Abstract

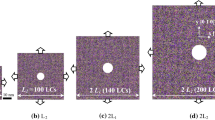

The grain-size-dependent microstructure evolution and overall mechanical behavior of polycrystalline NiTi thin films have not been widely studied under thermomechanical loading. We propose a non-isothermal phase field model with an additional grain boundary energy term introduced into the local energy density to take into account the contribution from the grain boundary in the polycrystalline system. We investigate the grain-size effects in the process of temperature-induced martensitic transformation, detwinning and reorientation of martensitic variants, and superelastic deformation. This multi-variant two-dimensional phase field study showed that, as the average grain size of the thin film drops from 1.5 μm to 10 nm, the temperature-induced martensitic transformation tends to be inhibited. The polytwinned martensitic microstructure tends to be replaced by single-variant martensite microstructure in the grains. The martensitic transformation will not even take place once the grain size is around 10 nm. Meanwhile, the stress-induced martensitic detwinning and reorientation are less active for all types of martensite variants. The shape memory functionality may be weakened with decreasing grain size. Regarding the superelastic behavior, the stress-induced martensitic transformation is delayed with decreasing average grain size. The stress plateau tends to be higher and less noticeable as the grain size drops. The underlying mechanism of this grain-size effect is associated with the inhibiting effect of the grain boundary, the fraction of which will noticeably increase as the average grain size drops, and thus the phase transformation area will significantly reduce in the polycrystalline thin film.

Similar content being viewed by others

References

Choudhary, N., Kaur, D.: Shape memory alloy thin films and heterostructures for MEMS applications: a review. Sens. Actuators A Phys. 242, 162–181 (2016)

Farber, E., Zhu, J.N., Popovich, A., Popovich, V.: A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Process. 30, 761–767 (2020)

Kheirikhah, M.M., Rabiee, S., Edalat, M.E.: A review of shape memory alloy actuators in robotics. RoboCup 2010: Robot Soccer World Cup, vol. XIV, pp. 206–217 (2010)

Lobo, P.S., Almeida, J., Guerreiro, L.: Shape memory alloys behaviour: a review. Procedia Eng. 114, 776–783 (2015)

Chluba, C., Siemsen, K., Bechtold, C.: Microfabricated bioelectrodes on self-expandable NiTi thin film devices for implants and diagnostic instruments. Biosens. Bioelectron. 153, 112034 (2020)

Kohl, M., Just, E., Pfleging, W.: SMA microgripper with integrated antagonism. Sens. Actuator A Phys. 83(1), 208–213 (2000)

Vokoun, D., Kadeřávek, L., Balogová, J., Heller, L.: Effect of FIB milling on NiTi films and NiTi/Si micro-bridge sensor. Smart Mater. Struct. 29(1), 015001 (2019)

Grossmann, C., Frenzel, J., Sampath, V., Depka, T., Eggeler, G.: Elementary transformation and deformation processes and the cyclic stability of NiTi and NiTiCu shape memory spring actuators. Metall. Mater. Trans. A 40(11), 2530 (2009)

Barth, J., Krevet, B., Kohl, M.: A bistable shape memory microswitch with high energy density. Smart Mater. Struct. 19(9), 094004 (2010)

Mahabadi, R.K., Pazhooh, M.D., Shakeri, M.: On the free vibration and design optimization of a shape memory alloy hybrid laminated composite plate. Acta Mech. 232(1), 323–343 (2020)

Alambeigi, K., Mohammadimehr, M., Rabczuk, T.: Free and forced vibration analysis of a sandwich beam considering porous core and SMA hybrid composite face layers on Vlasov’s foundation. Acta Mech. 231(8), 3199–3218 (2020)

Nekouei, M., Raghebi, M., Mohammadi, M.: Free vibration analysis of laminated composite conical shells reinforced with shape memory alloy fibers. Acta Mech. 230(12), 4235–4255 (2019)

Fu, Y., Huang, W., Du, H., Huang, X., Tan, J., Gao, X.: Characterization of TiNi shape-memory alloy thin films for MEMS applications. Surf. Coat. Technol. 145(1), 107–112 (2001)

