Abstract

Over the years, risk management gains significant importance in laboratories of every kind. The safety of workers, the accuracy and reliability of laboratory results, issues of financial sustainability as well as the protection of the environment play an important role in decision-making in both industry and services. In order a laboratory to be considered as reliable, safe, and therefore competitive, it is recommended to comply with the requirements of international standards and other regulatory documents as well as to use tools and risk management procedures. In this paper, information is summarized concerning the terms “risk” and “risk management” which are then approached through the latest ISO 9001, ISO/IEC 17025, and ISO 14001 standards. The process of risk management based on the ISO 31000 standard is described, the options for treatment and the techniques that can be applied in the risk management process based on the latest ISO 31010 standard are grouped and indicated. Additionally, information from the literature is referred to the reasons that led the laboratories to integrate in their quality system risk management techniques, the most common mistakes that occur in the various phases of laboratory tests, their causes, their consequences as well as the proposed treatments. The aim of this work is to highlight significant challenges concerning the need to implement management procedures in the daily routine, to warn, raise awareness and inform about existing ways of risk management that can be implemented, methodologically and technically, to laboratories, under internationally recognized and updated standards.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The issue of risk management exists thousands of years [1]. The first appearance of risk management is in the Tigris-Euphrates valley in 3200 BC by the Asipu, who has been considered to be, among others, a risk consultant [2, 3]. Asipu carried out a risk analysis for each alternative action related to the risky event to be studied and after the completion of the analysis he proposed the most favorable alternative. The last step was to issue a final report engraved on a clay tablet that was given to the customer [4].

The difference between modern risk analysts and Asipu of ancient Babylon is that the former express their results as mathematical probabilities and intervals of confidence, while the latter with certainty, confidence, and power. However, to determine the causal relationship between cause and effect, both the ancient ancestors and current researchers rely on observational methods [2]. After World War II, large companies with diversified portfolios of physical assets began to develop self-insurance, which covered the financial consequences of an adverse event or accidental losses [5, 6]. Modern risk management was implemented after 1955 and first applied in the insurance industry [7].

The English term “risk” comes from the Greek word “rhiza,” which refers to the dangers of sailing around a cliff [2]. According to Kumamoto and Henley [8], the term “risk” is defined as a combination of five factors: probability, outcome, significance, causal scenario, and affected population. As far as a laboratory is concerned, “risk” is the probability of a laboratory error which may have adverse consequences [9], as includes factors that threaten health and safety of staff, environment, organization's facilities, organization's financial sustainability, operational productivity, and service quality [10]. Therefore, for testing laboratories, as risk can be considered the inability to meet customer needs, the provision of incorrect analytical results and failure to meet accreditation requirements, damage laboratory's reputation [11].

Plebani [12] defines risk management as the process by which risk is assessed and strategies are developed to manage it. The goal of any risk management process is to identify, evaluate, address, and reduce the risk to an acceptable level [13]. According to Dikmen et al. [14], risk management involves identifying sources of uncertainty (risk identification), assessing the consequences of uncertain events/conditions (risk analysis), thus creating response strategies based on expected results and, finally, based on the feedback received from the actual results and the emerging risk, the steps of identification, analysis and repetitive response events are performed throughout the life cycle of a project to ensure that the project objectives are achieved. Kang et al. [15], define risk management as an act of classification, analysis, and response to unforeseen risks, which are involved during the implementation of a project. Risk management involves maximizing the opportunity and impact of positive events and reducing the likelihood and impact of negative events to achieve the project objectives.

The concept of risk is already known to laboratories as it was indirectly included and in previous versions of ISO 9001 and, mainly via preventive measures to eliminate possible non-compliances and prevent their recurrence (ISO 9001:2008 [16], ISO/IEC 17025:2005 [17]). In the new versions of ISO 9001:2015 [18] and ISO/IEC 17025:2017 [19], however, the presence of risk-based thinking is more pronounced and imperative.

As the revised ISO/IEC 17025 is in line with ISO 9001 in terms of management requirements, a laboratory should examine the impact of threats as well as seize opportunities to increase management system efficiency to achieve improved results and to avoid negative effects [20]. There is no longer a separate clause on preventive measures and the concept of preventive action is expressed through the application of the risk and opportunities approach. The concept of risk is implied in each paragraph of the standard related to the factors that affect the validity of the results. Such factors are staff, facilities, environmental conditions, equipment, metrological traceability, technical records, etc. In addition, the creation of a formal risk management system is not a requirement of the standard, but each laboratory can choose the approach which is satisfactory and can be implemented for its needs [19, 20].

The revised ISO 14001 [20] is also in line with ISO 9001. Risk-based thinking provides a structured approach to managing environmental issues that are likely to affect the organization. Identifying environmental risks and potential opportunities is vital to an organization's success.

Finally, in ISO 31000:2018 [21], risk management is considered as the coordinated activities carried out for the management and control of an organization in relation to risk. Therefore, in order a laboratory to comply with the new versions of the standards, it is important to understand the risk-based thinking and to examine the functions, procedures, and activities related to risks and opportunities. To address the concern, this paper aims at attempting to explore the implementation of a risk-based thinking in laboratories, either testing or calibration, and at highlighting the challenges arisen toward this direction.

The risk management process

The risk management process can be applied at all levels of an organization, from strategy to project implementation. In addition, it must be an integral part of management and decision making and integrated into the structure, functions, and processes of the organization [9]. The integrated risk management process relies on a well-structured risk based-thinking which shall cover the whole quality management system.

