Abstract

Talc and 10-Å phase are hydrous phases that are implicated in fluid processes and rheological behaviour in subduction zones. Natural samples of talc show limited compositional variation away from the MgO–SiO2–H2O (MSH) endmember, with only substitution of Fe2+ for Mg occurring in significant amounts. In experiments at 2 GPa, talc containing 0.48 apfu Fe2+ begins to break down in the divariant field talc + anthophyllite + quartz at ~ 550 °C, a temperature ~ 270 °C lower than in the MSH system. At 4 GPa, Fe-bearing talc breaks down over a wide temperature interval in the divariant field talc + enstatite + coesite. The large decrease in temperature of the beginning of talc breakdown shows that Fe2+ is partitioned strongly into enstatite and anthophyllite with respect to talc. In phase reversal experiments at 6.5 GPa, the beginning of the dehydration of 10-Å phase containing 0.48 apfu Fe2+ was bracketed between 575 °C and 600 °C, a temperature ~ 100 °C lower than the MSH endmember reaction. The relative positions of the talc and 10-Å phase dehydration reactions indicate that the latter is able to accommodate greater Fe substitution, and is, therefore, more stable in Fe-bearing systems. In experiments at 6.2 GPa, 650 °C in the systems MgO–Al2O3–SiO2–H2O (MASH) and Na2O–MgO–Al2O3–SiO2–H2O (NMASH), 10-Å phase was synthesised that contains up to 0.5 apfu Al in the system MASH (compared to 0.8 in the starting material) and up to 0.4 apfu Al + 0.4 apfu Na in the system NMASH (compared to 0.7 of each of Al and Na in the starting material). Further experiments are required to determine if higher Al and Na contents in 10-Å phase are possible. The much higher Al and Na contents than found in talc indicate that, as with Fe, substitution of these elements enlarges the 10-Å phase stability field with respect to talc. In contrast to the effect of Fe, Al and Na also increase the stability of 10-Å phase relative to its thermal breakdown products enstatite + coesite.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Talc is an important carrier of H2O into the mantle at subduction zones, where it may occur in a wide range of rock types, from metamorphosed sediments to metabasites and metamorphosed ultramafic rocks (Evans and Guggenheim 1988). Its endmember composition is Mg3Si4O10(OH)2, making it most likely to form in Mg- and Si-rich bulk compositions. Such rocks include metasomatised peridotite in the descending slab, in which talc may be carried to mantle depths of at least 150 km (Pawley and Wood 1995), and mantle wedge peridotite metasomatised by silica-rich fluids escaping the slab. The fluid involved in its formation may be dominated by H2O or may be a complex C-O–H fluid (e.g. Bjerga et al. 2015; Sieber et al. 2018). Talc is an extremely weak mineral (with a value of 1 on Mohs’ hardness scale) and therefore its presence at the slab-mantle interface has important implications for rheology and seismic velocity (e.g. Hirauchi et al. 2013; Kim et al. 2013).

Talc is unusual among trioctahedral phyllosilicates in showing limited solid solution away from the endmember composition. Therefore, previous studies of talc stability have focussed on this composition. However, the talc in many natural rocks contains a small but significant amount of substitution of Fe2+ for Mg. The highest Fe contents for natural talc have been recorded in banded iron formations and low pressure hydrothermally altered deposits, where the maximum Fe contents are in the range of 0.9–1.35 apfu (Corona et al. 2015). Fe-rich talc has also been found in a number of high-pressure metamorphic rocks. For example, Chopin (1981) reported 8.2 wt% FeO (0.44 apfu Fe2+) in talc from the blueschist facies ‘Schistes lustrés’ of the Gran Paridiso Massif in the Western Alps. Previous experimental studies relating to Fe in talc have focussed on determining the maximum amount of Fe that can be accommodated in the talc structure. Corona et al. (2015) produced 100% yields of Fe-bearing talc with the composition of XFe = 0.33 (0.99 apfu). At Fe contents above XFe = 0.50 (1.5 apfu), Fe-talc was accompanied by fayalitic olivine and/or magnetite, before total replacement by minnesotaite Fe3Si4O10(OH)2 at increased Fe contents. Corona et al. (2015) proposed a Fe saturation limit in talc of 1.11 apfu, and that beyond this limit further Fe incorporation is accompanied by modulation of the tetrahedral sheet creating the minnesotaite structure.

After Fe, Al substitution represents the most significant deviation from endmember chemistry in talc, but at concentrations much lower than for Fe [e.g. up to 0.4 wt% (0.03 apfu) Al in the Schistes lustrés of the Western Alps, Chopin 1981]. Both Tschermak’s substitution (AlAlMg−1Si−1) and pyrophyllite substitution (AlAlMg−1Mg−1Mg−1) have been proposed as mechanisms to incorporate Al in talc.

At high pressures, talc reacts with water to form 10-Å phase (TAP), a phyllosilicate with a high water content that is suggested to be an important carrier of water into subduction zones beyond the depth at which talc breaks down (e.g. Fumagalli and Poli 2005; Pawley et al. 2011). It is related to talc through the incorporation of interlayer H2O. The amount of this interlayer H2O has long been a matter of debate, with 0.65–2 H2O pfu proposed in different studies. Fumagalli et al. (2001) inferred from swelling behaviour upon treatment with acetone that the extent of hydration depends on run duration, while Pawley et al. (2011) inferred from phase-equilibrium experiments that there is 1 H2O pfu which is independent of run duration. It has also been proposed (Welch et al. 2006) that a small amount of hydrogarnet substitution Si4+ → 4H+ is required to stabilise the interlayer H2O, giving rise to the TAP formula Mg3Si(4−x)H4xO10(OH)2.yH2O. A value of x of 0.17 was determined by 29Si MAS NMR spectroscopy for the samples studied by Welch et al. (2006).

