Abstract

The purpose of this study was to investigate the standard values of living, undamaged iron-wood (Casuarina equisetifolia) trees by different nondestructive techniques. This study also detects the transversal stress wave velocity (V) and tomogram, and resolves corresponding V maps of the trees with and without decay damage. First, a visual tree inspection form with seven categories of tree defects is proposed for tree hazard assessment. The range of demarcation between decay-damaged and sound wood occurred at an approximate V of 1461–1636 m/s by transversal stress wave velocity tomography. Different nondestructive evaluation parameters can serve as an index for diagnosing standard values (with or without decay). A positive significant relationship was found between the diameter and transversal minimum V of 2D in undamaged trees. Moreover, the product diameter × frequency of evaluated value by lateral impact vibration method tended to increase with increasing minimum V of 2D using tomography in undamaged and decay-damaged trees. Decay damage in iron-wood living trees could be inspected and detected by lateral impact vibration method and transversal stress wave velocity tomography for the general location and area of wood deterioration.

Similar content being viewed by others

Introduction

The iron-wood (Casuarina equisetifolia) tree is a common landscape tree near seacoast in Taiwan. This type of tree often plants along both sides of the road for windbreak tree or protect forest. These trees growing on the roadside suffer from man-made and natural decay damage (Fig. 1), and often fall without warning. This could lead to risk of human casualties or result in property loss.

Concerns about public safety and urban tree conservation strongly support the development and application of rapid, precise, and cost efficient diagnostic techniques to detect decay and other types of structural defects in trees [1]. Standing trees must be evaluated to maintain in situ structural safety for tree risk assessment. Various nondestructive techniques (NDT) have been applied to detect decay and deterioration in trees to identify hazardous trees. NDT is the science of identifying the physical and mechanical properties of a piece of material without altering its end-use capabilities and then using this information to make decisions regarding appropriate applications [2]. Visual tree assessment, a systematic method of tree assessment using biological and biomechanical indicators to evaluate overall vitality and structural integrity of a tree, includes visual inspection of the tree to look for external evidence of internal defects, instrumental measurements of internal defects and evaluation of the residual strength of the wood [3]. Arboriculturists consider visual tree assessment (i.e., structural defects) an essential practice. This kind of assessment serves as the starting point for evaluating tree defects and providing basic information about tree growth performance and stability. Tree breakage depends on many features of the tree, including its height, width of crown, crown architecture, crown density in the branching and leaves, form, condition, physical wood properties, and species [4].

Stress wave or ultrasonic velocity evaluation measurements of wood have proven to be effective parameters for detecting and estimating deterioration in tree trunk and wood structures [2, 5]. NDT have been developed for tomographic investigation [6]. Stress wave or ultrasonic tomographic measurements in wood have been found to be effective in detecting and estimating decay in tree trunks [1, 7–15]. Stress wave or ultrasonic tomography has been proven to be the most effective technique for detecting internal decay, locating the position of defects, and estimating their size, shape and characteristics. In addition, because the location of decay is more important in terms of strength loss than just the size of the area of decay, stress wave or ultrasonic tomography allows specialist to determine relative strength loss [16].

A fractometer is a device that breaks the radial increment core along the direction of the fiber to measure the fracture strength [17]. Many diagnostic devices such as resistographs, stress wave or ultrasonic detectors, electrical conductivity meters and fractometers are available for detecting internal decay and other defects in living trees [18]. These NDT can be used in combination to achieve better accuracy in determining the location and extent of wood deterioration.

No detailed reports have been published about detecting wood decay damage in iron-wood (Casuarina equisetifolia) living trees by different nondestructive techniques. Therefore, the first objective of this study was to detect the evaluation parameters of living, undamaged (without decay) iron-wood trees by stress wave velocity tomography, lateral impact vibration, fractometer, and density profile techniques. We also generated tables of standard values (references) to aid in the use of these methods in wood deterioration surveys. A secondary objective was carried out to investigate transversal stress wave velocity tomogram (VT) and resolve corresponding stress wave velocity (V) maps of iron-wood trees with decay damage to understand the degree and extent of trunk deterioration for tree risk assessment.

