Abstract

In this work, a detailed characterization of LixMn2O4 spinel oxides is shown to demonstrate the correlation between the anomalous thermoelectric properties of this cathode material and its crystal and electronic structure. The analysis of structural and transport in LixMn2O4 cathode materials obtained by solid-state reaction and sol–gel method allows formulating a conclusion that the performance of manganese spinel-based cathode depends on the occurrence of anomalous electron effects. The recorded maxima in absolute values of thermoelectric power correspond to high diffusivity of electrons at the Fermi level. A correlation between the occurrence of thermoelectric peaks and effectiveness of deintercalation/intercalation of lithium has been shown. The obtained results indicate a beneficial effect of phase transition on electrochemical properties of lithium–manganese spinel cathode material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

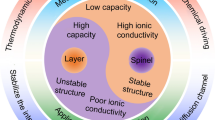

Manganese spinel, less expensive and environmentally friendlier than presently used in Li-ion batteries technology LiCoO2 oxide, seems to be an alternative cathode material. The LixMn2O4 manganese spinel owes its properties to a wide lithium content range that can be changed between 0 and 1 without crucial changes in the spinel structure of this oxide [1,2,3]. Diffusional lithium deintercalation/intercalation mechanism is the basis for its application as an electrode in a rechargeable battery.

At around 290 K, manganese spinel undergoes a phase transition from cubic to orthorhombic phase [4, 5] resulting in the ordering of manganese in the 3d metal sublattice. Many authors believe that this Jahn-Teller driven structural distortion is the reason for the insufficient cyclability of the manganese spinel-based batteries [6, 7]. In spite of a large number of works dealing mostly with electrochemical characteristics of lithium cells with LiMn2O4-based cathode materials [8,9,10,11,12,13,14,15,16,17], only few focuses on anomalous electronic effects near the temperature of the phase transition [18,19,20,21,22].

DFT calculations of both spinel phases by Grechnev et al. [23, 24] reveal a significant difference in the density of states near Fermi level between cubic and orthorhombic phase.

The purpose of this work is an attempt to relate the anomalous effects in thermoelectric power with the structural transition and electrochemical performance of spinel-based cathode materials. In order to accomplish this, detailed structural studies as a function of temperature for lithium–manganese spinels LixMn2O4 were carried out for a different lithium content.

Experimental

Lithium–manganese spinel oxides were synthesized using both solid-state reaction (SSR) [25] as well as sol–gel method (SG) described in details in [26]. The materials were then annealed in air at 800 °C for 24 h (solid-state reaction) and 6 h (sol–gel method) followed by quenching to room temperature. The obtained powders were pressed into pellets which served as cathodes in Li|Li+|LixMn2O4 cells. In the characteristic point on the charge curve, the loading process was stopped to obtain materials with a different degree of lithium content.

X-ray diffraction measurements (XRD) were performed in 2θ range of 10–110° with CuKα radiation using the PANalytical Empyrean diffractometer. For structural characterization of the materials as a function of temperature, Oxford Cryostat and Anton Paar furnace setups were used. The XRD data were refined using the Rietveld method, with GSAS/EXPGUI set of software [27].

For the measurements of electrical conductivity (σ) of the samples, a four-probe AC method was utilized in the range of 218 to 328 K. Measurements of thermoelectric power (α) were performed in the same temperature range using a dynamic method with variable temperature gradient.

Charge–discharge test as well as the determination of chemical lithium diffusion coefficients was carried out in CR-2032 Li|Li+|LixMn2O4 cells, with composite cathodes consisting of active material, carbon black, and PVDF (with a weight ratio of 8:1:1 respectively). LiPF6 salt in EC/DEC was used as an electrolyte. The cells were cycled with a current regime in the range of C/10 to 10 C with voltage cutoffs set as 3.5 and 4.3 V. The measurements of chemical diffusion coefficients of lithium were carried out using galvanostatic intermittent titration technique [28] at room temperature.

