Abstract

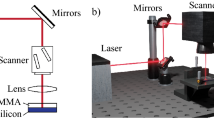

A magnetic field pulling-force assisted bonding technology is reported, which is used to bond a mirror plate with a released microactuator using adhesive. This bonding technology is not sensitive to the micromachining process, i.e., any process for microactuator fabrication containing the ferromagnetic structure layer can be used and bonded with a high surface quality mirror plate after released. The conventional wafer bonding technology bonds unreleased actuator with a mirror plate but it limits to the process compatible with the wafer bonding with a releasing step suitable for wafer bonding. Consequently not all processes (such as those mature and commercially available, and those being able to generate large displacement) can be used to fabricate micromirrors. The bonding technology proposed in this paper applies non-touching magnetic field pulling-force, instead of conventional compression mechanical force through touching, to bring the microactutor and a mirror plate in contact for bonding such as to avoid: (1) any plastic deformation or damage to the released micro actuator; and (2) the risk of sticking the actuator moving part to the substrate due to the adhesive squeezed out from the bonding surfaces. The bonding method is introduced and the critical parameters of the bonding method, i.e., distance between the magnet to the actuator is determined through simulations. A bonding mechanism is built and two different designs are bonded. Bonding results are measured, which verifies the bonding method. The bonding is characterized to have a strength of withstanding vibration for a few hours in frequency 20–200 Hz with 2–5 g acceleration and surviving in the temperature of −30 to 80 °C. After bonding a mirror plate with 15.6 m of the curvature radius and 2 nm of the roughness, the bonded micromirror is tested to have a quasi-static displacement of 120 μm.

Similar content being viewed by others

References

Ataman Ç, Lani S, Noell W, de Rooij N (2013) A dual-axis pointing mirror with moving-magnet actuation. J Micromechanics Microengineering 23(2):25002

Bai Y, Yeow JTW, Wilson BC (2010) Design, fabrication, and characterization of a 2-D SOI MEMS micromirror with sidewall electrodes for confocal MACROscope imaging, vol 19, no 3. Ph.D thesis, University of Waterloo, pp 619–631

Bai Y, Pallapa M, Chen A, Constantinou P, Damaskinos S, Wilson BC, Yeow JTW (2012) A 2D MEMS mirror with sidewall electrodes applied for confocal MACROscope imaging. J Microscopy 245(2):210–220

Chao F, He S, Chong J, Ben Mrad R, Feng L (2011) Development of a micromirror based laser vector scanning automotive HUD. In: 2011 IEEE International Conference on Mechatronics and Automation ICMA, pp 75–79

Cho HJ, Ahn CH (2002) Electroplated permanent magnet arrays. Structure 11(1):78–84

Cho I-J, Yoon E (2009) A low-voltage three-axis electromagnetically actuated micromirror for fine alignment among optical devices. J Micromechanics Microengineering 19(8):85007

Chong J, He S, Ben R (2012) Mrad, “Development of a vector display system based on a surface-micromachined micromirror”. IEEE Trans Ind Electron 59(12):4863–4870

Cowen A, Dudley B, Hill E, Walters M, Wood R (2009) MetalMUMPs design handbook a MUMPs ® process, pp 1–39

Debray A, Ludwig A, Bourouina T, Asaoka A, Tiercelin N, Reyne G, Oki T, Quandt E, Muro H, Fujita H (2004) Application of a multilayered magnetostrictive film to a micromachined 2-D optical scanner. J Microelectromechanical Syst 13(2):264–271

Fan C, He S (2015) A two-row interdigitating-finger repulsive-torque electrostatic actuator and its application to micromirror vector display. J Microelectromechanical Syst 24(6):2049–2061

He S, Chang JS (2009) Experimental verification of an out-of-plane repulsive-force electrostatic actuator using a macroscopic mechanism. Microsyst Technol 15(3):453–461

He S, Mrad RB (2003) Development of a novel translation micromirror for adaptive optics. Proc SPIE 5264:154–161

He S, Mrad RB (2005) Large-stroke microelectrostatic actuators for vertical translation of micromirrors used in adaptive optics. IEEE Trans Ind Electron 52(4):974–983

He S, Mrad RB (2008) Design, modeling, and demonstration of a MEMS repulsive-force out-of-plane electrostatic micro actuator. J Microelectromechanical Syst 17(3):532–547

He S, Mrad RB, Chang JS (2010) Development of a high-performance microelectrostatic repulsive-force rotation actuator. J Microelectromechanical Syst 19(3):561–569

Ho J, Haesoo K, Seung J, Lee K, Hyeon C, Jae J, Park H (2016) Electromagnetically actuated biaxial scanning micromirror fabricated with silicon on glass wafer. Microsyst Technol 1–11. doi:10.1007/s00542-016-2949-5

