Abstract

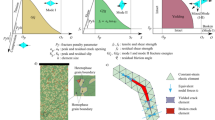

Granite is a heterogeneous material characterized by a significant population of mechanically distinct grain boundaries, which exert a substantial influence on crack propagation. An extended grain-based model was developed by integrating the geometric heterogeneity, represented by Voronoi tessellations, and the mechanical heterogeneity of grain boundary, as described by Weibull distribution. This study numerically investigates the influence of mechanical heterogeneity in grain boundary on the mechanical properties and microcracking behavior of semi-circular bend granite samples under mode I loading. The mechanical heterogeneity of grain boundary was assessed by independently varying the heterogeneity index, defined by the shape parameter m in the Weibull distribution. The findings indicate that the force–displacement curve and fracture toughness are primarily influenced by the parallel bond tensile strength and cohesion of grain boundary contacts. When the value of m in Weibull distribution is between 1.5 and 2, a compromise between failure patterns and diverse grain boundaries characterization can be reached. Considering the heterogeneous mechanical properties of grain boundary numerically is able to simulate the local stress concentration of the real rocks, thus accelerating the generation of microcracks and reflecting the brittleness of rock failure. Otherwise, the fracture toughness of the rock will may be overestimated. Generally speaking, models that consider grain boundary heterogeneity will produce larger fracture process zone and microscopically complex crack propagation patterns during loading, and these phenomena are more consistent with experimental observations than those models in which grain boundaries are homogeneous.

Highlights

-

1.

The mechanical heterogeneity of grain boundary in granite is quantitatively characterized by the Weibull distribution;

-

2.

The heterogeneous grain boundary could favor the local stress concentration, thus accelerating the generation of microcracks;

-

3.

Considering both geometric heterogeneity of granite and mechanical heterogeneity of grain boundary result in the generation of larger fracture process zone and microscopically complex crack propagation patterns under mode I loading.

Similar content being viewed by others

Data Availability Statement

All data generated or analyzed during this work are included in this published paper and are available from the corresponding author on reasonable request.

Abbreviations

- CCNBD:

-

Cracked chevron notched Brazilian disc

- SCB:

-

Semi-circular bend

- PFC:

-

Particle flow code

- GB:

-

Grain boundary

- IG:

-

Intra-grain

- DEM:

-

Discrete element method

- FDEM:

-

Finite discrete element method

- BPM:

-

Bonded particle model

- BBM:

-

Bonded block model

- GBM:

-

Grain-based model

- IGT, IGS:

-

Intra-grain tension and intra-grain shear

- GBT, GBS:

-

Grain boundary tension and grain boundary shear

- ROI:

-

Region of interest

- AE:

-

Acoustic emission

- JRC:

-

Joint roughness coefficient

- Z 2 :

-

The root mean square of the first derivative of a profile

- x i, z i :

-

The coordinates of the fracture surface profile

- M :

-

The number of sampling points

- d max :

-

The maximum deviation value

- Qtz:

-

Quartz

- Bi:

-

Biotite

- Kfs:

-

K-feldspar

- Pl:

-

Plagioclase

- KIC :

-

Fracture toughness

- ES :

-

Generalized stiffness

- θ :

-

The orientation of microcrack

- g s :

-

Surface gap

- k n, k s :

-

Normal stiffness and shear stiffness

- μ :

-

Friction coefficient

- \(\overline{\sigma}_{c}\) :

-

Parallel bond tensile strength

- \(\overline{c}\) :

-

Parallel bond cohesion

- \(\overline{\phi}\) :

-

Parallel bond friction angle

- \(\overline{k}_{n}\), \(\overline{k}_{s}\) :

-

Parallel bond normal stiffness and shear stiffness

- f :

-

The probability density function

- F :

-

The cumulative distribution function

- α :

-

The microparameter that follows Weibull distribution

- α 0 :

-

The reference value of the microparameter

- m :