Results and discussion

Structural studies of LixMn2O4

The pristine materials obtained from both synthesis routes (solid-state reaction and sol–gel), as well as the materials with a different lithium contend obtained via electrochemical deintercalation were structurally examined in 23–573-K temperature range in order to monitor the phase transition. With the use of Rietveld refinement method, lattice cell parameters, as well as phase composition of the materials, was determined. In Fig. 1a, detailed results of structural studies of LiMn2O4 obtained by a solid-state reaction are shown along with results of Rietveld refinement (Fig. 1c and e).

Enlargement of XRD patterns of LiMn2O4 obtained by the following: a solid-state reaction (SSR), b sol–gel method (SG). Evolution of lattice cell parameters of LiMn2O4cSSR and dSG. Phase transition: cubic → orthorhombic in electrochemically deintercalated LixMn2O4eSSR, fSG. For increasing the clarity of the graph, a mean error value was marked for one point. The red line indicates Li-ion cell working temperature

A spinel cubic phase with the \( Fd\overline{3}m \) space group is shown to exhibit single, sharp diffraction peaks for the temperature above 313 K. Below this temperature, the peak splits into three, what indicates an appearance of the second phase, indexed with Fddd space group. The cubic/orthorhombic ratio drops rapidly, reaching the value of 1:1 around room temperature (Fig. 1e, orange points). The phase transition, however, does not undergo completely, below 250 K the phase ratio is constant, with 30% of cubic phase. A linear change of cubic phase cell parameters was observed in the whole examined range.

Detailed structural studies of LiMn2O4SG together with results of Rietveld analysis are given in Fig. 1b. For this pristine material, phase transition is complete and occurs in 10 degrees lower temperature than for material from solid-state reaction. Below 123 K, only the orthorhombic Fddd phase is present (Fig. 1f).

The same examining procedure was carried out for electrochemically deintercalated manganese spinel materials both from solid-state reaction and from sol–gel method. Figure 1e illustrates the phase transition in the material from solid-state reaction as a function of temperature and lithium content. The temperature of the phase transition increases with the decrease of lithium content, the transition is also smoother, what results in higher amount of cubic phase in a lower temperature for materials with lower lithium concentration. For the materials obtained by partial lithium deintercalation from LiMn2O4SG, the phase transition is smoother than in materials derived from LiMn2O4SSR and is shifted towards lower temperature (Fig. 1f).

The obtained results indicate that the applied synthesis route (SSR or SG) affects the temperature of the phase transition and the composition of the phases of manganese spinel-based cathode material. Distinct from the solid-state reaction approach, the mixing of substrates in sol–gel method is performed at an atomic level, in our case at room temperature, what allows to shorten the time of the annealing process necessary to obtain a lithium–manganese oxide with a desired spinel phase. The differences of annealing times affect the small amounts of lithium that evaporate during the synthesis, what can slightly affect the stoichiometry of obtained materials, resulting in a shift of the temperature the of phase transition.

Microstructure

Figure 2 a and b show the morphology of the LiMn2O4 powder synthesized using the high-temperature method. A polycrystalline material with diverse microstructure was obtained. Agglomerates with diameters above 10 μm have been observed (Fig. 2a), while grain sizes are 0.5–2 μm. Inter-grain boundaries are clearly visible.

Figure 2 c and d show the morphology of the LiMn2O4 powder synthesized using the sol–gel method. A polycrystalline material with diverse microstructure was obtained. In the case of this material, also larger agglomerates with diameters above 10 μm have been observed (Fig. 2c), grain sizes are noticeably smaller, amounting to 0.2–0.7 μm. It is believed that this phenomenon is due to the fact that the annealing process was much shorter in case of the sol–gel synthesis route. This (SG) material was annealed in 800 °C for 6 h, what resulted in obtaining of much smaller grains than in the case of material from solid-state reaction (SSR), where the annealing process lasted 24 h.

Transport properties

Conductivity

The results of conductivity measurements of pristine LiMn2O4SSR and the materials obtained after its electrochemical deintercalation are shown in Fig. 3a. The observed conductivity vs. temperature dependence in the Arrhenius plot exhibits an activated character, what allowed to calculate activation energy.

