Abstract

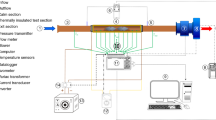

In the present work, design of experiments has been used to study the effect of thermal parameters on heat transfer enhancement in a double pipe heat exchanger using a passive technique. A twisted tape is considered as the heat augmentation device with tape width, tape pitch and mass flow rate as the input parameters and Nusselt number (Nu) and pressure drop (ΔP) as the output variables. Response Surface methodology (RSM) is used to develop a mathematical prediction model. The effect of the above input parameters on Nu and ΔP was investigated by ANOVA analysis. It showed that both linear and interaction terms are influencing the responses. Results reveal that mass flow rate and pitch of the tape are significant for Nu, whereas mass flow rate and tape width are significant for pressure drop. In the tested range, optimum conditions for higher Nu and lower ΔP were determined using RSM optimizer. Optimum values of Nu and ΔP were obtained corresponding to a tape pitch of 20 mm, width of 3.8 mm and a mass flow rate of 0.5 kg/s with optimum values for Nu and ΔP being 48 and 895 Pa.

Similar content being viewed by others

Abbreviations

- CCD:

-

Central composite design

- CFD:

-

Computational fluid dynamics

- Nu :

-

Nusselt number

- RSM:

-

Response surface methodology

- ΔP :

-

Pressure drop (Pa)

References

Arqub OA, Abo-Hammour Z (2014) Numerical solution of systems of second-order boundary value problems using continuous genetic algorithm. Inf Sci 279:396–415

Bansal G, Sodhi HS, Singh J (2014) Optimisation of machining parameters for MRR in boring operation using RSM. IJRMET 4(2)

Chiang KT, Chou CC, Liu NM (2009) Application of response surface methodology in describing the thermal performances of a pin-fin heat sink. Int J Therm Sci 48(6):1196–1205

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C (2010a) Thermo hydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of center wings and alternate-axes. Exp Thermal Fluid Sci 34:1151–1161

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2010b) Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int Commun Heat Mass Transf 37:39–46

El Maakoul A, Laknizi A, Saadeddine S, Abdellah AB, Meziane M, El Metoui M (2017) Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger. Energy Convers Manag 133:76–86

Esfe MH, Hajmohammad MH (2017) Thermal conductivity and viscosity optimization of nanodiamond-Co3O4/EG (40: 60) aqueous nanofluid using NSGA-II coupled with RSM. J Mol Liq 238:545–552

Kou G, Ergu D, Lin C, Chen Y (2016) Pairwise comparison matrix in multiple criteria decision making. Technol Econ Dev Econ 22(5):738–765

Kumar S, Dinesha P (2018) Optimization of engine parameters in a bio diesel engine run with honge methyl ester using response surface methodology. Measurement 125:224–231

Kumar A, Prasad BN (2000) Investigation of twisted tape inserted solar water heaters—heat transfer, friction factor and thermal performance results. Renew Energy 19:379–398

Kumar SP, Mahanta P, Dewan A (2003) A study of laminar flow in a large diameter annulus with twisted tape inserts. In: Proceedings of 2nd international conference on heat transfer, fluid mechanics, and thermodynamics, Victoria Falls, Zambia

Kumar S, Pai PS, Rao BS, Vijay GS (2016) Prediction of performance and emission characteristics in a biodiesel engine using WCO ester: a comparative study of neural networks. Soft Comput 20(7):2665–2676

Lohrasbi S, Sheikholeslami M, Ganji DD (2017) Multi-objective RSM optimization of fin assisted latent heat thermal energy storage system based on solidification process of phase change material in presence of copper nanoparticles. Appl Therm Eng 118:430–447

Makadia AJ, Nanavati JI (2013) Optimisation of machining parameters for turning operations based on response surface methodology. Measurement 46(4):1521–1529

Minitab Statistical software (2007) Release 15 for windows

Noothong W, Eiamsa-ard S, Promvonge P (2006) Effect of twisted-tape inserts on heat transfer in a tube. In: 2nd joint international conference on sustainable energy and environment (SEE 2006) Bangkok, Thailand, pp 1–5

Pai D, Rao S, Shetty R (2012) Application of Taguchi and RSM for metal removal rate and surface roughness in grinding of DRAC’s. IJEMS 3(1):1–8

Pardhi CK, Baredar P (2013) Performance improvement of double pipe heat exchanger by using tabulator. IJESET 2(4):881–885

Patel HS, Makadia RN (2013) A review on performance evaluation and CFD analysis of double pipe heat exchanger. Paripex-Indian J Res 2(4):84–86

Rao S, Milkey KR, Samsudin AR, Dubey AK, Kidd P (2014) Comparision between Taguchi and RSM methodology in modeling CO2 laser machining. JJMIE 8(1):35–42

Rashidi S, Eskandarian M, Mahian O, Poncet S (2018) Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. https://doi.org/10.1007/s10973-018-7070-9

Ray S, Date AW (2003) Friction and heat transfer characteristics of flow through square duct with twisted tape insert. Int J Heat Mass Transf 46:889–902

Salem MR, Althafeeri MK, Elshazly KM, Higazy MG, Abdrabbo MF (2017) Experimental investigation on the thermal performance of a double pipe heat exchanger with segmental perforated baffles. Int J Therm Sci 122:39–52

Sarada N, Raju S, KalyaniRadha AV, Shyam K (2010) Enhancement of heat transfer using varying width twisted tape inserts. Int J Eng Sci Technol 2(6):107–118

Shoo P (2011) Optimization of turning parameters for surface roughness using RSM and GA. Adv Prod Eng Manag 3:197–208

Un Z, Bi W (2009) Convective heat transfer enhancement in a circular tube using twisted tape. J Heat Transf 131(8):81–91

Zhou Y, Kou G, Ergu D (2012) Three-grade preventive maintenance decision making. Proc Rom Acad A Math Phys Tech Sci Inf Sci 13:133–140

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by the author.

Additional information

Communicated by V. Loia.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Dinesha, P. Optimization of thermal parameters in a double pipe heat exchanger with a twisted tape using response surface methodology. Soft Comput 22, 6261–6270 (2018). https://doi.org/10.1007/s00500-018-3374-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-018-3374-8