Shin, D.D., Lee, D.G., Mohanchandra, K.P., Carman, G.P.: Thin film NiTi microthermostat array. Sens. Actuators A Phys. 130, 37–41 (2006)

Jayachandran, S., Akash, K., Mani Prabu, S.S.: Investigations on performance viability of NiTi, NiTiCu, CuAlNi and CuAlNiMn shape memory alloy/Kapton composite thin film for actuator application. Compos. Part B Eng. 176, 107182 (2019)

Otsuka, K., Ren, X.: Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 50(5), 511–678 (2005)

Lai, T.Y., Lin, K.P., Liang, S.W., Fang, T.H.: Mechanical properties and mechanism of NiTi pillars using in-situ compression and indentation. Mater. Res. Express 6(4), 045036 (2019)

Yin, H., He, Y., Moumni, Z., Sun, Q.P.: Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 88, 166–177 (2016)

Tsuchiya, K., Hada, Y., Koyano, T.: Production of TiNi amorphous/nanocrystalline wires with high strength and elastic modulus by severe cold drawing. Scripta Mater. 60(9), 749–752 (2009)

Pan, G., Cao, Z., Wei, M., Shi, J., Meng, X.: Thickness and grain size dependence of B2-R martensitic transformation behaviors in nanoscale TiNi films. Mater. Lett. 130, 285–288 (2014)

Delville, R., Malard, B., Pilch, J., Sittner, P., Schryvers, D.: Microstructure changes during non-conventional heat treatment of thin Ni–Ti wires by pulsed electric current studied by transmission electron microscopy. Acta Mater. 58(13), 4503–4515 (2010)

Pan, G., Cao, Z., Wei, M., Xu, L., Meng, X.: Superelasticity of TiNi thin films induced by cyclic nanoindentation deformation at nanoscale. Mater. Sci. Eng. A 600, 8–11 (2014)

Ahadi, A., Sun, Q.: Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi-effects of grain size. Appl. Phys. Lett. 103(2), 021902 (2013)

Ahadi, A., Sun, Q.: Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi. Acta Mater. 76, 186–197 (2014)

Sun, Q., Aslan, A., Li, M., Chen, M.: Effects of grain size on phase transition behavior of nanocrystalline shape memory alloys. Sci. China Technol. Sci. 57(4), 671–679 (2014)

Ahluwalia, R., Lookman, T., Saxena, A., Albers, R.C.: Landau theory for shape memory polycrystals. Acta Mater. 52(1), 209–218 (2004)

Cho, J.Y., Idesman, A.V., Levitas, V.I., Park, T.: Finite element simulations of dynamics of multivariant martensitic phase transitions based on Ginzburg–Landau theory. Int. J. Solids Struct. 49(14), 1973–1992 (2012)

Malik, A., Yeddu, H.K., Amberg, G.: Three dimensional elasto-plastic phase field simulation of martensitic transformation in polycrystal. Mater. Sci. Eng. A 556, 221–232 (2012)

Sun, Y.Z., Luo, J., Zhu, J.: Phase field study of the microstructure evolution and thermomechanical properties of polycrystalline shape memory alloys: grain size effect and rate effect. Comput. Mater. Sci. 145, 252–262 (2018)

Sun, Y.Z., Luo, J., Zhu, J., Zhou, K.: A non-isothermal phase field study of the shape memory effect and pseudoelasticity of polycrystalline shape memory alloys. Comput. Mater. Sci. 167, 65–76 (2019)

Zhu, J., Luo, J., Sun, Y.: Phase field study of the grain size and temperature dependent mechanical responses of tetragonal zirconia polycrystals: a discussion of tension-compression asymmetry. Comput. Mater. Sci. 172, 109326 (2020)

Mikula, J., Quek, S.S., Joshi, S.P., Wu, D.T., Ahluwalia, R.: The role of bimodal grain size distribution in nanocrystalline shape memory alloys. Smart Mater. Struct. 27(10), 105004 (2018)

