Abstract

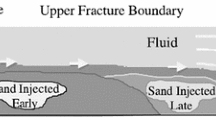

A proppant transport simulator coupled with multi-planar 3D (multi-PL3D) fracture propagation has been developed to examine the proppant distribution among multiple hydraulic fractures during multi-cluster fracturing in a horizontal well. The multi-PL3D fracture model considers wellbore friction, multi-fracture stress interaction, fluid leak-off, and multi-scale propagation regimes. The proppant transport is described by the two-phase (slurry/proppant) flow equations that consider proppant settling, jamming and flow regime transition. A high-resolution weighted essentially non-oscillatory (WENO) finite difference (FD) scheme is adopted to solve the nonlinear proppant transport equations. An efficient time-stepping scheme is developed to solve the solid/fluid coupling equations and moving boundaries for the multi-PL3D model. The proppant transport model and multi-PL3D model are both validated against previously published results. Using the model, we examine the proppant distributions under different injection schedules, proppant sizes, proppant density, and fluid viscosity. Results show that proppant distribution among multiple fractures is different as the flow rate and fracture width distribution vary due to multi-fracture stress interaction. The proppant in the middle cluster settles remarkably as the flow rate is lowest among the multiple clusters. The proppant is usually jammed at the pinch point, where the fracture width reduces sharply. Proppant adding schedule has a significant effect on the proppant distribution. A constant-concentration results in a proppant stack at the fracture front. In contrast, an increasing concentration favors the prop of the near-wellbore fracture. The proppant distribution area ratio (defined as the proppant distribution area divided by the fracture area) is only 20% for 20/40 mesh proppant, while the ratio is 45% for 100 mesh proppant. Slick water can increase the fracture area but not favor promoting the proppant distribution area ratio. The results can be helpful for proppant design for multi-cluster fracturing in a horizontal well.

Similar content being viewed by others

Availability of data and material

This is a theoretical work for which no data need to be made available.

Abbreviations

- \(t\) :

-

Injection time

- \({t}_{0}\) :

-

Leak-off time

- \({t}_{\mathrm{settle}}\) :

-

Settling time

- \({C}_{l}\) :

-

Carter leak-off coefficient

- \({Q}_{t}\) :

-

Total injection rate

- n :

-

Number of HFs in a stage

- \({Q}_{k}\) :

-

Injection rate into the kth HF

- \({p}_{w}\) :

-

Wellbore pressure

- \({p}_{in}\) :

-

Inlet pressure of HF

- \({p}_{c}\) :

-

Wellbore friction

- \({p}_{p}\) :

-

Perforation friction

- \({f}_{c}\) :

-

Darcy–Weisbach friction factor

- \({r}_{w}\) :

-

Wellbore radius

- \({\rho }^{p}\) :

-

Proppant density

- \({\rho }^{s}\) :

-

Slurry density

- μ :

-

Fluid viscosity

- \({V}_{w}\) :

-

Flow velocity

- \(\mathrm{Re}\) :

-

Reynolds number

- \(\varepsilon\) :

-

Wellbore roughness

- \({n}_{p}\) :

-

Number of perforation holes

- \({d}_{p}\) :

-

Diameter of perforation holes

- \(K\) :

-

Discharge coefficient

- \({\sigma }_{h}\) :

-

Minimum horizontal principal stress

- \({C}_{g}\) :

-

Green function

- \(w\) :

-

Fracture width

- \(p\) :

-

Fluid pressure in the HF

- \(d\) :

-

Distance from the fracture tip

- \({K}_{\mathrm{Ic}}\) :

-

Mode I of fracture toughness

- G :

-

Shear modulus

- \(E\) :

-

Young’s modulus

- \(v\) :

-

Poisson’s ratio

- \({\varvec{C}}\) :

-

Coefficient influence matrix

- \(\overline{\phi }\) :

-

Normalized proppant concentration

- \({{\varvec{q}}}^{s}\) :

-

Flux of the slurry

- \({{\varvec{q}}}^{p}\) :

-

Flux of the proppant

- \({\tilde{q }}^{p}\) :

-

Numerical flux

- \({\overline{\phi }}_{in}\) :

-

Injection proppant concentration

- \({q}_{l}^{s}\) :

-

Flux of fluid leak-off

- u :

-

Conserved quantity

- \({\widehat{Q}}^{s}\), \({\widehat{Q}}^{p}\), and \({\widehat{G}}^{p}\) :

