Abstract

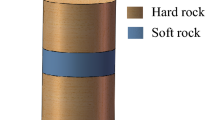

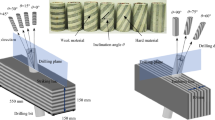

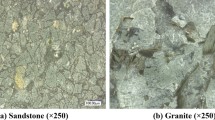

The tensile strength and cracking behavior of layered rocks in a tensile stress field are one of the most significant characteristics of rock masses, which may strongly affect the stability of rock structures. The study presented here investigated the effect of layer spacing and inclination angle on the indirect tensile strength, crack development, failure pattern, and contact force chain of layered disks under diametral loading using experimental and numerical investigations. Numerous experimental models made from plaster were examined under diametral loading, and a two-dimensional Particle Flow Code (PFC2D) was adopted for in depth simulation of the failure process. Both numerical and experimental results were found to be in great agreement and showed that the increase in the layer orientation up to 15° results in the peak in the tensile strength followed by a decrease. Specimens with the spacing ratio (SR) of 0.5 and 0.1 showed the highest and lowest tensile and compressive stresses at the disk center, respectively. Moreover, the numerical analysis indicated the formation of three failure pattern types: TL, PB, and TL-PB. Tensile cracks mainly formed in the direction of diametral loading, and their maximum number formed at 15° and SR = 0.5. Additionally, the shear ones formed in a conjugate system and had negligible numbers. The analysis of the contact force chain showed that the layers do not affect the compressive force chain at α < 45° but at higher angles, the stronger layers transfer compressive force. However, when α ranges from 0° to 30°, tensile forces are distributed in stronger layers, and with an increase in α, the concentration of these forces in these layers diminishes and the forces are reoriented in the direction of diametral loading.

Similar content being viewed by others

Abbreviations

- ISRM:

-

International society for rock mechanics

- TL:

-

Through layer fracture pattern

- PB:

-

Parallel to layer fracture pattern

- TL-PB:

-

Mixed fracture pattern

- PFC:

-

Particle flow code

- FJ-BPM:

-

Flat-jointed bonded-particle model

- DEM:

-

Discrete element method

- SR:

-

Spacing ratio

- UCS:

-

Uniaxial compressive strength (MPa)

- E :

-

Modulus of elasticity (GPa)

- σ t :

-

Tensile strength (MPa)

- ν :

-

Poisson’s ratio

- E c :

-

Particle modulus of elasticity (GPa)

- \(\overline{\lambda }\) :

-

Radius multiplier

- φ Fj :

-

Friction coefficient of flat-joint bonds

- σ t -Fj :

-

Tensile strength of flat-joint bonds (MPa)

- c Fj :

-

Cohesion coefficient of flat-joint bonds (MPa)

- \({t}_{l}\) :

-

Thickness of the layers (mm)

- t :

-

Disk thickness (mm)

- \(\overline{E}_{c}\) :

-

Elastic modulus of flat-joint bonds (GPa)

- k n :

-

Normal stiffness of ball contacts (N/m)

- k s :

-

Shear stiffness of ball contacts (N/m)

- R max :

-

Maximum radius of balls (mm)

- R min :

-

Minimum radius of balls (mm)

- \(\overline{k}_{s}\) :

-

Shear stiffness of flat-joint bonds (N/m)

- \(\overline{k}_{n}\) :

-

Normal stiffness of flat-joint bonds (N/m)

- σ xx , σ yy, σ xy :

-

Stress tensor components in global coordinate x,y (MPa)

- α :

-

Layer inclination angle (◦)

- D :

-

Disk diameter (mm)

- P :

-

Applied load at the failure of the disk (N)

References

Aadnoy, B., Looyeh, R.: Petroleum Rock Mechanics : Drilling Operations and Well Design, 2nd edn. Gulf Professional Publishing, Oxford (2011)

Abdullah, R., Tsutsumi, T., Amin, M.F.M., et al.: Evolution on deformation behaviour of brazilian test under different contact area using particle image velocimetry and finite element modelling. Measurement 159, 107796 (2020). https://doi.org/10.1016/j.measurement.2020.107796

Al-Harthi, A.A.: Effect of planar structures on the anisotropy of Ranyah sandstone, Saudi Arabia. Eng. Geol. 50, 49–57 (1998). https://doi.org/10.1016/S0013-7952(97)00081-1

Amadei, B.: Importance of anisotropy when estimating and measuring in situ stresses in rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 33, 293–325 (1996). https://doi.org/10.1016/0148-9062(95)00062-3

Amir Hosseini, M., Kamrava, S., Sahimi, M., Tahmasebi, P.: Effect of wettability on two-phase flow through granular porous media: fluid rupture and mechanics of the media. Chem. Eng. Sci. 269, 118446 (2023). https://doi.org/10.1016/J.CES.2023.118446

