Abstract

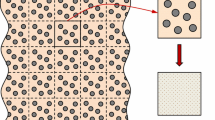

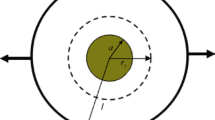

The present paper deals with a novel method to predict the effective elastic behavior of heterogeneous continuous materials using discrete element method. This work uses a numerical approach based on a hybrid particulate-lattice model in which discrete elements are linked by cohesive forces through beam elements. Mechanical tests, carried out on particulate composite material, are performed in terms of effective elastic properties and stress fields which exhibit a good adequation with other numerical and analytical approaches such as the finite element method and the Fast Fourier Transform based method. As an example, the proposed approach is performed to predict the elastic properties of a ceramic/resin composite as well as the local effects by means of equivalent Von Mises stress.

Similar content being viewed by others

Abbreviations

- \(\epsilon \) :

-

Imposed strain in tensile and shear tests

- \(\nu _{M}\) :

-

Macroscopic Poisson’s ratio

- \(\rho _\mu \) :

-

Microscopic mass density

- \(\rho _M\) :

-

Macroscopic mass density

- \(\sigma _{d}\) :

-

Deviatoric stress tensor

- \(\sigma _{eq}\) :

-

Equivalent Von-Mises stress

- \(\theta _{i}\) :

-

Rotation of particle i

- \(\varepsilon _{rel}\) :

-

Relative error

- \(A_{\mu }\) :

-

Cross-section of the beam

- \(c_{r}\) :

-

Contrast of properties

- D :

-

Diameter of cylindrical inclusions

- D :

-

Diameter of the cylinders

- \(d_{\alpha }\) :

-

Branch vector of contact \(\alpha \)

- \(D_{Z}\) :

-

Variance parameter

- E :

-

Effective Young’s modulus

- \(E^{i}\) :

-

Young’s modulus of the inclusion phase

- \(E^{m}\) :

-

Young’s modulus of the matrix phase

- \(E_{\mu }\) :

-

Microscopic Young’s modulus

- \(E_{M}\) :

-

Macroscopic Young’s modulus

- \(F^{j \rightarrow i }\) :

-

Force of interaction of the particle j on the particle i

- \(F_{i}^{ext}\) :

-

External force acting on particle i

- G :

-

Effective shear modulus

- \(I_{i}\) :

-

Quadratic moment of inertia of the particle i

- \(k_n\) :

-

Normal stiffness parameter

- \(k_t\) :

-

Tangential stiffness parameter

- \(K_{V}^{i}\) :

-

Set of contacts in the specimen i of volume V

- L :

-

Length of the pattern

- L :

-

Length of the representative pattern

- \(M^{j \rightarrow i }\) :

-

Moment of interaction of the particle j on the particle i

- \(m_{i}\) :

-

Elementary mass of the particle i

- \(M_{i}^{ext}\) :

-

External moment acting on particle i

- \(n_{r}\) :

-

Number of realizations

- \(R_i\) :

-

Radius of particle i

- \(r_{\alpha }\) :

-

Reaction force of contact \(\alpha \)

- \(r_{\mu }\) :

-

Dimensionless radius of the beam

- \(u_{n}^{i}\) :

-

Normal displacement of particle i

- \(u_{t}^{i}\) :

-

Tangential displacement of particle i

- Z :

-

Investigated property

References

Cundall, P.A.: A computer model for simulating progressive large-scale movements in block rock mechanics. Proc. Symp. Int. Soc. Rock Mech. 1, 132–150 (1971)

Cleary, P.W., Campbell, C.S.: Self-lubrication for long run-out landslides: examination by computer simulation. J. Geophys. Res. Solid Earth 98(B12), 21911–21924 (1993)

Campbell, C.-S., Cleary, P.-W., Hopkins, M.-A.: Large-scale landslide simulations: global deformation, velocities, and basal friction. J. Geophys. Res. Solid Earth 100(B5), 8267–8283 (1995)

Cleary, P.-W.: Dem simulation of industrial particle flows: case studies of dragline excavators, mixing in tumblers and centrifugal mills. Powder Technol. 209(1–3), 83–104 (2000)

