Abstract

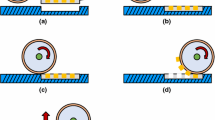

Printed electronics refers to the technology of fabricating electronic devices by applying the printing process method to thin films. Printed electronics is regarded as a promising industry of the future because of its relatively low cost, simple process, and high mass production capacity, which are all superior to existing manufacturing methods. Roll-to-roll printing is a suitable technology for printed electronics with large-scale and high-speed mass production. To commercialize roll-to-roll printing technology, it is necessary to develop technology for position control of the web, tension control of the web, printing pressure control, and functional ink development. Among them, the printing pressure uniformization by the printing pressure control is an important factor that significantly affects the printing quality. In the roll-to-roll printing process, the functional ink is transferred by the nip generated by the printing pressure. That is, if the nip can be kept uniform by applying the printing pressure uniformly, the uniformity of the line width and thickness of the printed pattern is improved. This nip occurs on a line connecting the geometric center of the two rolls, and the centers of the two rolls are on the orbit line by each roll runout. Therefore, the print pressure can be estimated through the change in the inter-center distance of the rolls caused by the roll runout. In this study, we propose a method of printing pressure uniformization using roll runout. After establishing initial conditions that minimize change in printing pressure, load cells are used to estimate and verify the initial conditions that minimized the change in the inter-center distance of rolls, and pressure sensitive paper is used to verify whether the actual printing pressure is minimized.

Similar content being viewed by others

References

Choi KH, Thanh TT, Kim HC, Yang BS, Kim DS (2009) On new approach for gravure/offset printing pressure control algorithm development using the full state feedback controller. In: IEEE ISAM, pp 88–94

Choi BO, Jo J, Kim DS, Lim KJ, Ryu BS (2011) True rolling technique of new gravure-offset printing for R2R over-piling. J KSPE 28(10):1131–1140

Jung M, Kim Y, Oh D (2016) A robust position measurement system for precision alignment of roll-to-roll printing using alignment patterns and light quantity. Microsyst Technol 22(6):1381–1387

Kang D, Kim H, Lee E, Choi YM, Jo J, Lee TM (2014) Measurement and compensation of synchronization error in offset printing process. J KSPE 31(6):477–481

Lee JS, Lee CW (2013) Analysis of thermal effect on tension of a moving web in roll-to-roll printed electronics. J KSMPE 12(5):9–15

Seo Y, Kim YM, Oh D (2013) A position measurement system for precision alignment of roll-to-roll printing and sensitivity analysis of thermal deformation. Microsyst Technol 19(9–10):1539–1548

Shin K (2006) Roll to roll technology for display manufacturing. J KSME 46(12):62–66

Acknowledgements

This research was supported by the mid-career researchers program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (No. 2018R1A2B6003891).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, Y., Kim, M., Kim, T. et al. Printing pressure uniformization of a roll-to-roll system using roll runout. Microsyst Technol 24, 4561–4568 (2018). https://doi.org/10.1007/s00542-018-3941-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-3941-z