Abstract

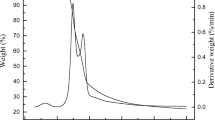

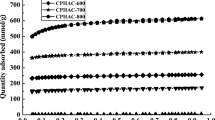

In this work, the de-ashed cocoa pod husk (CPH) was reused as an excellent precursor for preparing high-surface-area activated carbons (ACs) by physical activation with carbon dioxide (CO2) as a gasifying agent. A series of experiments were accomplished at different activation temperatures (i.e., 600, 700, 800, and 900 °C) and holding times (i.e., 0, 30, 60, 90, and 120 min). Results indicated that the yields of the resulting ACs showed a decreasing trend with increasing both the activation temperature and holding time, but their pore properties and true densities led to an increasing trend. The lowest yield (about 10 wt%) was obtained at 900 °C for holding 120 min, showing that the resulting AC had the highest Brunauer–Emmet–Teller (BET) surface area (over 1300 m2/g). Furthermore, the resulting ACs were mainly microporous based on the Type I of the nitrogen (N2) adsorption–desorption isotherms. On the other hand, the chemical compositions of the resulting ACs contained about 88 wt% carbon, 8 wt% oxygen and 3–4 wt% hydrogen/nitrogen/sulfur according to the elemental analysis and scanning electron microscopy–energy dispersive spectroscopy (SEM–EDS).

Similar content being viewed by others

References

Rufford TE, Zhu J, Hulicova-Jurcakova D (2014) Green carbon materials: advances and applications. Pan Stanford, Singapore

Bansal RC, Donnet JB, Stoeckli F (1988) Active carbon. Marcel Dekker, New York

Marsh H, Rodriguez-Reinoso F (2006) Activated carbon. Elsevier, Amsterdam

Abioye AM, Ani FN (2015) Recent development in the production of activated carbon electrodes from agricultural waste biomass for supercapacitors: a review. Renew Sustain Energy Rev 52:1282–1293

Chen M, Shao LL (2016) Review on the recent progress of carbon counter electrodes for dye-sensitized solar cells. Chem Eng J 304:629–645

Chan WH, Mazlee MN, Ahmad ZA, Ishak MAM, Shamsul JB (2017) The development of low cost adsorbents from clay and waste materials: a review. J Mater Cycles Waste Manag 19:1–14

Ioannsidou O, Zabaniotou A (2007) Agricultural residues as precursor for activated carbon production—a review. Renew Sustain Energy Rev 11:1966–2005

Paraskeva P, Kalderis D, Diamadopoulos E (2008) Production of activated carbon from agricultural by-products. J Chem Technol Biotechnol 83:581–592

Alslaibi TM, Abustan I, Ahmad MA, Foul AA (2013) A review: Production of activated carbon from agricultural byproducts via conventional and microwave heating. J Chem Technol Biotechnol 88:1183–1190

Yahya MA, Al-Qodah Z, Ngah CMZ (2015) Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew Sustain Energy Rev 46:218–235

Okiyama DCG, Navarro SLB, Rodrigues CEC (2017) Cocoa shell and its compounds: applications in the food industry. Trends Food Sci Technol 63:103–112

Oddoye EOK, Agyente-Badu CK, Gyedu-Akoto E (2013) Cocoa and its by-products: identification and utilization. In: Watson RR, Preedy VR, Zibadi S (eds) Chocolate in health and nutrition. Springer, New York, pp 23–37

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2011) Using cocoa (Theobroma cacao) shell-based activated carbon to remove 4-nitrophenol from aqueous solution: kinetics and equilibrium studies. Chem Eng J 178:461–467

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2012) Cocoa (Theobroma cacao) shell-based activated carbons by CO2 activation in removing of cationic dye from aqueous solution: kinetics and equilibrium studies. Chem Eng Res Des 90:1480–1490

Bello OS, Siang TT, Ahmad MA (2012) Adsorption of Remazol Brilliant Violet-5R reactive dye from aqueous solution by cocoa pod husk-based activated carbon: Kinetics, equilibrium and thermodynamic studies. Asia-Pac J Chem Eng 7:378–388

Cruz G, Pirila M, Huuhtanen M, Carrion L, Alvarenga E, Keiski R (2012) Production of activated carbon from Cocoa (Theobroma cacao) pod husk. J Civ Environ Eng. https://doi.org/10.4172/2165-784X.1000109