In this context, the risk assessment stage consists of three sub-stages: risk identification, risk analysis and risk evaluation. The purpose of risk identification is to find, recognize and describe the risks that positively or negatively affect the achievement of the objectives of the organization, even those whose sources are not under its control [9]. According to Elkington and Smallman [22], risk identification is the most important phase of risk analysis, and emphasis is given in the fact that potential risks should be identified at each stage. Hallikas et al. [23] also state that the identification phase is fundamental to implement risk management, as by recognizing sources of risk, future uncertainties can be identified, and preventive measures can be taken. During risk analysis, the impact of a risk is assessed while during risk evaluation any additional action is determined.

After completing the risk assessment stage, the risk shall be treated including options such as avoiding risk, taking or increasing risk to pursue an opportunity, removing the risk source, changing the likelihood, changing the consequences, sharing the risk (e.g., through contracts, insurance), or maintaining the risk with a documented decision. All the above steps should be monitored and reviewed to ensure and improve the quality and effectiveness of risk management. The results of the process should be recorded and reported throughout the organization to provide information for decision making, for the improvement of risk management activities and for the interaction with stakeholders [9].

Risk assessment techniques

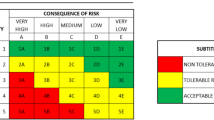

Risk assessment, which is often expressed in relation to sources, possible events, consequences, and likelihood, can be a very difficult process, especially when these relationships are complex. A variety of risk assessment techniques is depicted in Table 1. However, the choice of techniques is not random but some factors must be first taken into account, such as the purpose of the assessment, the needs of stakeholders, any legal, regulatory and contractual requirements, the operating environment and the scenario, how much important is the decision to be made, any defined decision criteria and their form, the time available before a decision is made, the given information and expertise and the complexity of the situation [24].

The most used techniques for identifying risk are the failure modes and effects analysis (FMEA) as well as the failure modes, effects, and criticality analysis (FMECA). FMEA/FMECA can be applied at all levels of an organization and performed at any level of analysis of a system, from block diagrams to detailed elements of a system or steps of a process [25]. This fact leads to several sub-types of FMEA such as system FMEA, design FMEA, process FMEA, and service delivery FMEA. As defined by its name, FMEA is a systematic method designed to identify potential failure modes for a product or process before it occurs and to assess the risk. In FMEA, the system or process under consideration is broken down into individual components. For each element, the ways in which it may fail, the causes and effects of failure are examined. FMECA is a FMEA followed by criticality analysis, which means that for each failure its importance is also assessed. The calculation of the risk in FMEA method includes the multiplication of three risk parameters; the severity (S), the occurrence (O) and the detection (D), in order to produce a risk priority number (RPN, RPN = S × O × D). However, in FMECA, failure modes are classified by their criticality [26]. A quantitative measure of criticality can be derived from actual failure rates and a quantitative measure of consequences, if known. FMEA can be used to provide information for analysis to other techniques such as fault tree analysis (FTA). FTA is a commonly used technique for understanding consequences and likelihood of risk. It is a logic diagram that represents the relationships between an adverse event, which is typically a system failure, and the causes of the event which are the component of failure. It uses logic gates and events to model the above-mentioned relationships. FTA can be used both qualitatively to identify the potential causes and pathways to the peak event and quantitatively to calculate the probability that the peak event will occur [27, 28].

Another technique which is commonly used in organizations is failure reporting, analysis and corrective action system (FRACAS). It is a technique for identifying and correcting the deficiencies in a system or a product and, thus, prevent further occurrence of them [29]. It is based upon the systematic reporting and analysis of failures, making, thus, maintenance of historical data a crucial issue. It is also necessary for the organization to have a database management system. The database is established to store all the required data which are records on all reported failures, failure analyses, and corrective actions [30].

Risk identification and treatment in laboratories

Risk identification is the first and most important phase of risk management [22]. In the identification phase, the possible sources of risk which concern the entire activity of the laboratory are recorded [31].

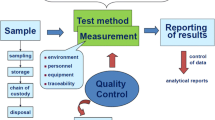

To identify potential sources of risk associated with the testing process, laboratories should create a process map outlining the steps in the testing process from generating the request for test to reporting the testing result. This map should include all stages of the pre-analytical, analytical, and post-analytical process [10]. An example of such a map is given in Fig. 1.

Process map of the main functions of a testing laboratory [10]

According to the research of Plebani and Carraro [32] and Plebani [13], most errors occur during the pre-analytical ranging between 46 % and 68 %, followed by post-analytical errors with a range of 19 % to 47 %, while during the analytical stage the fewest errors occur ranging between 7 % and 13 %. Table 2 outlines the main sources of risk in each of these three stages.

After completing the risk assessment stage, the laboratory is asked to select an appropriate treatment to maintain the risk at an acceptable level [37]. The measures taken should be monitored for their effectiveness to evaluate the success of any failure reduction effort. This evaluation is achieved by monitoring the values of the quality indicators set by the laboratory [35]. Examples of quality indicators are given in Table 3. According to Lippi et al. [38], the most effective strategy to reduce uncertainties in diagnostic laboratories is to develop and implement an integrated quality management system. The success of efforts to reduce errors must be monitored to assess the effectiveness of the measures taken [39].

Possible risks in laboratories are identified below in more detail along with their appropriate treatment.

Sample

Samples are the items sent by customers to the laboratory for testing or calibration in order detailed and reliable results to be provided in a predefined time scale. Therefore, the consequences can be serious if there is loss or any other inconsistency with the samples, their analysis, and related procedures. Normally, samples taken from the laboratory go through a sampling process prior to the analytical procedures. Heterogeneous samples must be homogenized before sampling, otherwise the results obtained are not reliable, especially when the analytes are contained in traces in the sample under study [12].

Sample-related inconsistencies of the pre-analytical phase have already been summarized in Table 2. The strategy to prevent pre-analytical errors consists of five interrelated steps [43,44,45]:

-

1.