Given that the main crystal chemical change on transforming from talc to TAP is the incorporation of H2O in the interlayer of the talc structure, it might be expected that TAP would retain the same minor element composition as the talc from which it forms. However, the structure of TAP more closely resembles that of a mica than of talc (Fumagalli et al. 2001), with the interlayer H2O equivalent to the interlayer K+ or Na+ in mica, which opens up the possibility of substitutions such as Si4+ + H2O (TAP) =Al3+ + Na+ (aspidolite) or Si4+ + H2O (TAP) = Al3+ + K+ (phlogopite). The latter substitution was proposed by Fumagalli et al. (2009) to explain K deficiency in phlogopite encountered in high-pressure experiments on a K-doped lherzolite and was confirmed by Tao et al. (2017) in high-pressure experiments on a hydrated basalt. The latter authors produced TAP containing up to 0.4 K pfu. The Al content of their samples was much higher than required to charge balance the K, and the samples also contained much lower Mg contents than in typical TAP, and so Tao et al. (2017) proposed that their TAP is closer to a hydrated pyrophyllite [Al2Si4O10(OH)2] than a hydrated talc.

As well as mica-like substitutions, it has also been proposed that TAP can form a mixed-layer mineral with chlorite, allowing it to incorporate significant Al contents without the addition of interlayer cations. Fumagalli and Poli (2005) reported the synthesis of TAP containing up to 10.53 wt% Al2O3 (0.8 apfu Al), which they described as a mixed-layer mineral consisting of layers of TAP and clinochlore in the ratio 1:1, analogous to the mineral kulkeite, a 1:1 chlorite:talc mixed-layer phyllosilicate first described by Schreyer et al. (1982).

Here we report the results of an experimental study of the high-pressure stability of a typical Fe-talc composition, and of TAP with the same Mg:Fe ratio as the Fe-talc. We have also explored the incorporation of Al into TAP and whether Na also substitutes into TAP. From a comparison of the stabilities of Fe-bearing talc and TAP and their ability to incorporate other cations into their structures, we suggest that in typical compositions in subduction zones, the talc stability field is reduced with respect to the simple system MgO–SiO2–H2O (MSH) whereas the TAP stability field is much expanded.

Experimental procedure

Fe-talc and Fe-TAP (FMSH) experiments

An initial experiment used an Fe-rich starting material made from natural fayalite (Fo47Fa53) combined with silica glass, placing it on the join between talc and the hypothetical Fe-talc endmember at a ratio of 1.41 Mg: 1.59 Fe. The experiment at 2 GPa, 700 °C, with excess H2O, produced fayalite + quartz. This starting material was modified for subsequent experiments by adding pure synthetic talc to give a more Mg-rich bulk composition (FMSH2) with Mg: Fe = 2.52: 0.48. This composition is close to the maximum Fe content typically observed in natural talc samples from high-pressure metamorphic rocks (e.g. Chopin 1981). The starting material was homogenised by grinding in an agate pestle and mortar. All results reported here used either this starting material or the product of a previous experiment using this starting material.

The piston-cylinder and multi-anvil apparatus at the University of Manchester were used for experiments at pressures < 4 GPa and ≥ 4 GPa, respectively. Details of the apparatus and calibration are given in Bromiley and Pawley (2003). For each experiment, ~ 10 mg of powder was sealed in a 2.0 or 2.5 mm diameter Au capsule together with ~ 2 mg H2O. Also placed in the capsule was a small amount of ground graphite, used as an ƒO2 buffer. Maintaining constant ƒO2 was an important consideration in these experiments. Au was used to prevent hydrogen diffusion since it has negligible permeability to hydrogen at temperatures below 700 °C (Chou 1986) and hence limits oxidisation and the formation of Fe-oxides. The addition of a small amount of ground graphite to act as an ƒO2 buffer was based on the experimental method and assumptions of Fumagalli and Poli (2005), that given the relatively high volume of water added to the capsule and the low Fe content of the starting material, redox reactions would have a limited effect on the fluid added, therefore fixing the H:O ratio at 2:1.

Most experiments were synthesis experiments, in which run products are assumed to represent equilibrium assemblages. However, there is a danger that slow kinetics in low-temperature experiments will lead to disequilibrium assemblages, possibly containing metastable phases or not facilitating the growth of stable phases. Some additional experiments were therefore designed to be reversal experiments; such experiments typically use a mixture of reactants and products as starting material, and reaction direction is determined by observing changes in phase proportions.

Experimental run products were analysed using powder X-ray diffraction (XRD). Textures were observed using a FEI XL30 Environmental Scanning Electron Microscope (SEM), and Fourier Transform Infrared (FTIR) spectroscopy was used to examine Mg/Fe site occupancy in the octahedral sites in talc. FTIR spectra were obtained using a Spotlight 400 Infrared Spectrometer in attenuated total reflectance (ATR) mode. Quantification of relative peak intensities was performed using OriginPro software.

Al-TAP experiments (MASH and NMASH)

Experiments in the MASH system were conducted using a starting mixture (MASH1) composed of silica ground from glass (SiO2), synthetic brucite [Mg(OH)2], and a previously-synthesised sodium-free glaucophane gel (Mg3Al2Si8O22). The composition of MASH1 lies on the talc/TAP-‘Tschermak’s talc’ join (Fig. 1). The choice of this starting composition is based on the assumption of a Tschermak’s substitution (AlAlMg−1Si−1) acting in TAP to incorporate Al.