-

Shape parameter of Weibull distribution

- σ yy :

-

Vertical stress

- N :

-

Number of microcracks

References

Alneasan M, Behnia M (2021) An experimental investigation on tensile fracturing of brittle rocks by considering the effect of grain size and mineralogical composition. Int J Rock Mech Min Sci 137:104570. https://doi.org/10.1016/j.ijrmms.2020.104570

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Brace WF (1961) Dependence of fracture strength of rocks on grain size. In: Proceedings of the 4th Symposium on Rock Mechanics, pp 99–103. University Park, Pennsylvania

Chen ZH, Tham LG, Yeung MR, Xie H (2006) Confinement effects for damage and failure of brittle rocks. Int J Rock Mech Min Sci 43:1262–1269. https://doi.org/10.1016/j.ijrmms.2006.03.015

Cho NA, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010. https://doi.org/10.1016/j.ijrmms.2007.02.002

Deng P, Liu Q, Lu H (2023) FDEM numerical study on the mechanical characteristics and failure behavior of heterogeneous rock based on the Weibull distribution of mechanical parameters. Comput Geotech 154:105138. https://doi.org/10.1016/j.compgeo.2022.105138

Feng G, Kang Y, Meng T, Hu YQ, Li XH (2017) The influence of temperature on mode I fracture toughness and fracture characteristics of sandstone. Rock Mech Rock Eng 50:2007–2019. https://doi.org/10.1007/s00603-017-1226-y

Funatsu T, Shimizu N, Kuruppu M, Matsui K (2015) Evaluation of mode I fracture toughness assisted by the numerical determination of K-resistance. Rock Mech Rock Eng 48:143–157. https://doi.org/10.1007/s00603-014-0550-8

Gao F, Stead D, Elmo D (2016) Numerical simulation of microstructure of brittle rock using a grain-breakable distinct element grain-based model. Comput Geotech 78:203–217. https://doi.org/10.1016/j.compgeo.2016.05.019

Guo TY, Wong LNY (2020) Microcracking behavior of three granites under mode I loading: Insights from acoustic emission. Eng Geol 278:105823. https://doi.org/10.1016/j.enggeo.2020.105823

Guo TY, Wong LNY (2021) Cracking mechanisms of a medium-grained granite under mixed-mode I-II loading illuminated by acoustic emission. Int J Rock Mech Min Sci 145:104852. https://doi.org/10.1016/j.ijrmms.2021.104852

Guo TY, Zhao Q (2022) Acoustic emission characteristics during the microcracking processes of granite, marble and sandstone under mode I loading. Rock Mech Rock Eng 55(9):5467–5489. https://doi.org/10.1007/s00603-022-02937-1

Hajiabdolmajid V, Kaiser P (2003) Brittleness of rock and stability assessment in hard rock tunneling. Tunn Undergr Sp Tech 18(1):35–48. https://doi.org/10.1016/S0886-7798(02)00100-1

Heinze T, Frank S, Wohnlich S (2021) FSAT–A fracture surface analysis toolbox in MATLAB to compare 2D and 3D surface measures. Comput Geotech 132:103997. https://doi.org/10.1016/j.compgeo.2020.103997

Hofmann H, Babadagli T, Zimmermann G (2015) A grain-based modeling study of fracture branching during compression tests in granites. Int J Rock Mech Min Sci 77:152–162. https://doi.org/10.1016/j.ijrmms.2015.04.008

Hu X, Xie N, Zhu Q, Chen L, Li P (2020) Modeling damage evolution in heterogeneous granite using digital image-based grain-based model. Rock Mech Rock Eng 53(11):4925–4945. https://doi.org/10.1007/s00603-020-02191-3

Hu WR, Liu K, Potyondy DO, Salmi EF, Sellers EJ, Zhang QB (2023a) Grain-based modelling of dynamic shear rupture of heterogeneous rock using a coupled continuum-discrete model. Int J Impact Eng 172:104420. https://doi.org/10.1016/j.ijimpeng.2022.104420