Development of clear written procedures.

-

2.

Enhancement of professionals' training.

-

3.

Automation of functions, both for support functions and for executive functions.

-

4.

Monitor of quality indicators.

-

5.

Improvement of communication between professionals and encouraging interservice collaboration.

The written procedures should clearly describe how the sample is analyzed, collected, labeled, transported, and prepared. To ensure that written procedures are followed consistently, those performing the pre-analytical activities must be well-trained to understand, in addition to the appropriate procedures, their important steps and the consequences of not following the instructions faithfully [46].

Modern technologies, such as robotics and information management systems, should also find efficient ways to reduce errors. A laboratory information management system (LIMS) is a computerized system that collects, processes and stores information produced by the laboratory. Although originally created solely to automate experimental data, it is nowadays used in many laboratory activities [47,48,49,50]. LIMS consists of sample management functions such as sample registration, barcode labeling and sample tracking. Using an integrated LIMS, the custody chains and the distribution records of the samples can be systematically kept, operations can be improved by adding features such as model management and sample testing while statistics concerning the number and type of samples, analyses findings, reporting time, number and origin of customers, and many others can be very easily estimated [12], 51]. Thus, by automating certain steps in the pre-analytic workstations, the number of people participating in this phase and the number of manual steps required are reduced. In addition, barcodes simplify the routing and tracking of samples. For example, an electronic order entry system (COES) simplifies the examination order by eliminating the need for the order to be transcribed by a second person [35].

To avoid problems caused by a lack of adequate storage space, the laboratory should regularly assess its capacity to handle samples, including available storage space. Therefore, the laboratory should know or proactively estimate the number of samples it can handle and store at a given time, in a manner that whenever the number of incoming samples exceeds its handling capacity, measures can be timely taken such as temporary reassignment of personnel or arrangement of makeshift storage areas [12].

Personnel

The human factor is present at every stage of the pre-, analytical and post-analytical process. According to Ho and Chen [52], human error is the leading cause of laboratory accidents. Wurtz et al. [53] reported that reduced mental and physical condition, due to exhaustion, is often the cause of laboratory accidents. However, apart from causing accidents, the human factor is also responsible for any mistake that can occur at any stage of the analytical process, from the collection and recording of samples to the processing of results. The occurrence of human error and its subsequent outcome cannot be usually predicted [12].

The techniques used to assess the human factor's contribution to the reliability and security of a system are called the human factor reliability analysis (HRA) [24]. The first industry to develop and implement HRA was the nuclear industry [54] concluding that most accidents were due to human error rather than equipment malfunction. Since then, HRA has been applied to many “high risk” industries, such as the aerospace, railways, shipping, automotive, oil, gas, chemical, military components, and air traffic control industries. HRA has been also applied in the healthcare sector, in the installation of telecommunications equipment, in the design of computer software and hardware, as well as in many manual operations such as lathe operation.

To avoid unpleasant consequences occurred by human factor, personnel throughout the organization should be trained appropriately and effectively to be able to perform procedures in accordance with the requirements of ISO standards or other regulations [35]. Furthermore, to avoid staff burnout, some automation systems should be installed and implement in laboratories such as laboratory automation systems, electric wheeled vehicle systems to transport the samples and automatic result verification procedures [55]. McDonald et al. [56] argue that using a LIMS with highly automated laboratory equipment, researchers can perform repeatable experiments without human intervention. Finally, another measure that can reduce the occurrence of human errors is the continuous supervision of staff and raising awareness [12].

Reagents and waste

The ever-increasing number of laboratories in recent years has led to an increase in industrial waste, such as waste, liquid waste, and sewage. Most liquid waste is hazardous industrial waste, which affects human health and causes environmental pollution. The management of this waste therefore involves many risks. There have been, for example, many accidents and injuries due to mismanagement of chemical waste [34, 52]. Yu and Chou [57] reported that the most common risk in laboratories is chemical reagents because they can cause immediate damage or cumulative pathological changes to the inside and outside of the human body, as they can cause fire, explosion, poisoning, and corrosion. Additionally, Lin et al. [34] following their research on university laboratories-related fires and explosions related to chemical reagents, refers that many causes of accidents were based on improper chemical management including improper storage, use, transportation, and disposal of chemicals.

To mitigate or even avoid the adverse risks of chemicals, their proper management is required. For example, the storage of chemical reagents should be done by category, in a controlled environment and in well-ventilated areas. Flammable materials should be separated from non-flammable materials and stored in areas that provide protection from projectiles, while stock checks should be frequent. Special care should be also taken when transporting them. For example, wooden trays could be used for transport and always with the use of personal protective equipment [58].

Waste should be recycled and disposed properly. For example, chemicals should be neutralized before disposal. It is necessary to install smoke alarms, as well, fire extinguishers, surveillance cameras, showers and eyewash stations, the existence of marked escape corridors and means of collective protection as well as the use of means of personal protection. Detailed procedures, clear instructions as well as appropriate training are also of crucial importance [52, 58].

Environmental conditions

Laboratories are exposed to various types of hazards (biological, chemical, radioactive and others), making them highly hazardous for the environment [59]. Moreover, the work environment of the laboratories may be exposed to more than one hazard at the same time, which further increases the risk. Marque et al. [58] states that chemistry laboratories are unhealthy and dangerous environments, and those involved in research work are exposed to many potential sources of risk as they treat chemical reagents but also encounter equipment that is a source of heat and electricity. In chemical laboratories, there are many potential risks as they contain flammable, explosive, and poisonous chemicals. There are also risks in biological laboratories especially for laboratory staff who treat pathogens, as they are much more likely to be infected with an infectious disease than anyone else [60].