Pristine material exhibits a specific hysteresis in the temperature characteristic of conductivity, connected with cubic → orthorhombic phase transition. The latter exhibits lower conductivity. For the deintercalated materials, identical results were obtained during cooling and heating cycle (Fig. S1 in supplementary material), the hysteresis disappeared; however, changes in the activation energy were visible. With the decrease of lithium content, an increase in conductivity was observed in the whole examined temperature range, what can be ascribed to a higher content of better conducting cubic phase (Fig. 1e). Analogous measurements were carried out for pristine LiMn2O4SG and the materials obtained after its electrochemical deintercalation are shown in Fig. 3b.

Similar to the material from solid-state reaction, the one from sol–gel method exhibits a distinctive hysteresis in the temperature characteristic of conductivity, connected with phase transition, however, shifted towards lower temperature, what is consistent with structural studies (lower temperature of phase transition for LiMn2O4SG). The conductivity increases with the lithium deintercalation degree; calculated activation energies of electrical conductivity are presented in Table 1.

In case of all the measured samples, very high values of linear correlation were obtained, and the error of Ea does not exceed 0.01 eV. The phase transition affects also the conductivity of the sample; hence, depending on the phase ratio, one sample can have more than one activation energies in the measured temperature range, so there is no general linear dependency of chemical composition and activation energy; however, it can be observed that with the increase of lithium deintercalation degree, a decrease in activation energy and a decrease of lattice cell parameters were observed. Together with results of thermoelectric power, it indicates on polaron as the mechanism of charge transport, regardless of synthesis method.

Thermoelectric power

In Fig. 4, results of thermoelectric power measurements of LixMn2O4SSR are shown as a function of temperature and lithium content.

For the pristine LiMn2O4 material, a sharp − 600 μV K−1 peak in the thermoelectric power was obtained (Fig. 4a) around 283 K, both during cooling and heating of the sample. This behavior (thermoelectric peak) does not find a theoretical explanation and can be attributed to the phase transition. Negative values of the thermoelectric power in the whole examined temperature range indicate that electrons are the predominant charge carriers. For Li0.9Mn2O4SSR, a sharp − 900 μV K−1 peak during heating was observed (Fig. 4b) around room temperature. The highest absolute value of the peak was observed for x = 0.7 (− 2500 μV K−1). For higher degrees of deintercalation x ≤ 0.6, the effects are not as visible, and shifted towards lower temperatures.

The same measurement procedure was carried out for electrochemically deintercalated materials obtained from the spinel from sol–gel method (LiMn2O4SG). The results are shown in Fig. 5.

Similarly to the pristine material from solid-state reaction, in the one from sol–gel method, the anomalous effects (peaks of value − 500 μV K−1) in thermoelectric power were observed; however, they were shifted towards lower temperature 260 K. These results are in a good agreement with structural and conductivity studies. Electrochemically deintercalated Li0.9Mn2O4 exhibited two sharp peaks in the characteristic (Fig. 5b), again shifted towards lower temperatures. Materials with lower lithium content (Fig. 5c–f) did not exhibit such significant peaks.

These distinctive peaks in thermoelectric power appear in the temperature of phase transition, where cubic to orthorhombic phase ratio is 1:1.

Lithium diffusion coefficient

The results of lithium diffusion coefficients for both spinel materials obtained by GITT method are shown in Fig. 6. The obtained results of lithium diffusion coefficient D are consistent with data found in literature derived from different techniques: GITT [29, 30], PITT [31, 32], and EIS [33] (see Tab. S1. in Supplement) with a characteristic minimum around x = 0.7 for LiMn2O4 obtained from sol–gel method from this work.

a Lithium chemical diffusion coefficient as a function of lithium content x in LixMn2O4 cathode materials obtained by solid-state reaction and sol–gel method. To increase the clarity of the plot, the mean error was marked for one point. b Correlation between chemical diffusion coefficient of lithium and values of thermoelectric peak for LixMn2O4