Materials and methods

First, the experiment was carried out in situ on 34 sound iron-wood trees in Miaoli county (18 sampled trees) and Tanyuan city (16 sampled trees), Taiwan. These trees were inspected in December, 2014, when the trees were about 30–50 years old with average diameters at breast height (DBHs) of 39.2 cm. Multiple stress wave measurements (Fakopp enterprise, Agfalva, Hungary) were carried out at eight equidistant points (eight probes) along the circumference of the trunks. All sensors were located in the trees at about 130 cm above ground and the transducer was connected at an angle of 90° to the trunk axis to detect the propagated travel time and stress wave velocities. The transmitter probe was first positioned at point 1 with stress wave pulses acquired by the receiver probe at the other seven points. Hammer tapping was done from points 1 to 8, respectively. Measurements were repeated with the transmitter probe positioned at each point, thus giving 28 [for a complete round trip: 7 receiving probes × 8 transmitter probes ÷ 2 (the same path was measured twice)] independent propagation time measurements for each investigated section. A complete data matrix was obtained through this measurement process at each test location.

The circumference of each cross section and the distances between sensors were measured using a tape measure. These measurements served as inputs for the system software to map the approximate geometric form of the cross sections. First, upon completing stress wave velocity measurements, a tomogram was constructed for each cross section using the ArborSonic software. Second, due to differences in species and paths, a two-dimensional (2D) image was obtained using the above software based on original stress wave transmission times (no adjusted and regularized times) to help better understand the experimental values in this study. To quantitatively assess the tomograms, all corresponding stress wave velocities were further calculated at each pixel of the tomogram were further calculated by visualizing and converting the tomograms to yield stress wave velocity maps of the cross sections (e.g., Figs. 2, 3).

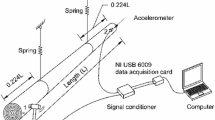

After the stress wave velocity information of each cross section provided by the tomograms was tabulated, the resonant frequencies were measured using a portable lateral impact vibration meter (Ponta, World Enterprise, Japan) to diagnose the wood quality inside a standing tree. The product D × F (m Hz) of the resonance frequency F of the vibration or the sound of an impacted tree trunk and the trunk diameter D serve as the diagnosis index.

Finally, 5-mm diameter cores were cut from the trunk using an increment borer. A fractometer was used to evaluate the crushing strength of core samples (in green state) in the bark to the pith direction at an interval of 6 mm. Finally, a core specimen was mounted and processed into slices (wideness × thickness = 17 × 2.0 mm) for X-ray densitometric scanning. The conditioned slices (air-dried) were subjected to a direct-reading X-ray densitometer (QTRS-01X Tree Ring Analyzer, Quintek Measurement Systems (QMS), Knoxville, TN, USA) to determine the tree ring (wood) density profile. Table 1 summarizes these nondestructive evaluation methods used for tree assessment in this experiment.

The experiment was also carried out in situ on 15 different decay-damaged iron-wood street trees (trees planted along both sides of the road) in Miaoli county (ten sampled trees) and Tanyuan city (five sampled trees), Taiwan. These trees were investigated in December, 2014, when the trees were about 30–50 years old with DBHs of 42.2 cm. Tree trunk deterioration was detected by stress wave velocity tomography (using the same method described above). After the stress wave velocity tomography information (2D image) of each cross section provided by the tomogram was tabulated, the sampling core method was conducted using an increment corer to understand the wood deterioration (with or without decay damage) by the visual method. Finally, the resonant frequencies were measured using a portable lateral impact vibration meter to diagnose the living tree and the product D × F (m Hz) serve as the diagnosis index (as described above).

Results

Seven categories of tree defects and appearance were inspected by the visual tree inspection form (Table 2). The seven main defects were decayed wood, cracks, root problems, weak branch unions, cankers, poor tree architecture (trunk and branch), and dead trees, tops, or branches. First, the iron-wood trees were inspected visually, focusing on different decay-damaged trees.

The evaluated parameters of different nondestructive techniques, including the average lateral impact vibration performance, green crushing strength, and air-dried wood density were 358.0 m Hz, 34.4 MPa, and 875.8 kg/m3, respectively (Table 3). The lateral impact vibration performance, green crushing strength, and air-dried wood density of a normal undamaged tree stem serves as the index of diagnosis or standard reference value.

The average minimum and maximum stress wave velocity (V min and V max) values were 1636 and 2539 m/s for the 24 undamaged iron-wood trees, respectively (Table 4). The mean stress wave velocity (V mean) of the tomogram was 2087 m/s. The V min and V max values were 1404 and 2570 m/s for the 15 decay-damaged iron-wood trees, respectively (Table 5). The V mean of the tomogram was 1987 m/s. Average V min value of the trunks in decay-damaged trees (Table 5) was clearly lower than that of the undamaged trees (Table 4). The V min value (1636 m/s) can be considered as the threshold values of diagnosis by stress wave velocity tomogram.