Projection from H2O in the MASH (red) and NMASH (blue) systems, showing the compositions of starting materials and relevant phases. Al- and Na-free phases are shown in black. The NMASH2 composition was measured by X-ray fluorescence; the compositions of the other starting materials are calculated from the weighed amounts of the component gels, SiO2 and Mg(OH)2. “Tsch-Talc”=hypothetical Tschermak’s talc [Mg2Al2Si3O10(OH)2], Cs coesite, En enstatite, Jd jadeite, TAP 10-Å phase (shown with no Si → 4H substitution)

Experiments in the NMASH system were conducted using two different starting mixtures (NMASH1 and NMASH2) composed of silica ground from glass (SiO2), synthetic brucite [Mg(OH)2], and a previously-synthesised jadeite gel (NaAlSi2O6). Both compositions lie on or close to the talc/TAP-aspidolite join (Fig. 1). The choice of these starting compositions is based on the assumption that the substitution NaAl(H2O)−1Si−1 will act in TAP to incorporate Na + Al.

For each experiment, ~ 10 mg of powder was sealed in a 2 mm diameter Pt capsule together with ~ 1 mg H2O. Run products were identified using powder XRD, and qualitative compositional analyses obtained using a FEI Quanta 650 FEG-ESEM with EDS analysis using a low vacuum and uncoated, unpolished samples. EDS analysis points were selected by choosing clean-looking euhedral to subhedral TAP crystals, in order to avoid contamination by other phases.

Results and discussion of FMSH experiments

The experimental run conditions and results of FMSH experiments are shown in Table 1. Experiments at 2 and 4 GPa produced talc, with TAP occurring at higher pressures.

Experiments at 2 and 4 GPa

The 2 GPa assemblages contained anthophyllite and quartz in addition to talc, with the proportion of anthophyllite increasing as temperature increases. This is observed in the XRD patterns for 2 GPa samples (Fig. 2) by the growth of the anthophyllite peak at ~ 10.5°2 theta. In the highest temperature run (FTC7, 750 °C), anthophyllite crystals were up to 0.1 mm long. Anthophyllite crystals had clean, straight edges and showed no textural evidence of reaction with talc (Fig. 3a).

Backscattered electron images of a FTC7 (2 GPa, 750 °C), showing platy talc and prismatic anthophyllite b FTAP10 (5.2 GPa, 555 °C), showing platy TAP, c ATAP2 (6.2 GPa, 650 °C), showing TAP crystals up to 20 μm diameter (Mg-sursassite was not identified by SEM), d NATAP1 (6.2 GPa, 650 °C), showing a 40 μm diameter TAP crystal surrounded by finer grained TAP and acicular pyroxene crystals

Attempts to analyse the talc compositions using electron probe microanalysis (EPMA) were unsuccessful due to the small crystal size and difficulty in polishing the samples. Compositions were therefore investigated using FTIR. FTIR spectroscopy can, in theory, be used to determine Mg:Fe ratios, since with increasing FeMg-1 substitution, the main OH-stretching band in Mg-talc, at ~ 3676 cm−1, splits into 4 bands, and it can be assumed that the total amount of a cation (here Fe or Mg) in the octahedral sites is directly proportional to the band intensity, multiplied by the number of cations in each configuration (e.g. Driscall et al. 2005; Corona et al. 2015). The four possible configurations in talc are:

-

Mg–Mg–Mg-OH ~ 3676 cm−1 (band A).

-

Mg–Mg-Fe-OH ~ 3663 cm−1 (band B).

-

Mg–Fe–Fe-OH ~ 3646 cm−1 (band C).

-

Fe–Fe–Fe-OH ~ 3625 cm−1 (band D).

Figure 4 shows the FTIR spectra for Fe-bearing talc samples from experiments at 2 GPa. With decreasing temperature the intensities of Fe-rich bands increase, with the lowest temperature sample, FTC2 (550 °C), showing the highest intensities for the lower wavenumber bands. Since FTC2 contains only a trace of anthophyllite (Fig. 2), it is assumed that the talc in this sample has the same Fe content as the bulk composition (FMSH2), with an Fe# of 0.16 [where Fe# = Fe/(Mg + Fe)].

Stacked FTIR spectra for samples from 2 GPa experiments. The inset spectrum is for natural talc sample 1 (see Table 2)

Gaussian curves were fitted to the peaks in the FTIR spectra using OriginPro, relative intensities calculated, and Fe contents determined (Table 2). The calculated Fe content for sample FTC2 from FTIR spectroscopy (Fe# = 0.25) is significantly higher than the bulk composition (Fe# = 0.16). A similar discrepancy was observed for two samples of natural talc for which FTIR spectra and EPMA compositions were obtained. This suggests that there is a systematic difference between band intensities observed in ATR spectra compared to those observed in traditional transmission spectra, with intensity increasing markedly as wavenumber decreases from band A to band D (corresponding to increasing Fe). We have therefore applied a systematic correction to the measured intensities of bands B – D. The correction factor increases linearly from band A to band D and was adjusted until the calculated composition for sample FTC2 was the same as the known composition of the starting material. The same correction factor was applied to the natural talc samples and resulted in similar compositions to the measured values from EPMA (Table 2). This coefficient was then used to recalculate the Fe content in talc for samples FTC5 and FTC6 (Table 2). FTIR peak fitting was not successful for the highest temperature experiment (FTC7) due to overlap with OH-stretching bands for anthophyllite. As for talc, anthophyllite can contain varying amounts of Fe. The equivalent bands in anthophyllite to bands A-D in talc are at approximately 3661, 3648, 3630 and 3617 cm−1, respectively (Strens 1974). The overlap of these frequencies with talc bands is too close to allow the anthophyllite bands to be distinguished from the talc bands. It may also be the case that anthophyllite-talc peak overlap in experiment FTC6 has compromised its calculated talc Fe#.

We were unable to measure anthophyllite compositions by EPMA for the same reason as for talc (fine grain size and poor polish). We have therefore estimated compositions by assuming a constant Mg–Fe partition coefficient, KD, between talc and anthophyllite, where KD = Fe#Tc/Fe#Anth, and Fe# = Fe/(Mg + Fe). We used a value of KD of 0.214, which was calculated from the compositional data for coexisting talc and anthophyllite in samples from the Central Alps (Evans and Trommsdorff 1974). Using Fe#Tc for samples FTC5 and FTC6 from FTIR spectroscopy, the calculated values of Fe#Antℎ are shown in Table 3.