Moakher, M., Shinbrot, T., Muzzio, F.-J.: Experimentally validated computations of flow, mixing and segregation of non-cohesive grains in 3d tumbling blenders. Powder Technol. 109(1–3), 58–71 (2000)

Sève, B., Iordanoff, I., Berthier, Y.: A discrete solid third body model: influence of the intergranular forces on the macroscopic behaviour. In: Dowson, D., Dalmaz, G., Lubrecht, A.A., Priest, M. (eds), Tribology Research: From Model Experiment to Industrial Problem A Century of Efforts in Mechanics, Materials Science and Physico-Chemistry Proceedings of the 27th Leeds-Lyon Symposium on Tribology, vol. 39 of Tribology Series, pp. 361–368. Elsevier, (2001)

Fillot, N.: Etude m écanique de l’usure - modélisation par éléments discret des d ébites de trois ème corps solide. Master’s thesis, Ecole doctorale MEGA-INSA-Lyon, (2004)

Fillot, N., Iordanoff, I., Berthier, Y.: Modelling third body flows with a discrete element method -a tool for understanding wear with adhesive particles. Tribol. Int. 40, 973–981 (2007)

Bucher, F., Dmitriev, A.I., Ertz, M., Knothe, K., Popov, V.L., Psakhie, S.G., Shilko, E.V.: Multiscale simulation of dry friction in wheel/rail contact. Wear 261(7–8), 874–884 (2006)

Vargas, W.L., McCarthy, J.: Heat conduction in granular materials. AIChE J. 47, 1052–1059 (2001)

Haddad, H., Guessasma, M., Fortin, J.: Heat transfer by conduction using DEM–FEM coupling method. Comput. Mater. Sci. 81, 339–347 (2014)

Bourbatache, K., Guessasma, M., Bellenger, E., Bourny, V., Fortin, J.: DEM ball bearing model and defect diagnosis by electrical measurement. Mechanical Systems and Signal Processing41(1–2), 98–112 (2013)

Hentz, S., Donzé, F.-V., Daudeville, L.: Discrete element modelling of concrete submitted to dynamic loading at high strain rates. Comput. Struct. 82(29–30), 2509–2524 (2004)

Tan, Y., Yang, D., Sheng, Y.: Discrete element method (dem) modeling of fracture and damage in the machining process of polycrystalline sic. J. Eur. Ceram. Soc. 29(6), 1029–1037 (2009)

Jebahi, M., Charles, J.-L., Dau, F., Illoul, L., Iordanoff, I.: 3d coupling approach between discrete and continuum models for dynamic simulations (dem–cnem). Comput. Methods Appl. Mech. Eng. 255, 196–206 (2013)

Thakur, S.-C., Morrissey, J.-P., Sun, J., Chen, J.-F., Ooi, J.-Y.: Micromechanical analysis of cohesive granular materials using the discrete element method with an adhesive elasto-plastic contact model. Granul. Matter 16, 383–400 (2014)

André, D., Jebahi, M., Iordanoff, I., Charles, J.L., Néauport, J.: Using the discrete element method to simulate brittle fracture in the indentation of a silica glass with a blunt indenter. Comput. Methods Appl. Mech. Eng. 256, 136–147 (2013)

Schlangen, E., Garboczi, E.J.: Fracture simulations of concrete using lattice models: computational aspects. Eng. Fract. Mech. 57(2–3), 319–332 (1997)

Sheng, Y., Yang, D., Tan, Y., Ye, J.: Microstructure effects on transverse cracking in composite laminae by DEM. Compos. Sci. Technol. 70(14), 2093–2101 (2010)

Yang, D., Sheng, Y., Ye, J., Tan, Y.: Dynamic simulation of crack initiation and propagation in cross-ply laminates by DEM. Compos. Sci. Technol. 71(11), 1410–1418 (2011)

Maheo, L., Dau, F., André, D., Charles, J.L., Iordanoff, I.: A promising way to model cracks in composite using discrete element method. Compos. Part B: Eng. 71, 193–202 (2015)

Powell, D-J., Hayward, G.: A performance appraisal of flexible array structures using a facet ensemble scattering technique. In: Proceedings of the IEEE Ultrasonics Symposium, 2:753–756, (1991)

