Abstract

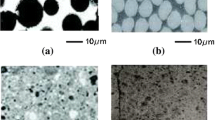

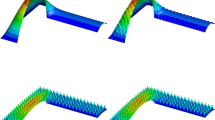

A probabilistic multiscale framework is proposed to characterize the probabilistic behaviors of macroscopic elastic properties of multiphase composite materials. The first-order perturbation-based stochastic homogenization method is extended to incorporate inherent randomness existed in multiphase constituents materials on basis of our previous work for porous material. Moreover, a generalized stochastic method is introduced to combine above with morphological nonparametric uncertainties. A numerical example for coated particulate composite material demonstrated the feasibility and effectiveness of proposed methods.

Similar content being viewed by others

References

Kageyama, H.: Automatic used CFRP technology: present and future. Automob. Technol. 68, 75–81 (2014). (in Japanese)

Gupta, N., Luong, D.D., Cho, K.: Magnesium matrix composite foams-density mechanical properties and applications. Metals 2, 238–252 (2012)

Lions, J.L.: Some methods in the mathematical analysis of systems sand their control. Science Press p1 (1981)

Guedes, J.M., Kikuchi, N.: Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput. Methods Appl. Mech. Eng. 83, 143–198 (1990)

Takano, N., Zako, M., Okuno, Y.: Multi-scale finite element analysis of porous materials and components by asymptotic homogenization theory and enhanced mesh superposition method. Model. Simul. Mater. Sci. Eng. 11, 137–156 (2003)

Takano, N., Fukasawa, K., Nishiyabu, K.: Structural strength prediction for porous titanium based on micro-stress concentration by micro-CT. Int. J. Mech. Sci. 52, 229–235 (2010)

Mcwilliams, B.A., Ramesh, K.T., Yen, C.F.: Probabilistic response of heterogeneous particle reinforced metal matrix composites with particle sized dependent strengthening. Comput. Mater. Sci. 79, 15–24 (2013)

Chen, Q., Zhu, H.H., Ju, J.W., Guo, F., Wang, L.B., Yan, Z.G., Deng, T., Zhou, S.: A stochastic micromechanical model for multiphase composites containing spherical inhomogeneities. Acta Mech. 226, 1861–1880 (2015)

Doitrand, A., Fagiano, C., Irisarri, F.X., Hisekorn, M.: Comparison between voxel and consistent meso-scale models of woven composites. Compos. Part A 73, 143–154 (2015)

Miyauchi, Y., Takano, N., Wen, P.: Stochastic homogenization analysis of FIB-SEM image-based hierarchical model of sprayed porous ZrO2. Mech. Eng. Lett. 1, 1–8 (2015)

Childers, E.P., Wang, M.O., Becker, M.L., Fisher, J.P., Dean, D.: 3D printing of resorbable poly tissue engineering scaffolds. MRS Bull. 40, 119–125 (2015)

Zheng, J., Xie, S., Lin, F., Hua, G., Yu, T., Reneker, D.H., Becker, M.L.: 4-Dibenzocyclooctynol as an initiator for poly: copper-free clickable polymer and nanofiber-based scaffolds. Polym. Chem 4, 2215–2218 (2013)

Koishi, M., Shiratori, M., Miyoshi, T., Miyano, A.: Stochastic homogenization method for composite materials with uncertain microstructures. Trans. JSME Part A 62, 2264–2269 (1996)

Kamiski, M., Lauke, B.: Probabilistic and stochastic analysis of the effective properties for the particle reinforced elastomers. Comput. Mater. Sci. 56, 147–160 (2012)

Ghanem, R.G., Venketeswaran, A., Suresh, R., Gupta, S.: A Spectral Approach, vol. 11501. pp. 12–18 (2003)

Sasikumar, P., Venketeswaran, A., Suresh, R., Gupta, S.: A data driven polynomial chaos based approach for stochastic analysis of CFRP laminated composite plates. Compos. Struct. 125, 212–227 (2015)

Starzewski, M.O.: Material spatial randomness: from statistical to representative volume element. Probab. Eng. Mech. 21, 112–132 (2006)

Eshelby, J.D.: Elastic inclusions and inhomogeneities. Prog. Solid Mech. 2, 89–140 (1961)

Sakata, S., Ashida, F., Ohsumimoto, K.: Stochastic homogenization analysis of a porous material with the perturbation method considering a microscopic geometrical random variation. Int. J. Mech. Sci. 77, 145–154 (2013)

Basaruddin, K.S., Takano, N., Akiyama, H.: Uncertainty modeling in the prediction of effective mechanical properties using stochastic homogenization method. Mater. Trans. 54, 1250–1256 (2013)

Tawara, D., Nagahata, M., Takano, N., Kinoshita, H., Abe, S.: Probabilistic analysis of mechanical behavior of mandibular trabecular bone using a calibrated stochastic homogenization model. Acta Mech. 226, 3275–3287 (2015)

Wen, P., Yokota, K., Takano, N.: Probabilistic prediction of homogenized property and update of prediction for spherical porous material considering microstructural uncertainties. J. Multiscale Model. (accepted)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, P., Takano, N. & Kurita, D. Probabilistic multiscale analysis of three-phase composite material considering uncertainties in both physical and geometrical parameters at microscale. Acta Mech 227, 2735–2747 (2016). https://doi.org/10.1007/s00707-016-1640-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-016-1640-3