Abstract

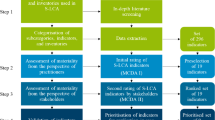

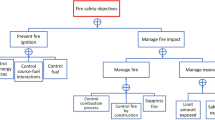

The purpose of this study was to compare the difference of the methodologies between ISO 22000:2005 and ISO 22000:2018. Compared to the methodology of food safety management system ISO 22000:2005, the methodology of ISO 22000:2018 has not been seen yet. The methodology established in this study was based on the differences of ISO 22000:2018 and ISO 22000:2005 and the abundant experiences of author toward the counseling of verification. The high-level structural management of ISO 22000:2018 can be integrated with other management systems. The risk which was assessed through the severity and possibilities could be converted into an opportunity according to the new method of risk evaluation of ISO 22000:2018 based on the CODEX HACCP. Relatedly, through the implementation of the HACCP system, the key regulatory terms relevant for adherence to ISO 22000:2018 have been added and revised. In particular, the new regulations state that the members of food safety management committees must either possess the expertise required to determine hazards or seek the assistance of outside experts when necessary. This regulation must be effectively implemented in the FSMS of small- and medium-sized enterprises throughout the world. In addition, the key terms and definitions of ISO 22000:2018 such as critical control points, prerequisite programs, and operation prerequisite programs are more clearly defined and consistent with the standard operating procedures of effective food safety management systems. ISO 22000:2018 also pays greater attention to the two “plan, do, check, action” (PDCA) cycles including food safety management system and food safety level. These two PDCA cycles emphasize the need for independent operation but should also be implemented such that they have close synergy and harmony with each other. This methodology was used for the verification of ISO 22000:2018 of seven factories.

Similar content being viewed by others

References

Hanak E, Boutrif E, Fabre P, Pineiro M (2000) Food safety management in developing countries. CIRAD-FAO, Montpellier

Dumond EJ (1994) Making best use of performance measures and information. Int J Oper Prod Manag 14(9):16–31

Redshaw B (2000) Evaluating organisational effectiveness. Ind Commer Train 32(7):245–248

Vlachos IP (2009) High-performance workplace practices for Greek companies. Euro Med J Bus 4(1):21–39

Theodoros HV, Ioannis SA (2008) Application of ISO22000 and comparison to HACCP for processing of ready to eat vegetables: Part I. Int J Food Sci Technol 43:1729–1741

Wallace C, Holyoak L, Powell C, Dykes F (2011) Re-thinking the HACCP team: an investigation into HACCP team knowledge and decision-making for successful HACCP development. Food Res Int 47(2):236–245

Azanza P, Zamora-Luna M (2005) Barriers of HACCP team members to guideline adherence. Food Control 16(1):15–22

Henroid DJ, Sneed J (2004) Readiness to implement hazard analysis critical control point (HACCP) systems in Iowa schools. J Am Diet Assoc 104:180–185

Taylor E, Taylor J (2004) Using qualitative psychology to investigate HACCP implementation barriers. Int J Environ Health Res 14(1):53–63

Al-Busaidi MA, Jukes DJ, Bose S (2017) Hazard analysis and critical control point (HACCP) in seafood processing: an analysis of its application and use in regulation in the Sultanate of Oman. Food Control 73(1):900–915

Ștefan ZP, Raluca D, Carmen V (2018) Comparative study of certification schemes for food safety management systems in The European Union context. Amfiteatru Econ 47(1):9–29

Joint FAO/WHO Food Standards Programme (2015) Codex alimentarius commission procedural manual, 24th edn. Food and Agriculture Organization & World Health Organization, Rome

ISO (2018) ISO 22000-food safety management systems requirements for any organization in the food chain. International Organization for Standardization, Geneva

FAO, WHO (2009) Food hygiene, 4th edn. Food and Agriculture Organization and World Health Organization, Rome

Rafeeque MK, Sekharan MN (2018) Multiple food safety management systems in food industry: a case study. Int J Food Sci Nutr 3(1):37–44

Konstantinos VK, Ioannis SA (2017) The role of auditing, food safety, and food quality standards in the food industry: a review. Compr Rev Food Sci Food Saf 16:760–775