Asadizadeh, M., Khosravi, S., Karimi, J., et al.: Mechanical behavior of single-flawed cylindrical specimens subjected to axial loading: a numerical investigation. Bull. Eng. Geol. Environ. 81, 442 (2022). https://doi.org/10.1007/s10064-022-02940-4

Bahaaddini, M., Serati, M., Masoumi, H., Rahimi, E.: Numerical assessment of rupture mechanisms in Brazilian test of brittle materials. Int. J. Solids Struct. 180–181, 1–12 (2019). https://doi.org/10.1016/j.ijsolstr.2019.07.004

Bahaaddini, M., Sharrock, G., Hebblewhite, B.K.: Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 49, 206–225 (2013a). https://doi.org/10.1016/j.compgeo.2012.10.012

Bahaaddini, M., Sharrock, G., Hebblewhite, B.K.: Numerical direct shear tests to model the shear behaviour of rock joints. Comput. Geotech. 51, 101–115 (2013b). https://doi.org/10.1016/j.compgeo.2013.02.003

Cai, M., Kaiser, P.: Numerical simulation of the Brazilian test and the tensile strength of anisotropic rocks and rocks with pre-existing cracks. Int. J. Rock Mech. Min. Sci 41, 478–483 (2004). https://doi.org/10.1016/j.ijrmms.2004.03.086

Chang, X., Zhao, H., Cheng, L.: Fracture propagation and coalescence at bedding plane in layered rocks. J. Struct. Geol. 141, 104213 (2020). https://doi.org/10.1016/j.jsg.2020.104213

Chen, S., Yue, Z.Q., Tham, L.G.: Digital image-based numerical modeling method for prediction of inhomogeneous rock failure. Int. J. Rock Mech. Min. Sci. 41, 939–957 (2004). https://doi.org/10.1016/J.IJRMMS.2004.03.002

Chen, S., Yue, Z.Q., Tham, L.G., Lee, P.K.K.: Modeling of the indirect tensile test for inhomogeneous granite using a digital image-based numerical method. Int. J. Rock Mech. Min. Sci. 41, 466–471 (2004). https://doi.org/10.1016/J.IJRMMS.2004.03.084

Cho, J.-W., Kim, H., Jeon, S., Min, K.-B.: Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int. J. Rock Mech. Min. Sci. 50, 158–169 (2012). https://doi.org/10.1016/j.ijrmms.2011.12.004

Debecker, B., Vervoort, A.: Two-dimensional discrete element simulations of the fracture behaviour of slate. Int. J. Rock Mech. Min. Sci. 61, 161–170 (2013). https://doi.org/10.1016/j.ijrmms.2013.02.004

Dorogoy, A., Banks-Sills, L.: Effect of crack face contact and friction on Brazilian disk specimens—a finite difference solution. Eng. Fract. Mech. 72, 2758–2773 (2005). https://doi.org/10.1016/J.ENGFRACMECH.2005.05.005

Douma, L.A.N.R., Regelink, J.A., Bertotti, G., et al.: The mechanical contrast between layers controls fracture containment in layered rocks. J. Struct. Geol. 127, 103856 (2019). https://doi.org/10.1016/j.jsg.2019.06.015

Duan, K., Kwok, C.Y.: Discrete element modeling of anisotropic rock under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 78, 46–56 (2015). https://doi.org/10.1016/j.ijrmms.2015.04.023

Erarslan, N., Liang, Z.Z., Williams, D.J.: Experimental and numerical studies on determination of indirect tensile strength of rocks. Rock Mech. Rock Eng. 45, 739–751 (2012). https://doi.org/10.1007/s00603-011-0205-y

Erarslan, N., Williams, D.J.: Experimental, numerical and analytical studies on tensile strength of rocks. Int. J. Rock Mech. Min. Sci. 49, 21–30 (2012). https://doi.org/10.1016/j.ijrmms.2011.11.007

Feng, G., Kang, Y., Wang, X., et al.: Investigation on the failure characteristics and fracture classification of shale under Brazilian test conditions. Rock Mech. Rock Eng. 53, 3325–3340 (2020). https://doi.org/10.1007/s00603-020-02110-6

He, J., Afolagboye, L.O.: Influence of layer orientation and interlayer bonding force on the mechanical behavior of shale under Brazilian test conditions. Acta Mech. Sin. 34, 349–358 (2018). https://doi.org/10.1007/s10409-017-0666-7

Imani, M., Nejati, H.R., Goshtasbi, K.: Dynamic response and failure mechanism of Brazilian disk specimens at high strain rate. Soil Dyn. Earthq. Eng. 100, 261–269 (2017). https://doi.org/10.1016/j.soildyn.2017.06.007