In the examined range of lithium content, LixMn2O4 obtained by a solid-state reaction exhibits higher diffusion coefficient than the material from sol–gel method. It would seem that taking into consideration the size of the grains in both materials, one could expect a different result (shortening the lithium diffusion path for smaller grains from sol–gel method). It is probable that much better kinetics of the process of lithium deintercalation/intercalation can be connected with the occurrence of phase transition. The material obtained in sol–gel method undergoes the phase transition in temperatures 10–20 degrees lower than room temperature; it also exhibits much lower absolute values of anomalous thermoelectric effects. It is believed that the differences in the lithium diffusion coefficient at different lithium content can be attributed to the differences in the anomalous thermoelectric power characteristics at around room temperature introduced by the phase transition and phase ratio Fddd:\( Fd\overline{3}m \) 1:1. The most significant difference in the lithium diffusion coefficient in both materials is observed for the composition x = 0.7, for which the highest value of peak in thermoelectric power was recorded (− 2500 μV K−1). The observed maxima in absolute values of Seebeck coefficient denote high electron diffusivity at the Fermi level—where charge transfer occurs during electrode process. It has been demonstrated that the material from solid-state reaction exhibits anomalous thermoelectric effects closer to the Li-ion cell working temperature than in the case of material from sol–gel method, what most probably is the reason for better kinetics of lithium deintercalation/intercalation.

To explain these phenomena, calculations of electronic structure done by Grechnev et al. [23, 24] turned out to be of great help. The Fermi level of cubic phase of LiMn2O4 is located in a local maximum of density of states (DOS), while for the orthorhombic phase, it is located in local minimum of DOS (Fig. 7). This severe difference in density of states in both coexisting phases is the reason behind the anomalous thermoelectric effects and high diffusivity of electrons affecting lithium deintercalation/intercalation process.

Densities of states for the AFM LiMn2O4 in the spinel (a total DOS; b finer structure of DOS at EF) and the orthorhombic structure (c total DOS; d finer structure of DOS at EF) [24]. Reprinted from Journal of Magnetism and Magnetic Materials, 258, G.E. Grechnev, R. Ahuja, B. Johansson, O. Eriksson, Electronic structure and magnetic properties of lithium manganese spinels, 287–289, Copyright (2018), with permission from Elsevier

Precise crystal structure studies revealed that the temperature in which significant thermoelectric peaks appear corresponds to the temperature in which ratio of coexisting phases is 1:1. Figure 6b illustrates a correlation between lithium chemical diffusion coefficient and values of thermoelectric peaks. It can be seen that the increase in value of the peak leads to higher values of lithium chemical diffusion coefficient.

Electrochemical properties

Figure 8a presents discharge capacities of Li|Li+|LixMn2O4 cells with cathode materials from both compared method of synthesis. The cells were charged and discharged with a current of C/10, C/5, C/2, 1 C, 2 C, 5 C, and 10 C. For each current value, first 10 cycles were recorded.

a Discharge capacity of Li|Li+|LixMn2O4 with reversibility of charge/discharge processes as a function of cycle numbers for various current loads. Hollow points correspond to reversibility (right axis), filled to capacity (left). b Charge curves of Li|Li+|LixMn2O4 (OCV and under load) with cathode materials from solid-state reaction and sol–gel method

The electrochemical tests revealed a similar discharge capacity around 120 mAh g−1 for both materials with C/10 current. However, the material from solid-state reaction exhibits higher capacities while discharged with higher currents (C/5–10 C). In Fig. 8b, a comparison of charge curves (OCV and under load C/10 and 5 C) for Li|Li+|LixMn2O4 with cathode materials from solid-state reaction and sol–gel method. Charge curves for both materials have similar shape; however, they are differed by the polarization. The material from solid-state reaction exhibits much lower overpotential in the cell, especially visible when charged with higher currents. It can explained by better diffusion kinetics of material from SSR (Fig. 6a): higher capacities recorded for the cells assembled with this material as the better-conducting samples exhibit lower overpotentials in working cell. The results of electrochemical tests are in good agreement with lithium diffusion coefficients and confirm the influence of anomalous thermoelectric effects on the performance of a cathode.