We have also calculated the proportions of talc and anthophyllite (and quartz) in our run products by mass balance, assuming that the phases sum to the bulk composition of the starting material. It should have been possible to compare this calculation with proportions obtained by Rietveld analysis of the XRD patterns. However, convergence in the least-squares analysis was not achieved due to the extreme extent of preferred orientation of both the talc and the anthophyllite. We do, however, observe that our calculated ratios of talc to anthophyllite in experiments FTC5 and FTC6 (98:2 and 92:8, respectively) are reasonably consistent with the relative intensities of the strongest peaks in the XRD patterns (Fig. 2), in which the relative intensity of the anthophyllite (210) peak (10.6°2θ) with respect to the neighbouring talc (001) peak, is approximately three times the value in FTC6 as it is in FTC5. There is a further small increase in relative intensities of the anthophyllite peaks in FTC7, suggesting that it contains a few % more anthophyllite than FTC6. Table 3 shows the estimated compositions of the talc and anthophyllite in FTC7 for an assumed anthophyllite concentration of 11%. The compositions were calculated by mass balance, using the same KD as used to calculate the anthophyllite compositions in samples FTC5 and FTC6. It must be noted that all these compositions and proportions are only approximate; the only way to obtain accurate values would be to directly measure the compositions of both phases in each run product.

Our results at 2 GPa demonstrate that the addition of Fe to the system MSH increases its variance, with the univariant reactions of the MSH system becoming divariant fields, within which talc with varying Mg/Fe content is stable. The breakdown reaction of Fe-bearing talc towards Mg-rich compositions can be written:

where Talc_2 is more Mg-rich than Talc_1, and the anthophyllite is more Fe-rich than the talc. Figure 5a shows the compositions of talc and anthophyllite from experiments at 2 GPa, with respect to the bulk composition, showing a shift towards Mg-rich compositions with increasing temperature.

Projection from H2O in the FMSH system showing the compositions of talc and a anthophyllite (samples FTC5, FTC6 and FTC7) and b enstatite (samples FTC9 and FTC10) Compositions (mol %) are from Table 3, with the bulk composition indicated by the red circle

Experiments at 4 GPa produced the assemblage talc + enstatite + coesite, with a small amount of enstatite in FTC10 (585 °C), increasing at higher temperature (FTC9 at 610 °C). Talc compositions were determined through FTIR spectroscopy. Enstatite compositions were calculated using a partition coefficient of 0.275, taken from the values reported by Evans and Trommsdorff (1974) for ‘typical’ enstatite and talc compositions for samples from the Central Alps (Table 3).

These experiments at 4 GPa show Fe-bearing talc breaking down through an analogous reaction to Reaction 1, involving enstatite instead of anthophyllite:

Figure 5b shows the compositions of talc and enstatite from experiments at 4 GPa, assuming a constant KD between talc and enstatite of 0.275.

The stability of talc in the FMSH system

The results of experiments in the FMSH system demonstrate that the thermal stability of talc is reduced relative to its stability in MSH, breaking down in a series of divariant reactions to anthophyllite and quartz at 2 GPa, and enstatite and coesite at 4 GPa. Our results can be compared with calculated reactions using existing thermodynamic data. Figure 6 shows the predicted stability relations for the bulk composition Mg2.52Fe0.48Si4O10(OH)2.H2O (FMSH2), modelled using the thermodynamic software Perple_X (Connolly 1990; Connolly and Petrini 2002) with thermodynamic data for solid phases from Holland and Powell (1998), including: enthalpies of Fe-talc and Fe-anthophyllite derived from Fe–Mg partitioning data from natural assemblages; ideal Fe–Mg solution models for talc and anthophyllite; Fe–Mg mixing model for orthopyroxene from Holland and Powell (1996); equation of state of H2O from Holland and Powell (1991). Also shown on Fig. 6 are the P–T conditions of Fe-talc experiments. Figure 6 shows that the calculated position of the beginning of the thermal breakdown of talc with Fe# = 0.16 (Reaction 1) is at 550 °C at 2 GPa. At this temperature we observed a trace of anthophyllite in our experiment (FTC2), so the calculation is in quite good agreement with our observation. According to the calculation, however, by 750 °C the conditions are just above the anthophyllite breakdown reaction, so our observation of significant anthophyllite at this temperature indicates that the addition of Fe expands the stability field of anthophyllite more than calculated in Perple_X. That anthophyllite is stable over such a wide temperature interval at 2 GPa is a testament to its strong preference for incorporating Fe; it would not have formed at all if Fe preferred to enter into talc.

P–T pseudosection for the bulk composition FMSH2 (Fe# = 0.16) in the FMSH system, produced using Perple_X software, with H2O in excess. Fields are labelled with their stable assemblage. Dots indicate the pressure/temperature conditions of our experiments. The dashed line indicates the positions of reactions in the MSH system: talc=enstatite + coesite/quartz + H2O, talc=anthophyllite + quartz + H2O, and anthophyllite=enstatite + quartz + H2O. Note that the Perple_X model includes a narrow field of Anth + En + Qz between the Anth + Qz and En + Qz fields that is too thin to show on the diagram. Also note that the form of this diagram, in which there is no two-phase field separating the one-phase Tc field from the three-phase Tc + Anth + Qz, Tc + Anth + Cs (not labelled) and Tc + En + Cs fields, is consistent with the form of Fig. 5, in which the talc composition is represented as a single line such that with increasing temperature talc reacts directly to a three-phase assemblage

At 4.0 GPa, the Perple_X calculation is consistent with our results, placing our experiments at 585 and 610 °C within the talc + enstatite + coesite field. Our results, therefore, suggest that the Perple_X modelling, in which the substitution of 0.48 apfu of Fe into talc initiates its dehydration at temperatures nearly 300 °C lower than in the system MSH over a wide range of pressures, is broadly correct. This substantial reduction in temperature demonstrates the strong partitioning of Fe into both enstatite and anthophyllite with respect to talc. As well as our Fe-bearing talc beginning to break down at a much reduced temperature than Mg-talc, it also completes its breakdown at a temperature ~ 50 °C lower than in the system MSH (compare the dashed lines in Fig. 6 with the adjacent solid lines).