Imani, M., Nejati, H.R., Goshtasbi, K., Nazerigivi, A. Effect of brittleness on the micromechanical damage and failure pattern of rock specimens. Smart Struct. Syst. 29(4), 535–547 (2022). https://doi.org/10.12989/SSS.2022.29.4.535

ISRM: The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring; 1974–2006, (2007)

Itasca Consulting Group Inc. PFC3D manual, (2022)

Khanlari, G., Rafiei, B., Abdilor, Y.: Evaluation of strength anisotropy and failure modes of laminated sandstones. Arab. J. Geosci. 8, 3089–3102 (2015). https://doi.org/10.1007/s12517-014-1411-1

Khanlari, G., Rafiei, B., Abdilor, Y.: An experimental investigation of the Brazilian tensile strength and failure patterns of laminated sandstones. Rock Mech. Rock Eng. 48, 843–852 (2015). https://doi.org/10.1007/s00603-014-0576-y

Lavrov, A., Vervoort, A.: Theoretical treatment of tangential loading effects on the Brazilian test stress distribution. Int. J. Rock Mech. Min. Sci. 39, 275–283 (2002). https://doi.org/10.1016/S1365-1609(02)00010-2

Li, K., Cheng, Y., Yin, Z.-Y., et al.: Size effects in a transversely isotropic rock under brazilian tests: laboratory testing. Rock Mech. Rock Eng. (2020). https://doi.org/10.1007/s00603-020-02058-7

Lin, H., Cao, P., Wang, Y.: Numerical simulation of a layered rock under triaxial compression. Int. J. Rock Mech. Min. Sci. 60, 12–18 (2013). https://doi.org/10.1016/j.ijrmms.2012.12.027

Liu, W.C., Tien, Y.M., Juang, C.H.: Numerical simulation for layered rock under Brazilian test. (2012)

Markides, C.F., Pazis, D.N., Kourkoulis, S.K.: (2010) Influence of friction on the stress field of the Brazilian tensile test. Rock Mech. Rock Eng. 441(44), 113–119 (2010). https://doi.org/10.1007/S00603-010-0115-4

Mokhtari, M., Tutuncu, A.N.: Impact of laminations and natural fractures on rock failure in Brazilian experiments: a case study on green river and niobrara formations. J. Nat. Gas. Sci. Eng. 36, 79–86 (2016). https://doi.org/10.1016/j.jngse.2016.10.015

Park, B., Min, K.-B.: Bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int. J. Rock Mech. Min. Sci. 76, 243–255 (2015). https://doi.org/10.1016/j.ijrmms.2015.03.014

Park, B., Min, K.-B., Thompson, N., Horsrud, P.: Three-dimensional bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int. J. Rock Mech. Min. Sci. 110, 120–132 (2018). https://doi.org/10.1016/j.ijrmms.2018.07.018

Pierce, M., Cundall, P., Potyondy, D., Mas Ivars, D.: A synthetic rock mass model for jointed rock. In: Proceedings of the first CA–US rock mechanics symposium, Vancouver, BC. pp 341–349, (2007)

Potyondy, D.O.: A flat-jointed bonded-particle material for hard rock. In: 46th US Rock Mechanics/Geomechanics Symposium 2012. pp 1510–1519, (2012)

Potyondy, D.O., Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41, 1329–1364 (2004). https://doi.org/10.1016/j.ijrmms.2004.09.011

Pros, A., Díez, P., Molins, C.: Numerical modeling of the double punch test for plain concrete. Int. J. Solids Struct. 48, 1229–1238 (2011). https://doi.org/10.1016/j.ijsolstr.2011.01.006

Serati, M., Bahaaddini, M., Roshan, H., et al.: On assessing the tensile cracking pattern in brittle rocks and solids. Bull. Eng. Geol. Environ. 80, 5867–5879 (2021). https://doi.org/10.1007/s10064-021-02249-8

Serati, M., Masoumi, H., Williams, D.J., Alehossein, H.: Modified Brazilian test for indirect measurement of tensile strength of brittle materials. In: 51st U.S. Rock Mech. Symp. ARMA-2017–0834. (2017)

Shabani, F., Kaviani-Hamedani, F.: Cyclic response of sandy subsoil layer under traffic-induced principal stress rotations: Application of bidirectional simple shear apparatus. Soil Dyn. Earthq. Eng. 164(2022), 107573 (2023). https://doi.org/10.1016/j.soildyn.2022.107573

Sun, W., Wu, S., Zhou, Y., Zhou, J.: Comparison of crack processes in single-flawed rock-like material using two bonded–particle models under compression. Arab. J. Geosci. 12, 156 (2019). https://doi.org/10.1007/s12517-019-4327-y