-

Functions of slurry flow

- \({Q}^{s}\), \({Q}^{p}\), and \({ G}^{p}\) :

-

Dimensionless functions

- H(x):

-

Heaviside unit step function

- N :

-

Ratio of fracture width to proppant diameter at screen-out

- h :

-

Fracture height

- \(V\) :

-

Fracture growth velocity

- \({v}_{settle}^{p}\) :

-

Proppant settling velocity

- \(\Delta x\) :

-

Element size in x direction

- \(\Delta y\) :

-

Element size in x direction

- \(\Delta t\) :

-

Time step for propagation

- \(\Delta {t}_{p}\) :

-

Time step for proppant transport

- \({\lambda }_{\mathrm{p}}\) :

-

Relaxation factor

- \({i}_{0},{j}_{0},{k}_{0}\) :

-

Indices of the injection point

- \(i,j,k\) :

-

Indices of the grid point

- \(s\) :

-

Internal stage number of RKL scheme

- \(\beta\) :

-

Smoothness indicator

- \(\omega\) :

-

Weight of WENO reconstruction

References

Adachi J, Siebrits E, Peirce A, Desroches J (2007) Computer simulation of hydraulic fractures. Int J Rock Mech Min 44(5):739–757. https://doi.org/10.1016/j.ijrmms.2006.11.006

Alotaibi MA, Miskimins JL (2015) Slickwater proppant transport in complex fractures: new experimental findings and scalable correlation. Presented at the SPE annual technical conference and exhibition, 28–30 Sept 2015. SPE-174828-MS. https://doi.org/10.2118/174828-MS

Barboza BR, Chen B, Li CF (2021) A review on proppant transport modeling. J Petrol Sci Eng 204:108753. https://doi.org/10.1016/j.petrol.2021.108753

Blyton CAJ, Gala DP, Sharma MM (2015) A comprehensive study of proppant transport in a hydraulic Fracture. SPE 174973-MS. https://doi.org/10.2118/174973-MS

Boyer F, Guazzelli É, Pouliquen O (2011) Unifying suspension and granular rheology. Phys Rev Lett 107(18):188301. https://doi.org/10.1103/PhysRevLett.107.188301

Bunger A, Cardella DJ (2013) Spatial distribution of production in a marcellus shale well: evidence for hydraulic fracture stress interaction. J Petrol Sci Eng 133:162–166. https://doi.org/10.1016/j.petrol.2015.05.021

Bunger A, Jeffrey RG, Zhang X (2014) Constraints on simultaneous growth of hydraulic fractures from multiple perforation clusters in horizontal wells. SPE J 19(04):608–620. https://doi.org/10.2118/163860-PA

Chen M, Zhang SC, Zhou T, Ma XF, Zou YS (2018) A Semi-analytical model for predicting fluid partitioning among multiple hydraulic fractures from a horizontal well. J Petrol Sci Eng 171:1041–1051. https://doi.org/10.1016/j.petrol.2018.07.031

Chen XY, Zhao JZ, Li YM, Yan WY, Zhang X (2019) Numerical simulation of simultaneous hydraulic fracture growth within a rock layer: implications for stimulation of low–permeability reservoirs. J Geophys Res-Sol EA 124:13227–13249. https://doi.org/10.1029/2019JB017942

Chen M, Zhang SC, Li SH, Ma XF, Zhang X, Zou YS (2020a) An explicit algorithm for modeling planar 3D hydraulic fracture growth based on a super-time-stepping method. Int J Solids Struct 191–192:370–389. https://doi.org/10.1016/j.ijsolstr.2020.01.011

Chen M, Zhang SC, Xu Y, Ma XF, Zou YS (2020b) A numerical method for simulating planar 3D multi-fracture propagation in multi-stage fracturing of horizontal wells. Petrol Expl Dev 47(1):171–183. https://doi.org/10.1016/S1876-3804(20)60016-7

Chen M, Zhang SC, Zhou T, Ma XF, Zou YS (2020c) Optimization of in-stage diversion to promote uniform planar multifracture propagation: a numerical study. SPE J 25(06):3091–3110. https://doi.org/10.2118/201114-PA

Cheng C, Bunger A, Peirce A (2016) Optimal perforation location and limited entry design for promoting simultaneous growth of multiple hydraulic fractures. Presented at The SPE hydraulic fracturing technology conference, The Woodlands, Texas, 9–11 Feb. https://doi.org/10.2118/179158-MS

Churchill SW (1977) Friction-factor equation spans all fluid-flow regimes. Chemical Engineering 84(24): 91–92.

