the single-batch assay, it enabled relatively efficient PHA production in the fed-batch assay. It was also noted that PHV was the main component of the PHA produced from propionate (65%), although PHB was mostly produced from other substrates, which was similar to the results of the single-batch assays (Fig. 2b). However, glucose could not be effectively used in the production of PHA by MMC, reaching a PHA content of only 18.5 wt%. Moreover, despite the improvement in substrate uptake, PHA synthesis capacity, and maximum PHA content in fed-batch experiments, the PHA yield for all substrates tested did not exhibit a significant change when compared to that in single-batch experiments, indicating the potential presence of a substrate limitation effect in the single-batch experiments.

As a general trend, the substrates that showed the higher PHA production in the single-batch assays also showed higher PHA production in the fed-batch assays, and it was confirmed that MMC can efficiently produce PHA from butyrate, propionate, lactate, and ethanol, in addition to acetate.

Discussion

The efficient production of PHA from various substrates may help implement a strategy that facilitates PHA production from a variety of waste streams using AS or MMC derived from AS as biocatalysts. In this study, we aimed to clarify which substrates can be utilized for efficient PHA production using the AS-derived MMC, in which PHA-accumulating bacteria were enriched by the ADD process using acetate as a typical substrate used for microbial PHA production.

Single-batch assays, which aimed to screen promising substrates for PHA production by acetate-enriched MMC, suggested that butyrate, lactate, pyruvate, and ethanol possess good potential, while propionate and glucose have little potential as substrates for PHA production. Fed-batch assays confirmed that MMC can efficiently produce PHA from butyrate, lactate, ethanol, and propionate with a final PHA content of over 30 wt%, but not from glucose. Notably, when butyrate was used as a substrate, MMC demonstrated a PHA synthesis capacity nearly equivalent to that of acetate. Considering the results of the single-batch assays, pyruvate may also serve as a promising substrate for efficient PHA production by MMC. This study revealed that MMC enriched on acetate can be used for efficient PHA production from a broader range of substrates than that previously reported [21, 33].

Although previous studies have explored the substrate versatility of MMC enriched on acetate, most have focused on the use of VFAs that share similar chemical properties with acetate [34]. Fradinho et al. [35] demonstrated that acetate-enriched photosynthetic MMC can also utilize butyrate and propionate to efficiently produce PHB and PHV, respectively. Lemos et al. [33] clarified that acetate-enriched MMC can also efficiently produce PHA using butyrate and propionate. The results of this study also confirmed that acetate-enriched MMC can efficiently produce PHA from VFAs, such as propionate and butyrate.

Meanwhile, Zhao et al. [21] attempted to produce PHA using an acetate-enriched MMC from glucose and starch in addition to VFAs; however, the MMC was incapable of synthesizing PHA from glucose and starch. Similarly, glucose could not be utilized for significant PHA production by a MMC established on a mixture of VFAs mainly containing acetate, propionate, and butyrate [36]. These findings are consistent with those of our study, which showed that glucose, sucrose, and fructose are not good substrates for PHA production in batch assays. Thus, acetate-enriched MMC cannot utilize simple saccharides for the efficient production of PHA.

Our study attempted to explore substrates that have not been previously utilized for PHA production by acetate-enriched MMCs. For the first time, we demonstrated that pyruvate, lactate, and ethanol could be good substrates for PHA production in addition to VFAs. Although lactate is well known as a substrate for the enrichment of MMC for efficient PHA production [37, 38], PHA production on lactate by MMC established using acetate has never been reported. Furthermore, studies on PHA synthesis from pyruvate [39] and ethanol [11, 40] are limited. The finding that acetate-enriched MMC can efficiently produce PHA from pyruvate and ethanol provides new insights into PHA production using these scarcely studied substrates.

