Abstract

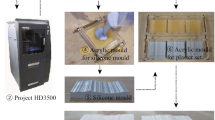

The 3D printing (3DP) technology to produce accurate tunnel physical models is tested to overcome difficulties in the traditional preparation methods of geotechnical physical models. Four kinds of tunnel models are prepared by 3D printers, with gypsum powder and PLA (polylactic acid) material used as the printing materials. Uniaxial compression experiments of the 3DP tunnel specimens show that the deformation and failure characteristics of the general tunnel model and single-fault tunnel model are similar to those of the artificial model. A comparative study also shows that the printed rockbolt and lining support structures significantly improve the bearing capacity of the tunnel, while faults significantly reduce the stability of the tunnel. These experimental results are similar to those of the artificial models, tunnel engineering case studies and numerical simulation results, demonstrating that 3DP technology can be applied to the experimental study of physical models of tunnels. Moreover, the digital speckle correlation method (DSCM) is adopted to expose the evolution of the displacement fields and the crack propagation of printed models that contain faults during loading. These digital results also support that 3DP physical specimens can be used to analyze the general and local stability of complicated faulted tunnels. The presented studies show that 3DP technology will considerably progress the development of rock/rock mass mechanics research with the further development in its technology and materials.

Similar content being viewed by others

References

3D print network (2016) Super Encyclopedia: the world’s most popular seven 3D printing technology detailed [Online]. http://3dprint.ofweek.com/2016-09/ART-132109-8500-30040401.html

3D Systems Inc (2013) ProJet® x60 Series:Professional 3D Printers [Online]. https://www.3dsystems.com/sites/default/files/projet-x60-series-us_0.pdf

3ddayin (2016) Change your world view of the five 3D printing industry “first” [Online]. http://www.3ddayin.net/news/shichangyanjiu/22171.html

Bachmann D, Bouissou S, Chemenda A (2004) Influence of weathering and pre-existing large scale fractures on gravitational slope failure: insights from 3-d physical modelling. Nat Hazards Earth Syst Sci 4(5/6):711–717

Barton NR (1972) A model study of rock-joint deformation. Int J Rock Mech Min Sci Geomech Abstr 9(5):579–582

Choi SO, Shin HS (2004) Stability analysis of a tunnel excavated in a weak rock mass and the optimal supporting system design. Int J Rock Mech Min Sci 41:876–881

Cook NGW (1965) The failure of rock. Int J Rock Mech Min Sci Geomech Abstr 2(4):389–403

Dyskin AV, Sahouryeh E, Jewell RJ, Joer H, Ustinov KB (2003) Influence of shape and locations of initial 3-D cracks on their growth in uniaxial compression. Eng Fract Mech 70(15):2115–2136

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Min Sci 36(3):279–289

Fereshtenejad S, Song JJ (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49(6):2065–2074

Godoi FC, Prakash S, Bhandari BR (2016) 3d printing technologies applied for food design: Status and prospects. J Food Eng 179:44–54

Grote DL, Park SW, Zhou M (2001) Dynamic behavior of concrete at high strain rates and pressures: I. Experimental characterization. Int J Impact Eng 25(9):869–886

He MC, Gong WL, Zhai HM, Zhang HP (2010) Physical modeling of deep ground excavation in geologically horizontal strata based on infrared thermography. Tunn Undergr Space Technol Inc Trenchless Technol Res 25(4):366–376

Head D, Vanorio T (2016) Effects of changes in rock microstructures on permeability: 3-D printing investigation. Geophys Res Lett 43(14):7494–7502

Henke K, Treml S (2013) Wood based bulk material in 3D printing processes for applications in construction. Eur J Wood Wood Prod 71(1):139–141

Holloway J (2012) 3D printer creates objects from moon rocks [Online]. http://www.gizmag.com/3d-printing-moon-rock/25212/

Hong SB, Eliaz N, Sachs EM, Allen SM, Latanision RM (2001) Corrosion behavior of advanced titanium-based alloys made by three-dimensional printing (3DP TM) for biomedical applications. Corr Sci 43(9):1781–1791

Huang D, Huang RQ, Zhang YX (2009) Analysis on influence of fault location and strength on deformation and stress distribution of surrounding rocks of large underground openings. J Civ Archit Environ Eng 31(2):68–73

Huang F, Zhu H, Xu Q, Cai Y, Zhuang X (2013) The effect of weak interlayer on the failure pattern of rock mass around tunnel–Scaled model tests and numerical analysis. Tunn Undergr Space Technol 35(4):207–218

Ishutov S, Hasiuk FJ, Harding C, Gray JN (2015) 3D printing sandstone porosity models. Interpretation 3(3):SX49–SX61