Cipolla C, Wallace J (2014) Stimulated reservoir volume: a misapplied concept? Presented at the SPE hydraulic fracturing technology conference, The Woodlands, Texas, 4–6 Feb. https://doi.org/10.2118/168596-MS

Cramer D, Friehauf K, Roberts G (2019) Integrating DAS, treatment pressure analysis and video-based perforation imaging to evaluate limited entry treatment effectiveness. Presented at the SPE hydraulic fracturing technology conference and exhibition, The Woodlands, Texas, 5–7 Feb. https://doi.org/10.2118/194334-MS

Crouch SL, Starfield AM (1983) Boundary element methods in solid mechanics: with applications in rock mechanics and geological engineering. George Allen and Unwin, Winchester,

Crump JB, Conway MW (1988) Effects of perforation-entry friction on bottom hole treating analysis. J Pet Technol 40(8):1041–1048. https://doi.org/10.2118/15474-PA

Dontsov EV (2021) A continuous fracture front tracking algorithm with multi layer tip elements (MuLTipEI) for a plane strain hydraulic fracture. https://arxiv.org/abs/2104.11184 [physics.geo-ph]

Dontsov E, Peirce A (2014) Slurry flow, gravitational settling, and a proppant transport model for hydraulic fractures. J Fluid Mech 760:567–590. https://doi.org/10.1017/jfm.2014.606

Dontsov EV, Peirce AP (2015a) Proppant transport in hydraulic fracturing: crack tip screen–out in KGD and P3D models. Int J Solids Struct 63:206–218. https://doi.org/10.1016/j.ijsolstr.2015.02.051

Dontsov EV, Peirce AP (2015b) A non-singular integral equation formulation to analyze multiscale behaviour in semi-infinite hydraulic fractures. J Fluid Mech. https://doi.org/10.1017/jfm.2015.451

Economides MJ, Nolte KG (2000) Reservoir stimulation, 3rd edn. Wiley, West Sussex

Fernández ME, Baldini M, Pugnaloni LA, Sanchez M, Guzzetti AR, Carlevaro CM (2015) Proppant transport and settling in a narrow vertical wedge–shaped fracture. In: 49th US rock mechanics/geomechanics symposium ARMA-2015–135

Gale JFW, Elliott S, Laubach SE (2018) Hydraulic fractures in core from stimulated reservoirs: core fracture description of HFTS slant core, Midland basin, West Texas. URTeC-2902624. https://doi.org/10.15530/URTEC-2018-2902624

Herskovits R, Kidd I, Fuss-Dezelic T, Shi JY, Wilcox C, Kaul T (2017) Mono & thin layer performance of small mesh size proppants in horizontal well fracture matrices. Presented at the SPE annual technical conference and exhibition, 9–11 Oct. SPE-187449-MS. https://doi.org/10.2118/187449-MS

Hosseini N, Khoei AR (2020) Numerical simulation of proppant transport and tip screen-out in hydraulic fracturing with the extended finite element method. Int J Rock Mech Min Sci 128:104247. https://doi.org/10.1016/j.ijrmms.2020.104247

Hu XD, Wu K, Song XZ, Yu W, Zuo LH, Li GS, Shen ZH (2019) Development of a new mathematical model to quantitatively evaluate equilibrium height of proppant bed in hydraulic fractures for slickwater treatment. SPE J 23(06):2158–2174. https://doi.org/10.2118/191360-PA

Isah A, Hiba M, Al-Azani K, Aljawad MS, Mahmoud M (2021) A comprehensive review of proppant transport in fractured reservoirs: experimental, numerical, and field aspects. J Nat Gas 88:103832. https://doi.org/10.1016/j.jngse.2021.103832

Kern LR, Perkins TK, Wyant RE (1959) The mechanics of sand movement in fracturing. J Pet Technol 11(7):55–57

King G (2010) Thirty years of gas shale fracturing: what have we learned? Presented at the SPE annual technical conference and exhibition, Florence, 19–22 Sept. SPE-133456-MS. https://doi.org/10.2118/133456-MS

