Abstract

Objectives

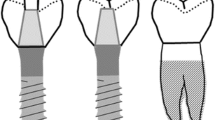

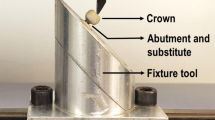

The aim of this study was to investigate the in vitro fatigue and fracture force of temporary implant-supported anterior crowns made of different materials with different abutment total occlusal convergence (TOC), with/without a screw channel, and with different types of fabrication.

Materials and methods

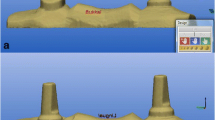

One hundred ninety-two implant-supported crowns were manufactured (4° or 8° TOC; with/without screw channel) form 6 materials (n = 8; 2 × additive, 3 × subtractive, 1 × automix; reference). Crowns were temporarily cemented, screw channels were closed (polytetrafluoroethylene, resin composite), and crowns were stored in water (37 °C; 10 days) before thermal cycling and mechanical loading (TCML). Fracture force was determined. Statistics: Kolmogorov–Smirnov, ANOVA; Bonferroni; Kaplan–Meier; log-rank; α = 0.05.

Results

Failure during TCML varied between 0 failures and total failure. Mean survival was between 1.8 × 105 and 4.8 × 105 cycles. The highest impact on survival presented the material (η2 = 0.072, p < .001). Fracture forces varied between 265.7 and 628.6 N. The highest impact on force was found for the material (η2 = 0.084, p < .001).

Conclusion

Additively and subtractively manufactured crowns provided similar or higher survival rates and fracture forces compared to automix crowns. The choice of material is decisive for the survival and fracture force. The fabrication is not crucial. A smaller TOC led to higher fracture force. Manually inserted screw channels had negative effects on fatigue testing.

Clinical relevance

The highest stability has been shown for crowns with a low TOC, which are manufactured additively and subtractively. In automix-fabricated crowns, manually inserted screw channels have negative effects.

Similar content being viewed by others

References

Albrektsson T, Donos N (2012) Implant survival and complications. The third EAO consensus conference 2012. Clin Oral Implants Res 23(Suppl 6):63–65. https://doi.org/10.1111/j.1600-0501.2012.02557.x

Pjetursson BE, Heimisdottir K (2018) Dental implants - are they better than natural teeth? Eur J Oral Sci 126(Suppl 1):81–87. https://doi.org/10.1111/eos.12543

Burns DR, Beck DA, Nelson SK (2003) A review of selected dental literature on contemporary provisional fixed prosthodontic treatment: report of the committee on research in fixed prosthodontics of the academy of fixed prosthodontics. J Prosthet Dent 90:474–497. https://doi.org/10.1016/s0022-3913(03)00259-2

Perry RD, Magnuson B (2012) Provisional materials: key components of interim fixed restorations. Compend Contin Educ Dent 33(59–60):62

González-Martín O, Lee E, Weisgold A et al. (2020) Contour management of implant restorations for optimal emergence profiles: guidelines for immediate and delayed provisional restorations. Int J Periodontics Restorative Dent 40:61–70. https://doi.org/10.11607/prd.4422

Kerby RE, Knobloch LA, Sharples S et al (2013) Mechanical properties of urethane and bis-acryl interim resin materials. J Prosthet Dent 110:21–28. https://doi.org/10.1016/S0022-3913(13)60334-0

Bauer R, Zacher J, Strasser T et al (2023) Dependence of the survival of 3D-printed temporary materials on the filler content. Int J Comput Dent 0:1–14. https://doi.org/10.3290/j.ijcd.b3759607

John P, Muthukumar B, Kumar MV (2015) Comparison of the effect of dentin bonding, dentin sealing agents on the microleakage of provisional crowns fabricated with direct and indirect technique-an invitro study. J Clin Diagn Res 9:ZC54–7. https://doi.org/10.7860/JCDR/2015/13534.6122

Hahnel S, Krifka S, Behr M et al (2019) Performance of resin materials for temporary fixed denture prostheses. J Oral Sci 61:270–275. https://doi.org/10.2334/josnusd.18-0150