Exposure to chemicals in the workplace can have adverse, acute, or long-term health effects. The dangers from potential exposure to chemicals are many and various, as some substances are toxic, carcinogenic, or irritating and others are flammable or pose a risk of biological contamination [61, 62]. In 2006, Chiozza and Plebani [63] reported that two decades ago, laboratory workers performed their work without following any safety procedures and, thus, put themselves in danger. Ho and Chen [52] referred that poor management of chemical waste in universities and non-profit laboratories has caused many accidents. Poor management of chemical waste can harm laboratory workers and lead to environmental pollution [36].

The U.S. Commission on Chemical Safety and Hazard Investigation has studied 120 laboratory accidents that occurred at various universities across the country from 2001 to 2011 [64]. From 2000 to 2015, there were 34 laboratory accidents, which caused 49 deaths. These accidents were caused by explosion, exposure to biological agents, exposure to toxic substances, suffocation, electric shock, fire, exposure to ionizing radiation and various other causes.

In addition to the risk to human health, environmental pollution and the destruction of laboratory property, there are other risk factors such as the production of unreliable results and customer dissatisfaction which also lead to the laboratory's bad reputation, making the application of risk management process imperative to the sustainability of the laboratory [12].

In order to tackle risk effectively, estimates based on effective risk management must be integrated into the analytical framework [14]. A prerequisite for the operation under appropriate environmental conditions, in a safe and competent laboratory, is the management by executives who can apply the theory of risk to reduce it to an acceptable level. Each laboratory should be able to assess the possible occurrence of errors and describe the steps needed to detect and prevent them to avoid any future adverse event [65].

Test methods

It is common practice, appropriate standard or formal methods, whenever available and after verification, to be preferred over methods developed internally in laboratories. Otherwise, in-house methods shall be fully validated. In this case, the risk is hidden in non-properly or partially, instead of fully, validated methods. In addition, an analytical method may have critical test steps or parameters, such as the quantity of reagents to be added in a particular step, the reaction time or a specific step to proceed without delay. The absence of critical steps leads to erroneous results.

To avoid the risk arisen from the use of internal analytical methods that are not properly validated, the laboratory should ensure that the method developed is fully validated for its intended use. To achieve this, a general method validation procedure shall exist, based on relevant international protocols, compiled from certified analysts involved in the design of method validation having extensive experience in related issues. In addition, according to the latest version of the ISO17025 standard, the specification of the method requirements must be recorded in detail during the method validation phase. Moreover, checks should be carried out to ensure that all requirements are met and, afterward, the declaration of method validity should be signed. Critical steps and parameters of the test methods should be appropriately marked in the respective written procedures to avoid any misunderstanding or omission by the analysts. Additionally, during staff methodological training, the importance of these points should be clearly explained [12].

Measurement

In the measurement process, issues that have been already mentioned above, such as samples treatment, environmental conditions, personnel and test methods affect the measurement results.

Another critical aspect is the need for appropriate and valid (certified, if applicable) reference materials that must be used to determine the metrological traceability of the analytical results in accordance with the requirements of ISO/IEC 17025. There are two types of reference materials involved in chemical testing which are the matrix reference materials for the validation of the methods and the pure reference standards used for the calibration of the equipment. The laboratory should retain procedures for safe handling, transport, storage, and use of reference materials to avoid possible contamination or deterioration. In addition, the laboratory should have studies on the stability of the solutions of the working standards prepared from reference standards. Matrix reference materials must be stored strictly in accordance with the storage conditions recommended by the manufacturers, and relevant records should be kept appropriately. Before use, at least a visual inspection should be performed to confirm that the materials are intact [12].

Although the occurrence and subsequent outcome of human error during test execution is usually unpredictable, it can nevertheless be minimized by strengthening personnel supervision and increasing awareness. Actions toward this direction includes on-site monitoring, verbal review, and control of experimental records, including sampling, sample analysis, data handling and reporting. The results of the monitoring actions should be maintained and whenever a deviation is found, corrective actions should be immediately taken. To avoid the risk that may arise from any inappropriate environmental conditions during measurement, the critical requirements for environmental conditions should be clearly indicated in the written procedures of the method to raise the awareness of the involved analysts. In addition, the continuous monitoring and periodic review of environmental conditions and the maintenance of relevant records are significant prerequisites. These actions not only allow subsequent inspection or evaluation, but also facilitates analysts to stay aware of the appropriate environmental conditions when performing tests [20, 66].

Quality control

The laboratory shall have quality control procedures to monitor the validity of the tests performed and the quality of the results. Procedures are divided into internal and external quality control procedures.

The main objective of internal quality control is to ensure the reliability of the results of the analytical process [67]. Internal quality control should be applied daily in the laboratory and for each laboratory test, to identify random and systematic errors as well as trends. For example, in each laboratory test, working standards of known concentration should be used to check the validity and accuracy of the test results through control charts, testing of internal blind samples, replicate tests using the same or different methods or intermediate checks on measurement equipment. It is also useful for the laboratory to retain appropriate control of its quality management system documents (e.g., procedures, instructions, calibration tables, specifications, alerts, etc.) for the purpose of updating and checking their validity, the control of the files, the control of the actions to treat threats and seizing opportunities, the control of corrective actions, etc.

External quality control, on the other hand, is performed by analyzing blind control samples sent to the laboratory by external, inter-laboratory comparison providers, to check the accuracy of results independently and objectively. The laboratory participating in an external quality control program must state the tests it performs, as well as the methods and instruments it uses, if required [68, 69]. The successful participation of a laboratory in external quality control programs provides objective proof of the adequacy of the laboratory to its customers as well as to the accreditation and regulatory bodies [70]. Non-valid results, however, indicate the existence of inconsistencies in the analysis chain of the samples, e.g., in the used test method, equipment or personnel [71] and shall carefully reviewed and appropriately corrected. Although tests must be performed in the same way as routine samples, the pre-analytical procedure, however, often differs as the samples sent may be in a different form (e.g., in a lyophilized form) or in different containers (e.g., in different types of tubes) and require different pre-analytical treatment. Therefore, the program organizer must provide clear instructions on the maintenance and preparation of external quality control samples [72].