Bowen, C.R., Bradley, L.R., Almond, D.P., Wilcox, P.D.: Flexible piezoelectric transducer for ultrasonic inspection of non-planar components. Ultrasonics 48, 367–375 (2008)

Lubachevsky, B.D., Stillinger, F.H.: Geometric properties of random disk packings. J. Stat. Phys. 60(5), 561–583 (1990)

Love, A.-E.-H.: A Treatise of Mathematical Theory of Elasticity. Cambridge, Cambridge (1927)

Weber, J.: Recherches concernant les contraintes intergranulaires dans les milieux pulvérulents. Bul. liaison P. et Ch., (1966)

de Saxcé, G., Fortin, J., Millet, O.: About the numerical simulation of the dynamics of granular media and the definition of the mean stress tensor. Mech. Mater. 36(12), 1175–1184, 2004. Topics in Micromechanics of Heterogeneous Materials

Nicot, F., Hadda, N., Guessasma, M., Fortin, J., Millet, O.: On the definition of the stress tensor in granular media. Int. J. Solids Struct. 50, 2508–2517 (2013)

Donev, A., Cissé, I., Sachs, D., Variano, E.-A., Stillinger, F.-H., Connelly, R., Torquato, S., Chaikin, P.-M.: Improving the density of jammed disordered packings using ellipsoids. Science 303, 990–993 (2004)

Cambou, B.: Behaviour of Granular Materials. illustrated ed, 1998

André, D., Iordanoff, I., Charles, J.L., Néauport, J.: Discrete element method to simulate continuous material by using the cohesive beam model. Comput. Methods Appl. Mech. Eng. 213–216, 113–125 (2012)

Fortin, J., Millet, O., de Saxcé, G.: Construction of an averaged stress tensor for a granular medium. Eur. J. Mech. Solids 22(4), 567–582 (2003)

Bardet, J.P., Vardoulakis, I.: The asymmetry of stress in granular media. Int. J. Solids Struct. 38(2), 353–367 (2001)

Cambou, B., Jean, M.: Micromécanique des Matériaux Granulaires. Hermès Science, Paris (2001)

Moulinec, H., Suquet, P.: A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 157, 69–94 (1998)

Michel, J.-C., Moulinec, H., Suquet, P.: Effective properties of composite materials with periodic microstructures: a computational approach. Methods Appl. Mech. Eng. 172, 109–143 (1999)

Eyre, D.-J., Milton, G.-W.: A fast numerical scheme for computing the response of composites using grid renement. J. Phys. III(6), 41–47 (1999)

Sanchez-Palencia, E.: Non-Homogeneous Media and Vibration Theory. Springer, Heidelberg (1980)

Saidi, A., Coorevits, P., Guessasma, M.: Homogenization of a sandwich structure and validity of the corresponding two-dimensional equivalent model. J. Sandw. Struct. Mater. 7, 17–30 (2005)

Mori, A., Tanaka, K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta metall. 21, 571–574 (1973)

M-S. tarzewski, M.-S.: Material spatial randomness: from statistical to representative volume element. Probab. Eng. Mech. 21(2), 112–132 (2006)

Kanit, T., Forest, S., Galliet, I., Mounoury, V., Jeulin, D.: Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int. J. Solids Struct. 40(13–14), 3647–3679 (2003)

Hashin, Z.: On elastic behaviour of fibre reinforced materials of arbitrary transverse phase geometry. J. Mech. Phys. Solids 13(3), 119–134 (1965)

Acknowledgments

The authors thank LMCPA (UVHC), SIRRIS, UMONS and INISMA-CRIBC (members of EMRA) for supplying the experimental data and the thermomechanical characterisation of the material.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

The authors would like to gratefully acknowledge the European Union for the financial support under the INTERREG IV France-Wallonie-Vlaanderen Program PRISTIFLEX (\(\hbox {N}^{\circ }\) FW 1.1.28), and the région de Picardie for funding the CASIMAT Program.

Rights and permissions

About this article

Cite this article

Haddad, H., Leclerc, W., Guessasma, M. et al. Application of DEM to predict the elastic behavior of particulate composite materials. Granular Matter 17, 459–473 (2015). https://doi.org/10.1007/s10035-015-0574-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-015-0574-0