Previous studies have investigated the substrate versatility for PHA production of MMCs generated with substrates other than VFAs. Moralejo-Gárate et al. [20] reported that MMC produced with glycerol could efficiently produce PHA using glucose, acetate, and lactate as substrates and that the PHA production efficiency on these substrates was higher than that on glycerol. Meanwhile, MMC enriched with glucose could efficiently utilize acetate for PHA production in addition to glucose [21]. In contrast to these studies, acetate-enriched MMC did not utilize glucose or glycerol for PHA production in this study. These results clearly indicate that the use of different substrates for MMC construction leads to differences in the range of substrates available for PHA production by the MMC. The different substrate versatilities observed in MMCs enriched on distinct substrates can be attributed to the differences in the enhanced pathways within PHA synthesis, depending on the enrichment substrate.

Figure 3 presents a simplified schematic depicting the pathways to synthesize PHB and PHV from the various substrates tested, summarized from PHA-synthesis routes identified in previous studies. Acetate can be directly converted into acetyl-CoA, which is a key compound in the PHA biosynthetic pathway [41]. Acetyl-CoA undergoes transformation into hydroxybutyryl-CoA for PHB biosynthesis and is also incorporated into the tricarboxylic acid (TCA) cycle, thereby contributing to bacterial metabolism and energy generation. The results of this study indicate that the pathway to synthesize PHB from acetate should be enhanced throughout (i.e., from acetate to PHB, through acetyl-CoA, acetoacetyl-CoA, and hydroxybutyryl-CoA) via enrichment by the ADD process.

The enhancement of PHB production from other substrates was likely achieved through the certain parts of the metabolic pathway enhanced in acetate-enriched MMC (Fig. 3). Butyrate is oxidized to butyryl-CoA, which is then preferentially incorporated into the enhanced PHB synthesis pathway via acetoacetyl-CoA and hydroxybutyryl-CoA rather than being utilized in the TCA cycle via acetyl-CoA. Lactate is converted into pyruvate through oxidation by lactate dehydrogenase, whereas pyruvate can undergo multiple metabolic fates. It can be hypothesized that lactate and pyruvate are converted into PHB using a portion of the enhanced metabolic pathway of MMC, namely, the conversion of acetyl-CoA to PHB. Ethanol can be metabolized into acetate via acetaldehyde, and it is reasonable to assume that acetate was subsequently converted into PHB by the acetate-enriched MMC. In contrast to these substrates, propionate was preferentially utilized to produce PHV rather than PHB, indicating that propionate was transformed into propionyl-CoA and acetyl-CoA, and subsequently into 3-hydroxyvaleryl-CoA, the immediate precursor of PHV production. Dionisi et al. [37] observed that the rates of propionate uptake and PHV synthesis in the presence of propionate and acetate were higher than in the presence of propionate alone, suggesting a certain relationship between acetate metabolism and PHV production from propionate. Thus, it seems possible that the PHV production capability on propionate was enhanced in the MMC established on acetate. In contrast, substrates closer to acetyl-CoA and with shorter PHA-producing pathways tended to exhibit higher PHA production rates than those with longer PHA-producing pathways, as reflected by the higher PHA production achieved using acetate and butyrate than that achieved using propionate, lactate, and ethanol (Table 1).

However, citrate and malate, both of which are essential intermediates in the TCA cycle, cannot be efficiently utilized as substrates for PHA production by MMC. This could be attributed to the irreversibility of the TCA cycle; citrate and malate in the TCA cycle cannot be converted into acetyl-CoA and subsequently utilized for PHA synthesis. In addition, glycerol and saccharides such as glucose could not be utilized as substrates for PHA production by MMC. This phenomenon could be attributed to the inherently complex metabolism of these substrates. Glycerol or saccharides require initial metabolism to form glucose-6-phosphate (glucose-6-P), which is subsequently converted into pyruvate via the Embden–Meyerhof–Parnas pathway, although glucose-6-P can also be converted into glycogen for intracellular storage [42]. It appears that various metabolites generated from glycerol and saccharides cannot be utilized for PHB production via the enhanced pathway in acetate-fed MMC enriched by the ADD process and are mostly stored intracellularly as glycogen or enter the TCA cycle via pyruvate.