Jeon S, Kim J, Seo Y, Hong C (2004) Effect of a fault and weak plane on the stability of a tunnel in rock—a scaled model test and numerical analysis. Int J Rock Mech Min Sci 41:658–663

Jiang C, Zhao GF (2015) A preliminary study of 3D printing on rock mechanics. Rock Mech Rock Eng 48(3):1041–1050

Jiang Q, Feng XT, Hatzor YH, Hao XJ, Li SJ (2014) Mechanical anisotropy of columnar jointed basalts: an example from the Baihetan hydropower station, China. Eng Geol 175:35–45

Jiang Q, Feng X, Song L, Gong Y, Zheng H, Cui J (2016a) Modeling rock specimens through 3D printing: tentative experiments and prospects. Acta Mech Sin 32(1):101–111

Jiang Q, Feng X, Gong Y, Song L, Ran S, Cui J (2016b) Reverse modelling of natural rock joints using 3D scanning and 3D printing. Comput Geotech 73:210–220

Jiang C, Zhao GF, Zhu J, Zhao YX, Shen L (2016c) Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech Rock Eng 49(10):3983–3998

Joshi SC, Sheikh AA (2015) 3D printing in aerospace and its long-term sustainability. Virtual Phys Prototyp 10(4):175–185

Ju Y, Xie H, Zheng Z, Lu J, Mao L, Gao F et al (2014) Visualization of the complex structure and stress field inside rock by means of 3d printing technology. Chin Sci Bull 59(36):5354–5365

Ju Y, Wang L, Xie H, Ma G, Zheng Z, Mao L (2017) Visualization and transparentization of the structure and stress field of aggregated geomaterials through 3D printing and photoelastic techniques. Rock Mech Rock Eng 50(6):1383–1407

Li Y, Zhang D, Fang Q, Yu Q, Xia L (2014) A physical and numerical investigation of the failure mechanism of weak rocks surrounding tunnels. Comput Geotech 61:292–307

Lin P, Wong RH, Tang CA (2015) Experimental study of coalescence mechanisms and failure under uniaxial compression of granite containing multiple holes. Int J Rock Mech Min Sci 77:313–327

Liu P, Ju Y, Ranjith PG, Zheng Z, Wang L, Wanniarachchi A (2016) Visual representation and characterization of three-dimensional hydrofracturing cracks within heterogeneous rock through 3D printing and transparent models. Int J Coal Sci Technol 3(3):284–294

Ma SP, Xu XH, Zhao YH (2004) The GEO-DSCM system and its application to the deformation measurement of rock materials. Int J Rock Mech Min Sci 41:292–297

Ma WL, Tao FH, Jia CZ, Yang JC (2014) Applications of 3D printing technology in the mechanical manufacturing. Appl Mech Mater 644:4964–4966 (Trans Tech Publications)

Meguid MA, Saada O, Nunes MA, Mattar J (2008). Physical modeling of tunnels in soft ground: a review. Tunn Undergr Space Technol Inc Trenchless Technol Res 23(2):185–198

Sachs EM, Haggerty JS, Cima MJ, Williams PA (1993). Three-dimensional printing techniques. US, US 5204055 A

Seki S, Kaise S, Morisaki Y, Azetaka S, Jiang Y (2008) Model experiments for examining heaving phenomenon in tunnels. Tunn Undergr Space Technol 23(2):128–138

SOI (2012) World’s first 3D printed reef. Sustainable Oceans International (SOI) Pty Ltd

Sterpi D, Cividini A (2004) A physical and numerical investigation on the stability of shallow tunnels in strain softening media. Rock Mech Rock Eng 37(4):277–298

Wong LNY, Einstein HH (2009) Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int J Rock Mech Min Sci 46(2):239–249

Zhang QY, Duan K, Jiao YY, Xiang W (2017) Physical model test and numerical simulation for the stability analysis of deep gas storage cavern group located in bedded rock salt formation. Int J Rock Mech Min Sci 94:43–54

Zhu WS, Li Y, Zhang L, Xin XL, Sun LF, Ma QS, Zhang L (2008) Geomechanical model test on stability of cavern group under high geostress. Chin J Rock Mechan Eng 27(7):1308–1314

Acknowledgements

The authors gratefully acknowledge the financial support from the State Key Research Development Program of China (Nos. 2016YFC0600707 and 2016YFC0801605), National Natural Science Foundation of China (Grant No. 51779251) and the Hubei Province outstanding youth fund (No. 2017CFA060).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, L., Jiang, Q., Shi, YE. et al. Feasibility Investigation of 3D Printing Technology for Geotechnical Physical Models: Study of Tunnels. Rock Mech Rock Eng 51, 2617–2637 (2018). https://doi.org/10.1007/s00603-018-1504-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1504-3