Artemev, A., Wang, Y., Khachaturyan, A.G.: Three-dimensional phase field model and simulation of martensitic transformation in multilayer systems under applied stresses. Acta Mater. 48(10), 2503–2518 (2000)

Artemev, A., Jin, Y., Khachaturyan, A.: Three-dimensional phase field model and simulation of cubic→tetragonal martensitic transformation in polycrystals. Philos. Mag. A 82(6), 1249–1270 (2002)

Ke, C., Cao, S., Ma, X., Zhang, X.: The twinning modes of B2–B19′ martensitic transformation in NiTi alloys—a phase field study. Adv. Mater. Res. 399, 1768–1772 (2011)

Levitas, V.I., Lee, D.W., Preston, D.L.: Interface propagation and microstructure evolution in phase field models of stress-induced martensitic phase transformations. Int. J. Plasticity 26(3), 395–422 (2010)

Mamivand, M., Asle, Z.M., El Kadiri, H., Chen, L.Q.: Phase field modeling of the tetragonal-to-monoclinic phase transformation in zirconia. Acta Mater. 61(14), 5223–5235 (2013)

Paranjape, H.M., Manchiraju, S., Anderson, P.M.: A phase field—finite element approach to model the interaction between phase transformations and plasticity in shape memory alloys. Int. J. Plasticity 80, 1–18 (2016)

Xu, B., Kang, G., Yu, C., Kan, Q.H.: Phase field simulation on the grain size dependent super-elasticity and shape memory effect of nanocrystalline NiTi shape memory alloys. Int. J. Eng. Sci. 156, 103373 (2020)

Cissé, C., Zaeem, M.A.: Design of NiTi-based shape memory microcomposites with enhanced elastocaloric performance by a fully thermomechanical coupled phase-field model. Mater. Des. 207, 109898 (2021)

Wang, Y., Khachaturyan, A.G.: Three-dimensional field model and computer modeling of martensitic transformations. Acta Mater. 45(2), 759–773 (1997)

She, H., Liu, Y., Wang, B., Ma, D.: Finite element simulation of phase field model for nanoscale martensitic transformation. Comput. Mech. 52(4), 949–958 (2013)

Zhong, Y., Zhu, T.: Phase-field modeling of martensitic microstructure in NiTi shape memory alloys. Acta Mater. 75, 337–347 (2014)

Ahluwalia, R., Quek, S.S., Wu, D.T.: Simulation of grain size effects in nanocrystalline shape memory alloys. J. Appl. Phys. 117(24), 244305 (2015)

Yeddu, H.K., Malik, A., Ågren, J., Amberg, G., Borgenstam, A.: Three-dimensional phase-field modeling of martensitic microstructure evolution in steels. Acta Mater. 60(4), 1538–1547 (2012)

Yeddu, H.K.: Phase-field modeling of austenite grain size effect on martensitic transformation in stainless steels. Comput. Mater. Sci. 154, 75–83 (2018)

Artemev, A., Jin, Y., Khchaturyan, A.G.: Three-dimensional phase field model of proper martensitic transformation. Acta Mater. 49, 1165–1177 (2001)

Cui, S., Wan, J., Zuo, X., Chen, N., Zhang, J., Rong, Y.: Three-dimensional, non-isothermal phase-field modeling of thermally and stress-induced martensitic transformations in shape memory alloys. Int. J. Solids Struct. 109, 1–11 (2017)

Heo, T.W., Chen, L.Q.: Phase-field modeling of displacive phase transformations in elastically anisotropic and inhomogeneous polycrystals. Acta Mater. 76, 68–81 (2014)

Mamivand, M., Asle Zaeem, M., El Kadiri, H.: Shape memory effect and pseudoelasticity behavior in tetragonal zirconia polycrystals: a phase field study. Int. J. Plasticity 60, 71–86 (2014)

Shu, Y.C., Yen, J.H.: Multivariant model of martensitic microstructure in thin films. Acta Mater. 56(15), 3969–3981 (2008)