The VT and corresponding V value maps were examined for the 34 undamaged and 15 decay-damaged iron-wood trees (Figs. 2, 3). The sampling core method was conducted using an increment corer to understand the wood deterioration. None of the tomograms of the undamaged iron-wood trees displayed a distinct pattern of high and low V in the cross section of the stem (Fig. 2). However, all tomograms of the decay-damaged iron-wood trees displayed a distinct pattern of high V (undamaged wood area) and low V (decay-damaged wood area) at the stem perimeter or center (Fig. 3). The standard deviation values of V min in decayed damaged trees (Table 5) were clearly higher than that of undamaged trees (Table 4).

The relationships between transversal stress wave velocities (V min, V max, and V mean) with the 2D diameters of undamaged iron-wood trees are shown in Fig. 4. The V min, V max, and V mean values generally increased with increasing diameter values. When expressed as the linear regression relationships, the determined coefficients (R 2) were 0.65–0.75. Statistical analysis showed that the relationships between stress wave velocity and diameter values were significant at 0.01 levels. This result shows that these V min values (about 1300–2000 m/s) tended to increase with increasing diameter (about 20–60 cm). Different diameter classes of tree affected the V min, V max, V mean of tomogram. The V min value can be considered as the threshold value of diagnosis by stress wave velocity tomography, and the V value was affected by diameter. Therefore, the V threshold value should be adjusted with the 2D diameter values.

The relationship between the diameter × frequency (D × F value, lateral impact vibration performance, m Hz) and the stress wave velocity (V min, V max, and V mean) values (m/s) of tomogram in undamaged and damaged trunk cross section is presented in Fig. 5. The D × F values generally increased with increasing stress wave velocity (V min, V max, and V mean) values. When expressed as the linear regression relationships, the determined coefficients (R 2) were 0.25–0.43. Statistical analysis showed the relationships between D × F and stress wave velocity (V min, V max, and V mean) values were significant at 0.01 levels. The result displayed that the D × F value of lateral impact vibration performance in undamaged or damaged living trees serves as the index of diagnosis for general soundness or preliminary decay status. Moreover, the stress wave velocity tomogram and the corresponding stress wave velocity maps of decay-damaged and undamaged iron-wood tree can detect the general location and area of wood deterioration.

Discussion

The average transversal stress wave velocity (V), lateral impact vibration performance (D × F), green crushing strength (C), and air-dried wood density (D) of a normal undamaged tree stem serves as the diagnosis index or standard reference value. We present a table of standard values for the future use of these device or methods for testing iron-wood trees. The D × F, C, and D values of three tree species are compared and displayed in Table 3 for comparison [19, 20]. The average V min values of iron-wood, Norfolk island pine, and hoop pine trees are 1636, 1129–1296, and 1154–1164 m/s, respectively. If detected values of nondestructive evaluation are lower than these reference values, the wood quality of the trunk show brings up questions which could require further investigation.

In this study, lower transversal stress wave velocities (map grids) were observed inside of the decay-damaged trees. Severe wood decay defects in have been reported when the stress wave velocity is reduced to 70 % of the characteristic values of sound wood [21]. In this study, the V mean value in the undamaged trees was 2087 m/s with the threshold at 1461 m/s (2087 × 0.7 m/s). Moreover, the average V min value of the tomogram in the undamaged trees was 1636 m/s. Therefore, the range of V min values (1461–1636 m/s) can be considered as the threshold values for diagnosis by stress wave velocity tomogram. Furthermore, the range of demarcation between decay-damaged and undamaged wood occurred at an approximate transversal stress wave velocity of 1461–1636 m/s. The reduction in stress wave velocity is indicative of serious damage, the location and extent of which can be seen in the map grids. The decay-damaged tree had a lower average and individual stress wave velocities compared with the undamaged tree.

Some studies have reported that a stress wave or ultrasonic tomogram cannot precisely evaluate the extent and location of decay or the type of defect [7, 9, 12–14]. For example, a stress wave and ultrasonic tomogram underestimates the internal decay and overestimates that in the periphery of the trunk. Therefore, to make better assessments of internal conditions and decay of trees, other more effective methods (e.g., visual drawings of the increment core, drilling resistance and use of a fractometer) should also be adopted in combination to enhance the accuracy of the information. For example, a drilling resistance technique or increment core method can be applied to determine the position and nature of a defect for proof [1, 9, 13, 14, 22].

