Abstract

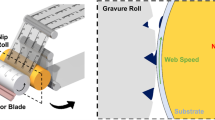

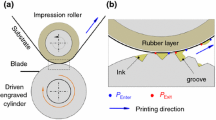

Recently, printed electronics technology can be used in conductive printed patterns and flexible displays. The transfer ratio in this process is influenced by the conditions of the printing surface, the properties of the conductive ink material, and the printing speed, which are important factors that affect the printing quality. This study examines the transfer characteristics of conductive ink transferred from various micro-patterns onto flexible film substrates using a roll-to-plate process. Various patterns with different aspect ratios were printed at different printing speeds to determine the ink transfer characteristics and printability. The optimum printing speed for characterizing the printing quality is related to the shape of the patterns, and it is more affected by the depth than the width of the pattern according to experiments. The transfer ratio increases with the force aspect ratio.

Similar content being viewed by others

References

Ahmed DH, Sung HJ, Kim DS (2011) Simulation of non-Newtonian ink transfer between two separating plates for gravure-offset printing. Int J Heat Fluid Flow 32:298–307

Ahn BJ, Han KJ, Ko SL (2010) Influence of micro pattern geometry and printing and curing conditions in gravure printing on printing performance when using conductive ink. Trans Korean Soc Mech Eng A 34(3):263–271

Dearden AL, Smith PJ, Shin DY, Reis N, Derby B, O’Brien P (2005) A low curing temperature silver ink for use in ink-jet printing and subsequent production of conductive tracks. Macromol Rapid Commun 26(4):315–318

Elsayad S, Morsy F, El-Sherbiny S, Abdou E (2002) Some factors affecting ink transfer in gravure printing. Pigm Resin Technol 31(4):234–240

Hagberg J, Pudas M, Leppävuori S, Elsey K, Logan A (2001) Gravure offset printing development for fine line thick film circuits. Microelectron Int Int J 18:32–35

Hahne P, Hirth E, Reis IE, Schwichtenberg K, Richtering W, Horn FM, Eggenweiler U (2001) Progress in thick-film pad printing technique for solar cells. Sol Energy Mater Sol Cells 65:399–407

Kim CH, Lee TM, Kim DS, Choi BO (2007) Distortion of printed patterns in printed electronics. J Korean Soc Precis Eng 24(8):74–80

Kim Y, Park S, Shin K, Bai C, Shim J (2016) Effect of cycloid movement on plate-to-roll gravure offset printing. Microsyst Technol 22(2):357–365

Lee S, Na Y (2010) Analysis on the ink transfer mechanism in R2R application. J Mech Sci Technol 24:293–296

Mikami Y, Nagae Y, Mori Y, Kuwabara K, Saito T, Hayama H et al (1994) A new patterning process concept for large area transistor circuit fabrication without using an optical mask aligner. IEEE Trans Electron Device 41(3):306–314

Otero TF, Cantero I (1999) Conducting polymers as positive electrodes in rechargeable lithium-ion batteries. J Power Sources 81:838–841

Oyama M (2010) Recent nanoarchitectures in metal nanoparticle-modified electrodes for electroanalysis. Anal Sci 26(1):1–12

Park SS, Jeon Y, Cho M, Bai C, Lee DY, Shim J (2012) The FEM based liquid transfer model in gravure offset printing using phase field method. Microsyst Technol 18:2027–2034

Pudas M, Hagberg J, Leppävuori S (2002) The absorption ink transfer mechanism of gravure offset printing for electronic circuitry. IEEE Trans Electron Packag Manuf 25:335–343

Pudas M, Hagberg J, Leppävuori S, Elsey K, Logan A (2004a) Methods for the evaluation of fine-line offset gravure printing inks for ceramics. Color Technol 120:119–126

Pudas M, Hagberg J, Leppävuori S (2004b) Printing parameters and ink components affecting ultra-fine-line gravure-offset printing for electronics applications. J Eur Ceram Soc 24:2943–2950

Sankaran AK, Rothstein JP (2012) Effect of viscoelasticity on liquid transfer during gravure printing. J Nonnewton Fluid Mech 175–176:64–75

Xing Y, Rosner DE (1999) Prediction of spherule size in gas phase nanoparticle synthesis. J Nanopart Res 1(2):277–291

Yin X, Kumar S (2005) Lubrication flow between a cavity and a flexible wall. Phys Fluids (1994–Present) 17(6):063101

Yin X, Kumar S (2006) Flow visualization of the liquid emptying process in scaled-up gravure grooves and cells. Chem Eng Sci 61(4):1146–1156

Yin W, Lee DH, Choi J, Park C, Cho SM (2008) Screen printing of silver nanoparticle suspension for metal interconnects. Korean J Chem Eng 25(6):1358–1361

Acknowledgements

This research was supported by the Yeungnam University research Grants in 2015.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jeong, S., Lee, C., Shim, J. et al. Experimental study of micro patterns on conductive ink transfer in a plate-to-roll system. Microsyst Technol 23, 5467–5475 (2017). https://doi.org/10.1007/s00542-017-3341-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3341-9