Abstract

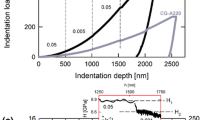

In the present study, nanoindentation and macroindentation tests are performed on a soft polymer: polyurethane (PU). Strong viscoelasticity is represented by the force-displacement data on both scales. A finite element method based on an inverse procedure is employed to identify the nonlinear viscoelasticity of PU. An appropriate viscoelastic model is chosen, and the corresponding parameters are identified by matching the experimental responses with the predictions of the computational model. At the very beginning, the uniaxial tensile test, which has a homogeneous deformation, is used to prove the isotropic properties and incompressibility of PU and to identify the viscoelasticity as a reference and verification source. The comparison between the identified results from nanoindentation and macroindentation allows to quantifying the adhesion effects in nanoindentation. The quantification is treated with a traction–separation relationship incorporated into the numerical adhesive contact model. Comparable strain rates in the macro-, nanoindentation and uniaxial tensile tests are considered to identify the viscoelasticity.

Similar content being viewed by others

Notes

The samples’ preparation by the Chair for Adhesion and Interphases in Polymers at Saarland University is gratefully acknowledged.

The nanoindentation experiments were performed using the device of the chair of material science and methodology at Saarland University under the direction of Prof. H. Vehoff.

References

Abaqus 6.11 analysis user’s manual. http://abaqus.ethz.ch:2080/v6.11/books/usb/default.htm

Baaser, H., Noll, R.: Simulation von elastomerbauteilen-materialmodelle und versuche zur parameterbestimmung, pp. 1–10. DVM-Tag Elastomere, Berlin (2009)

Bolzon, G., Maier, G., Panico, M.: Material model calibration by indentation, imprint mapping and inverse analysis. Int. J. Solids Struct. 41, 2957–2975 (2004)

Chen, Z.: Nanoindentation testing of soft polymers: Computation, experiments and parameters identification. Dissertation, Shaker Verlag, Aachen (2014)

Chen, Z., Diebels, S.: Modelling and parameter re-identification of nanoindentation of soft polymers taking into account effects of surface roughness. Comput. Math. Appl. 64, 2775–2786 (2012a)

Chen, Z., Diebels, S.: Nanoindentation of hyperelastic polymer layers at finite deformation and parameter re-identification. Arch. Appl. Mech. 82, 1041–1056 (2012b)

Chen, Z., Diebels, S.: Parameter re-identification in nanoindentation problems of viscoelastic polymer layers: small deformation. J. Appl. Math. Mech./Z. Angew. Math. Mech. (ZAMM) 93, 88–101 (2013)

Chen, Z., Diebels, S., Peter, N.J., Schneider, A.S.: Identification of finite viscoelasticity and adhesion effects in nanoindentation of a soft polymer by inverse method. Compu. Mater. Sci. 72, 127–139 (2013a)

Chen, Z., Scheffer, T., Seibert, H., Diebels, S.: Macroindentation of a soft polymer: identification of hyperelasticity and validation by uni/biaxial tensile tests. Mech. Mater. 64, 111–127 (2013b)

Drozdov, A.: Finite Elasticity and Viscoelasticity. World Scientific Publishing, Singapore (1996). Please check and confirm the inserted publisher location for the reference [10]

Fischer-Cripps, A.C.: Nanoindentation. Springer, New York (2004)

Giannakopoulos, A.E., Triantafyllou, A.: Spherical indentation of incompressible rubber-like material. J. Mech. Phys. Solids. 55, 1196–1211 (2007)

Govindjee, S., Simo, J.C.: Mullinseffect and the strainamplitude dependence of the storagemodulus. Int. J. Solids Struct. 29, 1737–1751 (1992)

Guessasma, S., Sehaki, M., Lourdin, D., Bourmaud, A.: Viscoelasticity properties of biopolymer composite material determined using finite element calculation and nanoindentation. Comput. Mater. Sci. 44, 371–377 (2008)

Gupta, S., Carrillo, F., Li, C., Pruitt, L., Puttlitz, C.: Adhesive forces significantly affect elastic modulus determination of soft polymeric materials in nanoindentation. Mater. Lett. 61, 448–451 (2007)

Hartmann, S., Gibmeier, J., Scholtes, B.: Experiments and material parameter identification using finite elements. Uniaxial tests and validation using instrumented indentation tests. Exp. Mech. 46, 5–18 (2006)

Hertz, H.: Über die Berührung fester elastischer Körper. J. f Reine u. Angew. Math. 92, 156–171 (1881)

Holzapfel, G.A.: Nonlinear Solid Mechanics: A Continuum Approach for Engineering. Lohn Wiley & Sons Ltd, England (2001)

Holzapfel, G.A., Simo, J.C.: A new viscoelastic constitutive model for continuous media at finite thermomechanical changes. Int. J. Numer. Methods Eng. 33, 3019–3034 (1996)

Huber, N., Tyulyukovskiy, E.: A new loading history for identification of viscoplastic properties by spherical indentation. J. Mater. Res. 19, 101–113 (2004)