Luthardt RG, Stössel M, Hinz M et al (2000) Clinical performance and periodontal outcome of temporary crowns and fixed partial dentures: a randomized clinical trial. J Prosthet Dent 83:32–39. https://doi.org/10.1016/s0022-3913(00)70086-2

Piplani A, Suresh Sajjan MC, Ramaraju AV et al (2016) An in-vitro study to compare the temperature rise in the pulp chamber by direct method using three different provisional restorative materials. J Indian Prosthodont Soc 16:36–41. https://doi.org/10.4103/0972-4052.161569

Kim S, Watts D (2004) Polymerization shrinkage-strain kinetics of temporary crown and bridge materials. Dent Mater 20:88–95. https://doi.org/10.1016/S0109-5641(03)00101-5

Balkenhol M, Knapp M, Ferger P et al (2008) Correlation between polymerization shrinkage and marginal fit of temporary crowns. Dent Mater 24:1575–1584. https://doi.org/10.1016/j.dental.2008.07.001

Alt V, Hannig M, Wöstmann B et al (2011) Fracture strength of temporary fixed partial dentures: CAD/CAM versus directly fabricated restorations. Dent Mater 27:339–347. https://doi.org/10.1016/j.dental.2010.11.012

Peng C-C, Chung K-H, Yau H-T et al (2020) Assessment of the internal fit and marginal integrity of interim crowns made by different manufacturing methods. J Prosthet Dent 123:514–522. https://doi.org/10.1016/j.prosdent.2019.02.024

Tahayeri A, Morgan M, Fugolin AP et al (2018) 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent Mater 34:192–200. https://doi.org/10.1016/j.dental.2017.10.003

Zimmermann M, Ender A, Egli G et al (2018) Fracture load of CAD/CAM-fabricated and 3D-printed composite crowns as a function of material thickness. Clin Oral Investig 23:2777–2784. https://doi.org/10.1007/s00784-018-2717-2

Lee W-S, Lee D-H, Lee K-B (2017) Evaluation of internal fit of interim crown fabricated with CAD/CAM milling and 3D printing system. J Adv Prosthodont 9:265–270. https://doi.org/10.4047/jap.2017.9.4.265

Kurbad A (2013) CAD/CAM-based polymer provisionals as treatment adjuncts. Int J Comput Dent 16:327–346

Schnutenhaus S, Neveling U, Luthardt RG (2018) Digital implantological workflow for a CAD/CAM immediate long-term temporary restoration for the edentulous maxilla. Int J Comput Dent 21:133–146

Abdullah AO, Pollington S, Liu Y (2018) Comparison between direct chairside and digitally fabricated temporary crowns. Dent Mater J 37:957–963. https://doi.org/10.4012/dmj.2017-315

Kessler A, Reymus M, Hickel R et al (2019) Three-body wear of 3D printed temporary materials. Dent Mater 35:1805–1812. https://doi.org/10.1016/j.dental.2019.10.005

Revilla-León M, Meyers MJ, Zandinejad A et al (2019) A review on chemical composition, mechanical properties, and manufacturing work flow of additively manufactured current polymers for interim dental restorations. J Esthet Restor Dent 31:51–57. https://doi.org/10.1111/jerd.12438

Abdullah AO, Tsitrou EA, Pollington S (2016) Comparative in vitro evaluation of CAD/CAM vs conventional provisional crowns. J Appl Oral Sci 24:258–263. https://doi.org/10.1590/1678-775720150451

Berli C, Thieringer FM, Sharma N et al (2020) Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J Prosthet Dent 124:780–786. https://doi.org/10.1016/j.prosdent.2019.10.024

Rosentritt M, Raab P, Hahnel S et al (2017) In-vitro performance of CAD/CAM-fabricated implant-supported temporary crowns. Clin Oral Investig 21:2581–2587. https://doi.org/10.1007/s00784-017-2057-7

Rosentritt M, Hahnel S, Engelhardt F et al (2017) In vitro performance and fracture resistance of CAD/CAM-fabricated implant supported molar crowns. Clin Oral Investig 21:1213–1219. https://doi.org/10.1007/s00784-016-1898-9

