Abstract

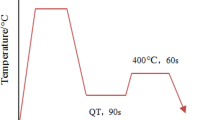

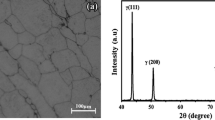

By applying a heat treatment, such as hardening and tempering, the properties of a heat treatable steel, like 42CrMo4, can be adjusted over a wide range. In addition to the heat treatment, an appropriate alloying concept is crucial to be able to guarantee an outstanding performance over a large variety of applications. In the present study, the effects of boron as a microalloying element on a heat treatable steel were examined. It is well known that boron, if added in a proper amount, can significantly retard the transformation of austenite to bainite or ferrite/pearlite in low alloyed steels. During the heat treatment, it diffuses to the austenite grain boundaries, where it reduces the driving force for the nucleation of new phases. In order to prove this theory in a heat treatable steel, a prior austenite grain boundary was prepared for atom probe tomography (APT). The specimen preparation was carried out by electro-polishing, etching, and sharpening by focused ion beam (FIB) in combination with transmission Kikuchi diffraction (TKD). In the reconstruction of the corresponding APT measurement, boron could be found at the same prior austenite grain boundary.

Zusammenfassung

Durch gezielte Wärmebehandlungen wie Härten und Anlassen können die Eigenschaften eines Vergütungsstahls wie 42CrMo4 in einem großen Bereich eingestellt werden. Zusätzlich zu einer optimierten Wärmebehandlung ist auch das Legierungskonzept entscheidend, wenn man eine herausragende Leistungsfähigkeit in einer Vielzahl von Anwendungen garantieren will. Die Wirkung von Bor als Mikrolegierungselement in einem Vergütungsstahl wurde in dieser Arbeit untersucht. Laut Literatur verzögert Bor in der richtigen Konzentration die Umwandlung von Austenit zu Bainit oder Ferrit/Perlit, indem es während der Wärmebehandlung an die Austenitkorngrenzen diffundiert und dort die Triebkraft für eine Keimbildung neuer Phasen verringert. Um diese Theorie in einem Vergütungsstahl zu verifizieren, wurde eine ehemalige Austenitkorngrenze für eine Untersuchung mit der Atomsonde präpariert. Die Probenpräparation erfolgte durch elektrolytisches Polieren, Ätzen und Spitzen mittels Focused Ion Beam (FIB) in Kombination mit Transmission Kikuchi Diffraktion (TKD). In der Rückkonstruktion der anschließenden Messung mit der Atomsonde konnte Bor an der ehemaligen Austenitkorngrenze gefunden werden.

Similar content being viewed by others

References

Keown, S. R.; Pickering, F. B.: Some aspects of the occurrence of boron in alloy steels, Materials science and technology, 11 (1977), no. 7, pp 225–234

He, X. L.; Chu, Y. Y.; Jonas, J. J.: The grain boundary segregation of boron during isothermal holding, Acta metallurgica, 37 (1989), no. 11, pp 2905–2916

Mun, D. J.; Shin, E. J.; Cho, K. C.; Lee, J. S.; Koo, Y. M.: Cooling rate dependence of boron distribution in low carbon steel, Metallurgical and materials transactions A, 43 (2012), no. 5, pp 1639–1648

Simcoe, C. R.; Elsea, A. R.; Manning, G. K.: Study of the effect of boron on the decomposition of austenite, Journal of metals, 7 (1955), pp 193–200

Melloy, G. F.; Slimmon, P. R.; Podgursky, P. P.: Optimizing the boron effect, Metallurgical transactions, 4 (1973), no. 10, pp 2279–2289

Miller, M. K.; Cerezo, A.; Hetherington, M. G.; Smith, G. D. W.: Atom probe field ion microscopy, Oxford: Clarendon Press, 1996

Schacht, E.; Richter, J.: Experiences with etching reagents to show former austenite grain boundaries in steels, Praktische Metallographie, 35 (1998), no. 7, pp 384–395

Babinsky, K.; De Kloe, R.; Clemens, H.; Primig, S.: A novel approach for site-specific atom probe specimen preparation by focused ion beam and transmission electron backscatter diffraction, Ultramicroscopy, 144 (2014), pp 9–18

Miller, M. K.; Forbes, R. G.: Atom probe tomography, Materials characterization, 60 (2009), no. 6, pp 461–469

Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T.: The morphology and crystallography of lath martensite in Fe-C alloys, Acta materialia, 51 (2003), no. 6, pp 1789–1799

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haslberger, P., Turk, C., Babinsky, K. et al. Boron Grain Boundary Segregation in a Heat Treatable Steel. Berg Huettenmaenn Monatsh 160, 204–208 (2015). https://doi.org/10.1007/s00501-015-0358-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-015-0358-1

Keywords

- Heat treatable steel

- Boron

- Austenite grain boundary

- Transmission Kikuchi diffraction

- Atom probe tomography