The wider substrate-utilization range of acetate-enriched MMC expands its practical utility. Given that acetate-enriched MMCs can also efficiently utilize other VFAs, such as butyrate and propionate, for PHA production, a wide range of VFA-containing waste streams can be utilized as potential substrates [43, 44]. Furthermore, dairy waste, whey wastewater, and confectionery industry effluents, characterized by high lactate concentrations [40, 45], also present potential for utilization as feedstock. Ethanol, another potential substrate for PHA production, is commonly generated as a by-product in acidic fermentation processes [46]. Nevertheless, further studies are needed to confirm the practical usefulness of acetate-fed-MMCs for PHA production from waste streams. Additionally, future research should address PHA production from a mixture of different substrates.

Conclusions

This study aimed to investigate the substrate versatility of MMC enriched with acetate, which is a typical substrate, for PHA production. The acetate-enriched MMC could efficiently produce PHA not only from VFAs, which share similar chemical properties with acetate and have often been utilized for PHA production, but also from lactate, pyruvate, and ethanol. These results suggest that PHA production is possible from a relatively wide range of substrates using MMCs cultivated on a single substrate, such as acetate. Evidence of substrate availability in AS-derived MMC, as presented herein, may allow for the rational selection of waste streams that can be used as cost-effective feedstocks for PHA production.

References

Zhang Q, Hu J, Lee DJ, Chang Y, Lee YJ (2017) Sludge treatment: current research trends. Bioresour Technol 243:1159–1172. https://doi.org/10.1016/j.biortech.2017.07.070

Pittmann T, Steinmetz H (2017) Polyhydroxyalkanoate production on wastewater treatment plants: process scheme, operating conditions and potential analysis for German and European municipal wastewater treatment plants. Bioengineering 4:54. https://doi.org/10.3390/bioengineering4020054

Valentino F, Morgan-Sagastume F, Campanari S, Villano M, Werker A, Majone M (2017) Carbon recovery from wastewater through bioconversion into biodegradable polymers. N Biotechnol 37:9–23. https://doi.org/10.1016/j.nbt.2016.05.007

Yadav B, Pandey A, Kumar LR, Tyagi RD (2020) Bioconversion of waste (water)/residues to bioplastics—a circular bioeconomy approach. Bioresour Technol 298:122584. https://doi.org/10.1016/j.biortech.2019.122584

Elmowafy E, Abdal-Hay A, Skouras A, Tiboni M, Casettari L, Guarino V (2019) Polyhydroxyalkanoate (PHA): applications in drug delivery and tissue engineering. Expert Rev Med Devices 16:467–482. https://doi.org/10.1080/17434440.2019.1615439

Meereboer KW, Misra M, Mohanty AK (2020) Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem 22:5519–5558. https://doi.org/10.1039/d0gc01647k

Cavaillé L, Grousseau E, Pocquet M, Lepeuple AS, Uribelarrea JL, Hernandez-Raquet G, Paul E (2013) Polyhydroxybutyrate production by direct use of waste activated sludge in phosphorus-limited fed-batch culture. Bioresour Technol 149:301–309. https://doi.org/10.1016/j.biortech.2013.09.044

Mengmeng C, Hong C, Qingliang Z, Shirley SN, Jie R (2009) Optimal production of polyhydroxyalkanoates (PHA) in activated sludge fed by volatile fatty acids (VFAs) generated from alkaline excess sludge fermentation. Bioresour Technol 100:1399–1405. https://doi.org/10.1016/j.biortech.2008.09.014

Takabatake H, Satoh H, Mino T, Matsuo T (2002) PHA (polyhydroxyalkanoate) production potential of activated sludge treating wastewater. Water Sci Technol 45(12):119–126. https://doi.org/10.2166/wst.2002.0417