Lecampion B, Desroches J (2015) Simultaneous initiation and growth of multiple radial hydraulic fractures from a horizontal wellbore. J Mech Phys Solids 82:235–258. https://doi.org/10.1016/j.jmps.2015.05.010

Lecampion B, Desroches J, Weng X, Burghardt J, Brown JEE (2015) Can we engineer better multistage horizontal completions? Evidence of the importance of near-wellbore fracture geometry from theory, lab and field experiments. Presented at the SPE hydraulic fracturing technology conference, The Woodlands, Texas, 3–5 Feb. https://doi.org/10.2118/173363-MS

Lecampion B, Bunger A, Zhang X (2018) Numerical methods for hydraulic fracture propagation: a review of recent trends. J Nat Gas Sci Eng 49:66–83. https://doi.org/10.1016/j.jngse.2017.10.012

LeVeque RJ (2002) Finite volume methods for hyperbolic problems. Cambridge Texts in Applied Mathematics, Cambridge University Press.

Linkov AM (2019) Modern theory of hydraulic fracture modeling with using explicit and implicit schemes. Comput Eng Finance Sci. https://arxiv.org/abs/1905.06811

Manchanda R, Bryant E, Bhardwaj P, Cardiff P, Sharma MM (2018) Strategies for effective stimulation of multiple perforation clusters in horizontal wells. SPE J 33(03):539–556. https://doi.org/10.2118/179126-PA

McClure M (2018) Bed load proppant transport during slickwater hydraulic fracturing: insights from comparisons between published laboratory data and correlations for sediment and pipeline slurry transport. J of Petrol Sci Engi 161:599–610. https://doi.org/10.1016/j.petrol.2017.11.043

McClure M, Picone M, Fowler G, Ratcliff D, Kang C, Medam S, Frantz J (2020) Nuances and frequently asked questions in field–scale hydraulic fracture modeling. SPE 199726-MS. https://doi.org/10.2118/199726-MS

Meyer CD, Balsara DS, Aslam TD (2014) A stabilized Runge–Kutta–Legendre method for explicit super-time-stepping of parabolic and mixed equations. J Comput Phys 257:594–626. https://doi.org/10.1016/j.jcp.2013.08.021

Mobbs AT, Hammond PS (2001) Computer simulations of proppant transport in a hydraulic fracture. SPE Prod Oper 16(02):112–121

Peirce A, Detournay E (2008) An implicit level set algorithm for modeling hydraulically driven fractures. Comput Method Appl M 197(33):2858–2885

Ramurthy M, Richardson J, Brown M, Sahdev N, Wiener J, Garcia M (2016) Fiber-optics results from an intra-stage diversion design completions study in the Niobrara formation of DJ basin. Presented at the SPE hydraulic fracturing technology conference, The Woodlands, Texas, 9–11 Feb. https://doi.org/10.2118/179106-MS

Raterman KT, Farrell HE, Mora OS, Janssen AL, Gomez GA, Busetti S et al (2018) Sampling s stimulated rock volume: an Eagle Ford example. SPE Reserv Eval Eng 21(04):927–941. https://doi.org/10.2118/191375-PA

Rivas E, Gracie R (2019) Numerical considerations for the simulation of proppant transport through fractures. J Petrol Sci Eng 180:1006–1021. https://doi.org/10.1016/j.petrol.2019.05.064

Rivas E, Gracie R (2020) A monolithic coupled hydraulic fracture model with proppant transport. Comput Methods Appl Me 372:113361. https://doi.org/10.1016/j.cma.2020.113361

Roberts G, Lilly TB, Tymons TR (2018) Improved well stimulation through the application of downhole video analytics. Presented at the SPE hydraulic fracturing technology conference and exhibition, The Woodland, Texas, 23–25 Jan. https://doi.org/10.2118/189851-MS

Roostaei M (2017) Numerical simulation of proppant transport in hydraulic fractures. PhD thesis, University of Alberta

Sesetty V, Ghassemi A (2019) Simulation and analysis of fracture swarms observed in the Eagle Ford field experiment. Presented at the SPE hydraulic fracturing technology conference and exhibition, The Woodlands, Texas, 5–7 Feb. SPE-194328-MS. https://doi.org/10.2118/194328-MS

Shiozawa S, McClure M (2016) Simulation of proppant transport with gravitational settling and fracture closure in a three–dimensional hydraulic fracturing simulator. J Petrol Sci Eng 138:298–314. https://doi.org/10.1016/j.petrol.2016.01.002