Rosentritt M, Behr M, van der Zel JM et al (2009) Approach for valuating the influence of laboratory simulation. Dent Mater 25:348–352. https://doi.org/10.1016/j.dental.2008.08.009

Rosentritt M, Siavikis G, Behr M et al (2008) Approach for valuating the significance of laboratory simulation. J Dent 36:1048–1053. https://doi.org/10.1016/j.jdent.2008.09.001

Huettig F, Prutscher A, Goldammer C et al (2016) First clinical experiences with CAD/CAM-fabricated PMMA-based fixed dental prostheses as long-term temporaries. Clin Oral Investig 20:161–168. https://doi.org/10.1007/s00784-015-1475-7

Sari T, Usumez A, Strasser T et al (2020) Temporary materials: comparison of in vivo and in vitro performance. Clin Oral Investig 24:4061–4068. https://doi.org/10.1007/s00784-020-03278-5

Zacher J, Bauer R, Strasser T et al (2020) Laboratory performance and fracture resistance of CAD/CAM implant-supported tooth-coloured anterior FDPs. J Dent 96:103326. https://doi.org/10.1016/j.jdent.2020.103326

Alifui-Segbaya F, Bowman J, White AR et al (2019) Characterization of the double bond conversion of acrylic resins for 3D printing of dental prostheses. Compend Contin Educ Dent 40:e7–e11

Loflin WA, English JD, Borders C et al (2019) Effect of print layer height on the assessment of 3D-printed models. Am J Orthod Dentofacial Orthop 156:283–289. https://doi.org/10.1016/j.ajodo.2019.02.013

Alam M, Chugh A, Kumar A et al (2022) Comparative evaluation of fracture resistance of anterior provisional restorations fabricated using conventional and digital techniques - An in vitro study. J Indian Prosthodont Soc 22:361–367. https://doi.org/10.4103/jips.jips_547_21

Yao J, Li J, Wang Y et al (2014) Comparison of the flexural strength and marginal accuracy of traditional and CAD/CAM interim materials before and after thermal cycling. J Prosthet Dent 112:649–657. https://doi.org/10.1016/j.prosdent.2014.01.012

Silva GC, Cornacchia TM, de Magalhães CS et al (2014) Biomechanical evaluation of screw- and cement-retained implant-supported prostheses: a nonlinear finite element analysis. J Prosthet Dent 112:1479–1488. https://doi.org/10.1016/j.prosdent.2014.06.010

Wittneben J-G, Millen C, Brägger U (2014) Clinical performance of screw- versus cement-retained fixed implant-supported reconstructions-a systematic review. Int J Oral Maxillofac Implants 29 Suppl:84–98. https://doi.org/10.11607/jomi.2014suppl.g2.1

Torrado E, Ercoli C, Al Mardini M et al (2004) A comparison of the porcelain fracture resistance of screw-retained and cement-retained implant-supported metal-ceramic crowns. J Prosthet Dent 91:532–537. https://doi.org/10.1016/j.prosdent.2004.03.014

Edmonds HM, Glowacka H (2020) The ontogeny of maximum bite force in humans. J Anat 237:529–542. https://doi.org/10.1111/joa.13218

Trulsson M, Gunne HS (1998) Food-holding and -biting behavior in human subjects lacking periodontal receptors. J Dent Res 77:574–582. https://doi.org/10.1177/00220345980770041001

Acknowledgements

The authors would like to thank individual manufacturers for providing material. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Laila Bein made Conceptualization, Writing, Investigation, Data Evaluation, Visualization, Michael Schmidt and Angelika Rauch editied and Martin Rosentritr made: Conceptualization, Supervision, Writing – Review & Editing.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Conflict of interest

Laila Bein declares that she has no conflict of interest.

Dr. Angelika Rauch declares that he has no conflict of interest.

Dr. Michael Schmidt declares that she has no conflict of interest.

Prof. Dr. Martin Rosentritt declares that he has third-party research projects with different dental companies.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bein, L., Rauch, A., Schmidt, M. et al. In vitro fatigue and fracture testing of temporary materials from different manufacturing processes in implant-supported anterior crowns. Clin Oral Invest 27, 4215–4224 (2023). https://doi.org/10.1007/s00784-023-05038-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-023-05038-7