The fact that our results are broadly consistent with calculations using Perple_X suggests that our experiments have reached equilibrium. Achieving equilibrium is an issue of concern in synthesis experiments involving talc, which can nucleate outside its stability field (e.g., Bozhilov et al. 2007). In the present study, the talc has every appearance of being an equilibrium phase, as its composition as determined by FTIR shows a systematic relationship with temperature, as does the variation in anthophyllite concentration determined by XRD. Also, while EDS analysis of these samples was not quantitative, it does suggest uniformity of composition within samples. For example, the talc crystals in run FTC7 (Fig. 3a) all show a similar intensity Fe peak in their spectra, and the anthophyllite crystals show a much higher intensity Fe peak. The 4 GPa experiments, in which talc coexists with enstatite + coesite, also produced consistency between phase proportions determined by XRD, FTIR spectra and Perple_X modelling.

Corona et al. (2015) synthesised 100% yields of Fe-bearing talc containing 0.5 apfu Fe2+ across the temperature range 400–550 °C at 0.2 GPa. This is a similar bulk composition to FMSH2 (0.48 apfu Fe2+). They also synthesised Fe-talc with 1.0 Fe pfu at these conditions. Their results are inconsistent with ours, and with the Perple_X calculation, in that they did not produce anthophyllite. The reason for this difference is unclear. It may relate to the different type of starting material, which could affect the nucleation and growth kinetics: Corona et al. (2015) used a mixture of MgO, SiO2 and metallic iron, with added H2O to oxidise the iron and provide the necessary H2O for talc to form, as compared to our starting material of synthetic talc, natural fayalite, SiO2 plus H2O.

Results and discussion of FMSH experiments at higher pressures

Experimental results are listed in Table 1 and shown in Fig. 7. Above ~ 5 GPa, talc is replaced by TAP. As for talc at 4 GPa, the TAP breaks down in a divariant field:

P-T pseudosection for the bulk composition FMSH2 (Fe# = 0.16) estimated from the results of FMSH experiments at P ≥ 4 GPa, with H2O in excess. Small circles (blue)=Tc + En + Cs; filled squares=TAP + Cs; open square=TAP + En + Cs; large filled circles=TAP + Tc + En + Cs; large open circle=En + Cs; left-pointing triangle=growth of TAP from En + Cs; right-pointing triangles=growth of En + Cs from TAP. Fields containing Fe-bearing talc and TAP are labelled with their stable assemblage, with subscripts indicating solid solution. Other labels relate to reactions in the MSH system shown as dashed lines: talc=enstatite + coesite + V (Pawley and Wood 1995); talc + V=TAP and TAP=enstatite + coesite + V (Pawley et al. 2011). For clarity, P-T error bars are shown for one representative data point

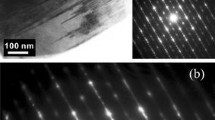

XRD patterns of these high-pressure samples indicate that the enstatite is monoclinic, from which we can infer that it has transformed from high-pressure clinoenstatite during the quench. This is consistent with measurements of the ortho-clino transition in enstatite (e.g. Akashi et al. 2009). Experiment FTAP10 at 5.2 GPa, 555 °C produced TAP plus minor coesite (Fig. 3b). Optical and XRD analysis showed no evidence of any other phases. Therefore, the Mg:Fe ratio of the TAP is assumed to be that of the bulk composition: 2.52 Mg: 0.48 Fe. Experiments at 6.5 GPa, 550 °C and 6.5 GPa, 575 °C produced assemblages containing TAP + minor coesite (FTAP2 and FTAP3). At 600 °C (FTAP1), TAP + enstatite + coesite were formed. Experiment FTAP9 at 6 GPa, 600 °C produced TAP + talc + enstatite + coesite. The presence of talc at a pressure well above the Mg-talc breakdown (located at < 5 GPa at 600 °C) is unexpected. However, the amount of talc is estimated as being significantly less than the amount of TAP, as the main talc basal spacing reflection in the XRD pattern (d = 9.35 Å) is completely masked by the main TAP peak at 10 Å. This sample is discussed in further detail below.

Experiments FTAP4—7 were designed to bracket the initial dehydration of Fe-bearing TAP at 6.5 GPa, marking the start of the TAP + enstatite + coesite divariant field. Experiment FTAP4, at 6.5 GPa and 600 °C, showed no change from a starting material of Fe-bearing TAP after a run of 24 h, in contrast to the result of the earlier synthesis experiment at the same conditions (FTAP1). This discrepancy is likely to have been caused by slow kinetics close to the reaction boundary. A repeat of this run at the same conditions, this time seeded with enstatite and coesite, resulted in the growth of enstatite + coesite (FTAP6), confirming the initial synthesis result. At the higher temperature of 620 °C (FTAP5), enstatite and coesite grew from a starting material of Fe-bearing TAP, confirming that P–T conditions were within the TAP + enstatite + coesite divariant field. Experiment FTAP7, at 6.5 GPa and 575 °C, showed an increase in TAP from a starting mixture of TAP + enstatite + coesite.