Conclusions

It was shown that the synthesis method of LiMn2O4 has a crucial meaning for its properties, what affects the effectiveness of deintercalation/intercalation of lithium. The analysis of transport properties (conductivity, thermoelectric power, and chemical diffusion coefficient of lithium) in LixMn2O4 cathode materials obtained by solid-state reaction and sol–gel method allows to formulate a conclusion that the performance of manganese spinel-based cathode depends on occurrence of anomalous electron effects. These distinctive peaks in thermoelectric power appear in the temperature of phase transition, where cubic to orthorhombic phase ratio is 1:1. The analysis of electronic structure calculation [23, 24] indicated on significant differences in density of states in both coexisting phases as a reason of occurrence of anomalous thermoelectric effects, what is more the recorded maxima in absolute values of thermoelectric power correspond to high diffusivity of electrons at the Fermi level. Furthermore, a correlation between the occurrence of thermoelectric peaks and effectiveness of deintercalation/intercalation of lithium has been shown by comparing the values of these peaks with lithium diffusion coefficient, what would suggest that the origin of the differences of kinetic properties on both materials is of electronic origin and induced by the phase transition. Phase transition near the room temperature (i.e., Li-ion cell’s working temperature) seems to be improving LixMn2O4-based cell performance.

References

Goodenough JB, Manthiram A, Wnetrzewski B (1993) Electrodes for lithium batteries. J Power Sources 43(1-3):269–275

Sugiyama J, Tamura T, Yamauchi H (1995) Elastic/anelastic behaviour during the phase transition in spinel LiMn2O4. J Phys Condens Matter 7(50):9755–9764

Kondracki Ł, Kulka A, Milewska A, Molenda J (2017) In-situ structural studies of manganese spinel-based cathode materials. Electrochim Acta 227:294–302

Hayakawa H, Takada T, Enoki H, Akiba E (1998) New findings on the structural phase transitions of spinel LiMn2O4 at low temperature. J Mater Sci Lett 17(10):811–812

Rodriguez-Carvajal J, Rousse G, Masquelier C, Hervieu M (1998) Electronic crystallization in a lithium battery material: columnar ordering of electrons and holes in the spinel LiMn2O4. Phys Rev Lett 81(21):4660–4663

Huang H, Vincent CA, Bruce PG (1999) Correlating capacity loss of stoichiometric and nonstoichiometric lithium manganese oxide spinel electrodes with their structural integrity. J Electrochem Soc 146(10):3649–3654

Yamada A, Tanaka M, Tanaka K, Sekai K (1999) Jahn–Teller instability in spinel Li–Mn–O. J Power Sources 81:73–78

Wang GX, Bradhurst DH, Liu HK, Dou SX (1999) Improvement of electrochemical properties of the spinel LiMn2O4 using a Cr dopant effect. Solid State Ionics 120(1-4):95–101

Robertson AD, Lu SH, Averill WF, Howard WF (1997) M3+-modified LiMn2O4 spinel intercalation cathodes I. Admetal effects on morphology and electrochemical performance. J Electrochem Soc 144(10):3500–3505

Kumagai N, Ooto H, Kumagai N (1997) Preparation and electrochemical characteristics of quaternary Li-Mn-VO spinel as the positive materials for rechargeable lithium batteries. J Power Sources 68(2):600–603

Striebel KA, Rougier A, Horne CR et al (1999) Electrochemical studies of substituted spinel thin films. J Electrochem Soc 146(12):4339–4347

Taniguchi I, Lim CK, Song D, Wakihara M (2002) Particle morphology and electrochemical performances of spinel LiMn2O4 powders synthesized using ultrasonic spray pyrolysis method. Solid State Ionics 146(3-4):239–247

Shigemura H, Sakaebe H, Kageyama H, Kobayashi H, West AR, Kanno R, Morimoto S, Nasu S, Tabuchi M (2001) Structure and electrochemical properties of LiFexMn2− xO4 (0⩽ x⩽ 0.5) spinel as 5 V electrode material for lithium batteries. J Electrochem Soc 148(7):A730–A736

Hwang K-T, Um W-S, Lee H-S, Song JK, Chung KW (1998) Powder synthesis and electrochemical properties of LiMn2O4 prepared by an emulsion-drying method. J Power Sources 74(2):169–174

Wang L, Li H, Huang X (2012) Electrochemical properties and interfacial reactions of LiNi0.5Mn1.5O4−δ nanorods. Prog Nat Sci Mater Int 22(3):207–212