Jeong JW, Kim S, Solgaard O (2012) Split-frame gimbaled two-dimensional MEMS scanner for miniature dual-axis confocal microendoscopes fabricated by front-side processing. J Microelectromechanical Syst 21(2):308–315

Leahy S, Lai Y (2016) An hourglass design with electrokinetic sampling and electrothermal actuation for micro biosensors. Sens Actuators B Chem 223:123–130

Liu B, Li D, Yang X, Li X (2006) Design and fabrication of a micro electromagnetic actuator. In: Proceedings of 1st IEEE International Conference on Nano Micro Engineered and Molecular Systems 1st IEEE-NEMS, pp 353–356

Loctite 312 (2004) Technical Data Sheet, Loctite [Online]

Loctite 736 (2004) Technical Data Sheet, Loctite [Online]

Ra H, Piyawattanametha W, Taguchi Y, Lee D, Mandella MJ, Solgaard O (2007) Two-dimensional MEMS scanner for dual-axes confocal microscopy. J Microelectromechanical Syst 16(4):969–976

Sadat SH, Kamiya D, Bagheri S, Horie M (2008) 2 Degree-of-freedom spiral micromirror manipulator. J Adv Mech Des Syst Manuf 2(2):265–270

Sadat SH, Kamiya D, Horie M (2009) Large-deflection spiral-shaped micromirror actuator. J Microelectromechanical Syst 18(6):1357–1364

Sadler DJ, Liakopoulos TM, Ahn CH (2000) Universal electromagnetic microactuator using magnetic interconnection concepts. J Microelectromechanical Syst 9(4):460–468

Solgaard O, Godil AA, Howe RT, Lee LP, Peter YA, Zappe H (2014) Optical MEMS: from micromirrors to complex systems. J Microelectromechanical Syst 23(3):517–538

Streque J, Talbi A, Pernod P, Preobrazhensky V (2012a) Pulse-driven magnetostatic micro-actuator array based on ultrasoft elastomeric membranes for active surface applications. J. Micromechanics Microengineering 22:95020

Streque J, Talbi A, Bonnerot C, Pernod P, Preobrazhensky V (2012) Magnetostatic micro-actuator based on ultrasoft elastomeric membrane and copper—permalloy electrodeposited structures. In: 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems, pp 1157–1160

Tang T, Fang W (2011) Magnetostatic torsional actuator with embedded nickel structures for the improvement of driving force and wobble. J Micromechanics Microengineering 21:095007

Van Kessel PF, Hornbeck LJ, Meier RE, Douglass MR (1998) A MEMS-based projection display. Proc IEEE 86(8):1687–1704

Wang Y, Gokdel YD, Triesault N, Wang L (2014) Magnetic-actuated stainless steel scanner for two-photon hyperspectral fluorescence microscope. J Microelectromechanical Syst 23(5):1208–1218

Weber N, Hertkorn D, Zappe H, Seifert A (2012a) Polymer/silicon hard magnetic micromirrors. J Microelectromechanical Syst 21(5):1098–1106

Weber N, Zappe H, Seifert A (2012b) An all-nickel magnetostatic MEMS scanner. J Micromechanics Microengineering 22(12):125008

Xue Y, He S (2017) A translation micromirror with large quasi-static displacement andhigh surface quality. J Micromechanics Microengineering 27(1):015009

Yang H-A, Fang W (2006) A novel coil-less lorentz force 2D scanning mirror using eddy current. In: 19th IEEE International Conference on Micro Electro Mechanical Systems, vol 16, no 3, pp 511–520

Yang Z, Jeong B, Vakakis A, Kim S (2015) A tip-tilt-piston micromirror with an elastomeric universal joint fabricated via micromasonry. J Microelectromechanical Syst 24(2):262–264

Zhou L, Kahn JM, Pister KSJ (2006) Scanning micromirrors fabricated by an SOI/SOI wafer-bonding process. J Microelectromechanical Syst 15(1):24–32

Zine-El-Abidine I, Okoniewski M (2007) A tunable radio frequency MEMS inductor using MetalMUMPs. J Micromechanics Microengineering 17(11):2280–2287

Zuo H, He S (2016) FPCB micromirror-based laser projection availability indicator. IEEE Trans Ind Electron 63(5):3009–3018

Zygo Nexview 3D optical surface profiler (2017) [Online]. http://www.zygo.com/?/met/profilers/nexview/

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, Y., He, S. Magnetic field assisted bonding technology for released micro actuator and mirror surface. Microsyst Technol 23, 4941–4955 (2017). https://doi.org/10.1007/s00542-017-3432-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3432-7