Jin, Y.M., Artemev, A., Khachaturyan, A.G.: Three-dimensional phase field model of low-symmetry martensitic transformation in polycrystal: simulation of ζ′2 martensite in AuCd alloys. Acta Mater. 49(12), 2309–2320 (2001)

Hu, S., Henager, C.H., Chen, L.Q.: Simulations of stress-induced twinning and de-twinning: a phase field model. Acta Mater. 58(19), 6554–6564 (2010)

Li, X., Su, Y.: A phase-field study of the martensitic detwinning in NiTi shape memory alloys under tension or compression. Acta Mech. 231(4), 1539–1557 (2020)

Yang, L., Dayal, K.: Formulation of phase-field energies for microstructure in complex crystal structures. Appl. Phys. Lett. 96(8), 081916 (2010)

Yamanaka, A., Takaki, T., Tomita, Y.: Elastoplastic phase-field simulation of martensitic transformation with plastic deformation in polycrystal. Int. J. Mech. Sci. 52(2), 245–250 (2010)

Su, Y., Liu, N., Weng, G.J.: A phase field study of frequency dependence and grain-size effects in nanocrystalline ferroelectric polycrystals. Acta Mater. 87, 293–308 (2015)

Cissé, C., Asle Zaeem, M.: A phase-field model for non-isothermal phase transformation and plasticity in polycrystalline yttria-stabilized tetragonal zirconia. Acta Mater. 191, 111–123 (2020)

Xi, S., Su, Y.: Phase field study of the microstructural dynamic evolution and mechanical response of NiTi shape memory alloy under mechanical loading. Materials 14(1), 183 (2021)

Thamburaja, P., Anand, L.: Polycrystalline shape-memory materials: effect of crystallographic texture. J. Mech. Phys. Solids 49, 709–737 (2001)

Hatcher, N., Kontsevoi, O.Y., Freeman, A.J.: Role of elastic and shear stabilities in the martensitic transformation path of NiTi. Phys. Rev. B 80(14), 144203 (2009)

Martins, R.M.S., Schell, N., Beckers, M., Silva, R.J.C., Mahesh, K.K., Braz Fernandes, F.M.: Role of the substrate on the growth of Ni–Ti sputtered thin films. Mater. Sci. Eng. A 481, 626–629 (2008)

Motazedian, F., Zhang, J., Wu, Z., Jiang, D., Sarkar, S.: Achieving ultra-large elastic strains in Nb thin films on NiTi phase-transforming substrate by the principle of lattice strain matching. Mater. Des. 197, 109257 (2021)

Kumar, A., Singh, D., Kaur, D.: Grain size effect on structural, electrical and mechanical properties of NiTi thin films deposited by magnetron co-sputtering. Surf. Coat. Technol. 203(12), 1596–1603 (2009)

Zhang, Q., Su, Y.: The frequency dependence of electromechanical behaviors of columnar- grained BaTiO3 nanofilms. Phys. Lett. A 384(12), 126374 (2020)

Waitz, T., Kazykhanov, V., Karnthaler, H.P.: Martensitic phase transformations in nanocrystalline NiTi studied by TEM. Acta Mater. 52(1), 137–147 (2004)

Ng, K.L., Sun, Q.P.: Stress-induced phase transformation and detwinning in NiTi polycrystalline shape memory alloy tubes. Mech. Mater. 38(1–2), 41–56 (2006)

Wang, X., Rein, M., Vlassak, J.J.: Crystallization kinetics of amorphous equiatomic NiTi thin films: effect of film thickness. J. Appl. Phys. 103(2), 023501 (2008)

Acknowledgements

The authors are grateful for the support of National Natural Science Foundation of China (Grant Nos. 11672036 and 12172046).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xi, S., Su, Y. A phase field study of the grain-size effect on the thermomechanical behavior of polycrystalline NiTi thin films. Acta Mech 232, 4545–4566 (2021). https://doi.org/10.1007/s00707-021-03074-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03074-6