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2013) The effects of acid leaching on porosity and surface functional groups of cocoa (Theobroma cacao)-shell based activated carbon. Chem Eng Res Des 91:1028–1038

Ahmad F, Daud WMAW, Ahmad MA, Radzi R, Azmi AA (2013) The effect of CO2 activation, on porosity and surface functional groups of cocoa (Theobroma cacao)—shell based activated carbon. J Environ Chem Eng 1:378–388

Pereira RG, Veloso CM, da Silva NM, de Sousa LF, Bonomo RCF, de Souza AO, Souza MOG, Fontan RCI (2014) Preparation of activated carbons from cocoa shells and siriguela seeds using H3PO4 and ZnCl2 as activating agents for BSA and α-lactalbumin adsorption. Fuel Process Technol 126:476–486

Saucier G, Adebayo MA, Lima EC, Cataluna R, Thue PS, Prola LDT, Puchana-Rosero MJ, Machado FM, Pavan FA, Dotto GL (2015) Microwave-assisted activated carbon from cocoa shell as adsorbent for removal of sodium diclofenac and nimesulide from aqueous effluents. J Hazard Mater 289:18–27

Simpson BK, Oldham JH, Martin AM (1985) Extraction of potash from cocoa pod husks. Agric Wastes 13:69–73

Suzuki M (1990) Adsorption engineering. Elsevier, Amsterdam

Usmani THU, Ahmad TW, Yousufzai AHK (1994) Preparation and liquid-phase characterization of granular activated-carbon from rice husk. Bioresour Technol 48:31–35

Liou TH, Wu SJ (2009) Characteristics of microporous/mesoporous carbons prepared from rice husk under base- and acid-treated conditions. J Hazard Mater 171:693–703

Hassan AF, Youssef AM (2014) Preparation and characterization of microporous NaOH-activated carbons from hydrofluoric acid leached rice husk and its application for lead (II) adsorption. Carbon Lett 15:57–66

Zhang X, Zhang S, Yang H, Shao J, Chen Y, Feng Y, Wang X, Chen H (2015) Effects of hydrofluoric acid pre-deashing of rice husk on physicochemical properties and CO2 adsorption performance of nitrogen-enriched biochar. Energy 91:903–910

Tsai WT, Liu SC, Chang CH (2012) Preparation and fuel properties of biochars from the pyrolysis of exhausted coffee residue. J Anal Appl Pyrol 93:63–67

Touray N, Tsai WT, Chen HL, Liu SC (2014) Thermochemical and pore properties of goat-manure-derived biochars prepared from different pyrolysis temperatures. J Anal Appl Pyrol 109:116–122

Gregg SJ, Sing KSW (1982) Adsorption, surface area, and porosity. Academic Press, London

Smith JM (1981) Chemical engineering kinetics, 3rd edn. McGraw-Hill, New York

Lowell S, Shields JE, Thomas MA, Thommes M (2006) Characterization of porous solids and powders: surface area, pore size and density. Springer, Dordrecht

Basu P (2013) Biomass gasification, pyrolysis and torrefaction, 2nd edn. Academic Press, San Diego

Touray N, Tsai WT, Li MH (2014) Effect of holding time during pyrolysis on thermochemical and physical properties of biochars derived from goat manure. Waste Biomass Valor 5:1029–1033

Liu SC, Tsai WT, Li MH, Tsai CH (2015) Effect of holding time on fuel properties of biochars prepared from the torrefaction of coffee residue. Biomass Convers Biorefin 5:209–214

Stavropoulos GG, Zabaniotou AA (2005) Production and characterization of activated carbons from olive-seed waste residue. Microporous Mesoporous Mater 82:79–85

Chang YM, Tsai WT, Li MH (2015) Characterization of activated carbon prepared from chlorella-based algal residue. Bioresources Technol 184:344–348

Acknowledgements

The authors thank Li-Jing Viscarb Co. (Pingtung, Taiwan) for offering a project grant. We also appreciate the Instrument Centers at National Chung Hsing University and National Pingtung University of Science and Technology for elemental analysis (EA) and scanning electron microscopy—Energy Dispersive Spectroscopy (SEM-EDS), respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, WT., Jiang, TJ. & Lin, YQ. Conversion of de-ashed cocoa pod husk into high-surface-area microporous carbon materials by CO2 physical activation. J Mater Cycles Waste Manag 21, 308–314 (2019). https://doi.org/10.1007/s10163-018-0791-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-018-0791-9