Ike M, Okada Y, Narui T, Sakai K, Kuro R, Soda S, Inoue D (2019) Potential of waste activated sludge to accumulate polyhydroxyalkanoates and glycogen using industrial wastewater/liquid wastes as substrates. Water Sci Technol 80:2373–2380. https://doi.org/10.2166/wst.2020.059

Beccari M, Dionisi D, Giuliani A, Majone M, Ramadori R (2002) Effect of different carbon sources on aerobic storage by activated sludge. Water Sci Technol 45:157–168. https://doi.org/10.2166/wst.2002.0103

Pei R, Est A, Ortiz-seco L, van Loosdrecht MCM, Kleerebezem R, Werker A (2022) Exploring the limits of polyhydroxyalkanoate production by municipal activated sludge. Environ Sci Technol 56:11729–11738. https://doi.org/10.1021/acs.est.2c03043

Carvalheira M, Hilliou L, Oliveira CSS, Guarda EC, Reis MAM (2022) Polyhydroxyalkanoates from industrial cheese whey: Production and characterization of polymers with differing hydroxyvalerate content. Curr Res Biotechnol 4:211–220. https://doi.org/10.1016/J.CRBIOT.2022.03.004

Matos M, Cruz RAP, Cardoso P, Silva F, Freitas EB, Carvalho G, Reis MAM (2021) Combined strategies to boost polyhydroxyalkanoate production from fruit waste in a three-stage pilot plant. ACS Sustain Chem Eng 9:8270–8279. https://doi.org/10.1021/acssuschemeng.1c02432

Bengtsson S, Werker A, Christensson M, Welander T (2008) Production of polyhydroxyalkanoates by activated sludge treating a paper mill wastewater. Bioresour Technol 99:509–516. https://doi.org/10.1016/j.biortech.2007.01.020

Villano M, Valentino F, Barbetta A, Martino L, Scandola M, Majone M (2014) Polyhydroxyalkanoates production with mixed microbial cultures: from culture selection to polymer recovery in a high-rate continuous process. N Biotechnol 31:289–296. https://doi.org/10.1016/j.nbt.2013.08.001

Palmeiro-Sánchez T, Val del Rio A, Fra-Vázquez A, Luis Campos J, Mosquera-Corral A (2019) High-yield synthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymers in a mixed microbial culture: effect of substrate switching and F/M ratio. Ind Eng Chem Res 58:21921–21926. https://doi.org/10.1021/acs.iecr.9b03514

Johnson K, Jiang Y, Kleerebezem R, Muyzer G, van Loosdrecht MCM (2009) Enrichment of a mixed bacterial culture with a high polyhydroxyalkanoate storage capacity. Biomacromol 10:670–676. https://doi.org/10.1021/bm8013796

Wang X, Carvalho G, Reis MAM, Oehmen A (2018) Metabolic modeling of the substrate competition among multiple VFAs for PHA production by mixed microbial cultures. J Biotechnol 280:62–69. https://doi.org/10.1016/j.jbiotec.2018.06.342

Moralejo-Gárate H, Kleerebezem R, Mosquera-Corral A, Campos JL, Palmeiro-Sánchez T, van Loosdrecht MCM (2014) Substrate versatility of polyhydroxyalkanoate producing glycerol grown bacterial enrichment culture. Water Res 66:190–198. https://doi.org/10.1016/j.watres.2014.07.044

Zhao J, Cui YW, Zhang HY, Gao ZL (2021) Carbon source applied in enrichment stage of mixed microbial cultures limits the substrate adaptability for PHA fermentation using the renewable carbon. Appl Biochem Biotechnol 193:3253–3270. https://doi.org/10.1007/s12010-021-03587-9

Inoue D, Fukuyama A, Ren Y, Ike M (2021) Optimization of aerobic dynamic discharge process for very rapid enrichment of polyhydroxyalkanoates-accumulating bacteria from activated sludge. Bioresour Technol 336:125314. https://doi.org/10.1016/j.biortech.2021.125314