All run products in the TAP experiments were too fine-grained to analyse by EPMA, though EDS analysis of sample FTAP10 suggested uniform Mg:Fe ratio and hence the complete reaction of the starting material. FTIR spectroscopic characterisation of the TAP was also not possible, due to the presence of broad O–H stretching bands associated with the interlayer H2O, which obscured the lower intensity bands associated with octahedral Mg and Fe. In the absence of compositional data for the TAP and enstatite, we can assume similar compositional relationships as for talc and enstatite, such that tie triangles between TAP, enstatite and coesite will have the same arrangement as in Fig. 5b.

The stability of the 10 Å phase in the FMSH system

Phase reversal experiments have demonstrated that the position of the Fe-bearing TAP (TAP84) dehydration reaction to enstatite and coesite begins at temperatures ~ 100 °C lower than that for end-member TAP (Fig. 7). Like talc, TAP breaks down in a divariant reaction (Reaction 3), forming progressively more Mg-rich compositions and partitioning Fe into enstatite. However, this reaction occurs at a higher temperature than the estimated position of the equivalent talc dehydration reaction (Reaction 2). The Perple_X-calculated position of Reaction 2 is shown in Fig. 6 as bending back to ~ 400 °C at 5 GPa. Given the range of uncertainties in this calculation, including in the equations of state of talc and H2O, and energetics of Mg–Fe mixing in talc and enstatite, this reaction position should be treated with considerable caution. Nevertheless, our results at 4 GPa indicate that Reaction 2 must occur below 585 °C at 4 GPa. Figure 7 shows the results of the high-pressure experiments with Reaction 2 shown as approximately parallel to the endmember talc breakdown reaction as determined in previous experimental studies. Reaction 3 is shown as vertical, as found for the endmember reaction by Pawley et al. (2011). The final breakdown reactions of talc and TAP in this FMSH system are shown as ~ 50 °C below the reactions in MSH, as calculated by Perple_X at lower pressures (Fig. 6). The higher thermal stability of TAP84 than Tc84 indicates that TAP is capable of accommodating higher concentrations of Fe in its structure than talc. In Fig. 7 we also show the expected shift to lower pressure of the reaction TAP = Tc + V due to the preference of TAP to incorporate Fe, as well as a field in which talc and TAP are expected to coexist.

The presence of minor talc at 6 GPa is unexpected since we have shown that the maximum stability of talc in the FMSH system is reduced with respect to the MSH system. A possible explanation may be that experimental P–T conditions lie on the vapour absent reaction talc=enstatite + coesite + TAP. The position of this reaction has not been determined in the system MSH, but must lie between the reaction Tc + V=TAP and the metastable extension of the reaction Tc = En + Cs + V. A consideration of Fig. 7 suggests that the P–T conditions of 6 GPa, 600 °C are too high for it to lie on this reaction. The formation of talc would also require the experiment not to contain excess water, whereas excess water was noted in this experiment. It is possible that whilst the entire capsule could retain excess water, water loss through cracks, or uneven distribution of water, could have led to gradients of water availability acting across the length of the capsule, causing regions where water was absent and leading to localised talc formation. This question remains unresolved.

Results and discussion of MASH and NMASH experiments

The results of the experiments are shown in Table 1. The MASH experiments (ATAP1, 2) produced assemblages containing TAP, coesite and minor Mg-sursassite. Mg-sursassite (Mg-Surs) is a high-pressure phase with the composition Mg5Al5Si6O21(OH)7 (Fig. 1). The NMASH experiments (NATAP1-3) produced assemblages containing TAP, enstatite, jadeite and coesite. The enstatite is clino-enstatite. TAP was the most abundant phase in all run products. The run duration of ATAP2 was nearly double the length of ATAP1, with the aim to produce larger crystal sizes, suitable for EPMA. However, a comparison of the samples’ textures using the SEM showed that increasing the run duration had no discernible effect on crystal size. Figure 3 shows typical textures of these experiments: the TAP from experiment ATAP2 is well-crystallised (some crystals with hexagonal shapes) but fine-grained (Fig. 3c), while in NATAP1 there are a few larger TAP crystals, but the sample is predominantly a mixture of TAP platelets and acicular pyroxene crystals (Fig. 3d).

EPMA of TAP from all experiments was unsuccessful due to the small grain size. However, EDS analysis using the SEM was successful in showing a small but significant amount of Al and Na in the TAP compositions. These are presented in Table 4 and plotted in Fig. 8. There is considerable scatter in the data, but two features of the NATAP samples are clear: (1) the number of apfu Na is the same as the number of apfu Al, (2) the NATAP3 crystals contain more Na and Al than the NATAP1 crystals. Figure 8 shows suggested tie triangles connecting coexisting phases, based on the observed phase assemblages and the TAP compositions. It should be noted that in Fig. 8a the TAP composition at the apex of the tie triangle was selected so that the bulk composition was not outside the tie triangle, while in Fig. 8b the minor coesite observed in the run products is not shown as a stable phase, and the NMASH2 bulk composition is clearly outside the NATAP3 tie triangle. It is possible that these discrepancies are due to the dissolution of components into the fluid at high pressure and temperature, with coesite possibly crystallising on quench. It could also be the case that the pyroxenes are not of endmember composition: Tschermak’s substitution in the enstatite would shift its composition towards the NaAlO2 apex of the triangle. It was not possible to analyse the pyroxene compositions in these experiments due to the very small size of the crystals.