In-depth tree assessments are warranted when a tree poses a high degree of risk to public safety and exhibits defects that cannot be fully evaluated by visual inspection [23]. However, micro-destructive methods can destroy the compartmentalization zone and break the existing barrier zone within the tree, allowing decay to spread into healthy wood. Therefore, when using decay detection devices, the number of drill holes or sensor sites for collecting the required critical field data should be kept to a minimum [9].

A larger thickness of the peripheral region and a higher ratio of peripheral wood toward the trunk base have significant implications for the tree structure and safety (sound and health). When iron-wood trees have trunk decay, deterioration or hazardous defects, the residual wall thickness (shell) and wood quality have been found to be marginally sufficient. Most experts [3, 23–25] agree that a ratio of 30–35 % of sound wood in the remaining wall is the threshold beyond which some action should be taken.

The transversal stress wave velocity values tended to increase with increasing diameter in this study (Fig. 4). In this experiment, transversal stress wave velocity was detected by eight fixed probes along the circumference on the trunks. The properties (quality) and thickness (residual wall) of the peripheral wood in a tree is very important for the tree’s structural safety and hazard evaluation. Generally, larger diameter trees with larger crowns need greater support while the trunks of smaller diameter trees with smaller crowns needs to withstand smaller forces. The own (dead) weight and crown volume of the larger diameter class were larger than those of the smaller diameter class in tree. The most important and most dangerous load on the trees is undoubtedly that created by wind, which can introduce bending stresses near the periphery of the stem [26]. Previous researches has indicated that the V max values of lean Norfolk island pine and lean hoop pine trees are than those of normal non-leaning trees [13, 14]. The leaning of a tree could result in reaction wood or larger gravity effects in the trunk of the tree. However, the V values of the cross section are totally influenced by the distribution of the cell structure, reaction wood, gravity, own weight, and other factors (i.e., combined action) in the tree. This might limit the application of stress wave velocity tomography. Further research is needed to clarify the intensities of individual factors in the future.

In this experiment, the D × F values generally increased with increasing stress wave velocity (V min, V max, and V mean) values. The D × F value of lateral impact vibration performance in living trees serves as the index of diagnosis. Moreover, the stress wave velocity tomogram of iron-wood living tree can detect the general location and area of wood deterioration. Therefore, first, this experiment suggests that the tree hazard assessment could be inspected by visual tree defects inspection. Then, general soundness or preliminary decay status could be detected by faster lateral impact vibration method. Second, the general location and area of wood deterioration could be used by transversal stress wave velocity tomography. Finally, the proposed approach can be combined with other non-destructive techniques to better examine and confirm the situations of trees.

Conclusions

A visual tree inspection form with seven categories of tree defects is proposed for tree hazard assessment in this study. The average transversal stress wave velocities were 1636–2539 m/s for undamaged iron-wood trees. Moreover, the average lateral impact vibration performance, green crushing strength, and air-dried wood density were 358.0 m Hz, 34.4 MPa, and 875.8 kg/m3, respectively. Different nondestructive evaluated parameters could serve as the index of the diagnosis value. A table of standard values for the future use of these nondestructive methods for testing iron-wood trees with and without decay damage is presented. Average V min values of the trunks in decay-damaged trees were clearly lower than those of sound trees. The stress wave velocity tomogram and corresponding stress wave velocity maps of decay-damaged and undamaged iron-wood tree can detect the general location and area of wood deterioration. Moreover, general soundness or preliminary decay status could be detected by faster lateral impact vibration method. The range of demarcation between decay-damaged and undamaged wood occurred at an approximate transversal stress wave velocity of 1461–1636 m/s. The stress wave velocity (V min, V max, and V mean) values increased with increasing diameter in sound trees, and the relationships could be represented by positive linear regression formulas. The V min and diameter values were 1300–2000 m/s and 20–60 cm in undamaged trees, respectively. These values can be considered as the threshold values of diagnosis by stress wave velocity tomography. The proposed approach can be combined with other non-destructive techniques to better examine and confirm the situations of trees.