Hu X, Hu H, Xie N, Huang Y, Guo P, Gong X (2023b) The effect of grain size heterogeneity on mechanical and microcracking behavior of pre-heated Lac du Bonnet granite using a grain-based model. Rock Mech Rock Eng 56:5923–5954. https://doi.org/10.1007/s00603-023-03381-5

Hu Y, Hu Y, Jin P, Zhao G, Zhao Z, Li C (2023c) Real-time mode-I fracture toughness and fracture characteristics of granite from 20 °C to 600 °C. Eng Fract Mech 277:109001. https://doi.org/10.1016/j.engfracmech.2022.109001

Hu X, Guo P, Xie N, Hu H, Lei G, Ma J, Gong X (2023d) Creep behavior and associated acoustic characteristics of heterogeneous granite containing a single pre-existing flaw using a grain-based parallel-bonded stress corrosion model. Rock Mech Rock Eng 56:4799–4832. https://doi.org/10.1007/s00603-023-03291-6

Huang L, Liu J, Zhang F, Dontsov E, Damjanac B (2019) Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Int J Solids Struct 176:207–220. https://doi.org/10.1016/j.ijsolstr.2019.06.018

Huang X, Qi S, Guo S, Zheng B, Zhao Q, Sha P, Wang TZ, Yao XL, Liang N, Chang JY, Rong X (2022) Effect of the crystal habit on micromechanical extensile behaviors of the crystalline rock during compression. Eng Geol 310:106874. https://doi.org/10.1016/j.enggeo.2022.106874

Inga CEC, Sinha S, Walton G, Holley E (2023) Modeling Brazilian tensile strength tests on a brittle rock using deterministic, semi-deterministic, and Voronoi bonded block models. Rock Mech Rock Eng 1–21. https://doi.org/10.1007/s00603-023-03329-9

International Society for Rock Mechanics (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. International Soc. for Rock Mechanics, Commission on Testing Methods.

Itasca Consulting Group Inc (2014) Particle flow code (PFC), Version 5.0. Minneapolis

Jing L (2003) A review of techniques, advances and outstanding issues in numerical modelling for rock mechanics and rock engineering. Int J Rock Mech Min Sci 40:283–353. https://doi.org/10.1016/S1365-1609(03)00013-3

Justo J, Konietzky H, Castro J (2022) Voronoi-based discrete element analyses to assess the influence of the grain size and its uniformity on the apparent fracture toughness of notched rock specimens. Rock Mech Rock Eng 55(5):2861–2877. https://doi.org/10.1007/s00603-022-02852-5

Kataoka M, Obara Y, Kuruppu M (2015) Estimation of fracture toughness of anisotropic rocks by semi-circular bend (SCB) tests under water vapor pressure. Rock Mech Rock Eng 48:1353–1367. https://doi.org/10.1007/s00603-014-0665-y

Kim JS, Lee KS, Cho WJ, Choi HJ, Cho GC (2015) A comparative evaluation of stress–strain and acoustic emission methods for quantitative damage assessments of brittle rock. Rock Mech Rock Eng 48:495–508. https://doi.org/10.1007/s00603-014-0590-0

Lan H, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res 115(B01202):1–14. https://doi.org/10.1029/2009JB006496

Li XF, Li X, Li HB, Zhang QB, Zhao J (2018) Dynamic tensile behaviours of heterogeneous rocks: the grain scale fracturing characteristics on strength and fragmentation. Int J Impact Eng 118:98–118. https://doi.org/10.1016/j.ijimpeng.2018.04.006

Li XF, Li HB, Zhao J (2019a) The role of transgranular capability in grain-based modelling of crystalline rocks. Comput Geotech 110:161–183. https://doi.org/10.1016/j.compgeo.2019.02.018