EDS analyses of TAP crystals from experiments a ATAP2, and b NATAP1 (open circles) and NATAP3 (filled circles). Starting materials are shown in grey. Tie triangles indicate coexisting phases; in (b) the dashed lines refer to experiment NATAP3. Other relevant phases from Fig. 1 are also shown

The TAP formed in our MASH experiments has a composition displaced from Mg-TAP along both AlAlMg-1Si-1 and AlAlMg-1Mg-1Mg-1 (towards “Tschermak’s talc” and pyrophyllite, respectively). The scatter in the data means that it is not possible to determine whether both these substitutions are actually occurring. Nevertheless, it is clear that the total Al content is similar to that reported by Fumagalli and Poli (2005) (up to 0.8 apfu Al). Their TAP composition is, however, distinctly different from ours, being displaced towards clinochlore. This difference may be due to the very different bulk compositions used, with ours having a much higher Si:Mg ratio. They describe their sample as a mixed-layer TAP-clinochlore, and suggest that the TAP domains may be Al-free. Our results show that Al may be incorporated into TAP without requiring the presence of clinochlore domains. If Al is incorporated through a pyrophyllite substitution, this would be consistent with a solid solution towards the Al-TAP synthesised by Tao et al. (2017). We cannot tell from our data whether the Al content of our TAP is constrained to a relatively low value by the Al content of the bulk composition (MASH1), so we do not know whether complete solid solution is possible towards the compositions of Tao et al. (2017) (their compositions are displaced towards pyrophyllite by approximately 0.75 AlAlMg-1Mg-1Mg-1).

TAP samples from the NMASH experiments appear to show a coupled substitution of Na + Al for Si. In experiments using both the NMASH1 and NMASH2 starting materials, the TAP compositions contain less Na + Al than the starting material. It is unclear why this is the case; we could be seeing a limit to the extent of the substitution, but if so, we would expect to find the same TAP compositions in both experiments. In any case, we have shown that TAP can incorporate at least 0.4 apfu Na, coupled with Al, suggesting that the substitution is NaAl(H2O)−1Si−1. This amount of Na is the same as the maximum amount of K in the samples of Tao et al. (2017).

Implications for the relative stability of talc and 10-Å phase

We can use our results, combined with results of previous studies and observations from natural samples, to discuss the effects of solid solution on the relative stabilities of talc and TAP, and hence their importance for transporting H2O into the Earth’s mantle at subduction zones. We will consider in turn the effects of (1) Fe2+, (2) Al, (3) Na and K.

-

1.

We have shown that substitution of Fe2+ for Mg in the talc structure lowers its stability with respect to its breakdown phases: anthophyllite at low pressure and enstatite at high pressure. The reason for this is the strong preference of Fe2+ for these breakdown phases. The talc in our experiments, with Fe# = 0.16 (0.48 Fe pfu), begins to break down at a temperature ~ 270 °C below its breakdown temperature in the system MSH at 2 GPa. The breakdown of this talc does not immediately liberate all of its water since it breaks down in a divariant reaction. However, its final decomposition occurs ~ 50 °C below the decomposition of endmember Mg-talc.

Fe-bearing TAP also breaks down at a lower temperature than endmember Mg-TAP, due to the preference of enstatite to incorporate Fe2+. However, the displacement of the beginning of the breakdown of TAP with Fe# = 0.16 is much less than for talc (Fig. 7). This suggests that Fe is partitioned more favourably into TAP than into talc. This is probably a reflection of the larger unit cell dimensions of TAP, both parallel and perpendicular to the sheets in the structure (Pawley et al. 2010). Therefore, the transformation of Fe-bearing talc to Fe-bearing TAP will occur at a shallower depth in a subducting slab than for the Mg-endmember.

-

2.

Analyses of natural talc samples show that it typically incorporates < 1 wt % Al2O3. Enstatite also typically only contains a small amount of Al, and calculation using Perple_X of the effect of Al on the breakdown of talc to enstatite + coesite shows a minor effect. On the other hand, our synthesis of TAP in the system MASH, combined with previous high-pressure studies using natural compositions, show that Mg-rich TAP can contain up to 10 wt % Al2O3 (this study and Fumagalli and Poli 2005), while Mg-poor TAP may contain up to ~ 20 wt % Al2O3 (Tao et al. 2017). We, therefore, predict that the thermal stability of Al-bearing TAP will increase relative to enstatite + coesite, and its low-pressure stability will increase with respect to talc. In the experiments of Fumagalli and Poli (2005), the highest temperature that TAP was observed was 680 °C. Their TAP compositions contain some Fe (up to 0.26 apfu), which will lower the thermal stability relative to that of endmember TAP (~ 700 °C, Pawley et al. 2011), but this will be offset by the effect of Al increasing the thermal stability. In contrast, the lowest pressure at which they observe TAP (4.8 GPa) is below that observed in previous studies on endmember TAP, demonstrating the combined effect of Al and Fe incorporation on the stability of TAP relative to talc.

-

3.

Natural talc typically contains very low concentrations of both Na and K. Therefore, Na- and K-bearing TAP will show an expanded stability field with respect to talc, and also with respect to enstatite + coesite since enstatite seldom shows solid solution towards jadeite (orthopyroxene typically contains ~ 0.005 Na pfu, Robinson 1980). In their experiments on a hydrated basalt composition, Tao et al. (2017) synthesised K-bearing Al-rich TAP at conditions well outside its stability in MSH: 650 and 750 °C at 4.0 GPa, and 800 °C at 5.5 GPa. This suggests that substitution of Na and K into the TAP structure is capable of expanding its stability field more than the incorporation of Al, and further reinforces the importance of TAP as a storage site for water in a range of compositions in subducting slabs.