Shu CW (1998) Essentially non-oscillatory and weighted essentially non-oscillatory schemes for hyperbolic conservation laws. In: Quarteroni A (eds) Advanced numerical approximation of nonlinear hyperbolic equations. Lecture Notes in Mathematics, Springer, Berlin, Heidelberg. https://doi.org/10.1007/BFb0096355

Skopintsev AM, Dontsov EV, Kovtunenko PV, Baykin AN, Golovin SV (2020) The coupling of an enhanced pseudo-3D model for hydraulic fracturing with a proppant transport model. Eng Frac Mech 236:107177. https://doi.org/10.1016/j.engfracmech.2020.107177

Stepanov AD (2018) Statistical method for tracing hydraulic fracture front without evaluation of the normal. In: International conference of adanced problems in mechanics, St. Petersburg, 25–30 June. APM-2018

Suppachoknirun T, Tutuncu AN (2017) Hydraulic fracturing and production optimization in Eagle Ford shale using coupled geomechanics and fluid flow model. Rock Mech Rock Eng 50:3361–3378. https://doi.org/10.1007/s00603-017-1357-1

Tsai K, Fonseca E, Degaleesan S, Lake E (2012) Advanced computational modeling of proppant settling in water fractures for shale gas production. SPE J 18(01):50–56. https://doi.org/10.2118/151607-PA

Ugueto GA, Huckabee PT, Molenaar MM, Wyker B, Somanchi K (2016) Perforation cluster efficiency of cemented plug and perf limited entry completions: insights from fiber optics diagnostics. Presented at the SPE hydraulic fracturing technology conference, Woodlands, Texas, 9–11 Feb. SPE-179124-MS. https://doi.org/10.2118/179124-MS

Ugueto GA, Todea F, Daredia T, Wojtaszek M, Huckabee PT, Reynolds A, Laing C, Chavarria JA (2019) Can you feel the strain? DAS strain fronts for fracture geometry in the BC Montney, Groundbirch. Presented at the SPE annual technical conference and exhibition, Calgary, 30 Sept–2 Oct. SPE-195943-MS. https://doi.org/10.2118/195943-MS

Wang JH, Elsworth D, Denison MK (2018) Propagation, proppant transport and the evolution of transport properties of hydraulic fractures. J Fluid Mech 855:503–534. https://doi.org/10.1017/jfm.2018.670

Wang D, Wang HB, Li FX, Chen M, Bunger AP (2020) Parameters affecting the distribution of pulsed proppant in hydraulic fractures. J Petrol Sci Eng 191:107125. https://doi.org/10.1016/j.petrol.2020.107125

Wang YL, Ju Y, Zhang H, Gong SC, Song JX, Li Y, Chen J (2021) Adaptive finite element-discrete element analysis for the stress shadow effects and fracture interaction behaviours in three-dimensional multistage hydrofracturing considering varying perforation cluster spaces and fracturing scenarios of horizontal wells. Rock Mech Rock Eng 54:1815–1839. https://doi.org/10.1007/s00603-021-02364-8

Weddle P, Griffin L, Pearson C (2018) Mining the Bakken II—pushing the envelope with extreme limited entry perforating. Presented at the SPE hydraulic fracturing technology conference and exhibition, The Woodlands, Texas, 23–25 Jan. SPE-189880-MS. https://doi.org/10.2118/189880-MS

Wu K, Olson J, Balhoff MT, Yu W (2017) Numerical analysis for promoting uniform development of simultaneous multiple-fracture propagation in horizontal wells. SPE Prod Oper 33(01):41–50. https://doi.org/10.2118/178925-PA

Yew CH (1997) Mechanics of hydraulic fracturing. Gulf Publishing Company, Houston

Zeng J, Li H, Zhang D (2016) Numerical simulation of proppant transport in hydraulic fracture with the upscaling CFD–DEM method. J Nat Gas Sci Eng 33:264–277. https://doi.org/10.1016/j.jngse.2016.05.030

Zeng QL, Liu ZL, Wang T, Gao Y, Zhuang Z (2018) Fully coupled simulation of multiple hydraulic fractures to propagate simultaneously from a perforated horizontal wellbore. Comput Mech 61(1–2):137–155. https://doi.org/10.1007/s00466-017-1412-5