Larcher D, Gérand B, Tarascon J-M (1998) Synthesis and electrochemical performances of Li 1+ y Mn 2− y O 4 powders of well-defined morphology. J Solid State Electrochem 2(3):137–145

Amatucci GG, Pereira N, Zheng T et al (1999) Enhancement of the electrochemical properties of Li1Mn2O4 through chemical substitution. J Power Sources 81:39–43

Molenda J, Marzec J, Świerczek K et al (2004) The effect of 3d substitutions in the manganese sublattice on the charge transport mechanism and electrochemical properties of manganese spinel. Solid State Ionics 171(3-4):215–227

Molenda J, Pałubiak D, Marzec J (2005) Transport and electrochemical properties of the Li y Cr x Mn 2− x O 4 (0< x< 0.5) cathode material. J Power Sources 144(1):176–182

Molenda J, Świerczek K, Marzec J, Liu RS (2003) Charge transport mechanism in LiCoyMn2-yO4 cathode material. Solid State Ionics 157(1-4):101–108

Molenda J, Ojczyk W, Marzec M et al (2003) Electrochemical and chemical deintercalation of LiMn2O4. Solid State Ionics 157(1-4):73–79

Molenda J, Świerczek K, Molenda M, Marzec J (2000) Electronic structure and reactivity of Li1-xMn2O4 cathode. Solid State Ionics 135(1-4):53–59

Grechnev GE, Ahuja R, Johansson B, Eriksson O (2002) Electronic structure, magnetic, and cohesive properties of LixMn2O4: theory. Phys Rev B 65(17):174408

Grechnev GE, Ahuja R, Johansson B, Eriksson O (2003) Electronic structure and magnetic properties of lithium manganese spinels. J Magn Magn Mater 258:287–289

Molenda J, Marzec J, Świerczek K et al (2004) The effect of 3d substitutions in the manganese sublattice on the electrical and electrochemical properties of manganese spinel. Solid State Ionics 175(1-4):297–304

Milewska A, Kondracki L, Molenda M, Bakierska M, Molenda J (2014) Structural, transport and electrochemical properties of LiNi0.5-yCuyMn1.5O4-delta spinel cathode materials. Solid State Ionics 267:27–31

Larson AC, Von Dreele RB (2000) General structure analysis system (GSAS). Los Alamos Natl Lab Rep LAUR:86–748

Weppner W, Huggins RA (1977) Determination of kinetic and thermodynamic parameters of mixed-conducting electrodes, and application to system Li-Sb. J Electrochem Soc 124(10):1569–1578

Deiss E (2005) Spurious chemical diffusion coefficients of Li+ in electrode materials evaluated with GITT. Electrochim Acta 50(14):2927–2932

Shaju KM, Subba Rao GV, Chowdari BVR (2003) Li ion kinetic studies on spinel cathodes, Li(M1/6Mn11/6)O4 (M = Mn, Co, CoAl) by GITT and EIS. J Mater Chem 13(1):106–113

Kim S, Pyun S (2002) Analysis of cell impedance measured on the LiMn2O4 film electrode by PITT and EIS with Monte Carlo simulation. J Electroanal Chem 528(1-2):114–120

Xie J, Kohno K, Matsumura T, Imanishi N, Hirano A, Takeda Y, Yamamoto O (2008) Li-ion diffusion kinetics in LiMn2O4 thin films prepared by pulsed laser deposition. Electrochim Acta 54(2):376–381

Tang SB, Lai MO, Lu L (2008) Study on Li+-ion diffusion in nano-crystalline LiMn2O4 thin film cathode grown by pulsed laser deposition using CV, EIS and PITT techniques. Mater Chem Phys 111(1):149–153

Acknowledgements

The work was realized by using the infrastructure of the Laboratory of Conversion and Energy Storage Materials in the Centre of Energy AGH.

Funding

The project was funded by the National Science Centre Poland (NCN) on the basis of the decision number UMO-2016/23/B/ST8/00199.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 675 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kondracki, Ł., Molenda, J. Beneficial effect of phase transition on kinetics of deintercalation/intercalation process in lithium–manganese spinel. J Solid State Electrochem 23, 837–846 (2019). https://doi.org/10.1007/s10008-018-04187-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-018-04187-0