Abstract

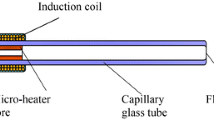

This paper designed a micro planar induction heater for thermal bubbles generation. The micro heater which consists of a micro planar coil, a copper heating plate and a glass slide was fabricated with MEMS fabrication process. The relations between the heating performance and the thickness of heating plate were studied in the simulation with the software of COMSOL. The experimental system has been built and the experimental tests for thermal bubble generation have been also carried out with the prototype. The process of thermal bubbles generation was recorded by the video camera. The frequency of AC current applied in the experiment is 100 kHz and the heating time of 1 s. The experimental results indicated that the micro heater has the best heating performance with the heating plate thickness of 12–16 μm, and the minimum power for thermal bubbles generation was only 0.427 W. This micro heater can be applied to a variety of thermal bubble devices, such as micro actuator, micro ejector and micro pump.

Similar content being viewed by others

References

Andersson H, van der Wijnggaart W, Nilsson P, Enoksson P, Stemme G (2001) A valve-less diffuser micropump for microfluidic analytical systems. Sens Actuators B 72:259–265

Chen M, Yuan L, Liu S (2007) Research on low-temperature anodic bonding using induction heating. Sens Actuators A 133:266–269

Hou Y, Liu B, Yang J (2014) Research on a large power thermal bubble micro-ejector with induction heating. Microsyst Technol. doi:10.1007/s00542-014-2367-5

Huang C, Tsou C (2014) The implementation of a thermal bubble actuated microfluidic chip with microvalve, micropump and micromixer. Sens Actuators A 210:147–156

Jeong OC, Konishi S (2007) Fabrication and drive test of pneumatic PDMS micro pump. Sens Actuators A 135:849–856

Jeong OC, Part SW, Yang SS, Pak JJ (2005) Fabrication of a peristaltic PDMS micropump. Sensors and Actuators A 123–124:453–458

Jung J-Y, Kwak H-Y (2007) Fabrication and testing of bubble powered micropumps using embedded microheater. Microfluid Nanofluid 3:161–169

Kranjc M, Zupanic A, Miklavcic D, Jarm T (2010) Numerical analysis and thermographic investigation of induction heating. Int J Heat Mass Transf 53:3585–3591

Li M, Xu H, Lee S-WR, Kim J, Kim D (2008) Eddy current induction heating for the solder reflow of area array packages. IEEE Trans Adv Packag 31:399–402

Liu B, Hou Y, Li D, Yang J (2015) A thermal bubble micro-actuator with induction heating. Sens Actuators A 222:8–14

Thompson K, Gianchandani YB, Booske J, Cooper RF (2002) Direct silicon—silicon bonding by electromagnetic induction heating. J Microelectromech Syst 11:285–292

Tsai J-H, Lin L (2002) A thermal-bubble-actuated micronozzle-diffuser pump. J Microelectromech Syst 11:665–671

Tsai J-H, Lin L (2007) Active microfluidic mixer and gas bubble filter driven by thermal bubble micropump. Sens Actuators A 97–98:665–671

van den Broek DM, Elwenspoek M (2008) Bubble nucleation in an explosive micro-bubble actuator. J Micromech Microeng 18:064003

Yokoyama Y, Takeda M, Umemoto T, Ogushi T (2004) Thermal micro pump for a loop-type micro channel. Sens Actuators A 111:123–128

Zhang K, Jian A, Zhang X, Wang Y, Li Z, Tam H (2011) Laser-induced thermal bubbles for microfluidic applications. Lab Chip 11:1389–1395

Acknowledgments

Project of the National Natural Science Foundation of China No. 51105011 supported this research. This work was supported by the Specialized Research Fund for the Doctoral Program of Higher Education (No. 20101103120002). China Scholarship Council supported this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, B., Hou, Y., Sun, J. et al. Study on the effect of heating plate thickness on the micro induction heater for thermal bubbles generation. Microsyst Technol 22, 1005–1011 (2016). https://doi.org/10.1007/s00542-015-2466-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2466-y