Inoue D, Suzuki Y, Sawada K, Sei K (2018) Polyhydroxyalkanoate accumulation ability and associated microbial community in activated sludge-derived acetate-fed microbial cultures enriched under different temperature and pH conditions. J Biosci Bioeng 125:339–345. https://doi.org/10.1016/j.jbiosc.2017.09.008

Dionisi D, Majone M, Vallini G, Di Gregorio S, Beccari M (2006) Effect of the applied organic load rate on biodegradable polymer production by mixed microbial cultures in a sequencing batch reactor. Biotechnol Bioeng 93:76–88. https://doi.org/10.1002/bit.20683

Chen Z, Guo Z, Wen Q, Huang L, Bakke R, Du M (2015) A new method for polyhydroxyalkanoate (PHA) accumulating bacteria selection under physical selective pressure. Int J Biol Macromol 72:1329–1334. https://doi.org/10.1016/j.ijbiomac.2014.10.027

Satoh H, Sakamoto T, Kuroki Y, Kudo Y, Mino T (2016) Application of the alkaline-digestion-HPLC method to the rapid determination of polyhydroxyalkanoate in activated sludge. J Water Environ Technol 14:411–421. https://doi.org/10.2965/jwet.16-027

Inoue D, Fukuyama A, Ren Y, Ike M (2019) Rapid enrichment of polyhydroxyalkanoate-accumulating bacteria by the aerobic dynamic discharge process: enrichment effectiveness, polyhydroxyalkanoate accumulation ability, and bacterial community characteristics in comparison with the aerobic dynamic feeding process. Bioresour Technol Rep 7:100276. https://doi.org/10.1016/j.biteb.2019.100276

Sakai K, Miyake S, Iwama K, Inoue D, Soda S, Ike M (2015) Polyhydroxyalkanoate (PHA) accumulation potential and PHA-accumulating microbial communities in various activated sludge processes of municipal wastewater treatment plants. J Appl Microbiol 118:255–266. https://doi.org/10.1111/jam.12683

Villano M, Beccari M, Dionisi D, Lampis S, Miccheli A, Vallini G, Majone M (2010) Effect of pH on the production of bacterial polyhydroxyalkanoates by mixed cultures enriched under periodic feeding. Process Biochem 45:714–723. https://doi.org/10.1016/j.procbio.2010.01.008

Serafim LS, Lemos PC, Oliveira R, Reis MAM (2004) Optimization of polyhydroxybutyrate production by mixed cultures submitted to aerobic dynamic feeding conditions. Biotechnol Bioeng 87:145–160. https://doi.org/10.1002/bit.20085

Srivastava AK, Gupta S (2011) Fed-batch fermentation—design strategies. In: Moo-Young M (ed) Comprehensive biotechnology, 2nd edn, vol 2. Elsevier, New York, pp 515–526. https://doi.org/10.1016/B978-0-08-088504-9.00112-4

Zeng S, Song F, Lu P, He Q, Zhang D (2018) Improving PHA production in a SBR of coupling PHA-storing microorganism enrichment and PHA accumulation by feed-on-demand control. AMB Express 8:1–12. https://doi.org/10.1186/s13568-018-0628-x

Lemos PC, Serafim S, Reis MAM (2006) Synthesis of polyhydroxyalkanoates from different short-chain fatty acids by mixed cultures submitted to aerobic dynamic feeding. J Biotechnol 122:226–238. https://doi.org/10.1016/j.jbiotec.2005.09.006

Chang HF, Chang WC, Tsai CY (2012) Synthesis of poly(3-hydroxybutyrate/3-hydroxyvalerate) from propionate-fed activated sludge under various carbon sources. Bioresour Technol 113:51–57. https://doi.org/10.1016/j.biortech.2011.12.138

Fradinho JC, Oehmen A, Reis MAM (2014) Photosynthetic mixed culture polyhydroxyalkanoate (PHA) production from individual and mixed volatile fatty acids (VFAs): substrate preferences and co-substrate uptake. J Biotechnol 185:19–27. https://doi.org/10.1016/j.jbiotec.2014.05.035