Tan, X., Konietzky, H., Frühwirt, T., Dan, D.Q.: Brazilian tests on transversely isotropic rocks: laboratory testing and numerical simulations. Rock Mech. Rock Eng. 48, 1341–1351 (2015). https://doi.org/10.1007/s00603-014-0629-2

Tavallali, A., Vervoort, A.: Failure of layered sandstone under Brazilian Test conditions: effect of micro-scale parameters on macro-scale behaviour. Rock Mech. Rock Eng. 43, 641–653 (2010). https://doi.org/10.1007/s00603-010-0084-7

Tavallali, A., Vervoort, A.: Behaviour of layered sandstone under Brazilian test conditions: layer orientation and shape effects. J. Rock Mech. Geotech. Eng. 5, 366–377 (2013). https://doi.org/10.1016/j.jrmge.2013.01.004

Tavallali, A., Vervoort, A.: Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 47, 313–322 (2010). https://doi.org/10.1016/j.ijrmms.2010.01.001

Vervoort, A., Min, K.-B., Konietzky, H., et al.: Failure of transversely isotropic rock under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 70, 343–352 (2014). https://doi.org/10.1016/j.ijrmms.2014.04.006

Wang, P., Cai, M., Ren, F.: Anisotropy and directionality of tensile behaviours of a jointed rock mass subjected to numerical Brazilian tests. Tunn. Undergr. Sp. Technol. 73, 139–153 (2018). https://doi.org/10.1016/j.tust.2017.12.018

Wang, Z., Yang, S., Tang, Y.: Mechanical behavior of different sedimentary rocks in the Brazilian test. Bull. Eng. Geol. Environ. 79, 5415–5432 (2020). https://doi.org/10.1007/s10064-020-01906-8

Xu, G., Gutierrez, M., He, C., Meng, W.: Discrete element modeling of transversely isotropic rocks with non-continuous planar fabrics under Brazilian test. Acta Geotech. 15, 2277–2304 (2020). https://doi.org/10.1007/s11440-020-00919-7

Xu, G., He, C., Chen, Z., Wu, D.: Effects of the micro-structure and micro-parameters on the mechanical behaviour of transversely isotropic rock in Brazilian tests. Acta Geotech. 13, 887–910 (2018). https://doi.org/10.1007/s11440-018-0636-7

Yang, S.-Q., Yin, P.-F., Huang, Y.-H.: Experiment and discrete element modelling on strength, deformation and failure behaviour of shale under Brazilian compression. Rock Mech. Rock Eng. 52, 4339–4359 (2019). https://doi.org/10.1007/s00603-019-01847-z

Yang, S.Q., Huang, Y.H.: Particle flow study on strength and meso-mechanism of Brazilian splitting test for jointed rock mass. Acta Mech. Sin. Xuebao 30, 547–558 (2014). https://doi.org/10.1007/s10409-014-0076-z

Yin, P.-F., Yang, S.-Q.: Experimental investigation of the strength and failure behavior of layered sandstone under uniaxial compression and Brazilian testing. Acta Geophys. 66, 585–605 (2018). https://doi.org/10.1007/s11600-018-0152-z

Yu, J., Shang, X., Wu, P.: Influence of pressure distribution and friction on determining mechanical properties in the Brazilian test: theory and experiment. Int. J. Solids Struct. 161, 11–22 (2019). https://doi.org/10.1016/j.ijsolstr.2018.11.002

Yu, Y., Yin, J., Zhong, Z.: Shape effects in the Brazilian tensile strength test and a 3D FEM correction. Int. J. Rock. Mech. Min. Sci. 43, 623–627 (2006)

Yu, Y., Zhang, J., Zhang, J.: A modified Brazilian disk tension test. Int. J. Rock Mech. Min. Sci. 46, 421–425 (2009). https://doi.org/10.1016/j.ijrmms.2008.04.008

Zhao, N.N., Feng, J.L.: Investigation on fracture mechanism of layered slate: experiment and beam-particle method. Environ. Earth Sci. 80, 788 (2021). https://doi.org/10.1007/s12665-021-10106-w

Zhu, W.C., Tang, C.A.: Numerical simulation of Brazilian disk rock failure under static and dynamic loading. Int. J. Rock Mech. Min. Sci. 43, 236–252 (2006). https://doi.org/10.1016/J.IJRMMS.2005.06.008

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors reported no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asadizadeh, M., Khosravi, S., Abharian, S. et al. Tensile behavior of layered rock disks under diametral loading: experimental and numerical investigations. Granular Matter 25, 21 (2023). https://doi.org/10.1007/s10035-023-01311-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01311-4