Zeng JS, Li H, Zhang DX (2019) Numerical simulation of proppant transport in propagating fractures with the multi–phase particle–in–cell method. Fuel 245:316–335. https://doi.org/10.1016/j.fuel.2019.02.056

Zhang GD, Li MZ, Gutierrez M (2017) Simulation of the transport and placement of multi–sized proppant in hydraulic fractures using a coupled CFD–DEM approach. Adv Powder Technol 28(7):1704–1718. https://doi.org/10.1016/j.apt.2017.04.008

Zhang CP, Liu S, Ma ZY, Ranjith PG (2021a) Combined micro-proppant and supercritical carbon dioxide (SC-CO2) fracturing in shale gas reservoirs: a review. Fuel 305:121431. https://doi.org/10.1016/j.fuel.2021.121431

Zhang FS, Wang XH, Tang MR, Du XF, Xu CC, Tang JZ, Damjanac B (2021b) Numerical investigation on hydraulic fracturing of extreme limited entry perforating in plug-and-perforation completion of shale oil reservoir in Changqing oilfield, China. Rock Mech Rock Eng 54:2925–2941. https://doi.org/10.1007/s00603-021-02450-x

Acknowledgements

The research was supported by the Natural Science Foundation of China (Grant No. 52104060), Shandong Provincial Natural Science Foundation (ZR2019QEE005). The first author thanks Dr. Xi Zhang (previous at CSIRO Energy) for coding the WENO scheme for proppant transport.

Author information

Authors and Affiliations

Contributions

MC and TG: conceived and implemented the WENO finite-difference algorithm. YZ, SZ, ZQ: designed the verification examples and analyzed the numerical case studies. MC: performed all the simulations and wrote the paper. All authors participated in discussing the results and reviewing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: The Critical Width of the Fracture Tip Using Universal Asymptotical Solutions

Define dimensionless variables (Dontsov and Peirce 2015b)

where \(V\) is fracture growth velocity.

The critical width satisfies

where \(b=\frac{{C}_{2}\left(\delta \right)}{{C}_{1}\left(\delta \right)}\chi\), \({C}_{1}\left(\delta \right)=\frac{4\left(1-2\delta \right)}{\delta \left(1-\delta \right)}\mathrm{tan}\left(\pi \delta \right)\), and \({C}_{2}\left(\delta \right)=\frac{16\left(1-3\delta \right)}{3\delta \left(2-3\delta \right)}\mathrm{tan}\left(\frac{3\pi }{2}\delta \right).\)

Equation (27) can be solved iteratively to find the critical width to activate a new element.

Appendix B: Influence Matrix of PL3D Displacement Discontinuity Method (DDM)

Displacement discontinuity method is an indirect boundary element method. For PL3D HFs, only normal displacement discontinuity is considered, and the normal stress induced by a normal displacement discontinuity is (Crouch and Starfield 1983)

where

The symbol || denotes Chinnery’s notation to represent the substitution

where \(a=0.5\Delta x\), \(b=0.5\Delta y\).

Appendix C: Second-Order RKL Numerical Scheme

The numerical scheme of a second-order RKL is (Meyer et al. 2014; Chen et al. 2020a)

where \({{\varvec{w}}}_{m}\) is the fracture width at the previous time step, \({{\varvec{w}}}_{m+1}\) is the fracture width for the current time step, \(\Delta t\) is the time step of the RKL scheme, and \(s\) is the internal stage number. The coefficients in Eq. (34) are provided

Appendix D: WENO Reconstruction Scheme

For the convenience of writing, the subscript j in the y-direction and k in the z-direction are omitted in this subsection.

(1) Reconstruction \({u}_{i+1/2}^{-}\) and \({u}_{i-1/2}^{-}\)

The approximation \({u}_{i+1/2}^{-}\) is WENO reconstruction from the total stencil one point biased to the left, that is \({S}^{T}=\left\{{u}_{i-2},{u}_{i-1},{u}_{i},{u}_{i+1},{u}_{i+2}\right\}\), as shown in Fig. 28.