Results reporting

The final step in the testing process is the results reporting. The risk of this stage may be the incorrect sending of results to the customer due to some falsification or even loss of data that may occur during the receipt, transfer, processing, and storage of data. Even if data handling software is used, data can be violated or modified by error or deceit [73].

To avoid the risk of reporting incorrect results to clients, the laboratory shall have two or even three-level data control procedures in place. When software is used to manipulate the data, these programs should be verified before use with appropriate protection to prevent tampering or accidental modification. However, for further improvement, these recording processes could be integrated into a LIMS which minimizes the need to manually transcribe data, and through appropriate electronic controls, data integrity can be ensured. The system could also record any failure as well as the corrective actions taken for reference. In cases where a declaration of conformity of the test to a specification or to a standard is requested, the laboratory is recommended to document the decision rules considering the relevant risk. This enhances the consistency of the results provided and avoids the risk of false acceptance or rejection [12].

To prevent late reporting of results to the client, the combination of a LIMS with a web-based reporting system can be used. This combination is an important tool with which clinical and analytical laboratories can significantly speed up the process of presenting their test results to their customers increasing their satisfaction and trust to the laboratory [49].

Impartiality – confidentiality

Impartiality and confidentiality are two aspects that are included in the general requirements of the latest edition of ISO/IEC 17025, giving special attention to the importance of effective risk management resulting from the lack of these aspects. In particular, the laboratory is obliged to identify the risk associated with its impartiality on an ongoing basis and to demonstrate how to eliminate or minimize this risk. For example, it should identify the risk arising from its activities, relationships with stakeholders (top management representatives, clients, service providers, etc.) or staff relationships. Impartiality is defined in ISO/IEC 17025:2017 standard as the existence of subjectivity in relationships that may affect the laboratory's impartiality and are based on ownership, governance, administration, staff, shared resources, finances, contracts and more.

However, impartiality is not always intentional but most of the time is done unintentionally by hard working, dedicated, honest and competent employees who try to do their job impartially but still fail. It is then considered as cognitive bias, which is widespread and implicit [74, 75]. The impact of such implicit bias is significant, as it affects not only the examiner's judgment, but also it creates phenomena known as “bias cascade” and “bias snowball.” The “bias cascade” effect occurs when irrelevant information spills from one stage to another, thereby creating bias. In the “snowball bias” effect, bias is not only simply carried over from one stage to the next but sequentially grows as unrelated information from a variety of sources integrating and influencing one another [76,77,78,79]. Therefore, it is extremely important to take the necessary steps to prevent and address bias.

The laboratory is also obliged to ensure the protection of confidential information concerning its customers and is responsible for managing all information received or generated during the execution of its activities. As impartiality and confidentiality adversely affect the laboratory's goals and compliance with the requirements of the ISO/IEC 17025 standard, they should be treated like any other risk. Therefore, an effective risk management system is required to deal with these risks [11, 80].

The above is achieved by upper management's commitment to impartiality and adopting appropriate policies, procedures, and best practices to monitor the risk of bias and, where necessary, taking action to prevent or mitigate it. Undoubtedly, appropriate training is a critical parameter to assure impartiality and confidentiality. Staff must be trained in relation to cognitive bias so that they understand the existence and importance of appropriate policies, procedures, and practices [11]. Ensuring confidentiality in laboratories also requires an effective and clearly defined laboratory management system that provides all relevant information, in an accessible format, including documentation of the laboratory's confidentiality policies, procedures and guidelines. A written confidentiality policy is therefore essential, providing clear instructions to all laboratory workers and being signed by them. A confidentiality agreement is a standard practice for many businesses and can remain in place indefinitely, protecting the laboratory even after staff leave, as well as from outside partners. There should be also a plan that outlines exactly how laboratory personnel should react in case that workplace confidentiality policies or procedures are being violated.

Paper documents and records should be kept in a secure location inaccessible to non-laboratory personnel, and when no longer needed, are destroyed before disposal. Special care should be also taken with mobile phones to avoid pictures of classified documents to be taken for unintended use. In addition, the electronic documentation is stored on a secure network and viewed only on secure devices.

Digitilization

Modern laboratories are increasingly dependent on computers and other electronic devices for both their administrative and analytical functions. For example, the results obtained from the laboratory equipment are automatically stored in raw data files. These technological developments create new opportunities but also risks [73]. Potential risks are data loss, the possibility of breaching and modifying raw data files generated by laboratory equipment, and incorrect input of information into LIMS. According to Tully et al. [81], the main risks faced by digital forensic laboratories that use quality standards include:

-

The existence of inaccurate or insufficient information in the technical files and the absence of a mechanism to detect subsequent changes in the files.

-

Problems with computer systems security, energy supply, use of passwords for files opening or computers use and data backup processes.

-

Absence or insufficiency of detailed procedures for the processing of digital data or the documented procedures are not followed consistently by the staff.

-

Lack of strong quality control mechanisms and problems with validation of methods. Computer systems used to store the data generated (raw and processed) can deal with problems leading to information loss. Under some circumstances, the original data files can be recovered from hard drives using appropriate digital methods, but these can be costly and time consuming. However, even if digital data can be preserved, it is malleable and subject to undetectable changes in its content or metadata. The lack of proper data retention procedures makes it more difficult or even impossible to retrieve the original files and verify their integrity. In addition, standard backup procedures do not have the fidelity of digital forensic mechanisms.

