Abstract

Si, Al, Cu, and Ag particles’ mixture which mainly composes pulverized silicon-based waste solar cells were individually separated by the batch flotation experiments with high recovery and content, and then a general flow chart of the sequential flotation procedure of n-component was postulated including 2-, 3-, and 4-components. The n-component mixture was separated to 1: n-1 or i: j (i + j = n) by a flotation procedure and n-1 times operation was necessary to divide into the individual component. The first flotation process to separate Al into the froth layer was carried out with a collector of SDS solution after dipping Si, Al, Cu, and Ag mixture into the SDS solution. Si was separated in the froth by the second flotation with a collector of a commercial neutral detergent after Al etching by HCl, and Si, Cu and Ag mixture dipped in the detergent. The Cu and Ag mixture was calcinated at 673 or 773 K and dipped into the detergent, and the third flotation with the collector of the detergent led to Cu in the froth and Ag in the sediment. The 4-component mixture was successfully separated into each component by the 3-consecutive flotation processes.

Similar content being viewed by others

References

Kaya M (2016) Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag 57:64–90

Wang C, Wang H, Fu J, Zhang L, Luo C, Liu Y (2015) Flotation separation of polyvinyl chloride and polyethylene terephthalate plastics combined with surface modification for recycling. Waste Manag 45:112–117

Truc NTT, Lee BK (2016) Sustainable and selective separation of PVC and ABS from a WEEE plastic mixture using microwave and/or mild-heat treatment with froth flotation. Environ Sci Technol 50:10580–10587

Wang J, Wang H, Wang C, Zhang L, Wang T, Zheng L (2017) A novel process for separation of hazardous poly (vinyl chloride) from mixed plastic wastes by froth flotation. Waste Manag 69:59–65

Jiang H, Zhang Y, Bian K, Wang H, Wang C (2022) Insight into the effects of aqueous species on microplastics removal by froth flotation: kinetics and mechanism. J Environ Chem Eng 10:107834

Zhang Y, Jiang H, Bian K, Wang H, Wang C (2021) A critical review of control and removal strategies for microplastics from aquatic environments. J Environ Chem Eng 9:105463

Eivazihollagh A, Tejera J, Svanedal I, Edlund H, Blanco A, Norgren M (2017) Removal of Cd2+, Zn2+, and Sr2+ by ion flotation, using a surface-active derivative of DTPA (C12-DTPA). Ind Eng Chem Res 56(38):10605–10614

Dey S, Paul GM, Pani S (2013) Flotation behaviour of weathered coal in mechanical and column flotation cell. Powder Technol 246:689–694

Jatav PP, Tajane SP, Mandavgane SA, Gaidhani SB (2019) A process of carbon enrichment of bottom slag ash for value-added applications. J Mater Cycles Waste Manag 21:539–546

Xie Q, Wang D, Han Z, Tao H, Liu S (2022) Removal of carbon and dioxins from municipal solid waste incineration fly ash by ball milling and flotation methods. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-022-01514-6

Altansukh B, Burmaa G, Nyamdelger S, Ariunbolor N, Shibayama A, Haga K (2014) Gold recovery from its flotation concentrate using acidic thiourea leaching and organosilicon polymer. Int J Soc Mater Eng Resour 20:29–34

Burat F, Demirag A, Safak MC (2020) Recovery of noble metals from floor sweeping jewelry waste by flotation-cyanide leaching. J Mater Cycles Waste Manag 22:907–915

Dinc NI, Tosun AU, Basturkcu OM, Burat F (2022) Recovery of valuable metals from WPCB fines by centrifugal gravity separation and froth flotation. J Mater Cycles Waste Manag 24:224–236

Mallampati SR, Lee C-H, Park MH, Lee B-K (2018) Processing plastics from ASR/ESR waste: separation of poly vinyl chloride (PVC) by froth flotation after microwave-assisted surface modification. J Mater Cycles Waste Manag 20:91–99

Qu YH, Li YP, Zou XT, Xu KW, Xue YT (2021) Microwave treatment combined with wetting agent for an efficient flotation separation of acrylonitrile butadiene styrene (ABS). J Mater Cycles Waste Manag 23:96–106

Wang J, Wang H, Wang C, Zhang L, Wang T, Zhang L (2017) A novel process for separation of hazardous poly (vinyl chloride) from mixed plastic wastes by froth flotation. Waste Manag 69:59–65