Li H, Yang C, Ding X, William NT, Yin H, Zhang S (2019b) Weibull linear parallel bond model (WLPBM) for simulating micro-mechanical characteristics of heterogeneous rocks. Eng Anal Bound Elem 108:82–94. https://doi.org/10.1016/j.enganabound.2019.07.018

Li XF, Li HB, Liu LW, Liu YQ, Ju MH, Zhao J (2020a) Investigating the crack initiation and propagation mechanism in brittle rocks using grain-based finite-discrete element method. Int J Rock Mech Min Sci 127:104219. https://doi.org/10.1016/j.ijrmms.2020.104219

Li H, Ma H, Shi X, Zhou J, Zhang H, Daemen JJK (2020b) A 3D grain-based model for simulating the micromechanical behavior of salt rock. Rock Mech Rock Eng 53(6):2819–2837. https://doi.org/10.1007/s00603-020-02085-4

Li XF, Li HB, Zhang GK, Ju MH, Zhao J (2021) Rate dependency mechanism of crystalline rocks induced by impacts: Insights from grain-scale fracturing and micro heterogeneity. Int J Impact Eng 155:103855. https://doi.org/10.1016/j.ijimpeng.2021.103855

Li YM, Zhao GF, Jiao Y, Yan C, Wang X, Shen L, Yang L, Liang Z, Li W, Zhou X, Li X, Liu F, Zhang K, Li X, Pan C, Le T (2023) A benchmark study of different numerical methods for predicting rock failure. Int J Rock Mech Min Sci 166:105381. https://doi.org/10.1016/j.ijrmms.2023.105381

Lisjak A, Grasselli G (2014) A review of discrete modeling techniques for fracturing processes in discontinuous rock masses. J Rock Mech Geotech Eng 6:301–314. https://doi.org/10.1016/j.jrmge.2013.12.007

Liu G, Cai M, Huang M (2018) Mechanical properties of brittle rock governed by micro-geometric heterogeneity. Comput Geotech 104:358–372. https://doi.org/10.1016/j.compgeo.2017.11.013

Liu Z, Xu H, Zhao Z, Chen Z (2019) DEM modeling of interaction between the propagating fracture and multiple pre-existing cemented discontinuities in shale. Rock Mech Rock Eng 52:1993–2001. https://doi.org/10.1007/s00603-018-1699-3

Liu XY, Xu DP, Li SJ, Qiu SL, Jiang Q (2023). An insight into the mechanical and fracture characterization of minerals and mineral interfaces in granite using nanoindentation and micro X-ray computed tomography. Rock Mech Rock Eng 1–17. https://doi.org/10.1007/s00603-023-03221-6

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. University of Manitoba, Winnipeg

Meng Y, Jing H, Zhou Z, Zhang L, Sun S (2022) Experimental investigation on the mixed-mode fracture behavior of rock-like material with bedding plane. Theor Appl Fract Mec 117:103159. https://doi.org/10.1016/j.tafmec.2021.103159

Mo C, Zhao J, Zhang D (2023) Mode I microscopic cracking process of granite considering the criticality of failure. J Geophys Res Solid Earth 128(10), e2023JB027040. https://doi.org/10.1029/2023JB027040

Miao S, Pan PZ, Yu P, Zhao S, Shao C (2020) Fracture analysis of Beishan granite after high-temperature treatment using digital image correlation. Eng Fract Mech 225:106847. https://doi.org/10.1016/j.engfracmech.2019.106847

Munjiza A (2004) The combined finite-discrete element method. John Wiley & Sons, Chichester

Peng J, Wong LNY, Teh CI (2017) Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J Geophys Res Solid Earth 122(2):1054–1073. https://doi.org/10.1002/2016JB013469

Peng J, Wong LNY, Teh CI, Li Z (2018) Modeling micro-cracking behavior of Bukit Timah granite using grain-based model. Rock Mech Rock Eng 51:135–154. https://doi.org/10.1007/s00603-017-1316-x