References

Akashi A, Nishihara Y, Takahashi E, Nakajima Y, Tange Y, Funakoshi K (2009) Orthoenstatite/clinoenstatite phase transformation in MgSiO3 at high-pressure and high-temperature determined by in situ X-ray diffraction: implications for nature of the X discontinuity. J Geophys Res 114:B04206

Bjerga A, Konopasek J, Pedersen RB (2015) Talc-carbonate alteration of ultramafic rocks within the Leka Ophiolite complex, central Norway. Lithos 227:21–36

Bozhilov KN, Brownstein D, Jenkins DM (2007) Biopyribole evolution during tremolite synthesis from dolomite and quartz in CO2-H2O fluid. Am Miner 92:898–908

Bromiley GD, Pawley AR (2003) The stability of antigorite in the systems MgO-SiO2-H2O (MSH) and MgO-Al2O3-SiO2-H2O (MASH): the effects of Al3+ substitution on high-pressure stability. Am Miner 88:99–108

Chopin C (1981) Talc-Phengite: a widespread assemblage in high-grade pelitic blueschists of the Western Alps. J Pet 22:628–650

Chou IM (1986) Permeability of precious metals to hydrogen at 2 kb total pressure and elevated temperatures. Am J Sci 286:638–658

Connolly JAD (1990) Multivariable phase-diagrams—an algorithm based on generalized thermodynamics. Am J Sci 290:666–718

Connolly JAD, Petrini K (2002) An automated strategy for calculation of phase diagram sections and retrieval of rock properties as a function of physical conditions. J Metamorph Geol 20:697–708

Corona JC, Jenkins DM, Dyar MD (2015) The experimental incorporation of Fe into talc: a study using X-ray diffraction, Fourier transform infrared spectroscopy, and Mössbauer spectroscopy. Contrib Miner Pet 170:1–15

Driscall J, Jenkins DM, Dyar MD, Bozhilov KN (2005) Cation ordering in synthetic low-calcium actinolite. Am Miner 90:900–911

Evans BW, Guggenheim S (1988) Talc, pyrophyllite, and related minerals. In: Bailey SW (ed) Hydrous phyllosilicates. Reviews in Mineralogy, vol 19. Mineralogical Society of America. Washington, D.C., pp 225–294

Evans BW, Trommsdorff V (1974) Stability of enstatite + talc, and CO2-metasomatism of metaperidotite, Val d’Efra, Lepontine Alps. Am J Sci 274:274–296

Fumagalli P, Poli S (2005) Experimentally determined phase relations in hydrous peridotites to 6.5 GPa and their consequences on the dynamics of subduction zones. J Pet 46:555–578

Fumagalli P, Stixrude L, Poli S, Snyder D (2001) The 10Å phase: a high-pressure expandable sheet silicate stable during subduction of hydrated lithosphere. Earth Planet Sci Lett 186:125–141

Fumagalli P, Zanchetta S, Poli S (2009) Alkali in phlogopite and amphibole and their effects on phase relations in metasomatized peridotites: a high-pressure study. Contrib Miner Pet 158:723–737

Hirauchi K, den Hartog SAM, Spiers CJ (2013) Weakening of the slab-mantle wedge interface induced by metasomatic growth of talc. Geology 41:75–78

Holland TJB, Powell R (1991) A Compensated-Redlich-Kwong (CORK) equation for volumes and fugacities of CO2 and H2O in the range 1 bar to 50 kbar and 100–1600. Contrib Miner Pet 109:265–273

Holland TJB, Powell R (1996) Thermodynamics of order-disorder in minerals: iI. Symmetric formalism applied to solid solutions. Am Miner 81:1425–1437

Holland TJB, Powell R (1998) An internally consistent thermodynamic data set for phases of petrological interest. J Metamorph Geol 16:309–343

Kim Y, Clayton RW, Asimow PD, Jackson JM (2013) Generation of talc in the mantle wedge and its role in subduction dynamics in central Mexico. Earth Planet Sci Lett 384:81–87

Pawley AR, Wood BJ (1995) The high-pressure stability of talc and 10 Å phase: potential storage sites for H2O in subduction zones. Am Miner 80:998–1003

Pawley AR, Welch MD, Lennie AR, Jones RL (2010) Volume behaviour of the 10 Å phase at high pressures and temperatures, with implications for H2O content. Am Miner 95:1671–1678

Pawley AR, Chinnery NJ, Clark SM, Walter MJ (2011) Experimental study of the dehydration of the 10-Å phase with implications for H2O content and stability in subducted lithosphere. Contrib Miner Pet 162:1279–1289

Robinson P (1980) The composition space of terrestrial pyroxenes – internal and external limits. In: Prewitt CT (ed) Pyroxenes. Reviews in Mineralogy, vol 7. Mineralogical Society of America. Washington, D.C., pp 419–494

Schreyer W, Medenbach O, Abraham K, Gebert W, Müller WF (1982) Kulkeite, a new metamorphic phyllosilicate mineral: ordered 1:1 chlorite/talc mixed-layer. Contrib Miner Pet 80:103–109

Sieber MJ, Hermann J, Yaxley GM (2018) An experimental investigation of C-O-H fluid-driven carbonation of serpentinites under forearc conditions. Earth Planet Sci Lett 496:178–188

Strens RGJ (1974) The common chain, ribbon, and ring silicates. In: Farmer VC (ed) The infrared spectra of minerals. Mineralogical Society, London

Tao R, Zhang L, Liu X, Bader T, Fei Y (2017) Phase relations and formation of K-bearing Al-10 Å phase in the MORB + H2O system: implications for H2O- and K-cycles in subduction zones. Am Miner 102:1922–1933

Welch MD, Pawley AR, Ashbrook SE, Mason HE, Phillips BL (2006) Si vacancies in the 10-Å phase. Am Miner 91:1707–1710

Acknowledgements

This work was supported by a Natural Environment Research Council PhD studentship to Harriet Howe. We thank Steve May for technical support in the high-pressure laboratory, Heath Bagshaw, Alastair Bewsher, Lewis Hughes, Paul Lythgoe and John Waters for assistance with analytical techniques, and David Jenkins and an anonymous reviewer for their constructive comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Timothy L. Grove.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Howe, H., Pawley, A.R. The effect of solid solution on the stability of talc and 10-Å phase. Contrib Mineral Petrol 174, 81 (2019). https://doi.org/10.1007/s00410-019-1616-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00410-019-1616-0