One way to preserve digital data is to create backups. However, routine backup procedures do not have the fidelity of digital preservation mechanisms for some critical data, such as those of forensic laboratories. Data files created by laboratory equipment and stored on computers can be modified by mistake or intentionally. Depending on the data type and the modification method, it may be possible to detect changes or amendments. Normal backup procedures, even those updated to preserve digital forensics data, are not foolproof. Data can be falsified, and the computer system can be refreshed to make it appear that the change was made at some point in the past [73].

To manage the risks of inadvertent alteration as well as intentional breach, the solution is to update the traditional practices of tracking data provenance and use digitized ledgers of global custody [82, 83]. These ledgers can be implemented in such a way that they are inviolable and independently verifiable.

The use of automated systems by specialized laboratory staff who interpret the results of the analyzes, can help maintain consistency and increase the effectiveness of the analysis. However, these systems, including those with artificial intelligence (AI) and machine learning (ML), can have errors resulting in erroneous results [84]. In addition, they are sensitive to bias due to poorly selected data sets, as well as lead to misinterpretations when the results are not fully understood [85]. For example, when automated AI/ML systems are used to support forensic research and forensic analysis, such as comparing faces in digital video or photographs, false-positive algorithms can lead to erroneous results [73].

Financial risk

Over the last years and due to the outbreak of the economic and health crises worldwide, the tight financial policy in many laboratories either of the public or the private sector, along with various bureaucratic obstacles, may have negative impact on their overall technological or economic growth. Laboratories should made efforts for cost cutting assuming that accurate knowledge of their test costs exists. It is common sense that many laboratories do not exactly know the cost of services they provide or, additionally, do not take early measures to timely upgrade their equipment and analytical instruments as well as to restore staff losses from resignations or retirements maybe due to reduced financial budget or state subsidies.

Adequate test cost accounting requires a joint effort between financial experts and those with a broad knowledge of laboratory testing. The absence of a solid cost accounting may lead to a risky incremental costing and, thus, up-to-date cost information to price laboratory services along with adequate programming of laboratory's financial and human needs (e.g., compiling a business plan) can proven to be efficient control measures for their financial sustainability and future development. Furthermore, top management representatives play a crucial role in finding or securing financial resources to cover the laboratory's human and infrastructure needs.

Conclusion

The complex activities and the operational framework of a modern laboratory involve many risks with adverse consequences for the testing outcomes, the health of workers and the environment. For this reason, risk management procedures should be integrated into the laboratories' quality system procedures and become integral part of their daily routine. Many methods have been developed to identify and assess risk. Most of them are described in ISO 31010:2019, while the general method instructions are referred in ISO 31000:2018.

The major sources of risk in a laboratory are the personnel themselves, the samples to be analyzed, the chemical reagents and waste, the equipment, the test methods, the measurement, the non-updated quality control procedures, the results reporting, the impartiality and confidentiality, the digitalization and, last but not least, the financial aspects. Implementing an efficient quality management system, the laboratory can reduce the risks to a tolerable level when clear procedures, continuous supervision, inspections, as well as training and continuous education of its staff and upgrades of its equipment with systems automation are maintained. A continuous management of risks is necessary for the emergence of new priorities and the continuous implementation of necessary actions for the purpose of safety and prevention.

Therefore, risk management is fundamental to ensure safe internal and external laboratory environment as well as to assure the delivering of reliable and competent services. Moreover, the implementation of a risk-based thinking can positively affect the outcome of regular assessments in order to explore opportunities for increasing the effectiveness of the management system and preventing negative effects.

References

Dallas MF (2006) Value and risk management: a guide to best practice. Blackwell Publishing Ltd., Oxford

Covello VT, Mumpower J (1985) Risk analysis and risk management: an historical perspective. Risk Anal 5:103–120

Grier B (1981) The early history of the theory and management of risk. Judgment and decision making group meeting, Philadelphia 1–13

Oppenheim L (1977) Ancient mesoporamia. University of Chicago Press, Chicago

Ehrlich J, Becker G (1972) Market insurance, self-insurance and self-protection. J Polit Econ 80:623–648

Dionne G, Eeckhoudt L (1985) Self-insurance, self-protection and increased risk aversion. Econ Lett 17(1–2):39–42

Dionne G (2013) Risk management: history, definition and critique. Risk Manag Insur Rev 16(2):147–166

Kumamoto H, Henley EJ (1996) Probabilistic risk assessment and management for engineers and scientist, 2nd edn. IEEE Press Marketing, New York

Nichols JH (2011) Laboratory quality control based on risk management. Ann Saudi Med 31(3):223–228

Dror IE, Pierce MS (2020) ISO standards addressing issues of bias and impartiality in forensic work. J Forensic Sci 65(3):800–808

Wong SK (2017) Risk-based thinking for chemical testing. Accred Qual Assur 22:103–108

Plebani M (2006) Errors in clinical laboratories or errors in laboratories medicine? Clin Chem Lab Med 44:750–759

Lemos DT, Almeida DLT (2001) Whole life cycle risk management. Assess Manag Environ Risks 4:401–407

Dikmen I, Birgonul MT, Anac C, Tah JHM, Aouad G (2008) Learning from risks: a tool for post-project risk assessment. Autom Constr 18(1):42–50

Kang LS, Kim S-K, Moon HS, Kim HS (2013) Development of a 4D object- based system for visualizing the risk information of construction projects. Autom Constr 31:186–203

ISO 9001:2008. Quality management system–requirements. International Organization for Standardization, Geneva

ISO/IEC 17025:2005. General requirements for the competence of testing and calibration laboratories. Geneva: International Organization for Standardization