Li W, Li Y (2022) Selective flotation separation of polycarbonate from plastic mixtures based on Fenton treatment combined with ultrasonic. J Mater Cycles Waste Manag 24:917–926

Ito M, Takeuchi M, Saito A, Murase N, Phengsaart T, Tabelin CB, Hiroyosshi N, Tsunekawa M (2019) Improvement of hybrid jig separation efficiency using wetting agents for the recycling of mixed-plastic wastes. J Mater Cycles Waste Manag 21:1376–1383

Ito M, Saito A, Murase N, Phengsaart T, Kimura S, Kitajima N, Takeuchi M, Tabelin CB, Hiroyosshi N (2020) Estimation of hybrid jig separation efficiency using a modified concentration criterion based on apparent densities of plastic particles with attached bubbles. J Mater Cycles Waste Manag 20:2071–2080

Union E (2012) Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off J Eur Union 197:38–71

Ministry of the Environment Government of Japan (2016) https://www.env.go.jp/press/102330.html. Accessed 20 Dec 2022

Doi T, Tsuda I, Unagida H, Murata A, Sakuta K, Kurokawa K (2001) Experimental study on PV module recycling with organic solvent. Sol Energy Mater Sol Cells 67:397–403

New Energy and Industrial Technology Development Organization (NEDO) (2019) https://www.nedo.go.jp/content/100901845.pdf. Accessed 20 Dec 2022

New Energy and Industrial Technology Development Organization (NEDO) (2019) https://www.nedo.go.jp/content/100901845.pdf. Accessed 20 June 2022

Park J, Park N (2014) Wet etching processes for recycling crystalline silicon solar cells from end-of-life photovoltaic modules. RSC Adv 4:34823–34829

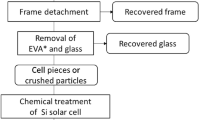

Klugmann-Radziemska E, Ostrowski P (2010) Chemical treatment of crystalline silicon cells as a method of recovering pure silicon from photovoltaic modules. Renew Energy 35:1751–1759

Takami K, Kobashi M, Shiraga Y, Uddin MA, Kato Y, Wu S (2015) Effect of HF and HNO3 concentration on etching rate of each component in waste crystalline silicon solar cells. Mater Trans 56:2047–2052

Matsubara T, Uddin MA, Kato Y, Kawanishi T, Hayashi Y (2018) Chemical treatment of copper and aluminum derived from waste crystalline silicon solar cell modules by mixed acids of HNO3 and HCl. J Sustain Metall 4:378–387

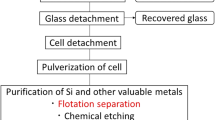

Dias P, Schmidt L, Gomes LB, Bettanin A, Veit H, Bernardes AM (2018) Recycling waste crystalline silicon photovoltaic modules by electrostatic separation. J Sustain Metall 4:176–186

Harada S, Uddin MA, Kato Y, Kawanishi T, Hayashi Y (2019) Separation between silicon and aluminum powders contained within pulverized scraped silicon-based waste solar cells by flotation method. J Sustain Metall 5:551–560

Kato Y, Harada S, Nishimura N, Uddin MA, Uchida Y (2023) Flotation kinetics of aluminum powders derived from waste crystalline silicon solar cells and its comparison between batch, continuous and column flotation practices. J Mater Cycles Waste Manag 25:826–834

Kao Corporation (2019) https://www.kao.com/jp/products/kyukyutto/inc-common/fabric/4901301288493/. Accessed 24 Dec 2022

Matsuoka I (1982) Flotation of oxide minerals. J Min Metall Inst Jpn 98:664–670

Koopal LK, Lee EM, Bohmer MR (1995) Adsorption of cationic and anionic surfactants on charged metal oxide surfaces. J Colloid Interface Sci 170(1):85–97

The Japan Institute of Metals and Materials (1980) Hitetsu Kinzoku Seiren (Non-ferrous smelting). Sendai, pp. 315–317

Behera M, Giri G (2014) Green synthesis and characterization of cuprous oxide nanoparticles in presence of a bio-surfactant. Mater Sci-Pol 32(4):702–708

Acknowledgements

We wish to express our appreciation for the opportunity to discuss experimental results with Prof. N. Fukuda, Okayama University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mizukawa, M., Nishimura, N., Uddin, M.A. et al. Sequential flotation of 4 components in silicon-based waste solar cells. J Mater Cycles Waste Manag 25, 2407–2416 (2023). https://doi.org/10.1007/s10163-023-01698-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01698-5