Trafialek J, Kolanowski W (2017) Implementation and functioning of HACCP principles in certified and non-certified food businesses: a preliminary study. Br Food J 119:710–728

ISO (2007) ISO 22005:2007-Traceability in the feed and food chain-General principles and basic requirements for system design and implementation. International Organization for Standardization, Geneva

ISO (2005) ISO 9001-quality management systems-requirements. International Organization for Standardization, Geneva

Kafetzopoulos DP, Psomas EL, Kafetzopoulos PD (2013) Measuring the effectiveness of the HACCP food safety management system. Food Control 33(2):505–513

FSPCA (2016) FSPCA preventive controls for human food participant manual, 1st edn. Food Safety Preventive Controls Alliance, Summit

Varzakas TH (2011) Application of ISO22000, failure mode, and effect analysis (FMEA) cause and effect diagrams and pareto in conjunction with HACCP and risk assessment for processing of pastry products. Crit Rev Food Sci Nutr 51(8):762–782

Fallah A, Farhoodi M, Moradi V (2013) An assessment on aflatoxin control in pistachio-processing units from raw material reception to packaging based on ISO 22000:2005 model. J Food Saf 33(4):379–386

Fernández-Segovia I, Pérez-Llácer A, Peidro B, Fuentes A (2014) Implementation of a food safety management system according to ISO 22000 in the food supplement industry: a case study. Food Control 43:28–34

Soman R, Raman M (2016) HACCP system—hazard analysis and assessment, based on ISO 22000:2005 methodology. Food Control 69:191–195

Tzamalis PG, Panagiotakos DB, Drosinos EH (2016) A ‘best practice score’ for the assessment of food quality and safety management systems in fresh-cut produce sector. Food Control 63:179–186

Moran F, Sullivan C, Keener K, Cullen P (2017) Facilitating smart HACCP strategies with process analytical technology. Curr Opin Food Sci 17:94–99

El autocontrol en los establecimientos alimentarios (2005) Agencia Catalana de Seguridad Alimentaria, Barcelona. http://web.gencat.cat/. Accessed 2005

Hazard analysis critical control points (HACCP)-principle 1: conduct a hazard analysis (2016) The Institute of Food and Agricultural Sciences, Florida. https://edis.ifas.ufl.edu/. Accessed February 2016

Food and Drug Administration (2017) Guideline of establishment the food safety supervision program in integrated commodity retailers. Food and Drug Administration, Ministry of Health and Welfare, Taipei

Ristić D (2013) A tool for risk assessment. Saf Eng 3(3):121–127

Climate-Safe Infrastructure Working Group (2018) Paying it forward: the path toward climate-safe infrastructure in California. Climate-Safe Infrastructure Working Group to the California State Legislature and the Strategic Growth Council, Sacramento

Embry-Riddle Aeronautical University (2014) Risk management plan. Embry-Riddle Aeronautical University, Florida

BSI (2017) Guide to protecting and defending food and drink from deliberate attack. British Standards Institution, London

FAO, WHO (2003) Recommended international code of practice - general principles of food hygiene. Food and Agriculture Organization and World Health, Geneva

Wallace C, Williams T (2001) Pre-requisites: a help or a hindrance to HACCP. Food Control 12:235–240

International Monetary Fund (2016) Global financial stability report. International Monetary Fund, Washington, DC

Xiong CW, Liu CH, Chen F, Zheng L (2017) Performance assessment of food safety management system in the pork slaughter plants of China. Food Control 71:264–272

Escanciano C, Santos-Vijande ML (2014) Reasons and constraints to implementing an ISO 22000 food safety management system: evidence from Spain. Food Control 40:50–57

Chen HJ, Chen YJ, Liu SL, Yang HT, Chen CS, Chen YS (2019) Establishment the CCP methodologies of seven major food processes in the catering industry to meet the core concepts of ISO 22000:2018 based on the Taiwanese experience. J Food Saf 39(5):1–10

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, H., Liu, S., Chen, Y. et al. Food safety management systems based on ISO 22000:2018 methodology of hazard analysis compared to ISO 22000:2005. Accred Qual Assur 25, 23–37 (2020). https://doi.org/10.1007/s00769-019-01409-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00769-019-01409-4