References

Wang X, Allison RB (2008) Decay detection in red oak trees using a combination of visual inspection, acoustic testing, and resistance microdrilling. Arboric Urban For 34:1–4

Pellerin RF, Ross RJ (2002) Nondestructive evaluation of wood. For Prod Soc, Madison, pp 150–200

Matheny NP, Clark JR (1994) A photographic guide to the evaluation of hazard trees in urban areas. Int Soc Arboric Champaign, IL, p 85

Gruber F (2008) Untenable failure criteria for trees: 1. The residual shell wall thickness rule. Arboric J 31:5–18

Lin CJ, Chiu CM, Wang SY (2000) Application of ultrasound in detecting wood decay in squirrel-damaged standing trees of Luanta China fir. Taiwan J For Sci 15:267–279

Rinn F (1999) Device for investigation materials. US-Patent US6813948; international Patent PCT/DE00/01467 (1999.05.11). (Basic patent describing sonic tomography)

Gilbert E, Smiley ET (2004) Picus sonic tomography for the quantification of decay in white oak (Quercus alba) and hickory (Carya spp.). Arboric J 30:277–281

Bucur V (2005) Ultrasonic techniques for nondestructive testing of standing trees. Ultrasonics 43:237–239

Wang X, Allison RB, Wang L, Ross RJ (2007) Acoustic tomography for decay detection in red oak trees. Research Paper FPL-RP-642. US Department of Agriculture, Madison

Deflorio G, Fink S, Schwarze FWM (2008) Detection of incipient decay in tree stems with sonic tomography after wounding and fungal inoculation. Wood Sci Technol 42:117–132

Lin CJ, Kao YC, Lin TT, Tsai MJ, Wang SY, Lin LD, Wang YN, Chan MH (2008) Application of an ultrasonic tomographic technique for detecting defects in standing trees. Int Biodeterior Biodegrad 43:237–239

Wang X, Wiedenbeck J, Liang S (2009) Acoustic tomography for decay detection in black cherry trees. Wood Fiber Sci 41:127–137

Lin CJ, Chang TT, Juan MY, Lin TT (2011) Detecting deterioration in royal palm (Roystonea regia) using ultrasonic tomographic and resistance microdrilling techniques. J Trop For Sci 23:260–270

Lin CJ, Chang TT, Juan MY, Lin TT, Tseng CL, Wang YN, Tsai MJ (2011) Stress wave tomography for the quantification of artificial hole detection in camphor trees (Cinnamomum camphora). Taiwan J For Sci 26:17–32

Lin CJ, Chung CH, Wu ML, Cho CL (2013) Detection of Phellinus noxius decay in Sterculia foetida tree. J Trop For Sci 25(4):487–496

Rinn F (2011) Basic aspects of mechanical stability of tree cross-sections. Arborist News, pp 52–54

Lin CJ, Wang SY, Chiu CM (2007) Crushing strength sampling with minimal damage to taiwania (Taiwania cryptomerioides) using a fractometer. Wood Fiber Sci 39:39–47

Larsson B, Bengtsson B, Gustafsson M (2004) Nondestructive detection of decay in living trees. Tree Physiol 24:853–858

Lin CJ, Huang YH, Huang GS, Wu ML (2015) Detection and evaluation of termite damage in Norfolk island pine (Araucaria heterophylla) trees by nondestructive techniques. J Exp For Nat Taiwan Univ 29:79–90

Lin CJ, Huang YH, Huang GS, Wu ML, Yang TH (2015) Detection of termite damage in hoop pine (Araucaria cunninghamii) trees by nondestructive techniques. J Trop For Sci (in press)

Bethge K, Mattheck C, Hunger E (1996) Equipment for detection and evaluation of incipient decay in trees. Arboric J 20:13–37

Wang X, Wiedenbeck J, Ross RJ, Forsman JW, Erickson JR, Pilon C, Brashaw B (2005) Nondestructive evaluation of incipient decay in hardwood logs. General Technical Report FPL-GTR-162. US Department of Agriculture, Madison

Pokorny JD (1992) Urban tree risk management: a community guide to program design and implementation. USDA Forest Service Northeastern Area State and Private Forestry, St. Paul

Harris RW, Clark JR, Matheny NP (2004) Arboriculture: integrated management of landscape trees, shrubs, and vines. Pearson Education, Upper Saddle River, pp 405–433

Hayes E (2007) Evaluating tree defects, a field guide. MN, Safetrees LLC, p 30

Mattheck C, Breloer H (1994) Field guide for visual tree assessment (VTA). Arboric J 18:1–23

Acknowledgments

The authors wish to thank the Experimental Forest, National Taiwan University and Taiwan Forestry Research Institute for financial support.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Lin, CJ., Huang, YH., Huang, GS. et al. Detection of decay damage in iron-wood living trees by nondestructive techniques. J Wood Sci 62, 42–51 (2016). https://doi.org/10.1007/s10086-015-1520-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-015-1520-9