The total stencil consists of three sub-stencil,\({S}_{1}=\left\{{u}_{i-2},{u}_{i-1},{u}_{i}\right\},{S}_{2}=\left\{{u}_{i-1},{u}_{i},{u}_{i+1}\right\},{S}_{3}=\left\{{u}_{i},{u}_{i+1},{u}_{i+2}\right\}.\) Moreover, the reconstruction is a nonlinear combination of interpolations in each three sub-stencil. For the sub-stencil \({S}_{1}\), a unique polynomial \({P}_{1}\left(x\right)={a}_{1}{x}^{2}+{b}_{1}x+{c}_{1}\) of degree at most two can be obtained from the following equations

where \({a}_{1}\), \({b}_{1}\), and \({c}_{1}\) are coefficients determined by solving Eq. (36). After simple algebra, the explicit formula for the approximation is

Similarly, the interpolation at \({x}_{i+\frac{1}{2}}\) can be obtained from the S2 and S3, respectively

When the solution is smooth, a 5th order interpolation can be calculated by a linear combination of each sub-stencil interpolation as

where \({\gamma }_{1}=1/10\), \({\gamma }_{2}=3/5,\mathrm{ and }{\gamma }_{3}=3/10.\)

When the solution is discontinuous around \({x}_{i+\frac{1}{2}}\), the WENO scheme is to reconstruct the approximation as a convex combination of each sub-stencil approximations \({u}_{i+\frac{1}{2}}^{\left(1\right)}\), \({u}_{i+\frac{1}{2}}^{\left(2\right)}\), and \({u}_{i+\frac{1}{2}}^{\left(3\right)}\)

where \({\omega }_{j}\ge 0\), \({\omega }_{1}+{\omega }_{2}+{w}_{3}=1\).

The nonlinear weights \({\omega }_{j}\) are determined based on the smoothness of \(u(x)\), which is measured by the smoothness indicator

With the smoothness indicator, the nonlinear weights are defined as

where \(\varepsilon\) is a small positive number to avoid the denominator to be zero, chosen as \(\varepsilon ={10}^{-6}\) in the study; \({\gamma }_{1}\)=1/10, \({\gamma }_{2}\)=3/5, \({\gamma }_{3}\)=3/10.

In the above WENO reconstruction, one point is biased to the left for the \({u}_{i+1/2}\) approximation, thus the result of reconstruction is \({u}_{i+1/2}^{-}\) using \({S}^{T}=\left\{{u}_{i-2},{u}_{i-1},{u}_{i},{u}_{i+1},{u}_{i+2}\right\}\). Similarly, we can reconstruct \({u}_{i-1/2}^{-}\) using \(\left\{{u}_{i-3},{u}_{i-2},{u}_{i-1},{u}_{i},{u}_{i+1}\right\}\) by translating one element to left of \({S}^{T}\).

(2) Reconstruction \({u}_{i-1/2}^{+}\) and \({u}_{i+1/2}^{+}\)

Using the total stencil \({S}^{T}\), we can reconstruct \({u}_{i-1/2}\) from each sub-stencil as

WENO reconstruction approximates the u by a nonlinear combination of each approximation in sub-stencil

where \({\omega }_{j}^{^{\prime}}\ge 0\), \({\omega }_{1}^{^{\prime}}+{\omega }_{2}^{^{\prime}}+{\omega }_{3}^{^{\prime}}=1\).

The nonlinear weights are defined as

where \(\varepsilon\) is a small positive number \(\varepsilon ={10}^{-6}\) in the study; \({\gamma }_{1}^{^{\prime}}\)=3/10, \({\gamma }_{2}^{^{\prime}}\)=3/5, \({\gamma }_{3}^{^{\prime}}\)=1/10.

In the above WENO reconstruction, one point is biased to the right for the \({u}_{i-1/2}\) approximation, thus the result of reconstruction is \({u}_{i-1/2}^{+}\) using \({S}^{T}=\left\{{u}_{i-2},{u}_{i-1},{u}_{i},{u}_{i+1},{u}_{i+2}\right\}\). Similarly, we can reconstruct \({u}_{i+1/2}^{+}\) using \(\left\{{u}_{i-1},{u}_{i},{u}_{i+1},{u}_{i+2},{u}_{i+3}\right\}\) by translating one element to right of \({S}^{T}\).

Rights and permissions

About this article

Cite this article

Chen, M., Guo, T., Zou, Y. et al. Numerical Simulation of Proppant Transport Coupled with Multi-Planar-3D Hydraulic Fracture Propagation for Multi-Cluster Fracturing. Rock Mech Rock Eng 55, 565–590 (2022). https://doi.org/10.1007/s00603-021-02694-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02694-7