Peng Y, Zhang T, Yu L, Li J, Gao Y, Tian W (2023) Numerical investigation on the effect of intergranular contact bonding strength on the mechanical properties of granite using PFC3D-GBM. Int J Numer Anal Met Geomech 1–23. https://doi.org/10.1002/nag.3488

Potyondy DO (2010) A grain-based model for rock: approaching the true microstructure. In: Paper presented at the proceedings of the rock mechanics in the Nordic Countries, Kongsberg, Norway, June 9–12

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364. https://doi.org/10.1016/j.ijrmms.2004.09.011

Qi S, Lan H, Martin D, Huang X (2020) Factors controlling the difference in Brazilian and direct tensile strengths of the Lac du Bonnet granite. Rock Mech Rock Eng 53:1005–1019. https://doi.org/10.1007/s00603-019-01946-x

Quey R, Dawson PR, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Method Appl M 200(17–20):1729–1745. https://doi.org/10.1016/j.cma.2011.01.002

Roy DG, Singh TN, Kodikara J (2018) Predicting mode-I fracture toughness of rocks using soft computing and multiple regression. Measurement 126:231–241. https://doi.org/10.1016/j.measurement.2018.05.069

Sabri M, Ghazvinian A, Nejati HR (2016) Effect of particle size heterogeneity on fracture toughness and failure mechanism of rocks. Int J Rock Mech Min Sci 81:79–85. https://doi.org/10.1016/j.ijrmms.2015.11.002

Sinha S, Walton G (2020) A study on Bonded Block Model (BBM) complexity for simulation of laboratory-scale stress-strain behavior in granitic rocks. Comput Geotech 118:103363. https://doi.org/10.1016/j.compgeo.2019.103363

Song Z, Yang Z, Zhang M, Wang F, Herbst M, Konietzky H (2023) Effect of heterogeneity on mechanical and micro-seismic behaviors of sandstone subjected to multi-level cyclic loading: a discrete element method investigation. J Rock Mech Geotech Eng 1–30. https://doi.org/10.1016/j.jrmge.2022.11.020

Tan X, Konietzky H, Chen W (2016) Numerical simulation of heterogeneous rock using discrete element model based on digital image processing. Rock Mech Rock Eng 49:4957–4964. https://doi.org/10.1007/s00603-016-1030-0

Tang X, Zhang Y, Xu J, Rutqvist J, Hu M, Wang Z, Liu Q (2022) Determining Young’s modulus of granite using accurate grain-based modeling with microscale rock mechanical experiments. Int J Rock Mech Min Sci 157:105167. https://doi.org/10.1016/j.ijrmms.2022.105167

Tse R, Cruden D (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16:303–307. https://doi.org/10.1016/0148-9062(79)90241-9

Wang X, Cai M (2019) A comprehensive parametric study of grain-based models for rock failure process simulation. Int J Rock Mech Min Sci 115:60–76. https://doi.org/10.1016/j.ijrmms.2019.01.008

Wang S, Zhou J, Zhang L, Han Z, Zhang F (2021) Parameter studies on the mineral boundary strength influencing the fracturing of the crystalline rock based on a novel grain-based model. Eng Fract Mech 241:107388. https://doi.org/10.1016/j.engfracmech.2020.107388

Wang S, Zhou J, Zhang L, Nagel T, Han Z, Kong Y (2023a) Modeling injection-induced fracture propagation in crystalline rocks by a fluid–solid coupling grain-based model. Rock Mech Rock Eng 1–34. https://doi.org/10.1007/s00603-023-03374-4

Wang ZY, Li YW, Wu ZJ (2023b) Hierarchical scaling model for size effect on tensile strength of polycrystalline rock. Int J Mech Sci 247:108171. https://doi.org/10.1016/j.ijmecsci.2023.108171

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

West I, Walton G (2023) Quantitative evaluation of the effects of input parameter heterogeneity on model behavior for bonded block models of laboratory rock specimens. Rock Mech Rock Eng 1–18. https://doi.org/10.1007/s00603-023-03248-9