ISO 9001:2015. Quality management system–requirements. International Organization for Standardization, Geneva

ISO/IEC 17025:2017. General requirements for the competence of testing and calibration laboratories. International Organization for Standardization, Geneva

ISO 14001:2015. Environmental management systems–requirements with guidance for use. International Organization for Standardization, Geneva

ISO 31000:2018. Risk management-guidelines, 2nd edn. International Organization for Standardization, Geneva, Switzerland

Elkington P, Smallman C (2002) Managing risks: a case study from the utilities sector. Int J Project Manage 20:49–57

Hallikas J, Karvonen I, Pulkkinen U, Virolainen V-M, Tuominen M (2004) Risk management processes in supplier networks. Int J Prod Econ 90:47–58

ISO 31010:2019. Risk management-risk assessment techniques, 2nd edn. International Organization for Standardization, Geneva, Switzerland

Huang J, You J-X, Liu H-C, Song M-S (2020) Failure mode and effect analysis improvement: a systematic literature review and future research agenda. Reliab Eng Syst Saf 199:106885

Pillay A, Wang J (2003) Modified failure mode and effects analysis using approximate reasoning. Reliab Eng Syst Saf 79(1):69–85

Bhattacharyya SK, Cheliyan AS (2019) Optimization of a subsea production system for cost and reliability using its fault tree model. Reliab Eng Syst Saf 185:213–219

Zio E (2009) Reliability engineering: old problems and new challenges. Reliab Eng Syst Saf 94(2):125–141

Chang J, Yoo S-J, Kim S (2021) Development and application of computerized risk registry and management tool based on FMEA and FRACAS for total testing process. Medicina 57:477

Lee JH, Chan S, Jang JS (2010) Research article: process-oriented development of failure reporting, analysis, and corrective action system. Int J Qual Stat Reliab 2010:213690

Vasilanikova A (2018) Risk management in accredited testing laboratories, Proceedings of the 29th DAAAM international symposium 1071–1075, B. Katalinic (Ed.), Published by DAAAM international, ISBN 978-3-902734-20-4, ISSN 1726-9679, Vienna, Austria

Plebani M, Carraro P (1997) Mistakes in a stat laboratory: types and frequency. Clin Chem 43(8):1348–1351

Piton A (2008) Risk-based assessment applied to QA GLP audits: how to fulfill regulatory requirements while making the best use of our common sense, knowledge, talents, and resources? Ann Ist Super Sanita 44(4):379–384

Lin CW, Kuo YC, Kuo SH (2002) Investigation on the fires and explosions in chemicals-related university laboratories. Taiwan's Ministry of Labor. Labor and Occupational Safety and Health Institute report

Rin DG (2009) Pre-analytical workstations: a tool for reducing laboratory errors. Clin Chim Acta 404(1):68–74

Kuo TY (2005) Discussion of waste liquid flowing arrangement and control system in lab of college. Master thesis, Institute of Environment Engineering National Central University

David RE, Dobreanu M (2015) Risk management in clinical laboratory: from theory to practice. Acta Medica Marisiensis 61(4):372–377

Lippi G, Simundic A-M, Mattiuzzi C (2010) Overview on patient safety in healthcare and laboratory diagnostics. J Croat Soc Med Biochem Lab Med 20(2):131–143

Fragkaki AG, Leontiou I-P, Kioukia-Fougia N, Tsivou M, Spyridaki M-H, Georgakopoulos CG (2006) Organization of the doping control laboratory in the Athens 2004 Olympic Games: a case study. Technovation 26:1162–1169

Gimenez-Marin A, Rivas-Ruiz F, Perez-Hidalgo MM, Molina-Mendoza P (2014) Preanalytical errors management in the clinical laboratory: a five-year study. Biochemia Medica 24(2):248–257

Plebani M, Sciacovelli L, Chiazza ML (2014) Harmonization of the pre-analytical quality indicators. Biochemica Medica 24:105–103

Sciacovelli L, Plebani M (2009) The IFCC Working Group on laboratory errors and patient safety. Clin Chim Acta 404(1):79–85

Bates DW, Gawande AA (2003) Improving safety with information technology. N Engl J Med 348(25):2526–2534

Plebani M, Bonini P (2002) Interdepartmental cooperation may help avoid errors in medical laboratories. Br Med J 324:423–424

Lippi G, Guidi GC (2007) Risk management in the preanalytical phase of laboratory testing. Clin Chem Lab Med 45(6):720–727

Da Rin G (2009) Pre-analytical workstations: a tool for reducing laboratory errors. Clin Chim Acta 404:68–74

Gibbon GA (1996) A brief history of LIMS. Lab Autom Inf Manage 32(1):1–5

Goodman N, Rozen S, Stein LD (1998) The LabFlow system for workflow management in large scale biology research laboratories. In: Proceedings. International conference on intelligent systems for molecular biology, 6:69–77

Skobelev DO, Zaytseva TM, Kozlov AD, Perepelitsa VL, Makarova AS (2011) Laboratory information management systems in the work of the analytic laboratory. Meas Tech 53(10):1182–1189

Casey E (2020) Standardization of forming and expressing preliminary evaluative opinions on digital evidence. Forensic Sci Int Digit Invest 32:200888

Sun D, Wu L, Fan G (2021) Laboratory information management system for biosafety laboratory. Saf Effic 3(1):28–34

Ho CC, Chen MS (2018) Risk assessment and quality improvement of liquid waste management in Taiwan University chemical laboratories. Waste Manage 78:578–588

Wurtz N, Papa A, Hukic M, Di Caro A, Leparc-Goffart I, Leroy E, Landini MP, Sekeyova Z, Dumler SJ, Bădescu D (2016) Survey of laboratory-acquired infections around the world in biosafety level 3 and 4 laboratories. Eur J Clin Microbiol Infect Dis 35(8):1247–1258