Huber, N., Nix, W.D., Gao, H.: Identification of elastic-plastic material parameters from pyramidal indentation of thin films. Proc. R. Soc. Lond. Ser. Math. Phys. Eng. Sci. 458, 1593–1620 (2002)

Johlitz, M., Diebels, S.: Characterisation of a polymer using biaxial tension tests. Part I: hyperelasticity. Arch. Appl. Mech. 81, 1333–1349 (2011)

Klötzer, D., Ullner, C., Tyulyukovskiy, E., Huber, N.: Identification of viscoplastic material parameters from spherical indentation data. Part II: experimental validation of the method. J. Mater. Res. 21, 677–684 (2006)

Koprowski-Theiß, N., Johlitz, M., Diebels, S.: Modelling of a cellular rubber with nonlinear viscosity functions. Exp. Mech. 51, 749–765 (2011)

Le Saux, V., Macro, Y., Bles, G., calloch, S., Moynea, S., Plessisa, S., Charrierb, P.: Identification of constitutive model for rubber elasticity from micro-indentation tests on natural rubber and validation by macroscopic tests. Mech. Mater. 43, 775–786 (2011)

Liao, Q., Huang, J., Zhu, T., Xiong, C., Fang, J.: A hybrid model to determine mechanical properties of soft polymers by nanoindentation. Thin Solid Films 16, 1043–1047 (2010)

Liu, K., VanLandingham, M.R., Ovaert, T.C.: Mechanical characterization of soft viscoelastic gels via indentation and optimization-based inverse finite element analysis. J. Mech. Behav. Biomed. Mater. 2, 355–363 (2009)

Lubliner, J.: A model of rubber viscoelasticity. Mech. Res. Commun. 12, 93–99 (1985)

Marckmann, G., Verron, E.: Comparison of hyperelastic models for rubber-like materials. Rubber Chem. Technol. 79, 835–858 (2005)

Mata, M., Alcalá, J.: The role of friction on sharp indentation. J. Mech. Phys. Solids 455, 145–165 (2004)

Oliver, W.C., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992)

Oliver, W.C., Pharr, G.M.: Measurement of hardness and elastic modulus by instrumented indentation: advance in understanding and refinements to methodology. J. Mater. Res. 19, 3–20 (2004)

Pharr, G.M., Oliver, W.C., Brotzen, F.R.: On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7, 613–617 (1992)

Rauchs, G., Bardon, J.: Identification of elasto-viscoplastic material parameters by indentation testing and combined finite element modelling and numerical optimization. Finite Elem. Anal. Des. 47, 653–667 (2011)

Rauchs, G., Bardon, J., Georges, D.: Identification of the material parameters of a viscous hyperelastic constitutive law from spherical indentation tests of rubber and validation by tensile tests. Mech. Mater. 42, 961–973 (2010)

Rivlin, R.S.: Large elastic deformations of isotropic materials. iv. Further developments of the general theory. Philos. Trans. R. Soc. Lond. A241, 379–397 (1948)

Sedlan, K.: Viskoelastisches Materialverhalten von Elstomerwerkstoffen: Experimentelle Untersuchung und Modellbildung. Dissertation, Universität Gesamthochschule Kassel (2000)

Simo, J.C.: On a fully three-dimensional finite-strain viscoelastic damage model: formulation and computational aspects. Comput. Methods Appl. Mech. Eng. 60, 153–173 (1987)

Sneddon, I.N.: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47–57 (1965)

Tyulyukovskiy, E., Huber, N.: Identification of viscoplastic material parameters from spherical indentation data. Part I: neural networks. J. Mater. Res. 21, 664–676 (2006)

Tyulyukovskiy, E., Huber, N.: Neural networks for tip correction of spherical indentation curves from bulk metals and thin metal films. J. Mech. Phys. Solids 55, 391–418 (2007)

Wang, J., Ovaert, T.C.: Computational mechanical property determination of viscoelastic/plastic materials from nanoindentation creep test data. J. Mater. Res. 24, 1245–1257 (2009)

Zhao, Y.P., Shi, X.H., Li, W.J.: Effect of work of adhesion on nanoindentation. Rev. Adv. Mater. Sci. 5, 348–353 (2003)

Acknowledgments

The authors are grateful to the DFG (German Science Foundation—Deutsche Forschungsgemeinschaft) for financial support through the Grant number Di 430/14. The work of the student research assistant Martin Müller at the Chair of Applied Mechanics, Univ. Saarland is appreciated. The authors thank Dipl.-Ing. M. Zamanzade at the Chair of Material Science and Methodology at Saarland University and B.Sc N. Peter and Dr. A. Schneider in the Leibniz Institute for New Materials (INM), Saarland University for useful discussion during the indentation experiments as well as Dipl.-Ing. L. Krogh at the Chair for Adhesion and Interphases in Polymers at Saarland University for supplying the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Diebels, S. Indentation of PU at different scales and computational modeling: identification of viscoelasticity and quantification of adhesion effects. Arch Appl Mech 85, 1225–1243 (2015). https://doi.org/10.1007/s00419-015-1008-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-015-1008-5