Wong LNY, Guo TY, Lam WK, Ng JYH (2019) Experimental study of cracking characteristics of Kowloon granite based on three mode I fracture toughness methods. Rock Mech Rock Eng 52:4217–4235. https://doi.org/10.1007/s00603-019-01882-w

Wu S, Sun W, Xu X (2022) Study on mode I fracture toughness of rocks using flat-joint model and moment tensor. Theor Appl Fract Mec 120:103403. https://doi.org/10.1016/j.tafmec.2022.103403

Xue F, Lin Z, Wang T (2023) Experimental study on cracking process and fracture properties of granite under mode I loading by acoustic emission and digital image correlation. Fatigue Fract Eng Mat Struct 46(5):1921–1936. https://doi.org/10.1111/ffe.13973

Yahaghi J, Liu H, Chan A, Fukuda D (2023) Development of a three-dimensional grain-based combined finite-discrete element method to model the failure process of fine-grained sandstones. Comput Geotech 153:105065. https://doi.org/10.1016/j.compgeo.2022.105065

Yin T, Li X, Xia K, Huang S (2012) Effect of thermal treatment on the dynamic fracture toughness of Laurentian granite. Rock Mech Rock Eng 45:1087–1094. https://doi.org/10.1007/s00603-012-0240-3

Zhang XP, Wong LNY (2014) Choosing a proper loading rate for bonded-particle model of intact rock. Int J Fract 189:163–179. https://doi.org/10.1007/s10704-014-9968-y

Zhang Y, Wong LNY (2018) A review of numerical techniques approaching microstructures of crystalline rocks. Comput Geosci 115:167–187. https://doi.org/10.1016/j.cageo.2018.03.012

Zhang Y, Wong LNY, Chan KK (2019) An extended grain-based model accounting for microstructures in rock deformation. J Geophys Res Solid Earth 124(1):125–148. https://doi.org/10.1029/2018JB016165

Zhang H, Chen L, Liu J, Li Y, Wang J (2022a) Influence of grain size and saturation on the fracture toughness of granitic rocks. Rock Mech Rock Eng 55(12):7881–7886. https://doi.org/10.1007/s00603-022-03006-3

Zhang X, Li Z, Wang X, Wang H, Li B, Niu Y (2022b) Thermal effect on the fracture behavior of granite using acoustic emission and digital image correlation: an experimental investigation. Theor Appl Fract Mec 121:103540. https://doi.org/10.1016/j.tafmec.2022.103540

Zhang S, Qiu S, Li P, Kou Y, Xie Z, Jia L (2023a) Mode I fracture behavior of heterogeneous granite: Insights from grain-based FDEM modelling. Eng Fract Mech 284:109267. https://doi.org/10.1016/j.engfracmech.2023.109267

Zhang T, Yu L, Peng Y, Jing H, Su H, Wei J (2023b) Effect of the mineral spatial distribution heterogeneity on the tensile strength of granite: Insights from PFC3D-GBM numerical analysis. J Rock Mech Geotech Eng 15(5):1144–1160. https://doi.org/10.1016/j.jrmge.2022.07.012

Zhou S, Zhuang X, Zhu H, Rabczuk T (2018) Phase field modelling of crack propagation, branching and coalescence in rocks. Theor Appl Fract Mec 96:174–192. https://doi.org/10.1016/j.tafmec.2018.04.011

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51778575). The authors would like to thank the anonymous reviewers and editors for their constructive suggestions which greatly improve the quality of this paper.

Funding

National Natural Science Foundation of China, 51778575, Xiaonan Gong

Author information

Authors and Affiliations

Contributions

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, X., Liao, D., Hu, H. et al. The Influence of Mechanical Heterogeneity of Grain Boundary on Mechanical and Microcracking Behavior of Granite Under Mode I Loading Using a Grain-Based Model. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-023-03752-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-023-03752-y