Jia Q, Wang H, Wang X (2013) Dynamic synthesis of polyhydroxyalkanoates by bacterial consortium from simulated excess sludge fermentation liquid. Bioresour Technol 140:328–336. https://doi.org/10.1016/j.biortech.2013.04.105

Dionisi D, Majone M, Papa V, Beccari M (2004) Biodegradable polymers from organic acids by using activated sludge enriched by aerobic periodic feeding. Biotechnol Bioeng 85:569–579. https://doi.org/10.1002/bit.10910

Jiang Y, Marang L, Kleerebezem R, Muyzer G, van Loosdrecht MCM (2011) Polyhydroxybutyrate production from lactate using a mixed microbial culture. Biotechnol Bioeng 108:2022–2035. https://doi.org/10.1002/bit.23148

Shen MY, Chu CY, Sawatdeenarunat C, Bhuyar P (2022) Production, downstream processing, and characterization of polyhydroxyalkanoates (PHAs) boosted by pyruvate supplement using mixed microbial culture (MMC) and organic wastewater. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-02170-w

Rangel C, Carvalho G, Oehmen A, Frison N, Lourenço ND, Reis MAM (2023) Polyhydroxyalkanoates production from ethanol- and lactate-rich fermentate of confectionary industry effluents. Int J Biol Macromol 229:713–723. https://doi.org/10.1016/j.ijbiomac.2022.12.268

Kessler B, Witholt B (2001) Factors involved in the regulatory network of polyhydroxyalkanoate metabolism. J Biotechnol 86:97–104. https://doi.org/10.1016/S0168-1656(00)00404-1

Carta F, Beun JJ, van Loosdrecht MCM, Heijnen JJ (2001) Simultaneous storage and degradation of PHB and glycogen in activated sludge cultures. Water Res 35:2693–2701. https://doi.org/10.1016/S0043-1354(00)00563-7

Cerrone F, Choudhari SK, Davis R, Cysneiros D, O’Flaherty V, Duane G, Casey E, Guzik MW, Kenny ST, Babu RP, O’Connor K (2014) Medium chain length polyhydroxyalkanoate (mcl-PHA) production from volatile fatty acids derived from the anaerobic digestion of grass. Appl Microbiol Biotechnol 98:611–620. https://doi.org/10.1007/s00253-013-5323-x

Dan T, Jing H, Shen T, Zhu J, Liu Y (2023) Performance of production of polyhydroxyalkanoates from food waste fermentation with Rhodopseudomonas palustris. Bioresour Technol. https://doi.org/10.1016/j.biortech.2023.129165

Colombo B, Calvo MV, Sciarria TP, Scaglia B, Kizito SS, D’Imporzano G, Adani F (2019) Biohydrogen and polyhydroxyalkanoates (PHA) as products of a two-steps bioprocess from deproteinized dairy wastes. Waste Manag 95:22–31. https://doi.org/10.1016/j.wasman.2019.05.052

Ballesteros M, Sáez F, Ballesteros I, Manzanares P, Negro MJ, Martínez JM, Castañeda R, Oliva Dominguez JM (2010) Ethanol production from the organic fraction obtained after thermal pretreatment of municipal solid waste. Appl Biochem Biotechnol 161:423–431. https://doi.org/10.1007/s12010-009-8877-4

Funding

Open Access funding provided by Osaka University. This study was supported by JSPS KAKENHI Grant Number JP23H01539 and by JST SPRING Grant Number JPMJSP2138.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ren, Y., Inoue, D. & Ike, M. Potential of activated sludge-derived mixed microbial culture enriched on acetate to produce polyhydroxyalkanoates from various substrates. J Mater Cycles Waste Manag 26, 2355–2365 (2024). https://doi.org/10.1007/s10163-024-01974-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-024-01974-y