Kirwan B (1994) A guide to practical human reliability assessment. Taylor & Francis, London

Lou AH, Elnenaei MO, Sadek I, Thompson S, Grocker BD, Nassal BA (2017) Multiple pre- and post-analytical lean approaches to the improvement of the laboratory turnaround time in a large core laboratory. Clin Biochem 50:864–869

McDonald MJ, Rice DP, Desai MM (2016) Sex speeds adaptation by altering the dynamics of molecular evolution. Nature 531(7593):233–236

Yu SW, Chou KS (2001) Introduction to chemical process safety. GauLih Book Co., Ltd

Marques KCO, Yoshida LS, Siqueira Neto AT, Dias A (2017) Risk analysis in chemistry laboratory. In 24th ABCM International Congress of Mechanical Engineering, Proceeding of COBEM, 3–8 Dec 2017. Brazil: Curitiba, PR

Raab SS (2006) Improving patient safety through quality assurance. Arch Pathol Lab Med 130(5):633–637

Skinhøj P, Søeby M (1981) Viral hepatitis in Danish health care personnel, 1974–78. J Clin Pathol 34(4):408–411

Hollensead SC, Lockwood WB, Elin RJ (2004) Errors in pathology and laboratory medicine: consequence and prevention. J Surgery Oncol 88:161–181

Food and Drug Administration (FDA) (2020) Office of regulatory affairs, division of field investigations. (Current Edition). Investigations operations manual

Chiozza ML, Plebani M (2006) Clinical governance: from clinical risk management to continuous quality improvement. Clin Chem Lab Med 44:694–698

CSB (2011) Texas Tech University Laboratory Explosion (No. No. 2010-05-I-TX). Office of congressional, public, and board affairs, Washington, DC

Mortimer ST, Mortimer D (2015) Quality and risk management in the IVF laboratory, 2nd edn. United Kingdom, Cambridge University Press

Lemos J, Gaspar PD, Lima TM (2022) Environmental risk assessment and management in industry 4.0: a review of technologies and trends. Machines 10(8):702

van Rossum HH (2022) Technical quality assurance and quality control for medical laboratories: a review and proposal of a new concept to obtain integrated and validated QA/QC plans. Crit Rev Clin Lab Sci 59(8):586–600

Buratta A (1995) External quality assessment programs in Lombardy Italy. Annali-Istituto Superiore di Sanita 31(1):157–161

Badrick T (2021) Integrating quality control and external quality assurance. Clin Biochem 95:15–27

WHO (2016) WHO manual for organizing a national external quality assessment programme for health laboratories and other testing sites. World Health Organization, Geneva

Libeer JC (2001) External quality assurance programmes in medical laboratories. Accred Qual Assur 6:151–153

Sturgeon C (2013) External quality assessment schemes for immunoassays. In: Wheeler M (ed) Hormone assays in biological fluids. Humana Press, Totowa, NJ, pp 291–305

Casey E, Souvignet TR (2020) Digital transformation risk management in forensic science laboratories. Forensic Sci Int 316:110486

Dror IE (2018) Biases in forensic experts. Science 360(6386):243

Dror IE (2016) A hierarchy of expert performance (HEP). J Appl Res Mem Cogn 5(2):121–127

Dror IE (2012) Cognitive bias in forensic science. The 2012 yearbook of science and technology. McGraw-Hill, New York, NY, pp 43–45

Kassin SM, Dror IE, Kukucka J (2013) The forensic confirmation bias: prob- lems, perspectives, and proposed solutions. J Appl Res Mem Cognit 2(1):42–52

Dror IE, Stoel R (2014) Cognitive forensics: human cognition, contextual information and bias. In: Bruinsma G, Weisburd D (eds) Encyclopedia of criminology and criminal justice. Springer, New York, NY, pp 353–363

Edmond G, Tangen J, Searston R, Dror IE (2015) Contextual bias and cross-contamination in the forensic sciences: the corrosive implications for investigations, plea bargains, trials and appeals. Law Probab Risk 14:1–25

Mianes RL, ten Caten CS (2017) Organization of proficiency schemes by testing and calibration laboratories. Accred Qual Assur 22:119–123

Tully G, Cohen N, Compton D, Davies D, Isbell R, Watson T (2020) Quality standards for digital forensics: learning from experience in England & Wales. Forensic Sci Int Digit Invest 32:200905

Burri X, Casey E, Bollé T, Jaquet-Chiffelle D-O (2020) Chronological independently verifiable electronic chain of custody ledger using blockchain technology. Forensic Sci Int Digit Invest 33:300976

Jaquet-Chiffelle D-O, Casey E, Bourquenoud J (2020) Tamperproof timestamped provenance ledger using blockchain technology. Forensic Sci Int Digit Invest 33:300977

Murray D (2015) Queensland authorities confirm ‘miscode’ affects DNA evidence in criminal cases. https://www.couriermail.com.au/news/queensland/queensland-authorities-confirm-miscode-affects-dna-evidence-in-criminal-cases/news-story/833c580d3f1c59039efd1a2ef55af92b. Accessed 10 Nov 2022

Margagliotti G, Bollé T (2019) Machine learning and forensic science. Forensic Sci Int 298:138–139

Funding

Open access funding provided by HEAL-Link Greece.

Author information

Authors and Affiliations

Contributions

ET wrote the main manuscript text. AGF contributed to the writing process while both AGF and ANP made critical corrections. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tziakou, E., Fragkaki, A.G. & Platis, A.Ν. Identifying risk management challenges in laboratories. Accred Qual Assur 28, 167–179 (2023). https://doi.org/10.1007/s00769-023-01540-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00769-023-01540-3